Patents

Literature

46results about How to "Prevent misinstallation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

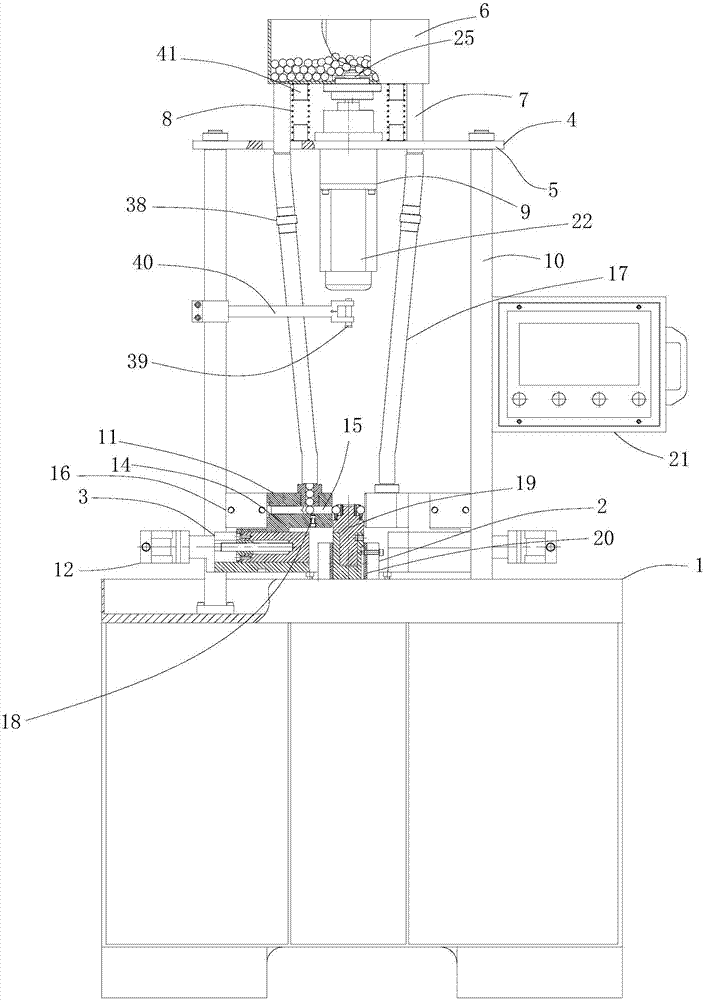

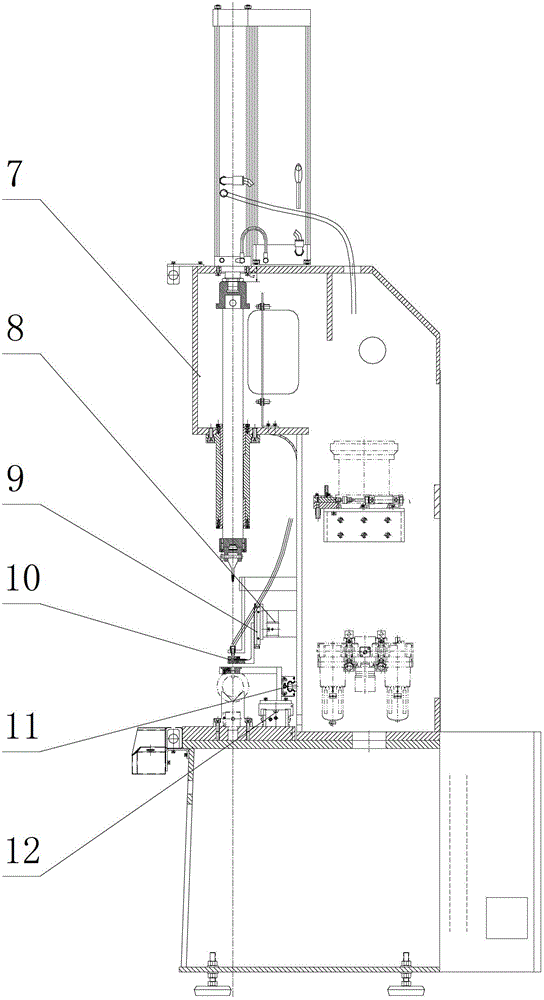

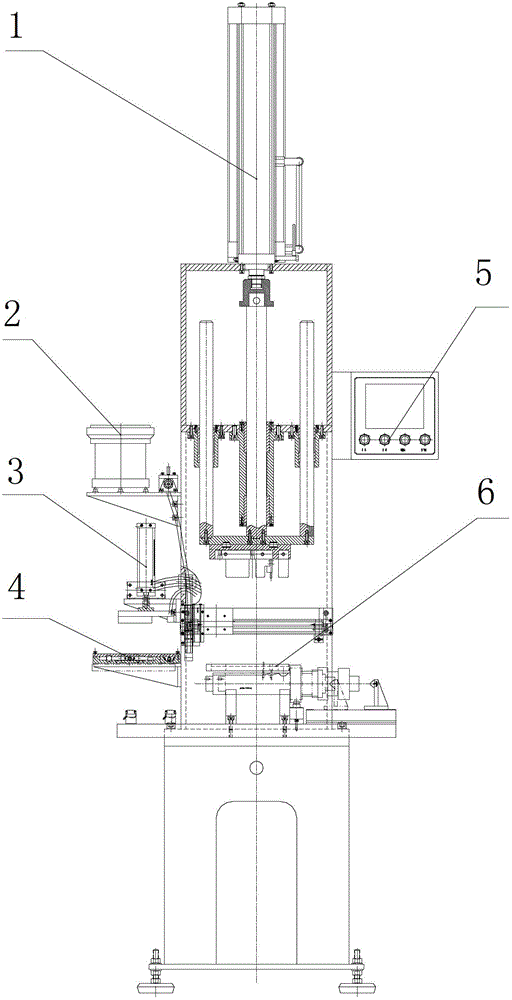

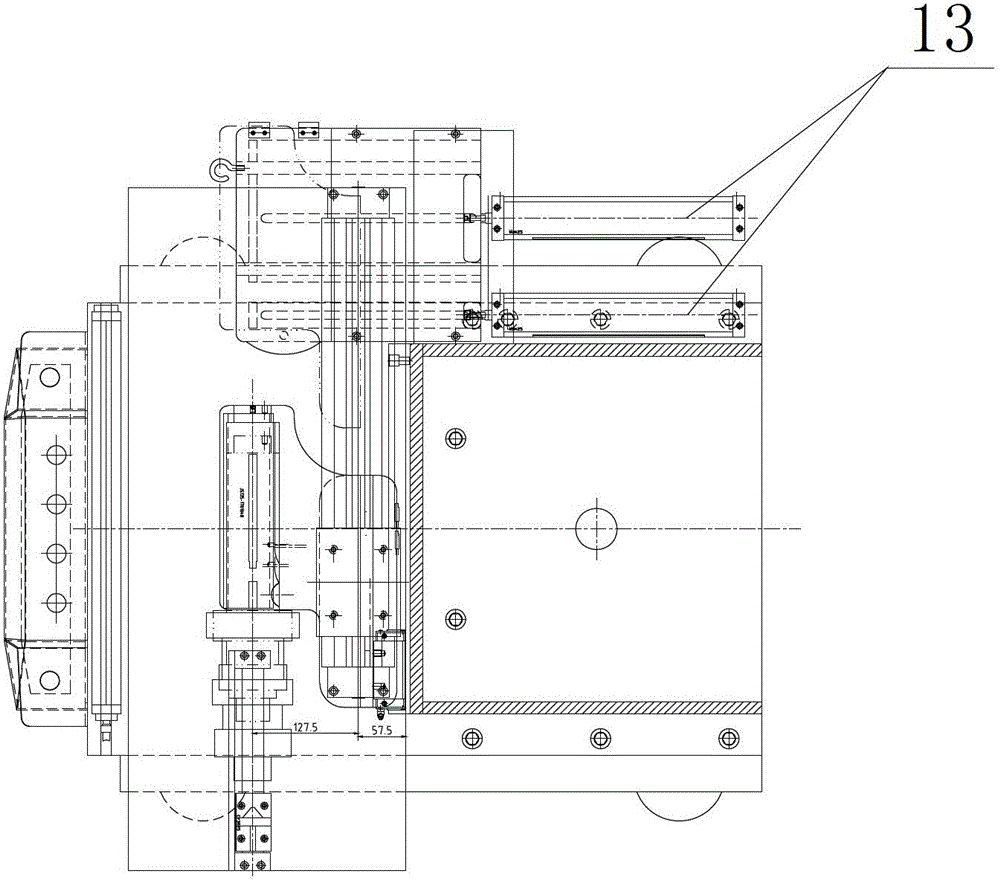

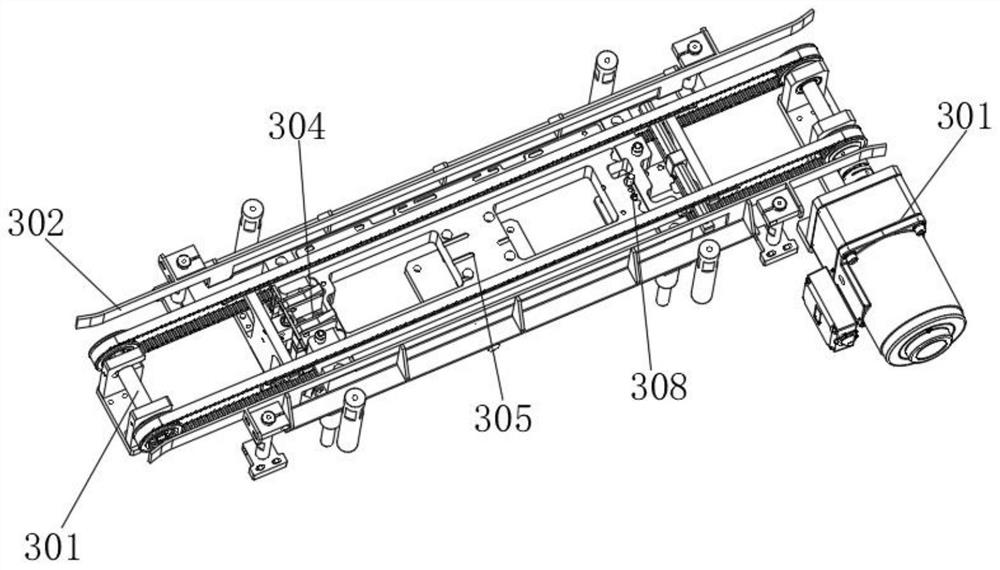

Transmission countershaft key and pin full-automatic press-fitting unit

InactiveCN103846661AGuaranteed assembly accuracyImprove assembly efficiencyAssembly machinesMetal working apparatusUltimate tensile strengthMechanical engineering

The invention belongs to the technical field of transmission assembly and particularly relates to a transmission countershaft key and pin full-automatic press-fitting unit comprising a body, a press-fitting device, an elastic cylindrical pin separating mechanism, an elastic cylindrical pin conveying mechanism, a key feeding mechanism, and a key conveying mechanism; the press-fitting device, the elastic cylindrical pin separating mechanism, the elastic cylindrical pin conveying mechanism, the key feeding mechanism and the key conveying mechanism are mounted on the body. A plurality of elastic cylindrical pins to be press-fitted are separated by the elastic cylindrical pin separating mechanism and then fall into the elastic cylindrical pin conveying mechanism; the elastic cylindrical pin conveying mechanism conveys the elastic cylindrical pins to be above a transmission countershaft positioned on the body; the elastic cylindrical pins are press-fitted into pinholes of the transmission countershaft by the press-fitting device; keys to be press-fitted fall into the key conveying mechanism through the key feeding mechanism; the key conveying mechanism conveys the keys to be above the transmission countershaft; the keys are press-fitted into key grooves of the transmission countershaft by the press-fitting device. The transmission countershaft key and pin full-automatic press-fitting unit has the advantages that assembly precision is guaranteed, labor intensity is reduced for operators, and assembly efficiency is improved.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

