Fastener tape threading automatic assembly machine

An automatic assembly machine and fastener technology, applied in accessories, travel products, applications, etc., can solve the problems of large labor input, large floor space, increased production costs, etc., to reduce labor costs, reduce labor input, and save pendulum. effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

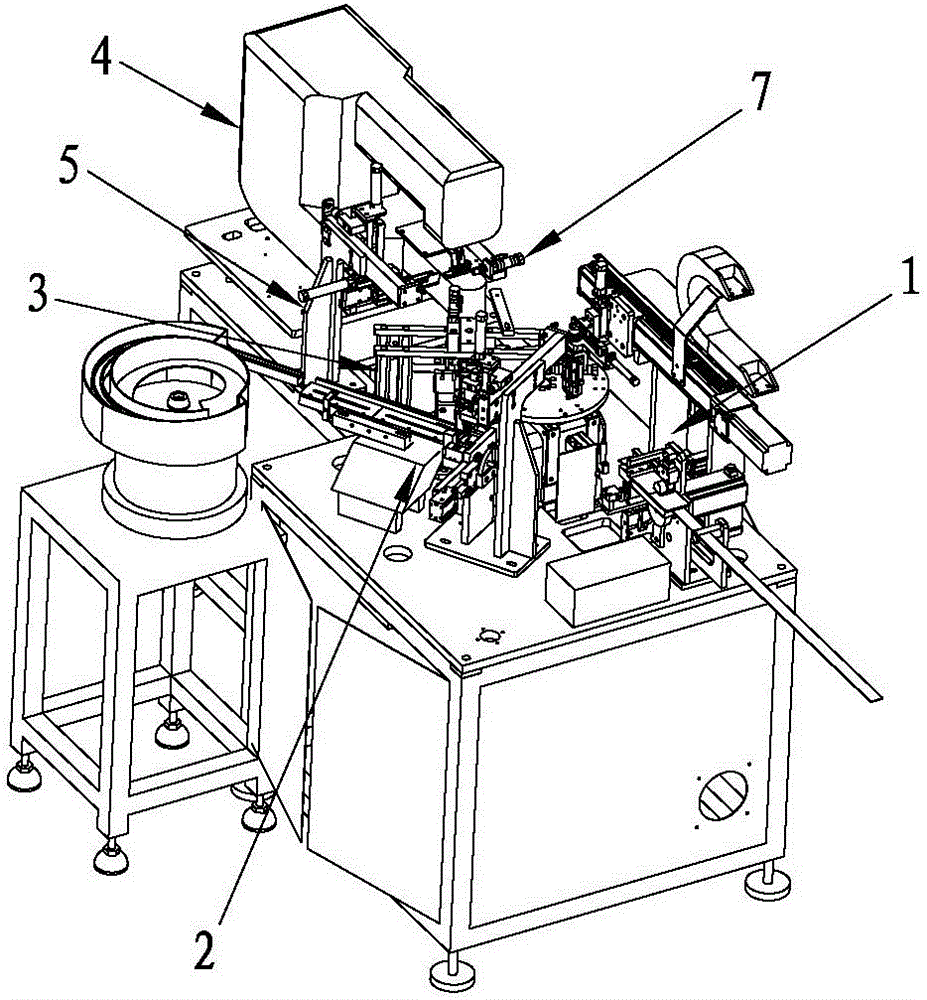

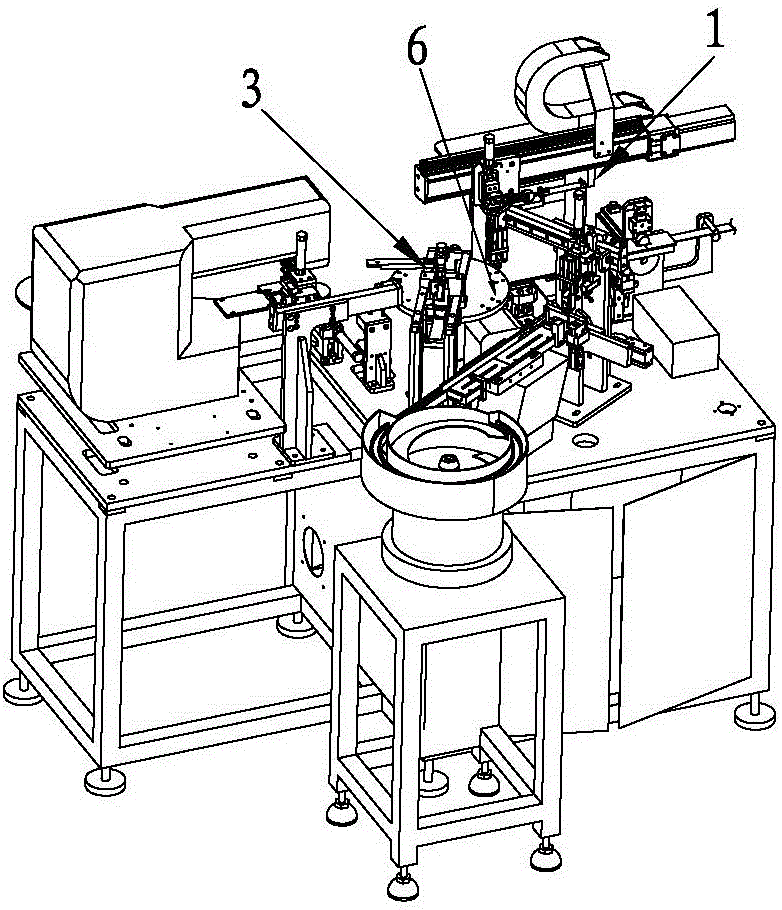

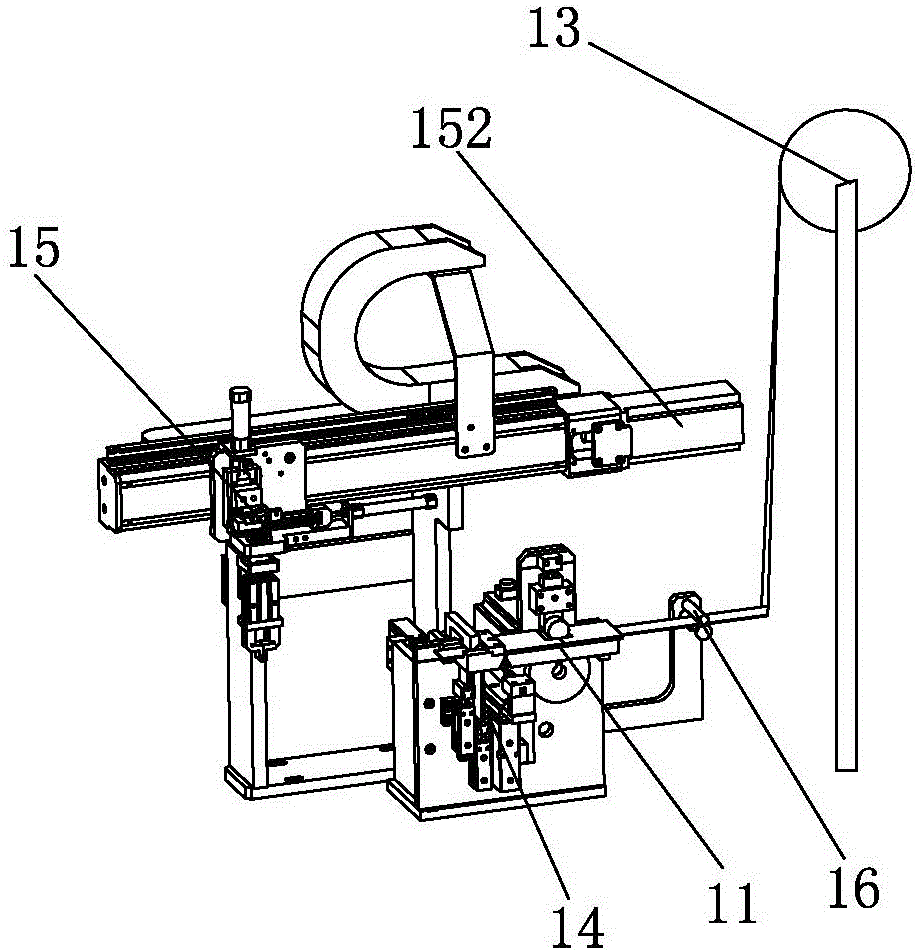

[0072] Such as Figure 1 to Figure 12 Shown, a kind of fastener belt threading automatic assembly machine, comprises machine table and turntable device, and described turntable device is arranged on the upper end of machine table, and the four weeks of described turntable device are successively provided with webbing feeding device 1, fastener feeding device The device 2, the fastener wrapping device 3, the knotting car 4 and the feeding device 5 for loading the knotting car 4 also include the unloading device 7 for discharging the material of the knotting car 4.

[0073] This embodiment adopts fully automated assembly and processing to avoid the phenomenon of wrong installation and missing installation. One worker can be in charge of multiple devices, reducing labor input and labor costs. Moreover, the device of the present invention is small ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com