Contact-type lamp holder for wedge-shaped bulb

A technology for lamp holders and bulbs, which is applied in the direction of incandescent lamps, discharge lamps, incandescent lamp parts, etc., can solve the problem of contact lamp holders without SAE wedge-shaped bulbs, and achieve the effect of saving wires and facilitating installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

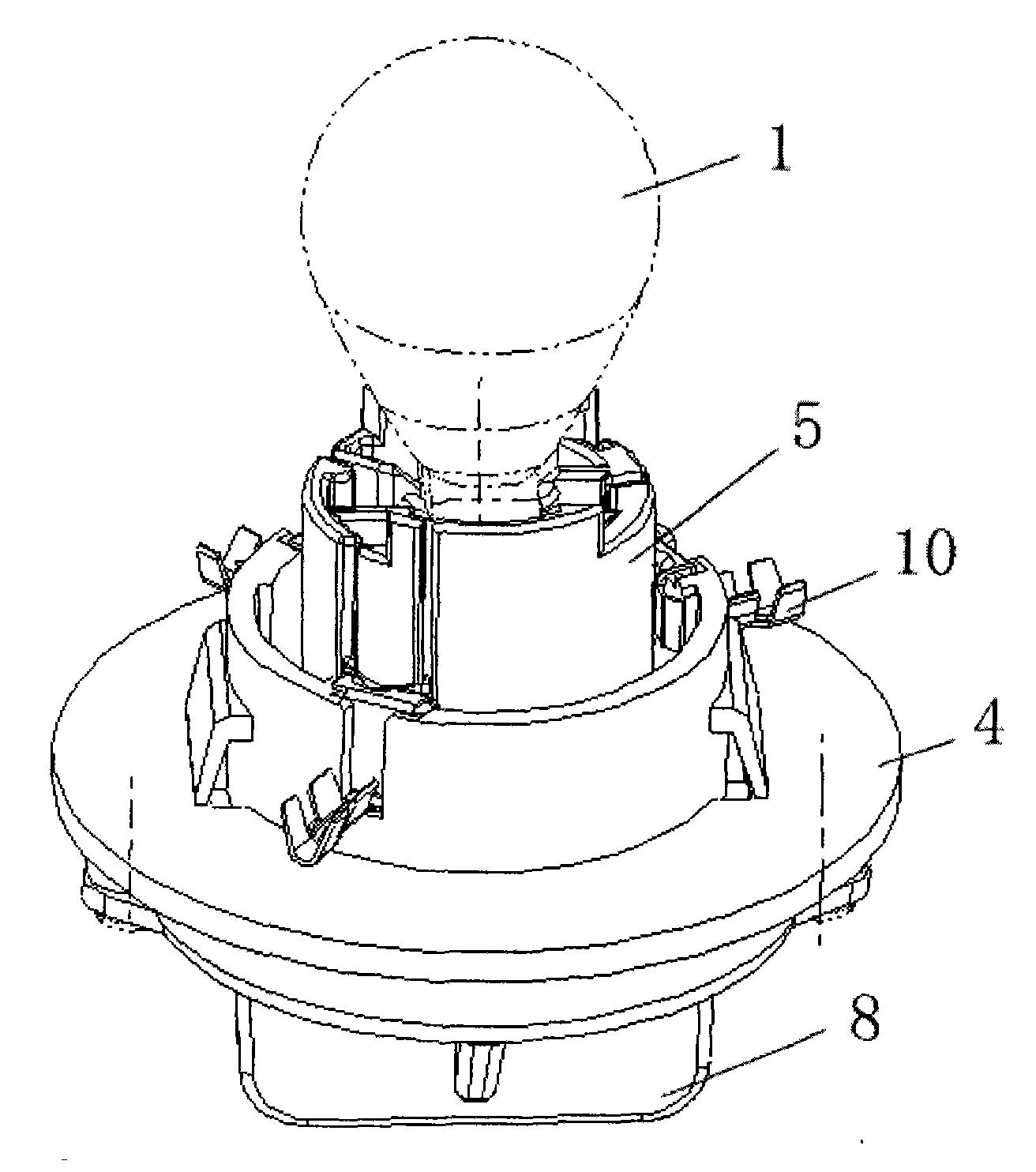

[0058] Such as Figure 19 As shown, the included angle between the main axis direction of the bulb 1 and the drawing direction of the lamp body is 0 degree, that is, the contact type lamp holder in the case of being parallel, or close to parallel.

[0059] Such as Figure 19 As shown, the contact-type lamp holder is installed in sequence along the main axis of the lamp axis: a cathode contact piece 10 in contact with the wedge-shaped bulb socket 2, a lamp holder hole collar 4, an anode contact piece 11, a cylindrical insert 5, Sealing ring 7, handle 8. The lamp holder hole collar 4 can be directly made on the lamp body, that is, in this embodiment, the lamp body hole collar 6 and the lamp holder hole collar 4 are integrated. A cathode electrical contact piece 10 is provided on the wall of the lamp socket hole collar 4, and an anode electrical contact piece 11 is provided on the outer wall of the cylindrical insert 5, and the wedge-shaped socket piece for installing and clamp...

Embodiment 2

[0068] The angle between the main axis direction of the bulb and the drawing direction of the lamp body is 90 degrees, that is, the contact type lamp holder in the vertical situation, or close to the vertical situation, such as Figure 18 As shown, the contact-type lamp holder is installed in sequence along the main axis of the lamp axis: the cathode contact piece 10 in contact with the wedge-shaped bulb socket 2, the lamp body hole collar 6, the lamp holder hole collar 4, and the anode contact piece 11. Cylindrical insert 5, sealing ring 7, handle 8. That is, in this embodiment, the lamp body hole collar 6 and the lamp holder hole collar 4 are respectively formed, and the lamp holder hole collar is fixed to the lamp body hole with screws, and the others are the same as in Embodiment 1, and this Invented contact lamp holder.

Embodiment 3

[0070] Except that the cylindrical insert and the handle are integrally formed, the contact lamp holder of the present invention is obtained as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com