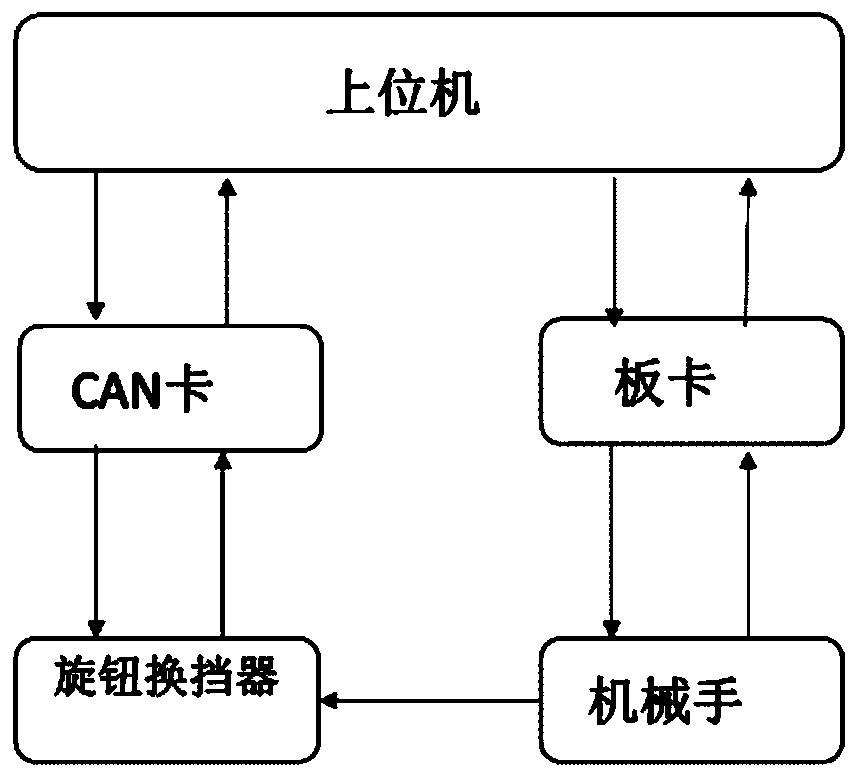

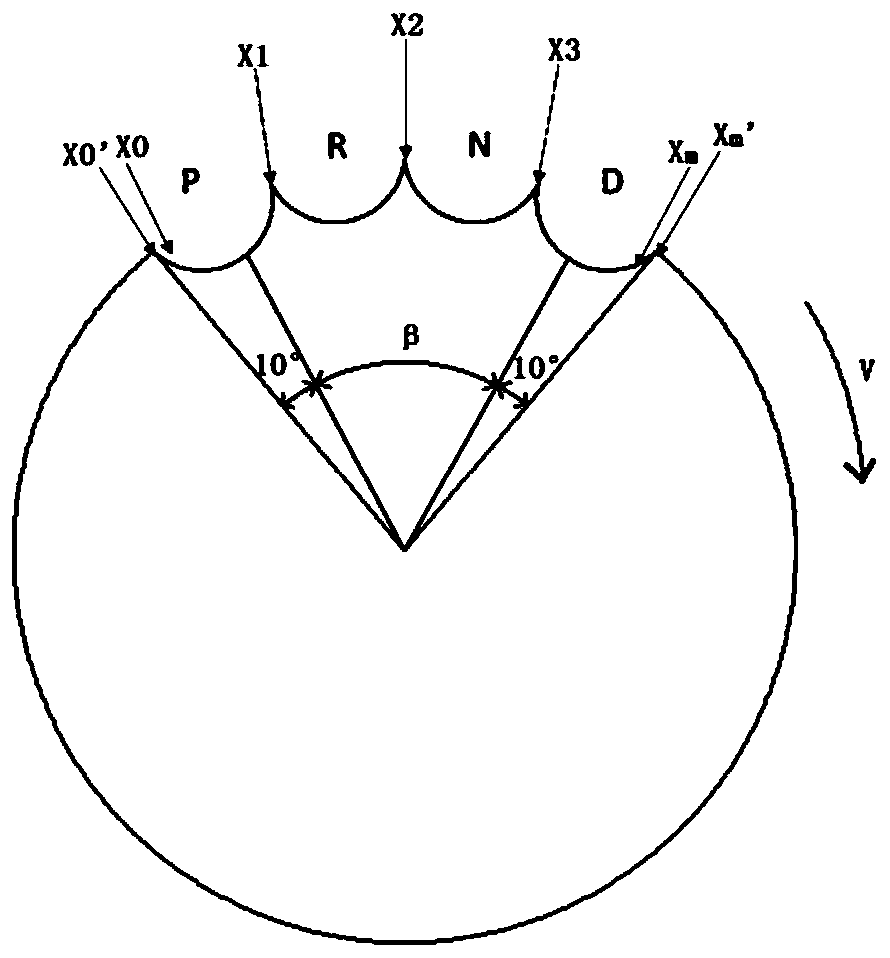

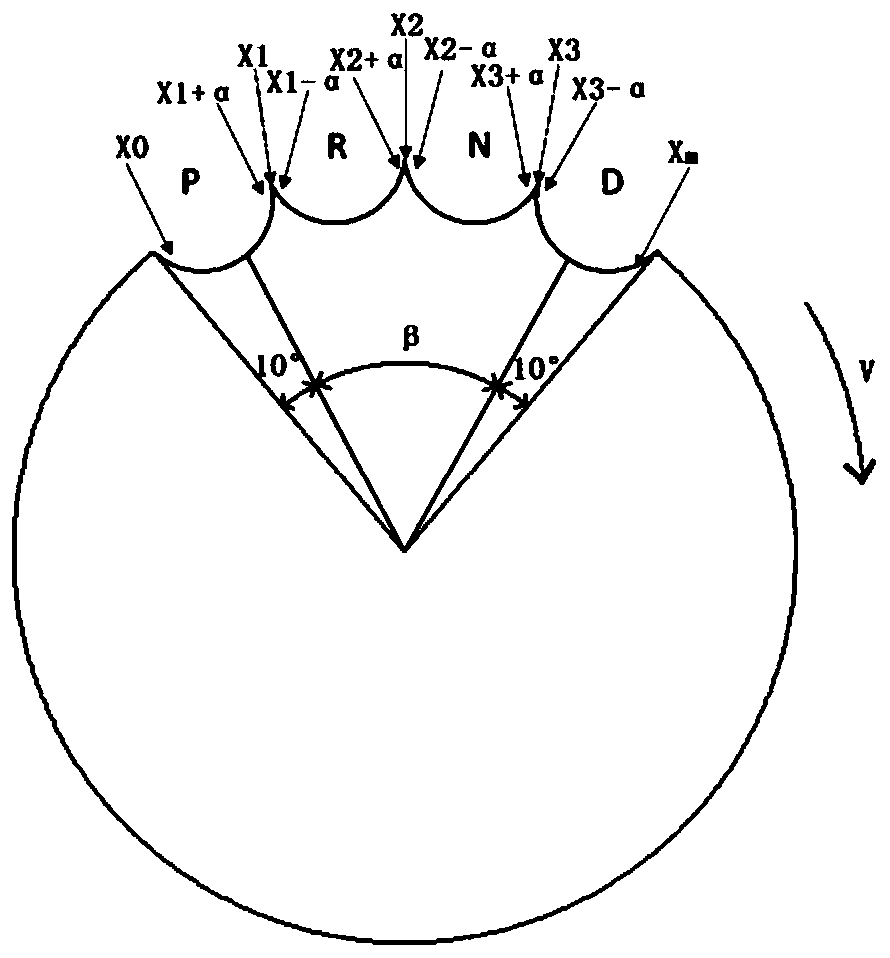

Gear self-learning method of knob shifter

ActiveCN110056643AEliminate installation errorsEliminate errorsGearing controlEngineeringStudy methods

The invention discloses a gear self-learning method of a knob shifter. a left dead center position and a right dead center position of the knob shifter are detected, taking the measured left stoppingpoint angle value X0 and the right stopping point angle value Xm as reference, the gear angle range of each gear of the knob shifter is calculated through self-learning, the installation error of theknob shifter and the error of the hall sensor can be eliminated to the maximum degree, so that the accuracy of the gear angle range obtained by self-learning is improved, so that the accuracy of the gear position recognition and judgment of the knob shifter is improved, and the driving safety is guaranteed; moreover, whether the left stopping point angle value X0 and the right stopping point anglevalue Xm of the knob shifter can be measured through the step S1, whether the limiting pins of the knob shifter at the left stopping point and the right stopping point are correctly installed or notis judged so as to prevent the workers from being misloaded and neglected.

