Pressing-mounting equipment for pressing-mounting of cylinder cover guide pipe and seat ring

A technology for press-fitting cylinders and conduits, which is applied to metal processing equipment, metal processing, manufacturing tools, etc. It can solve the problems of low press-fit efficiency and press-fit accuracy, reduce work efficiency, increase equipment investment, etc., and improve press-fit accuracy and pressing efficiency, improving production efficiency and reducing cost input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

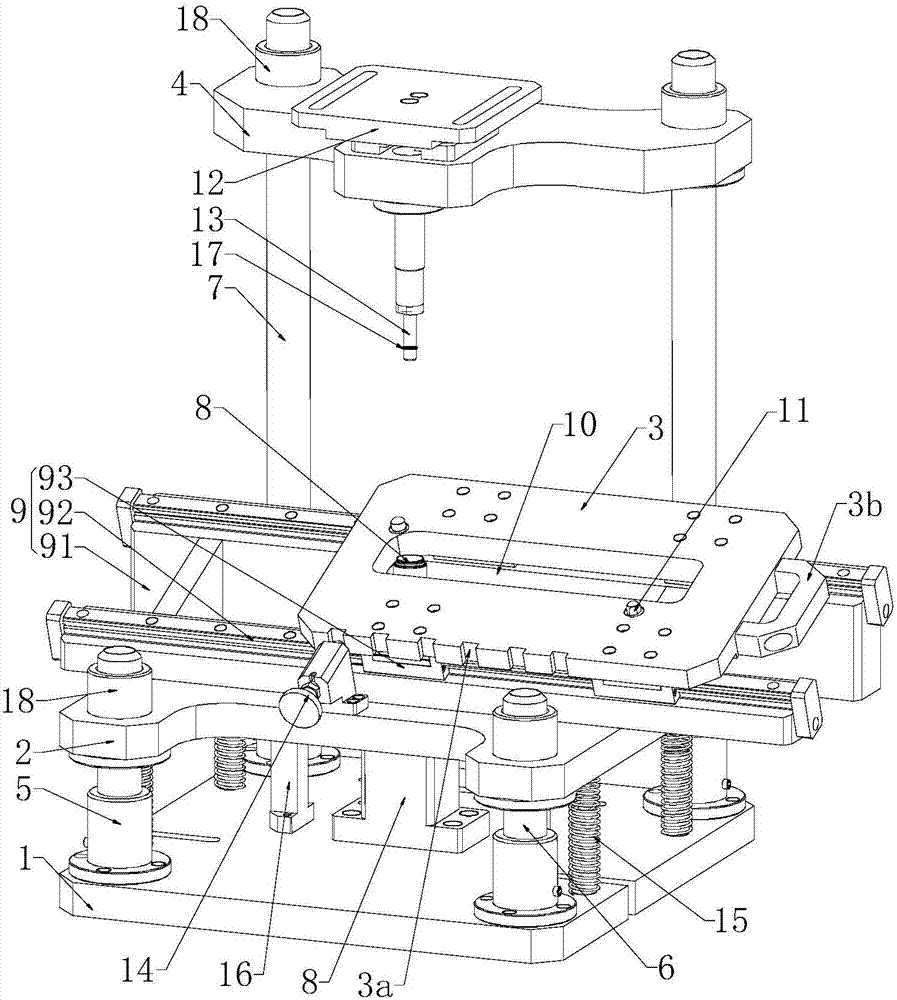

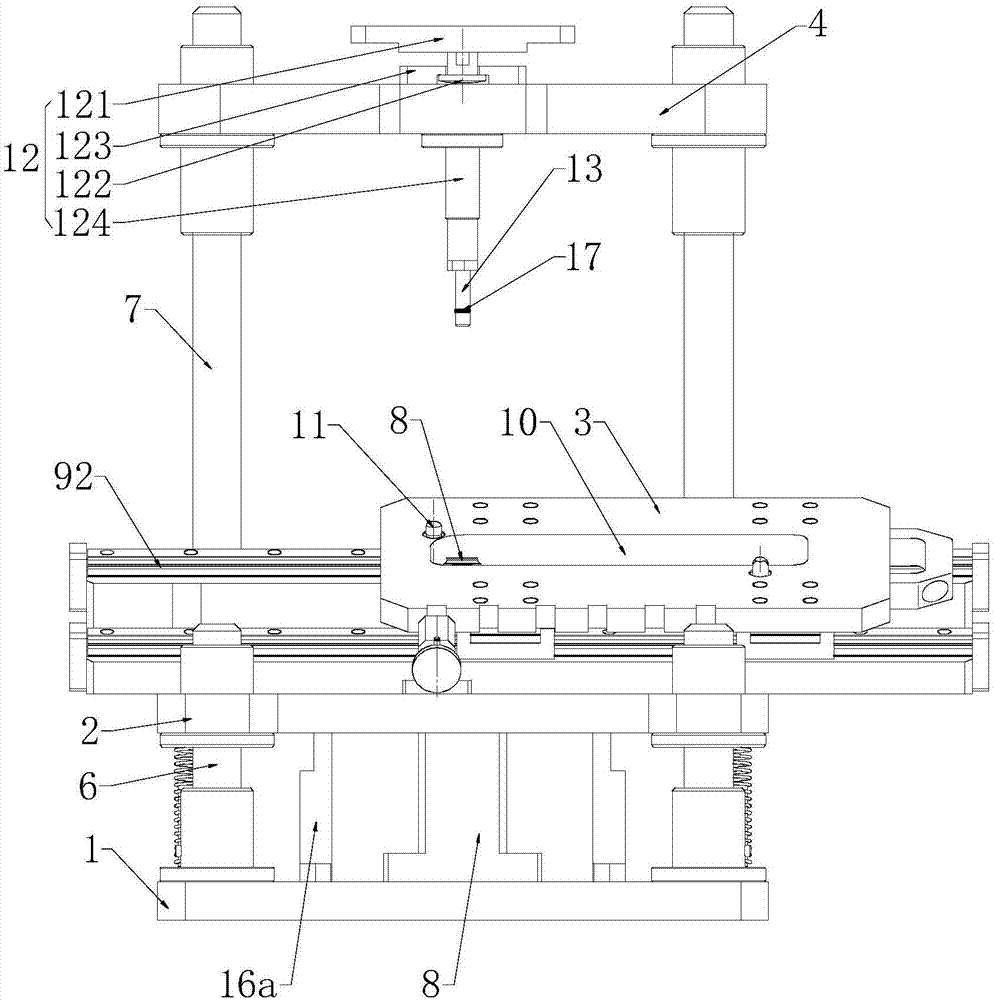

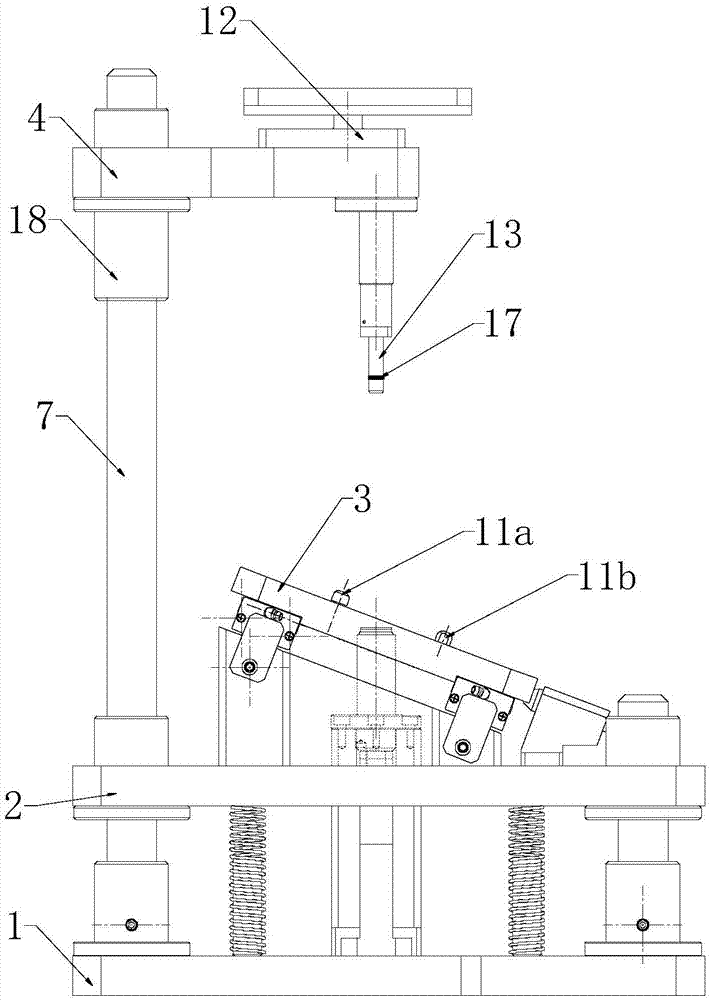

[0028] The specific embodiments and working principles of the present invention will be further described in detail below with reference to the accompanying drawings.

[0029] Such as Figure 1 ~ Figure 4 As shown, a press-fitting device for press-fitting a cylinder head pipe and a seat ring includes a foot plate 1, a bottom plate 2, a supporting plate 3, and a top plate 4. At least two are respectively fixed on the foot plate 1 through a guide sleeve 5. A short upright 6 and at least two long uprights 7, the bottom plate 2 is supported on the short upright 6 and the long upright 7 by sliding sleeves of linear bearings 18, and a positioning shaft 8 is also fixed on the foot plate 1. The upper part of the bottom plate 2 is installed with the inclined support plate 3 through the sliding support mechanism 9. A processing slot 10 is opened in the center of the support plate 3, and the upper part of the positioning shaft 8 extends into the processing slot 10, The supporting plate 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com