Owner:GAC COMPONENT CO LTD

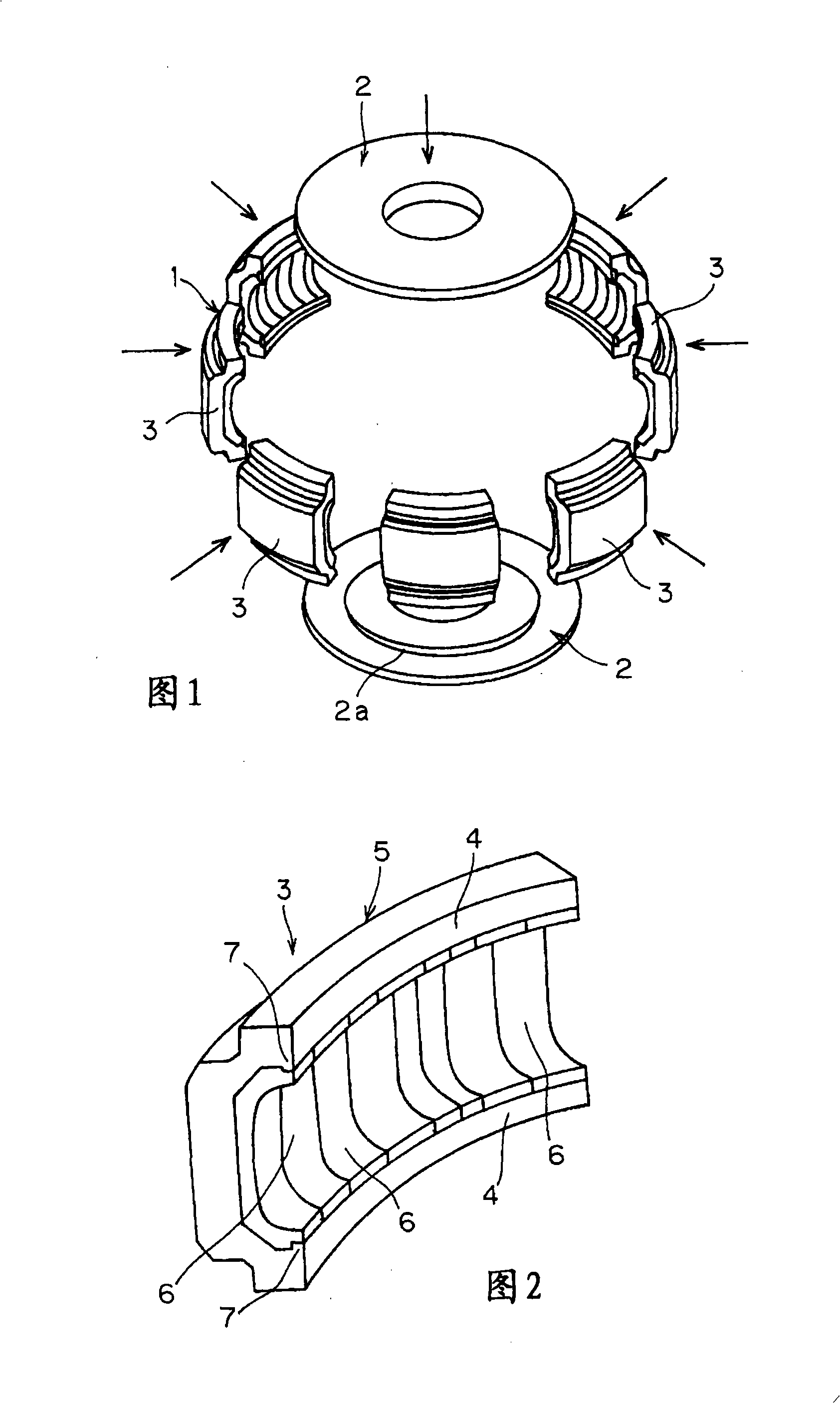

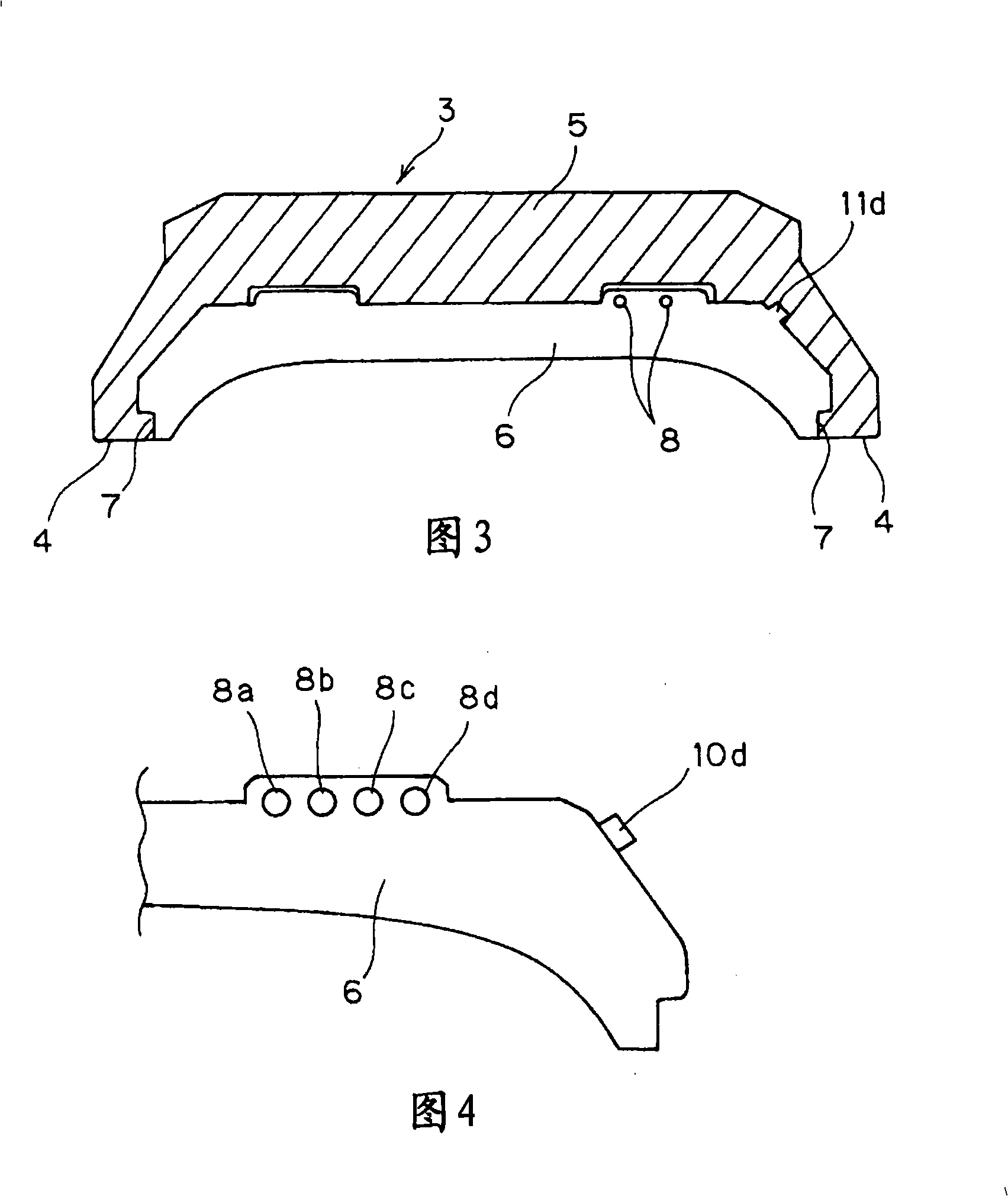

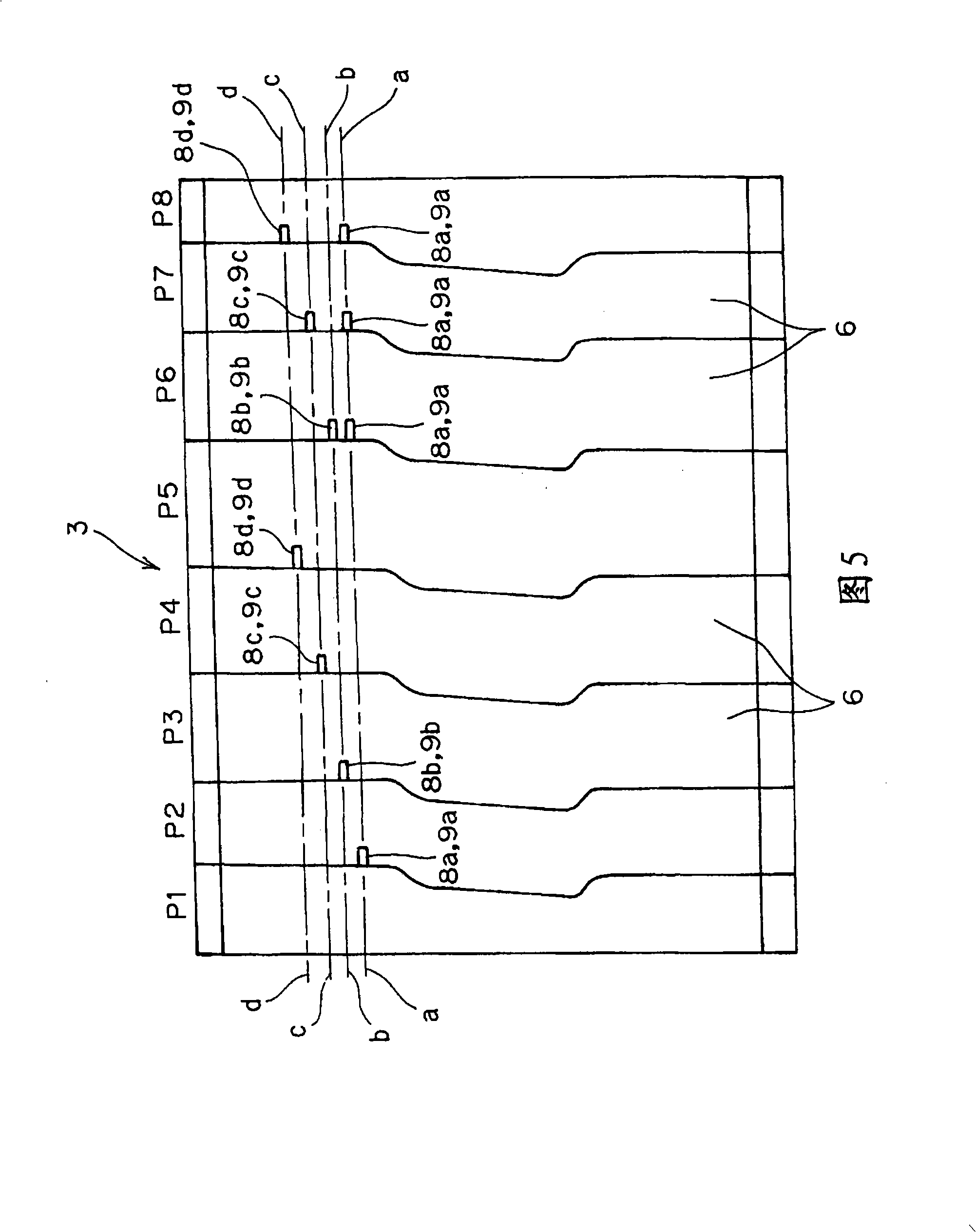

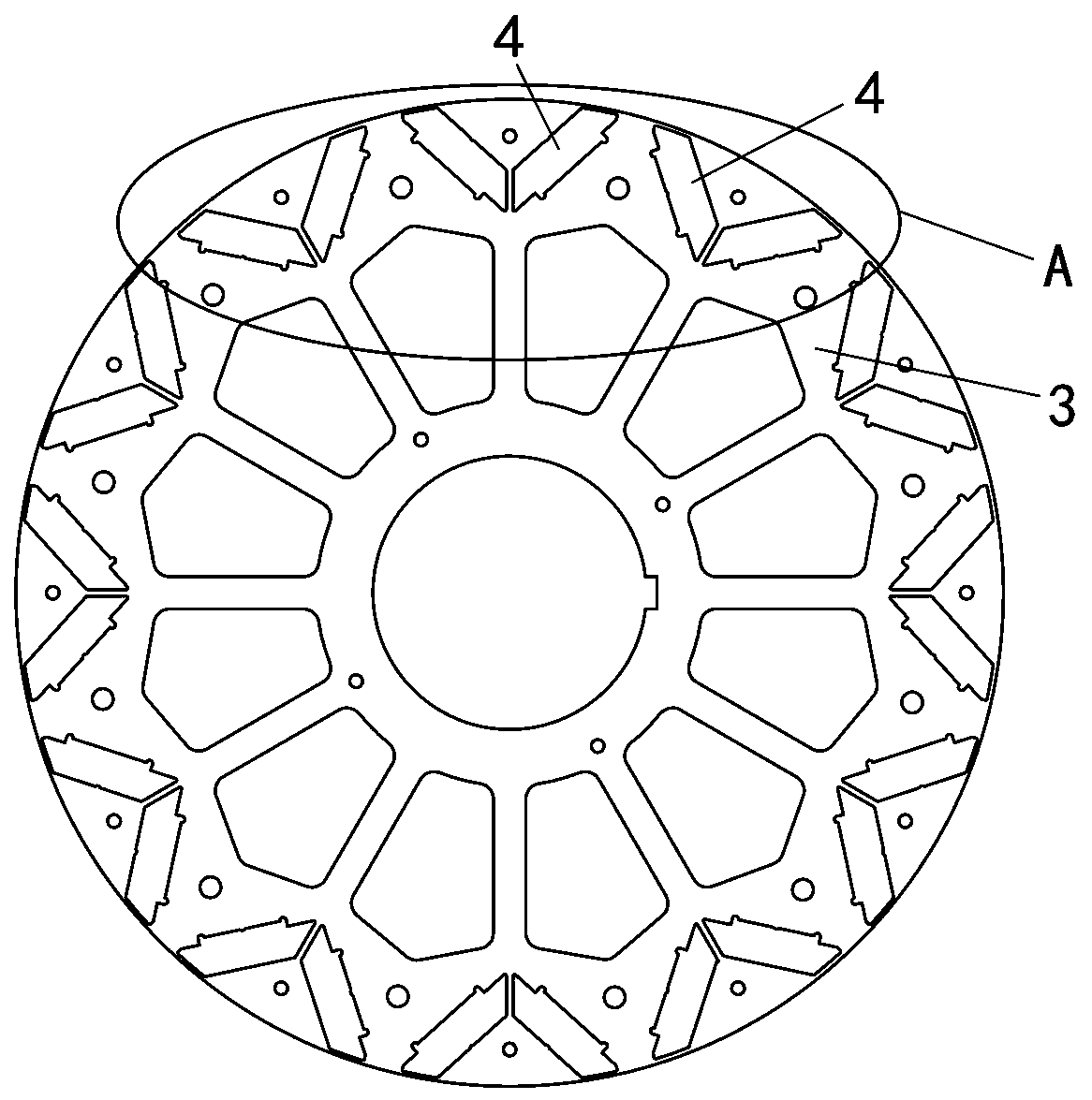

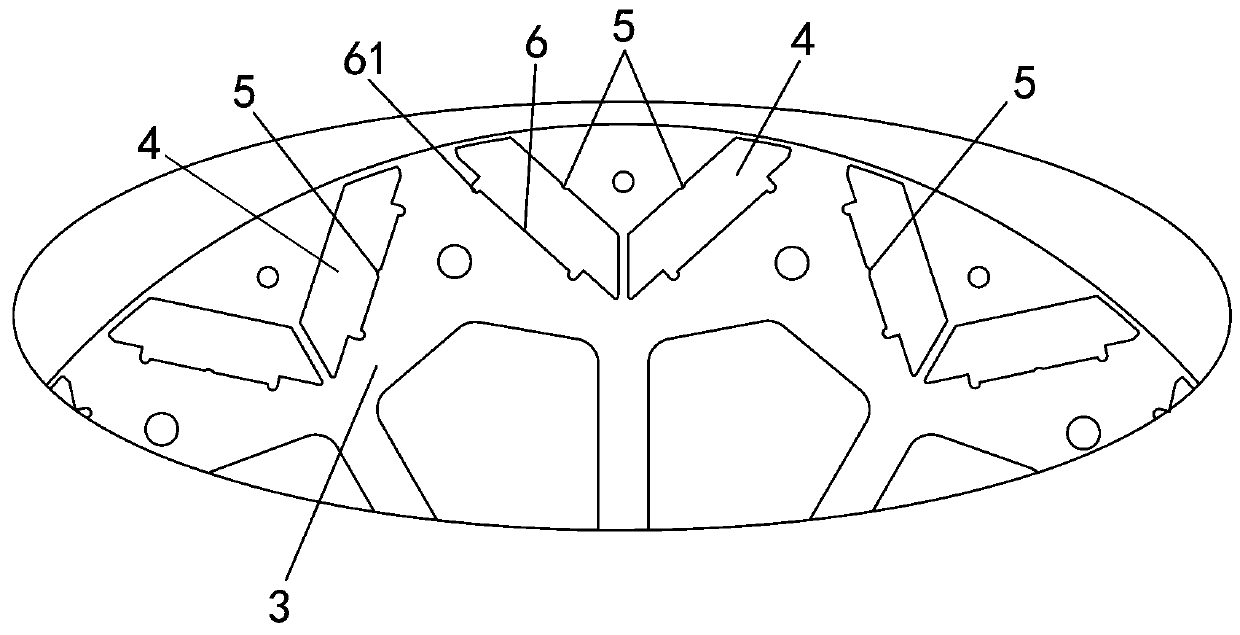

Metal mold for vulcanizing tire treads

A metal mold for vulcanizing tire treads reliably preventing incorrect assembling of split pieces. The metal mold 1 for vulcanizing tire treads to form a tread of a tire, comprises a plurality of sector molds 3 equipped with a plurality of pieces 6 which are arranged on the inner circumferential surface of a casing 5 and are split in the circumferential direction in which a tread pattern of the tire is formed, wherein among the adjacent pieces 6 in the sector molds 3, a protuberance 8 is formed on the contact surface of the one piece 6, a dent 9 corresponding to the protuberance 8 is formed in the contact surface of the another piece 6, and the positions for forming the protuberance 8 and the dent 9 are differed for each of the adjacent pieces 6 in the sector molds 3.

Owner:TOYO TIRE & RUBBER CO LTD

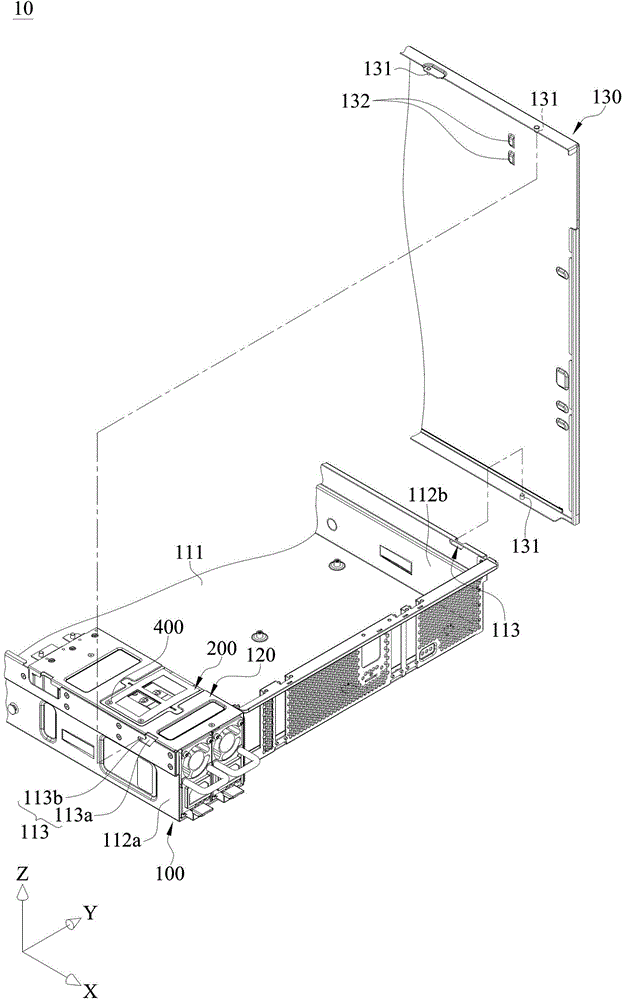

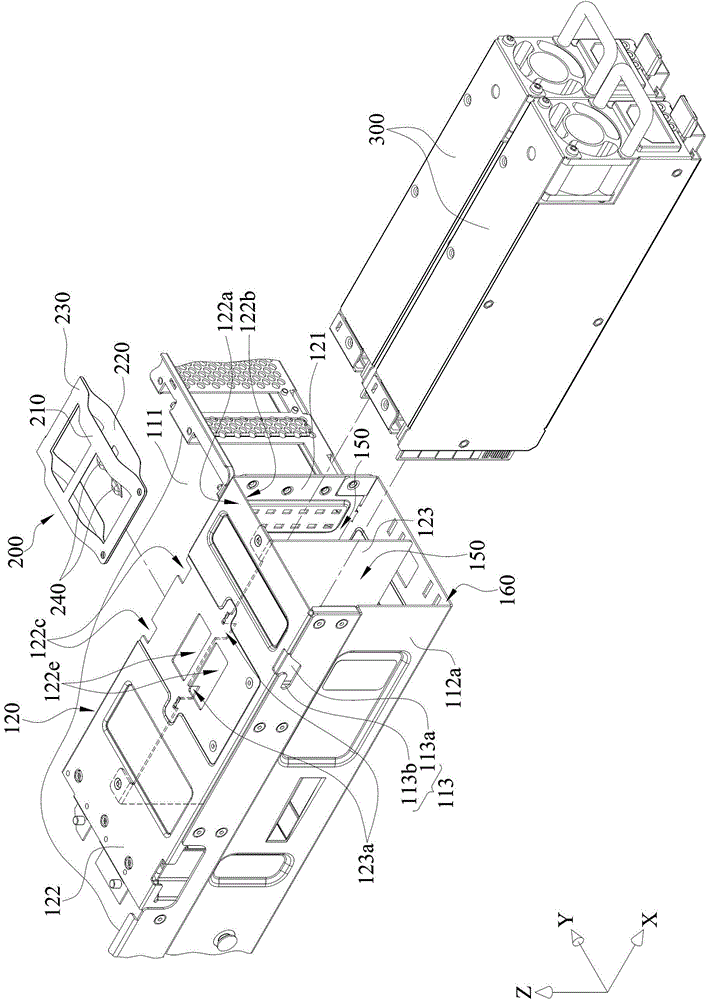

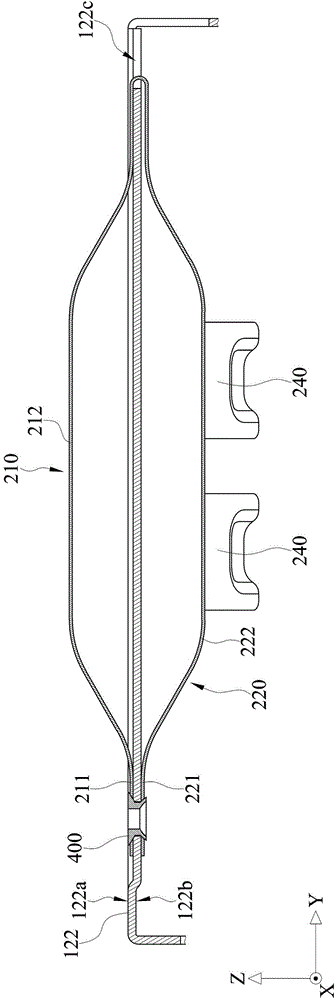

Server

ActiveCN106325398APrevent misinstallationAvoid exposureServersClosed casingsEngineeringElectric shock

The invention discloses a server, which comprises a case, a protection element and at least one power supply, wherein the case comprises a case body, a power shield body and a cover body; the power shield body is arranged on the case body to form at least one assembling channel; the cover body is detachably arranged on the case body and covers the power shield body; the protection element is assembled on the power shield body; and the protection element comprises a pressed elastic sheet and a first stop elastic sheet, wherein the pressed elastic sheet and the first stop elastic sheet are each provided with a bent section and are opposite at an interval, one end of the pressed elastic sheet and one end of the first stop elastic sheet are jointly fixed on the power shield body to form a fixing end, the other end of the pressed elastic sheet and the other end of the first stop elastic sheet are arranged on the power shield body together in a slippage way, so that a connection sheet drives the stressed elastic sheet and the first stop elastic sheet to be oppositely bent or flattened together, and the first stop elastic sheet is extruded towards the inner side of the power shield body to stop the power supply when the pressed elastic sheet and the first stop elastic sheet are both bent. By use of the server, a phenomenon that a user installs the power supply by mistake when the cover body is not covered can be avoided so as to prevent the user from being exposed in an environment with an electric shock risk.

Owner:WISTRON ZHONGSHAN +1

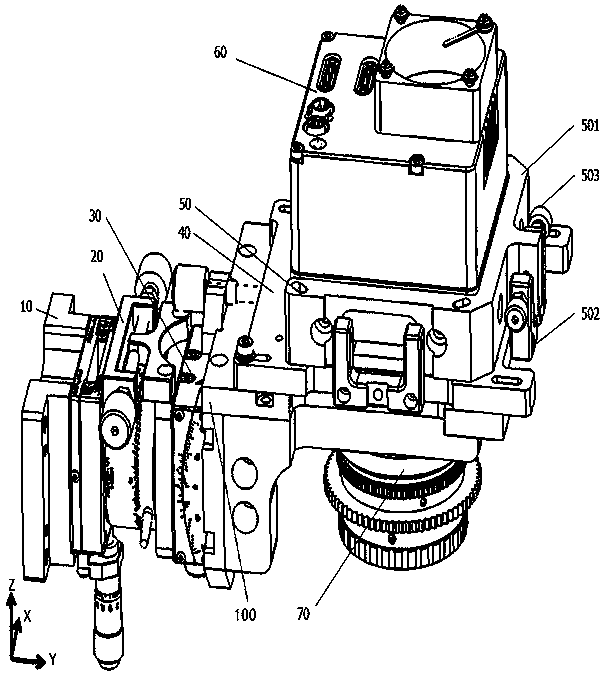

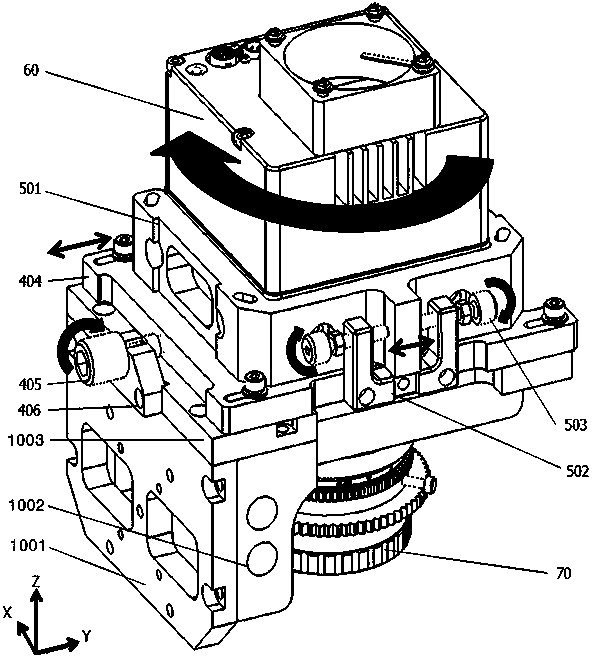

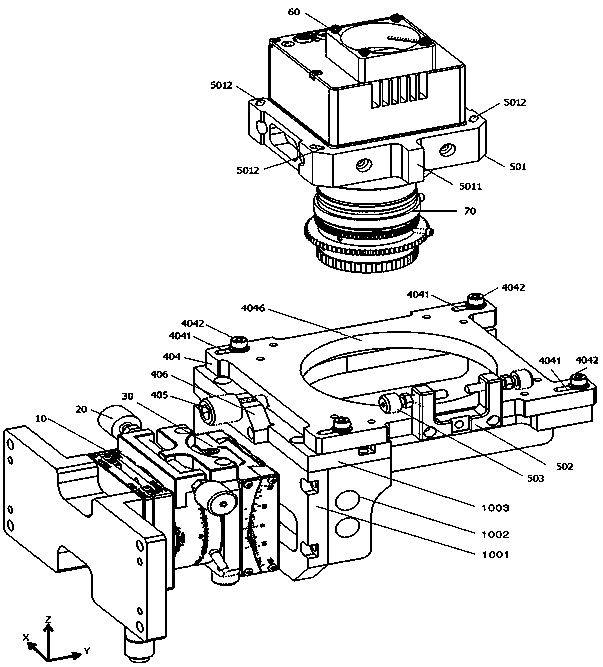

Camera mounting device, camera adjustment mechanism and detection equipment

ActiveCN110594546AReduce design costReduce manufacturing costTelevision system detailsColor television detailsPolarizerEngineering

The invention discloses a camera mounting device, a camera adjustment mechanism and detection equipment. The camera mounting device comprises a standard frame and a camera posture adjusting mechanism,the standard frame comprises a XZ plane fixing plate and a XY plane fixing plate connected with the XZ plane fixing plate, the XZ plane fixing plate is arranged perpendicular to the Y axis direction,the XY plane fixing plate is arranged perpendicular to the Z axis direction, the camera posture adjusting mechanism is arranged on the XZ plane fixing plate and is fixed to the detecting equipment, and a camera module is detachably arranged on the XY plane fixing plate. The XY plane fixing plate can be suitable for a combination mode of multiple cameras and lenses, and has universality and can beas a standard part, the cameras and the lenses with different mounting patterns can be arranged on a detection camera mounting device and can adapt to functions such as focusing, aperture adjusting,polarizer adjusting and the like of the plurality of lenses, after generalization, the problems that manufacturing and assembly are difficult to identify and mistakenly assembled due to many kinds areavoided, and the use flexibility of assembling and field adjusting machines is increased.

Owner:WUHAN JINGLI ELECTRONICS TECH +1

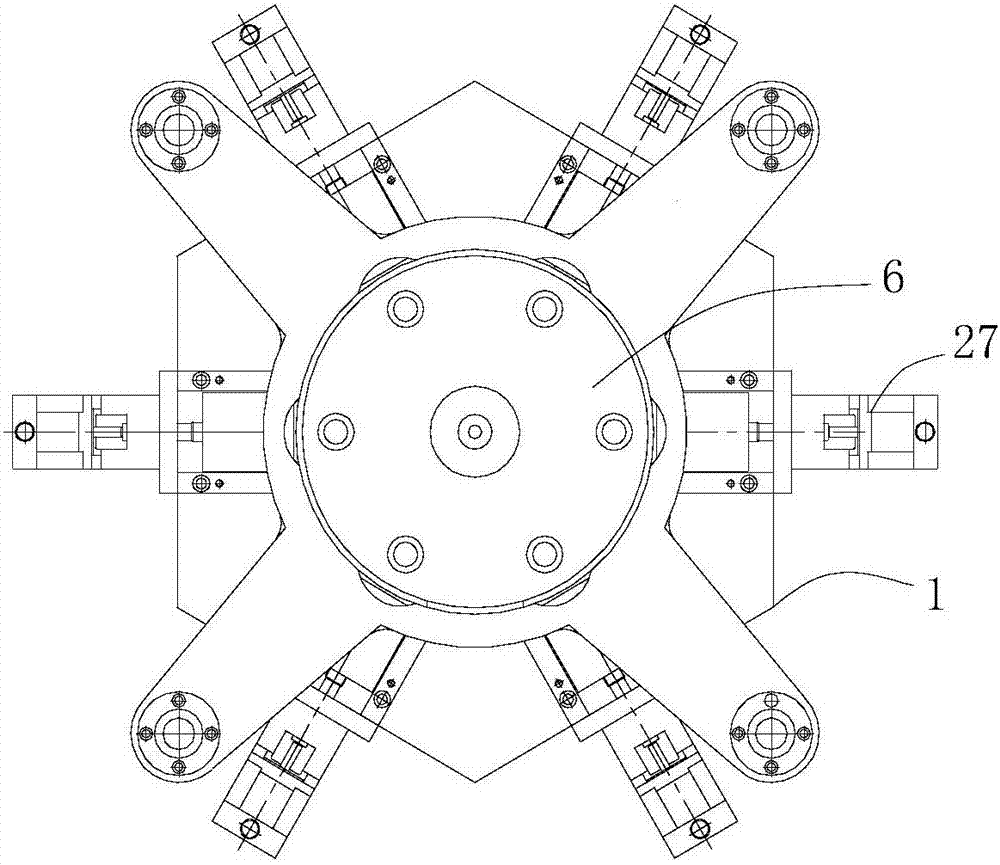

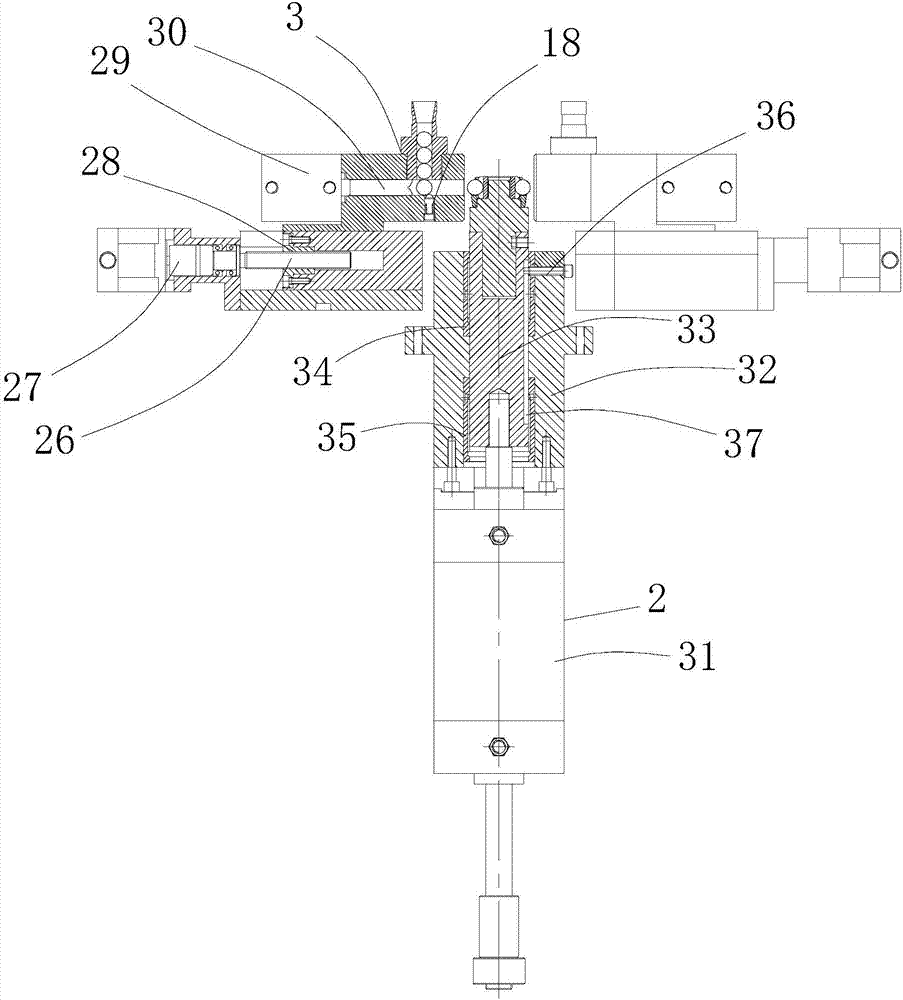

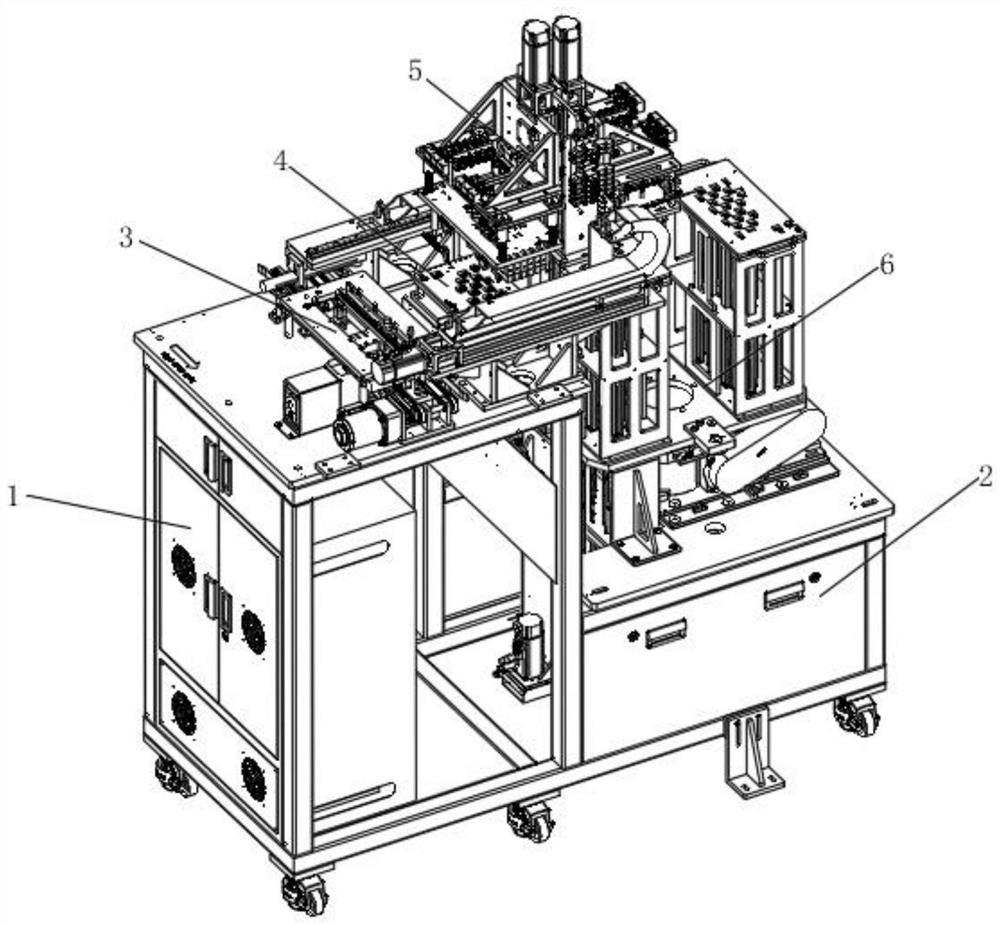

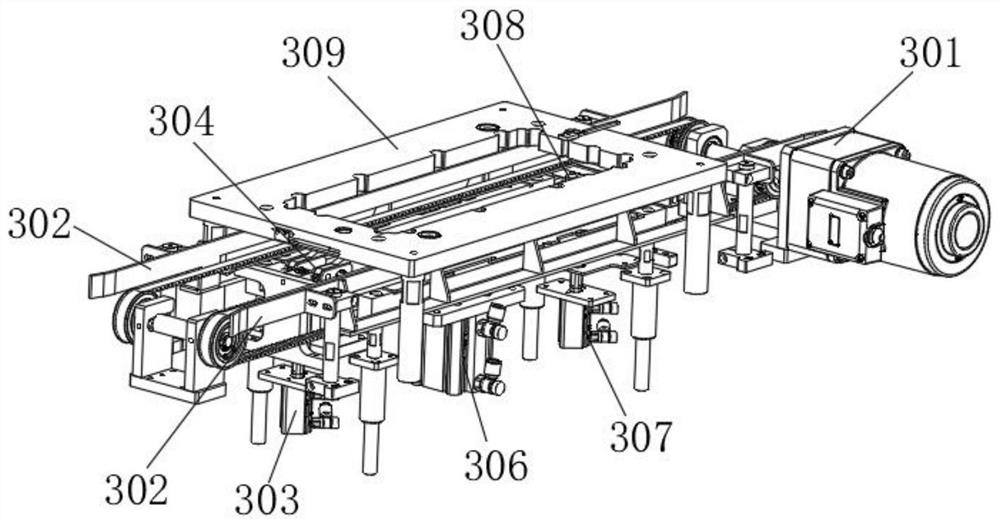

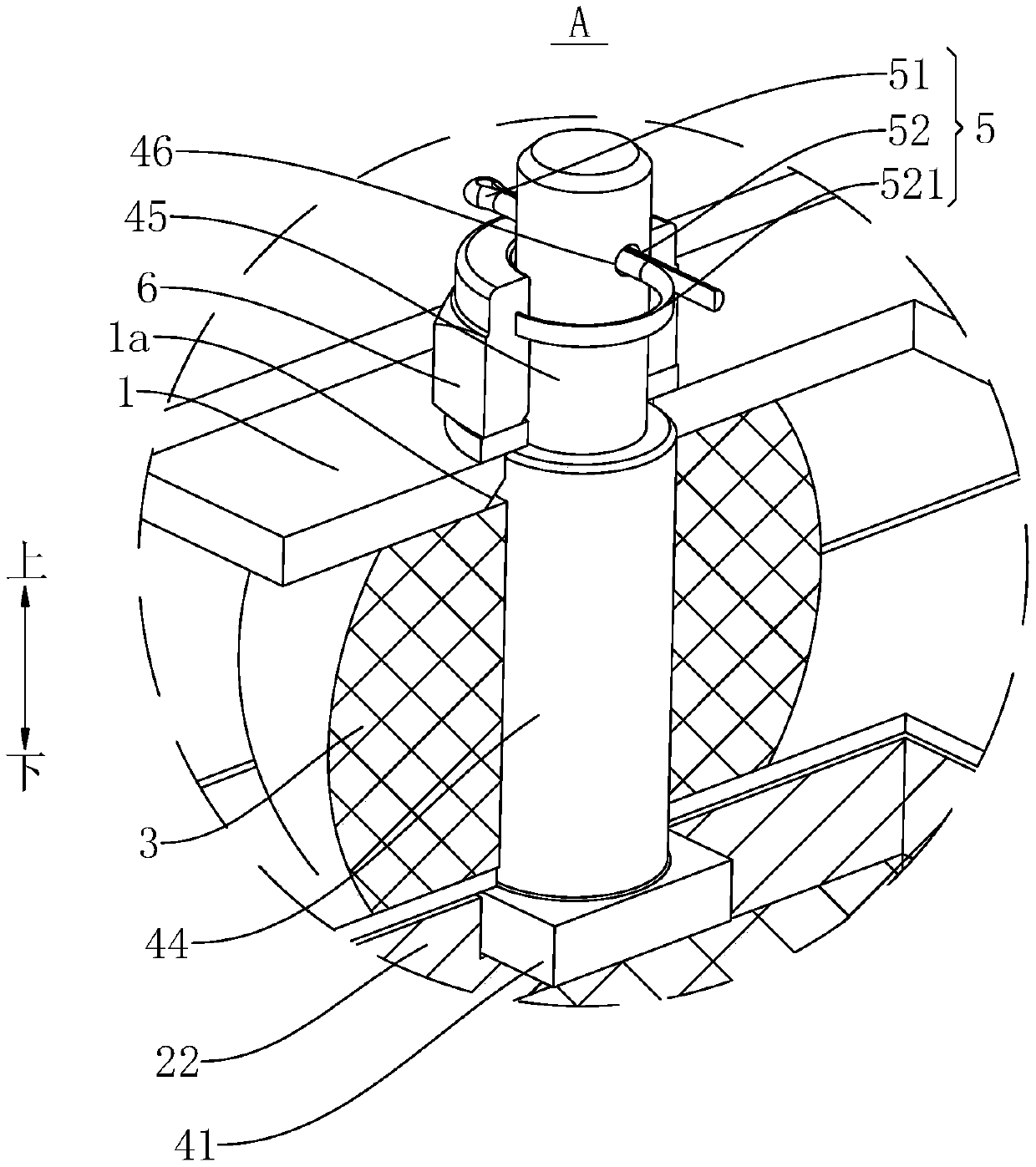

Pressing-assembling device for force-transmitting steel balls of universal joint

ActiveCN107350777AGuaranteed assembly accuracyReduce labor intensityMetal working apparatusMetallurgyUniversal joint

The invention provides a pressing-assembling device for force-transmitting steel balls of a universal joint. According to the pressing-assembling device, a steel ball feeding mechanism supplies steel balls one by one to steel ball pressing-assembling mechanisms, a workpiece positioning machine mechanism is used for positioning a workpiece and enabling the workpiece to stay in a correct position, and the steel ball pressing-assembling mechanisms press the steel balls into the workpiece. Compared with the prior art, assembling of the steel balls is automatically completed by the pressing-assembling device, so that the labor intensity of operators is reduced, the steel balls are pressed and assembled by the corresponding steel ball pressing-assembling mechanisms in the assembling process, the assembling precision of the steel balls can be effectively guaranteed, and the usability of the universal joint is optimized; compared with traditional manual assembling steel ball process, the steel balls are mechanically assembled, the efficiency is improved, and the assembling speed of the pressing-assembling device is five seconds per steel ball while original manual assembling speed is about eight seconds per steel ball; and the phenomena of neglected-assembling of the steel balls can exist when the steel balls are assembled manually, by adopting the pressing-assembling device to assemble the steel balls, the steel ball pressing-assembling mechanisms can work at the same time so that the phenomenon of the neglected-assembling can be effectively avoided.

Owner:ZHEJIANG ODM TRANSMISSION TECH

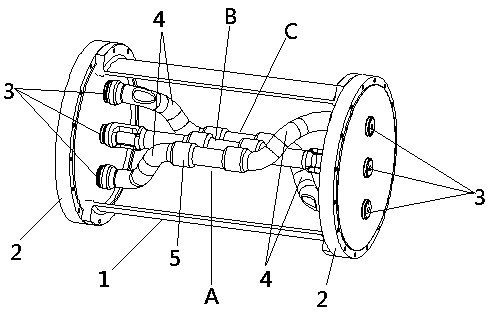

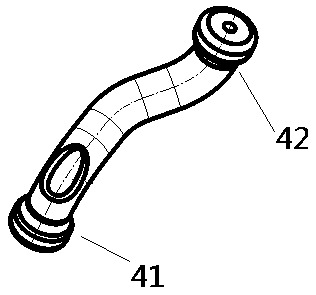

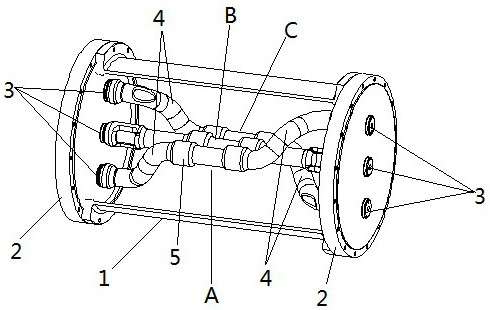

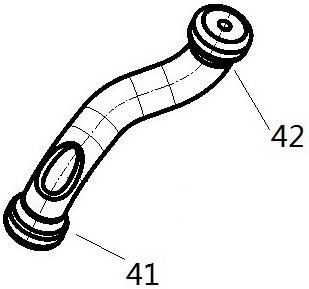

Three-phase conductor commutation connector

ActiveCN111129890AAchieve connectionRealize phase sequence interchangeSwitchgear arrangementsCoupling device detailsElectrical conductorEngineering

The invention relates to a three-phase conductor phase-change connector which comprises a sealing cylinder and sealing flanges installed at two ends of the sealing cylinder, the two sealing flanges are each provided with three through connection inserts, and the through connection inserts on the two sealing flanges are arranged in the same straight line in the extending direction. A three-phase conductor is arranged in the sealing cylinder, and two ends of the three-phase conductor are correspondingly connected with the three switching inserts on the two sealing flanges respectively; and two-phase conductors at two sides in the three-phase conductors are provided with bending sections, so that two ends of each phase of conductor in the two-phase conductors are respectively connected with the two switching inserts which are arranged on the two sealing flanges and are positioned at two sides of the axis of the sealing cylinder body. By means of the arrangement, under the condition that the three-phase arrangement modes of the two ends of the three-phase conductor commutation connector are the same, the phase sequence interchange of a phase A and a phase C can be achieved, in the actual use process, the three-phase conductor commutation connector is directly installed at a three-phase connector of equipment, the phase sequence interchange of the phase A and the phase C is achieved, and therefore, the connection of three-phase different-phase-sequence equipment is achieved.

Owner:PINGGAO GRP +2

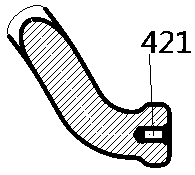

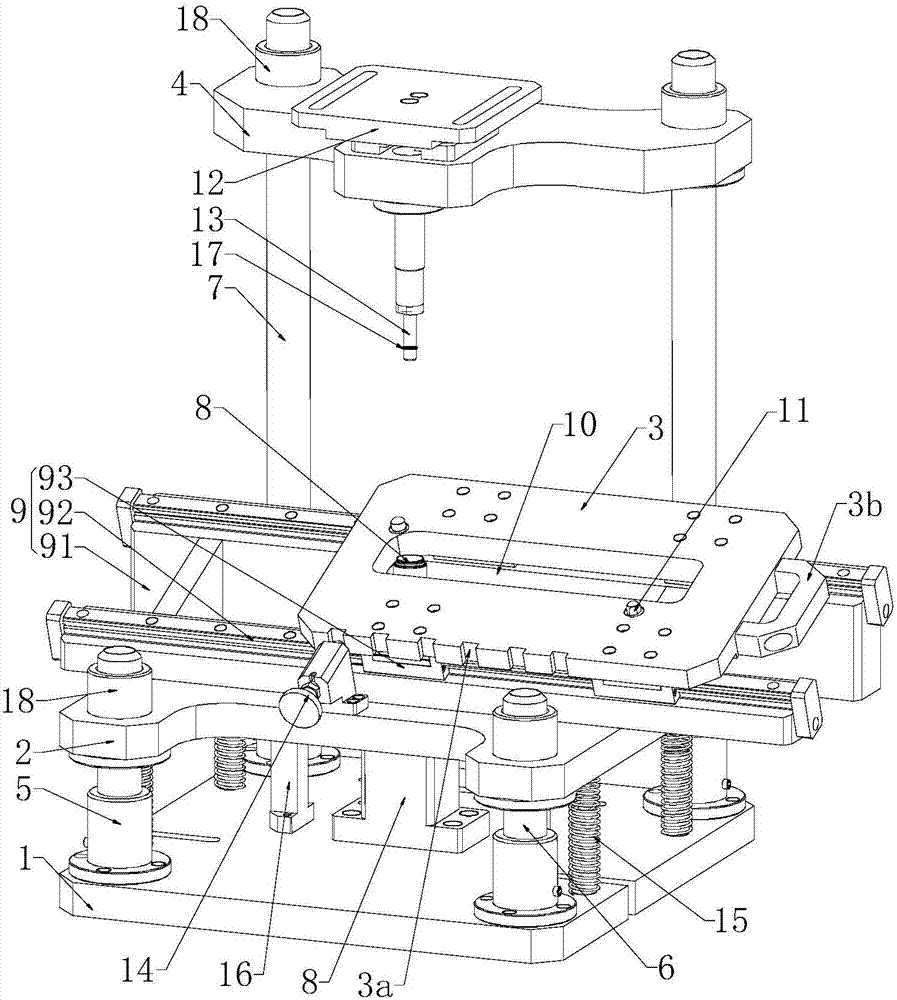

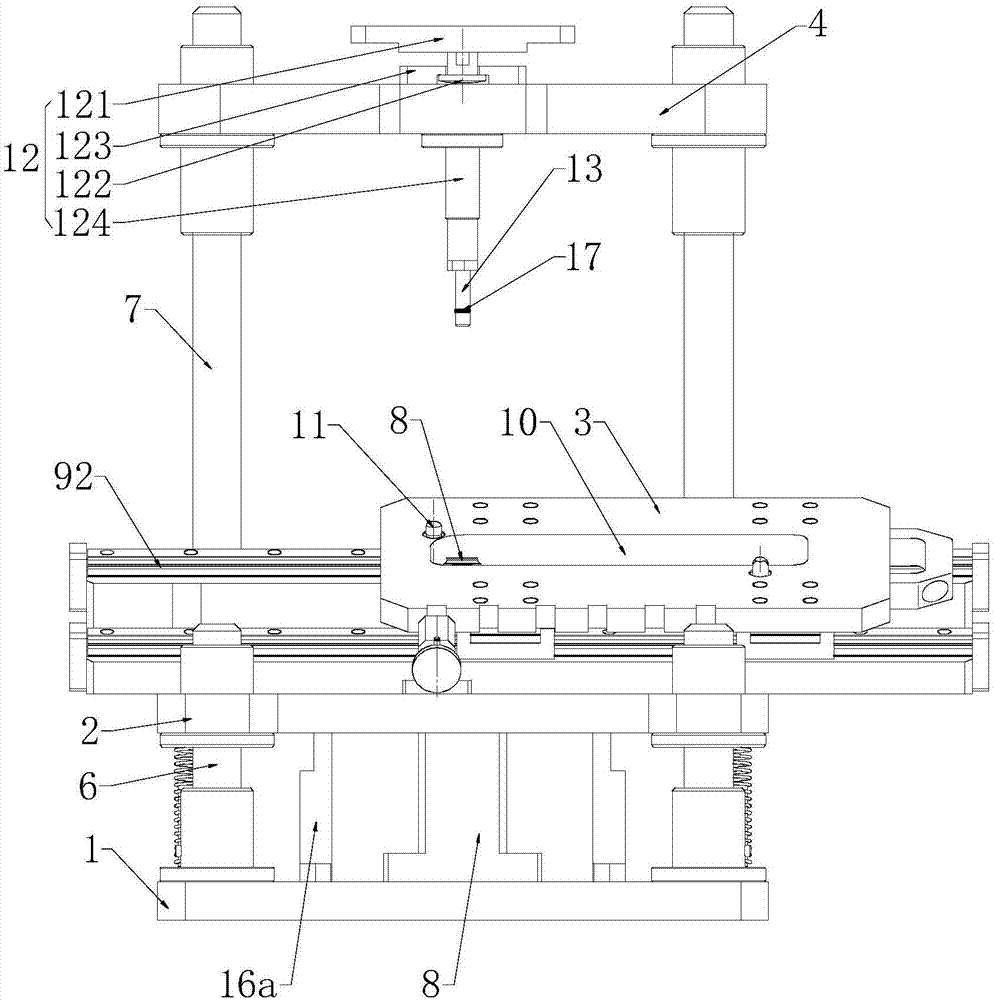

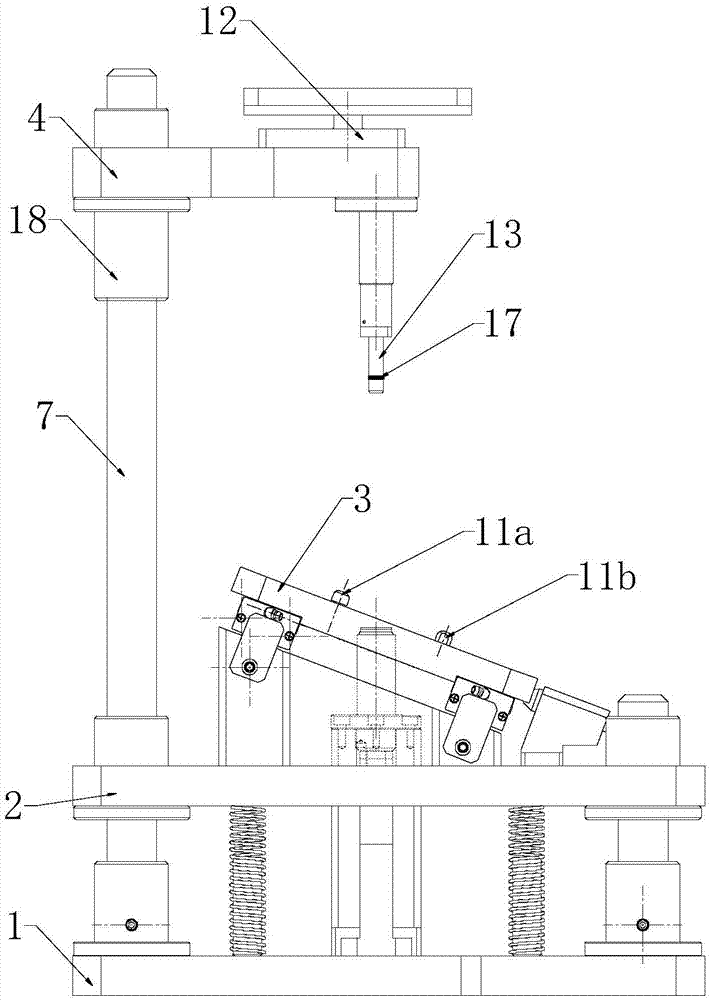

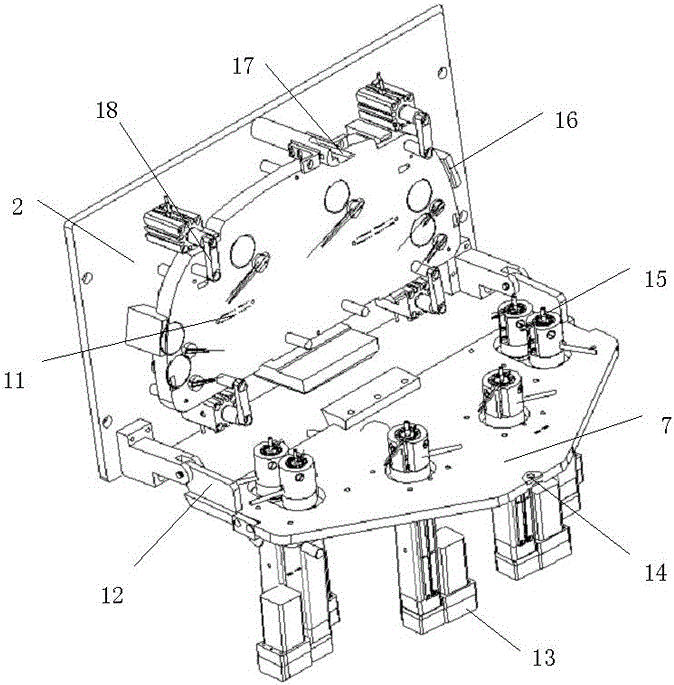

Pressing-mounting equipment for pressing-mounting of cylinder cover guide pipe and seat ring

PendingCN107971729AIncrease productivityPrecise positioningMetal working apparatusOutput deviceEngineering

The invention discloses pressing-mounting equipment for pressing-mounting of a cylinder cover guide pipe and a seat ring. The pressing-mounting equipment comprises a foot plate, a bottom plate, a supporting plate and a top plate; at least two short vertical columns and at least two long vertical columns are fixed to the foot plate through guiding sleeves; the bottom plate is supported on the shortvertical columns and the long vertical columns in sliding and sleeving modes; a positioning shaft is further fixed to the foot plate; the obliquely-arranged supporting plate is mounted above the bottom plate through a sliding supporting mechanism; and a machining groove is formed in the center of the supporting plate, and the upper portion of the positioning shaft extends into the machining groove; a positioning pin assembly is arranged on the supporting plate; the top plate is supported on the upper portions of the long vertical columns in sliding and sleeving modes, and a pressure transferassembly for being connected to a pressure output device is arranged in the middle of the top plate; and the lower end of the pressure transfer assembly is connected with a guide pipe fixing sleeve which corresponds to the positioning shaft in position. The pressing-mounting equipment has the remarkable effects that pressing-mounting work of the cylinder cover guide pipe and the seat ring is completed by the equipment instead of manual work, and the advantages of high pressing-mounting efficiency, low equipment input and good product quality are achieved.

Owner:CHONGQING SCI & TECH CO LTD YINGXI

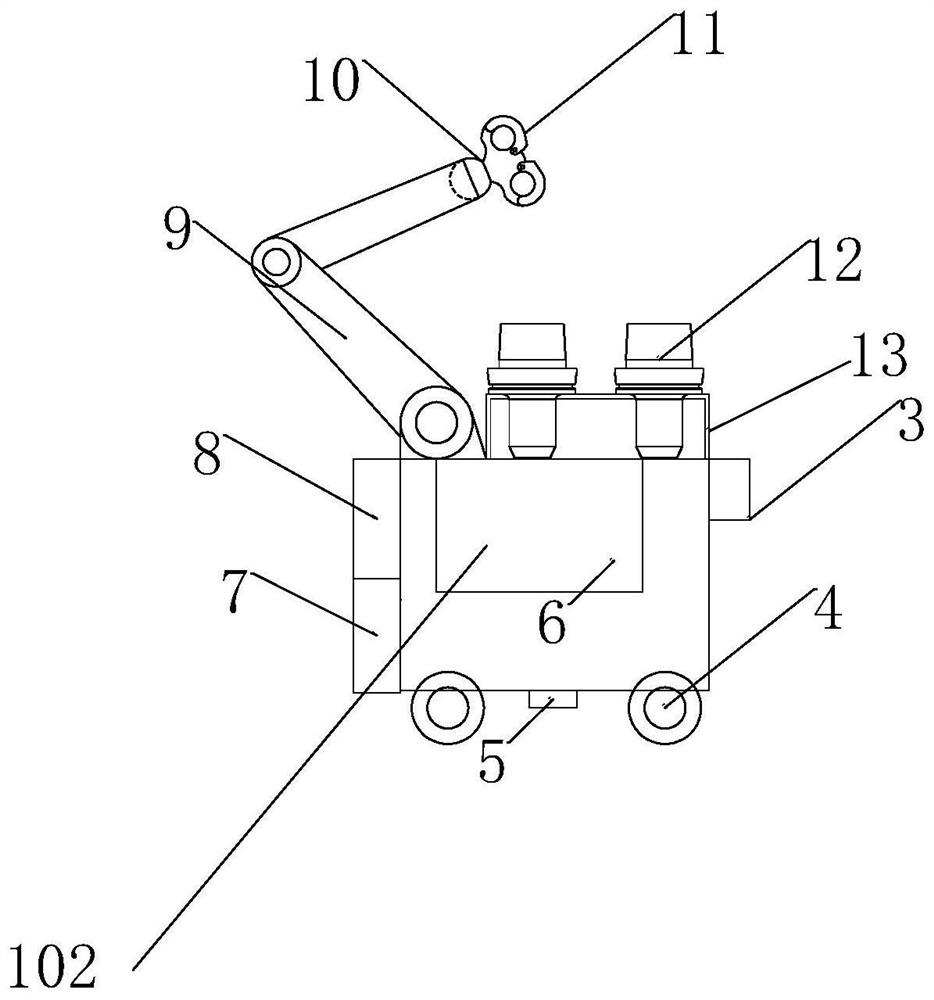

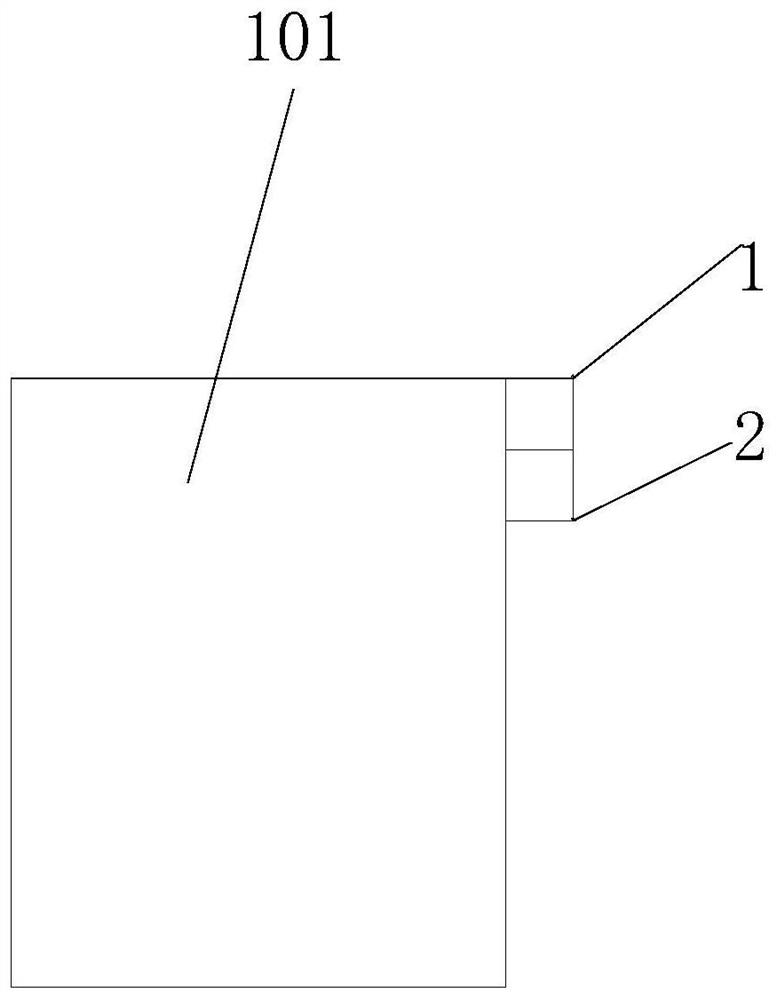

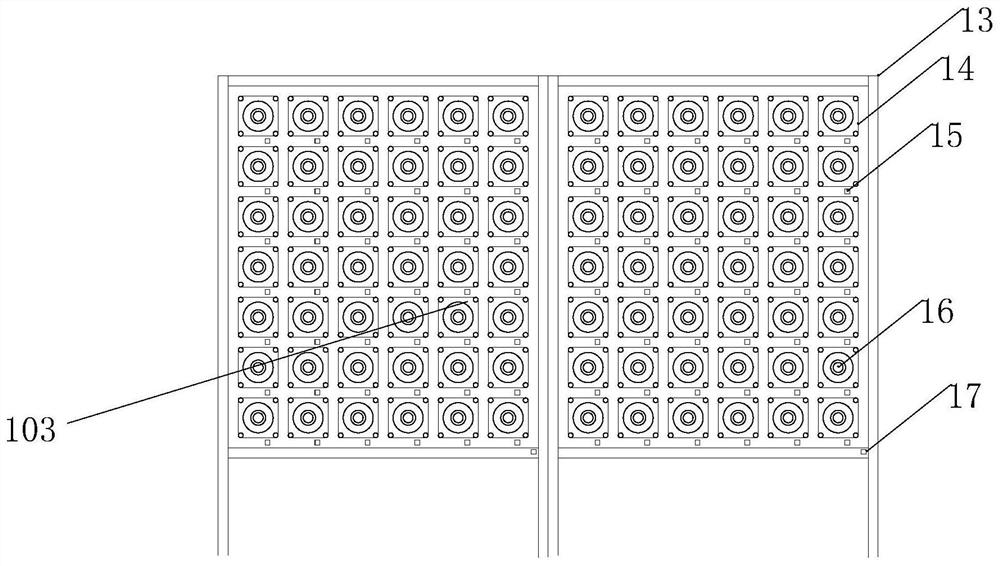

Machining center shared tool rest/tool magazine system and method capable of achieving infinite expansion

The invention provides a machining center shared tool rest / tool magazine system and method capable of achieving infinite expansion. A machining center end 101, a moving trolley 102 with a robot arm and a tool magazine component 103 are included. The machining center end 101 comprises a first machining center tool mounting position positioning point 1 and a machine equipment sequence identifier 2. The first machining center tool mounting position positioning point 1 and the machine equipment sequence identifier 2 are mounted on the machining center shared tool rest / tool magazine system capable of achieving infinite expansion. The moving trolley 102 with the robot arm runs in the machining center shared tool rest / tool magazine system capable of achieving infinite expansion. The moving trolley 102 with the robot arm can run to the tool magazine part 103. By means of the machining center shared tool rest / tool magazine system and method capable of achieving infinite expansion, limitation of opening a tool magazine can be broken through, the tool magazine can be shared by multiple machining devices, and meanwhile the tool magazine has better expandability.

Owner:上海德舒赫金属制品有限公司

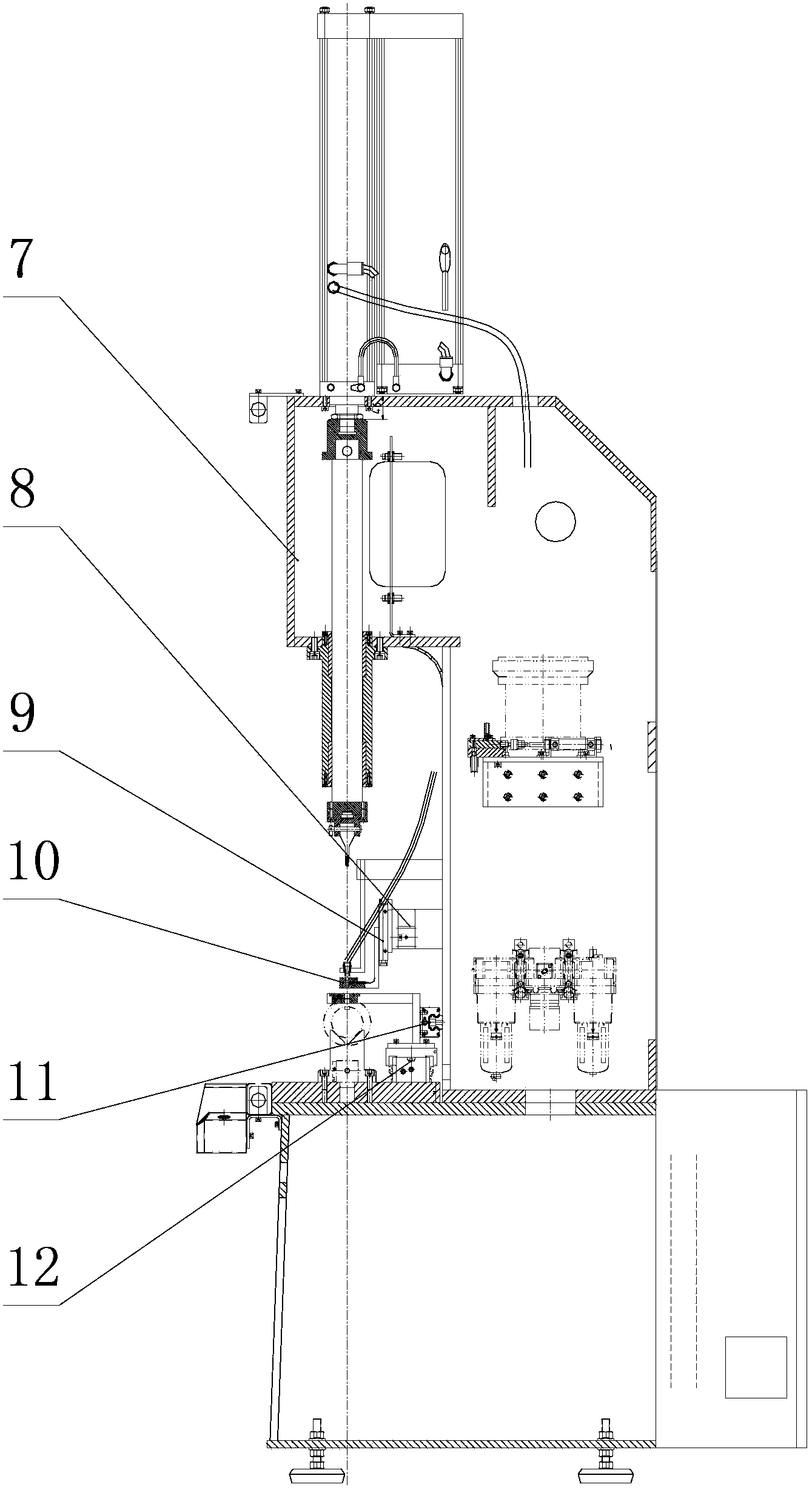

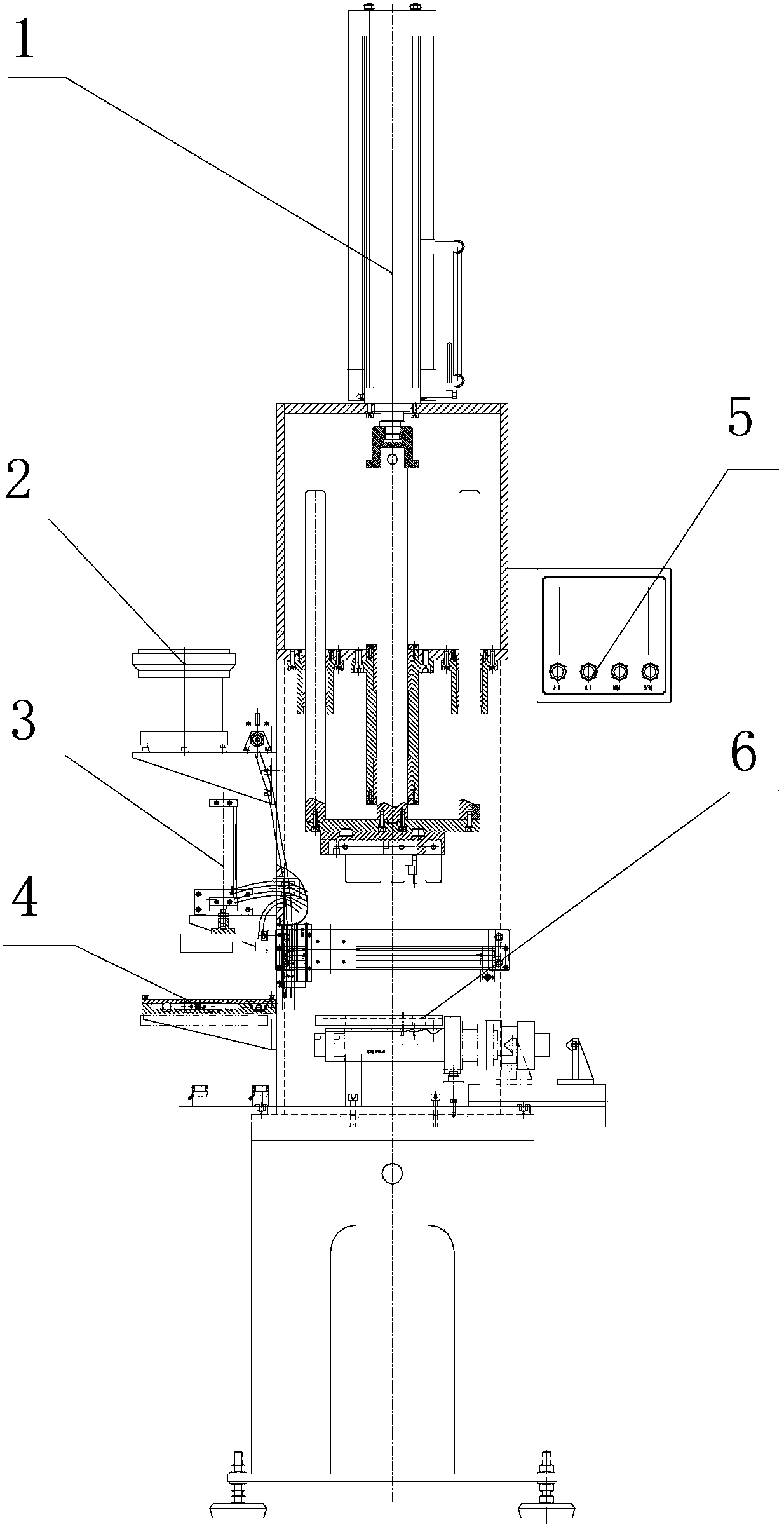

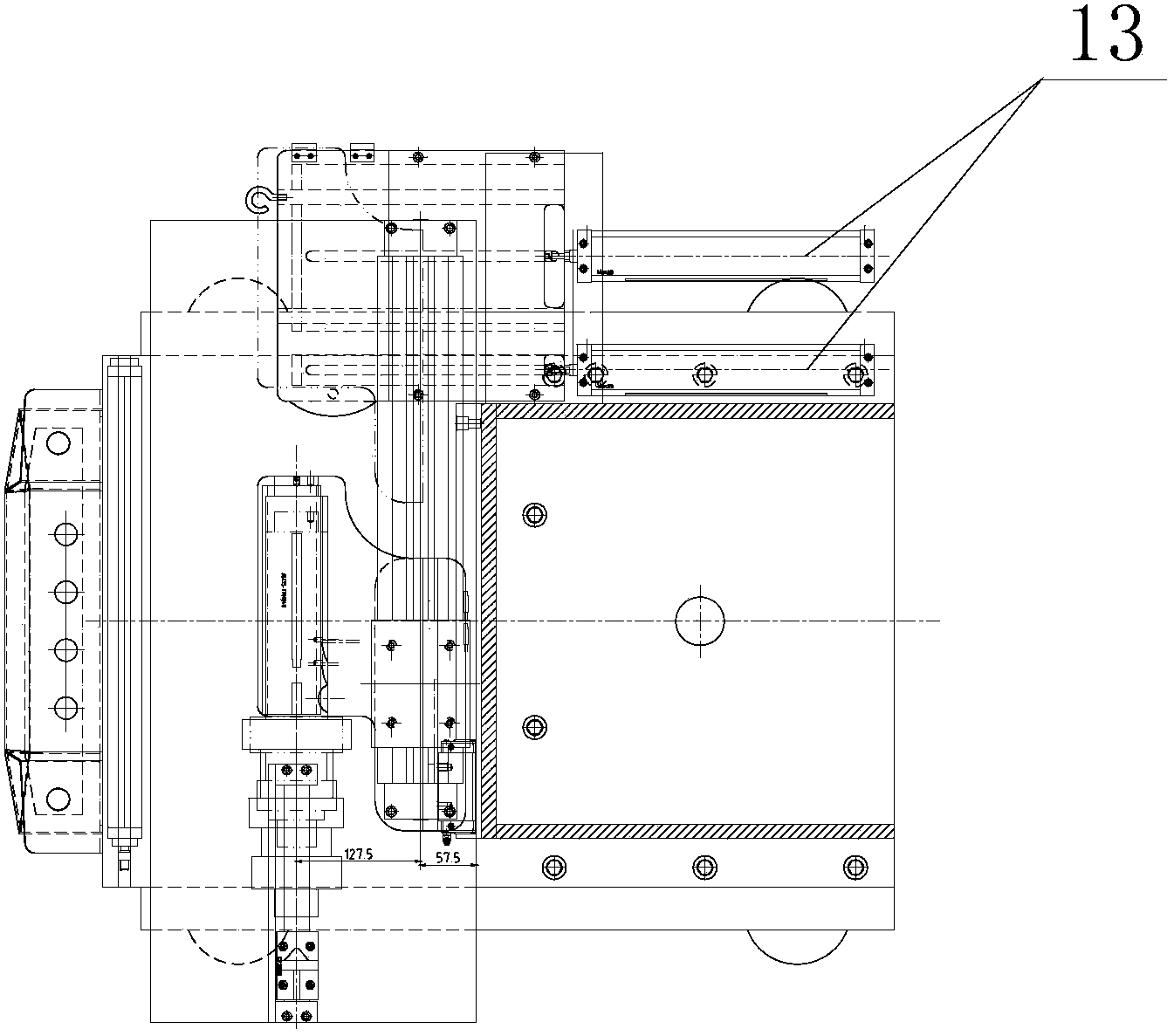

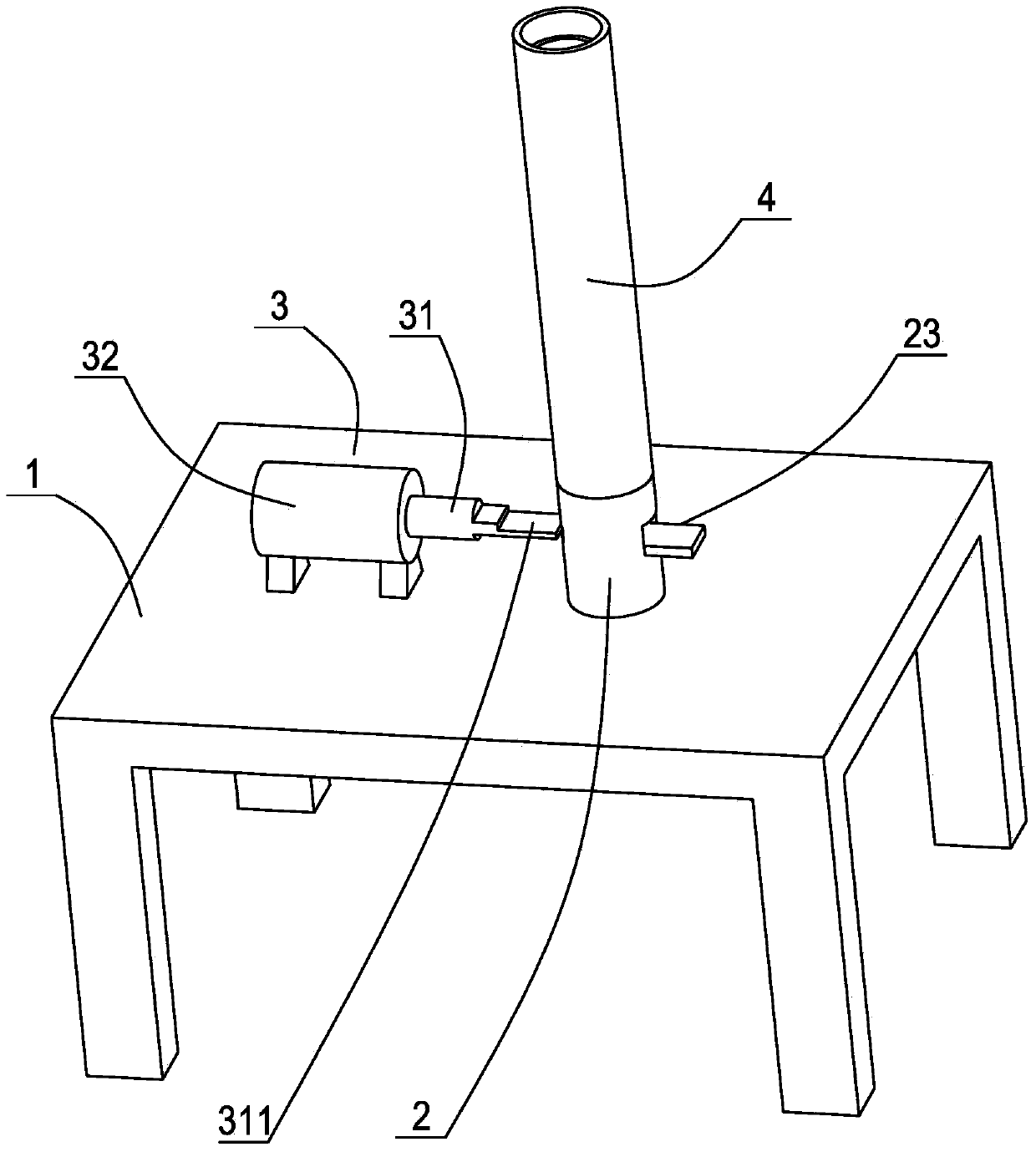

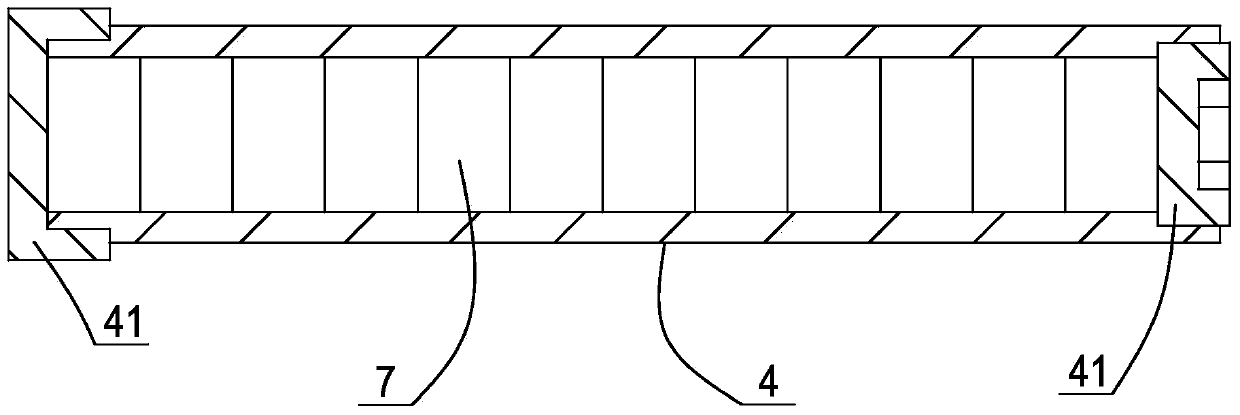

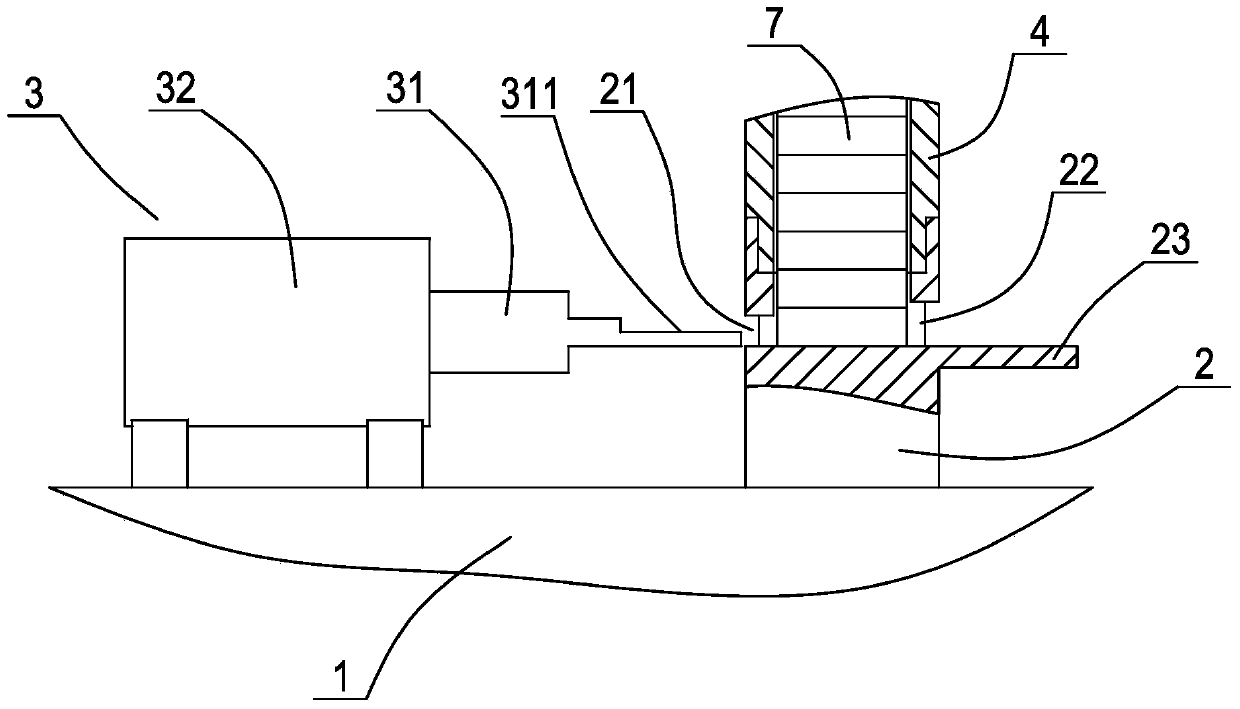

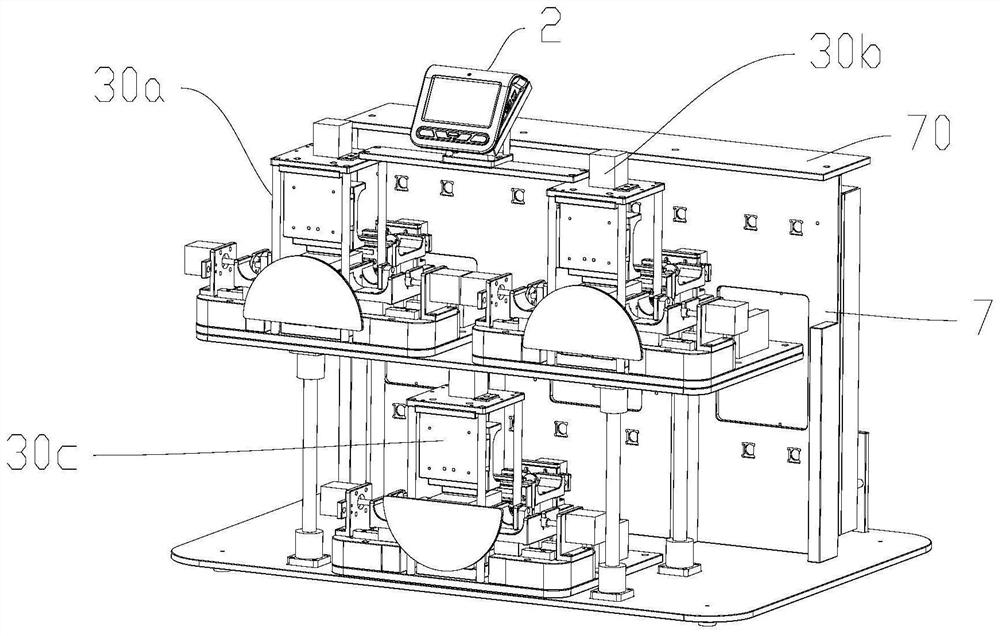

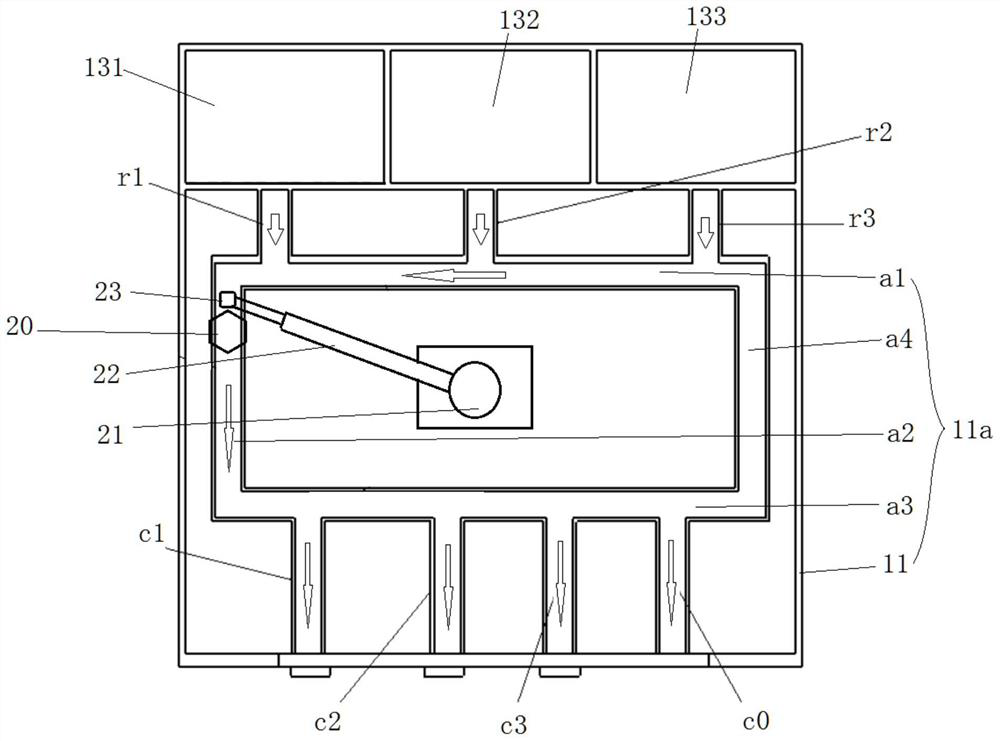

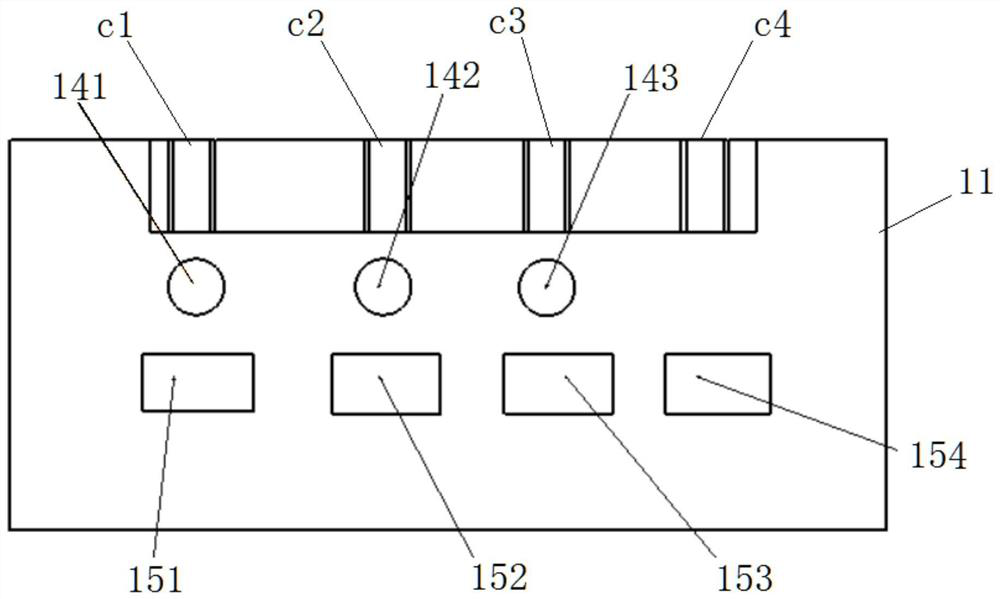

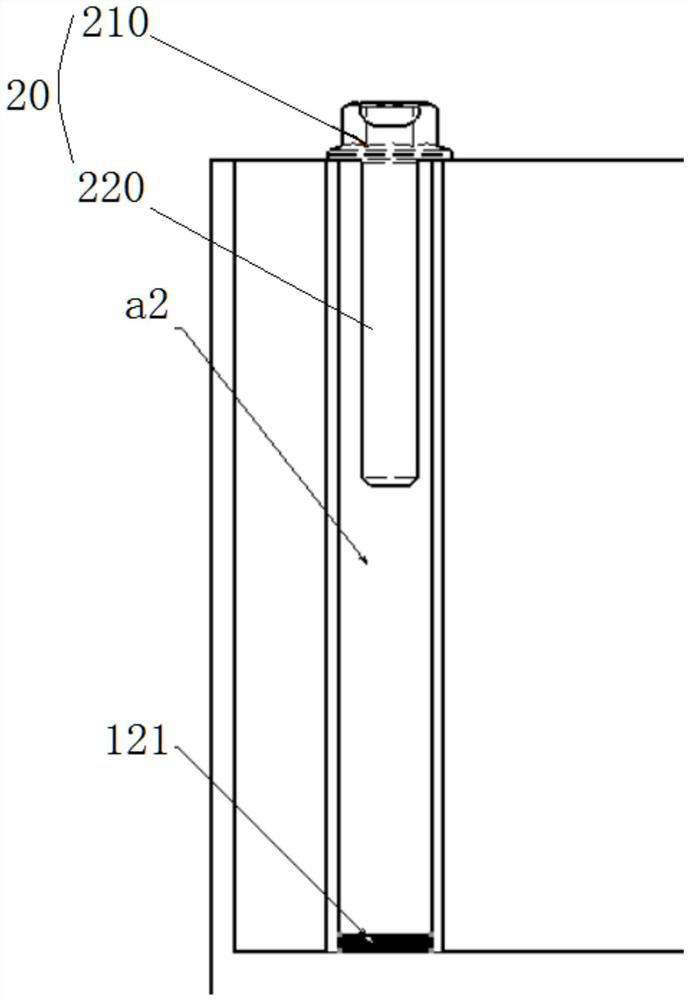

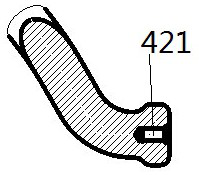

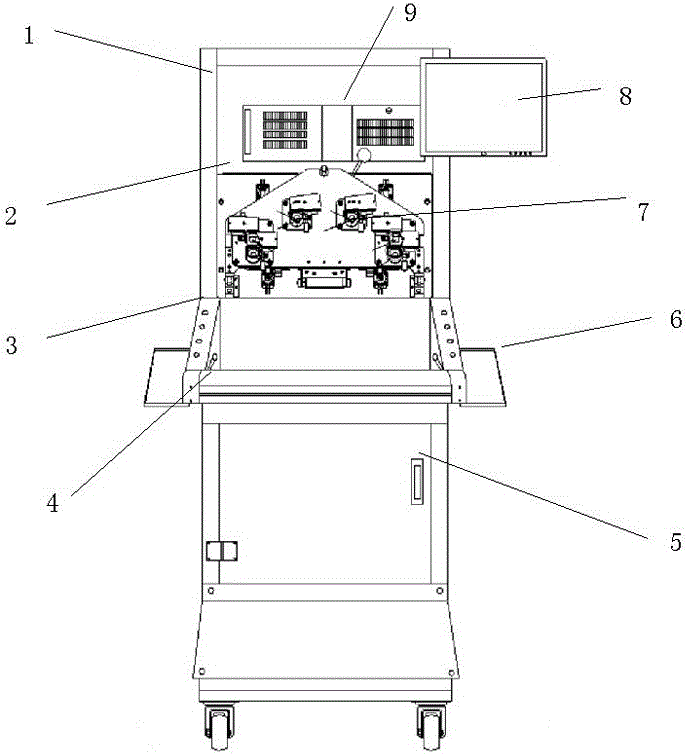

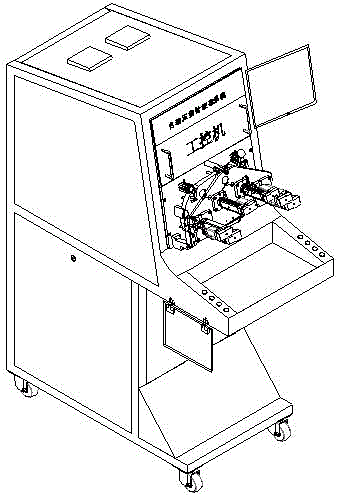

Automatic press-fitting unit for transmission intermediate shaft key pins

InactiveCN103846661BGuaranteed assembly accuracyImprove assembly efficiencyAssembly machinesMetal working apparatusUltimate tensile strengthAssembly machine

The invention belongs to the technical field of transmission assembly and particularly relates to a transmission countershaft key and pin full-automatic press-fitting unit comprising a body, a press-fitting device, an elastic cylindrical pin separating mechanism, an elastic cylindrical pin conveying mechanism, a key feeding mechanism, and a key conveying mechanism; the press-fitting device, the elastic cylindrical pin separating mechanism, the elastic cylindrical pin conveying mechanism, the key feeding mechanism and the key conveying mechanism are mounted on the body. A plurality of elastic cylindrical pins to be press-fitted are separated by the elastic cylindrical pin separating mechanism and then fall into the elastic cylindrical pin conveying mechanism; the elastic cylindrical pin conveying mechanism conveys the elastic cylindrical pins to be above a transmission countershaft positioned on the body; the elastic cylindrical pins are press-fitted into pinholes of the transmission countershaft by the press-fitting device; keys to be press-fitted fall into the key conveying mechanism through the key feeding mechanism; the key conveying mechanism conveys the keys to be above the transmission countershaft; the keys are press-fitted into key grooves of the transmission countershaft by the press-fitting device. The transmission countershaft key and pin full-automatic press-fitting unit has the advantages that assembly precision is guaranteed, labor intensity is reduced for operators, and assembly efficiency is improved.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Keycap assembling machine

PendingCN112828556AReduce labor intensityOmit handlingMetal working apparatusSlide plateIndustrial engineering

The invention relates to a keycap assembling machine which comprises a left rack and a right rack. The left rack is sequentially provided with a conveying mechanism, a positioning mechanism and an adsorption assembling mechanism from left to right. The positioning mechanism comprises a positioning bottom plate, a deviation rectifying air cylinder, a positioning sliding plate, a material stirring block, a keycap carrying plate and a keycap positioning plate. The adsorption assembling mechanism comprises a base, an X linear module, an assembling sliding plate, a first Z linear module, a second Z linear module, an assembling suction head, a floating plate, a spring, a feeding suction head and an air blowing pipe, and a feeding mechanism is arranged on the right rack. The keycap assembling machine has the beneficial effects that keycaps can be automatically fed and installed, the production efficiency is improved, the labor intensity of workers is reduced, the processes of carrying and taking parts and the like are omitted, the parts are prevented from being damaged and mistakenly assembled, and high assembling quality can be guaranteed.

Owner:苏州镭拓精工机械科技有限公司

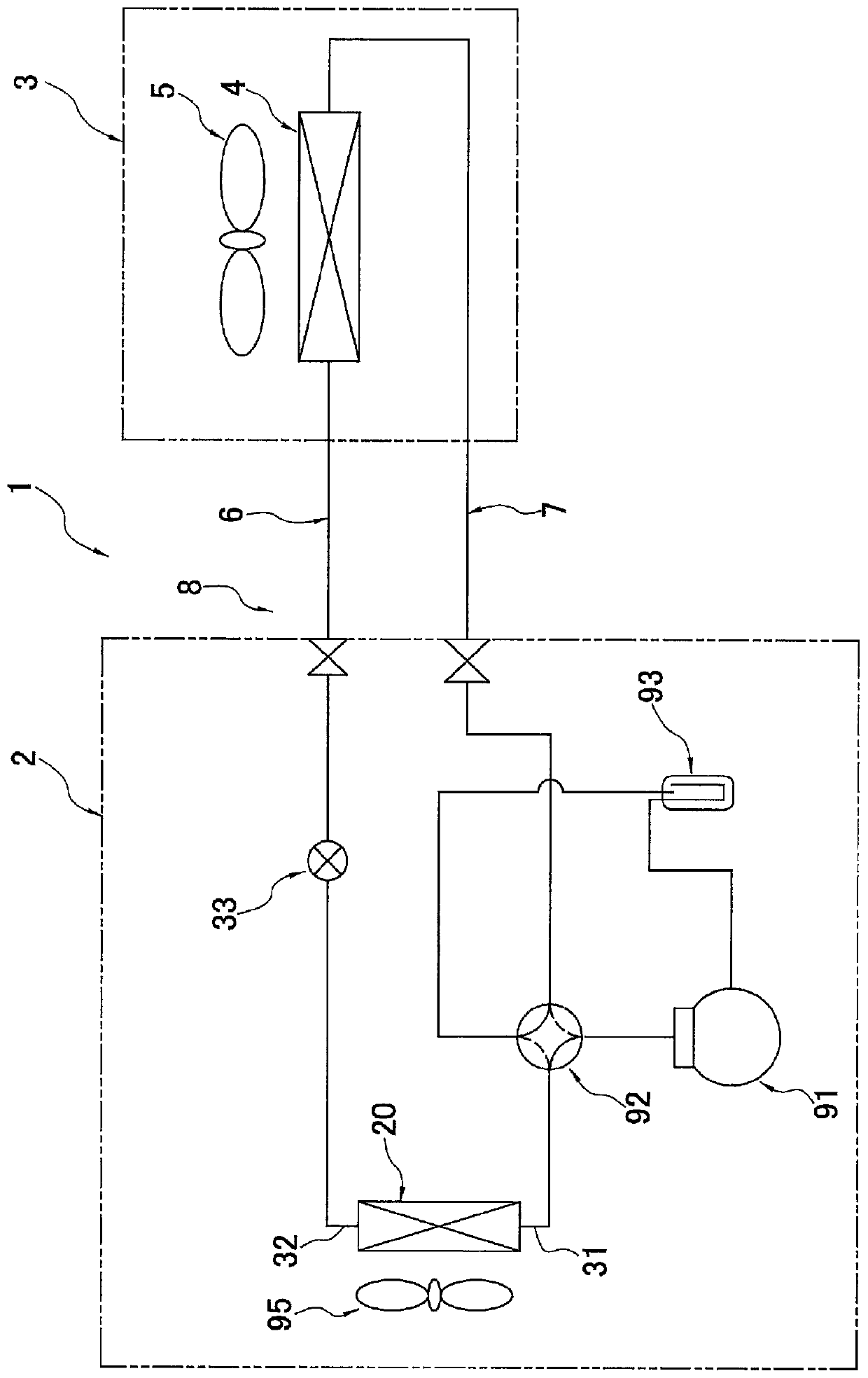

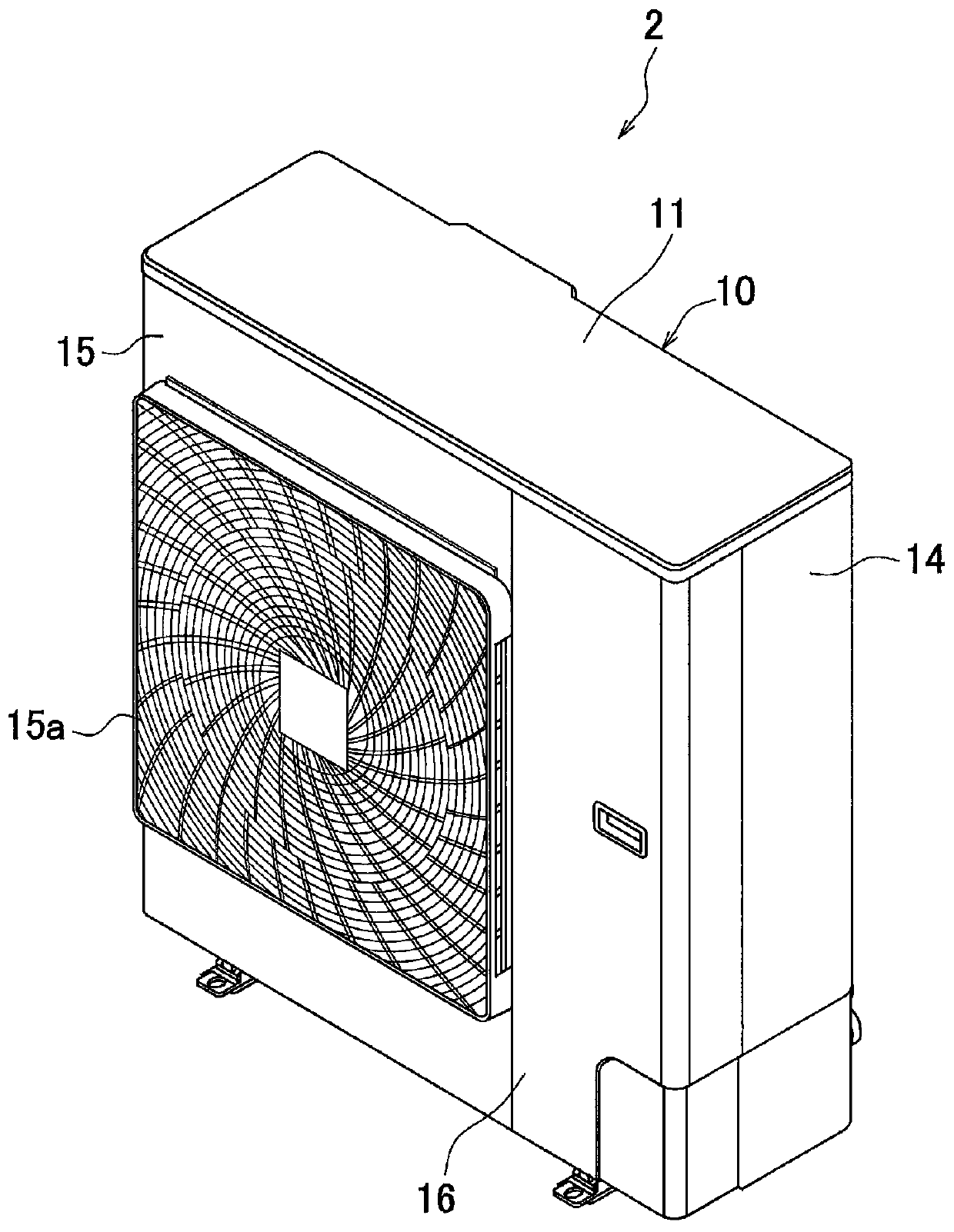

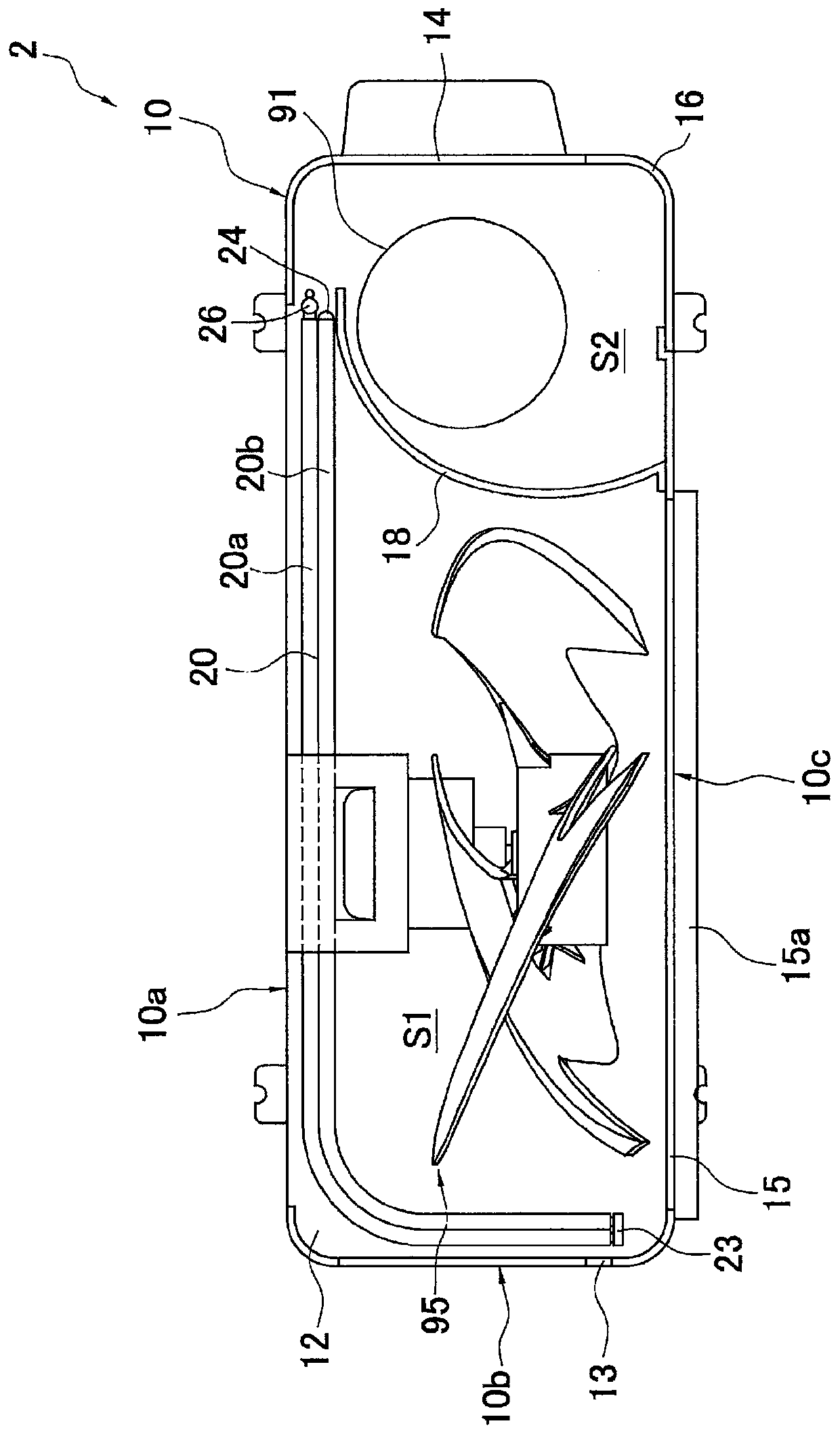

Heat exchanger and air conditioner

ActiveCN109791034AIncrease heat transfer areaAvoid frostEvaporators/condensersStationary conduit assembliesEngineeringRefrigerant

Provided are a heat exchanger and an air conditioner such that it is possible to minimize the difference between the states of the refrigerant flowing through flat perforated pipes on the windward side and the leeward side even with minimal difference between the compression strengths of the flat perforated pipes on the windward side and the leeward side. An outdoor heat exchanger (20) comprises aplurality of flat perforated pipes (50), a folded header (24), a plurality of heat transfer fins (40), and a partition member (70) that is provided with perforated-side uneven portions (88a) on the leeward side. In the outdoor heat exchanger (20), the space (61a, 61b) inside the folded header (24) to which the flat perforated pipes (50) are connected is configured such that more refrigerant flowson the windward side of the airflow direction than on the leeward side.

Owner:DAIKIN IND LTD

Vaporizer

InactiveCN107343975AAdjustable distanceGuaranteed stabilityMedical atomisersEngineeringMechanical engineering

The invention discloses a vaporizer, which relates to the technical field of sprayers or vaporizers specially used for therapeutic purposes. The vaporizer comprises a cup body, a cup core, an umbrella cap, a cup cover and an umbrella cap driving component, wherein the umbrella cap is positioned by the cup core, the umbrella cap is in threaded connection with the umbrella cap driving component. Threads are used for driving, thread movement is changed into lifting movement of the umbrella cap, so that the umbrella cap can only move up and down between curved plates in the cup cover to achieve the adjustment of a distance between the umbrella cap and the cup core, thereby achieving adjustment of atomization particles.

Owner:INNER MONGOLIA YING HUA RONG TAI HI TECH DEV +1

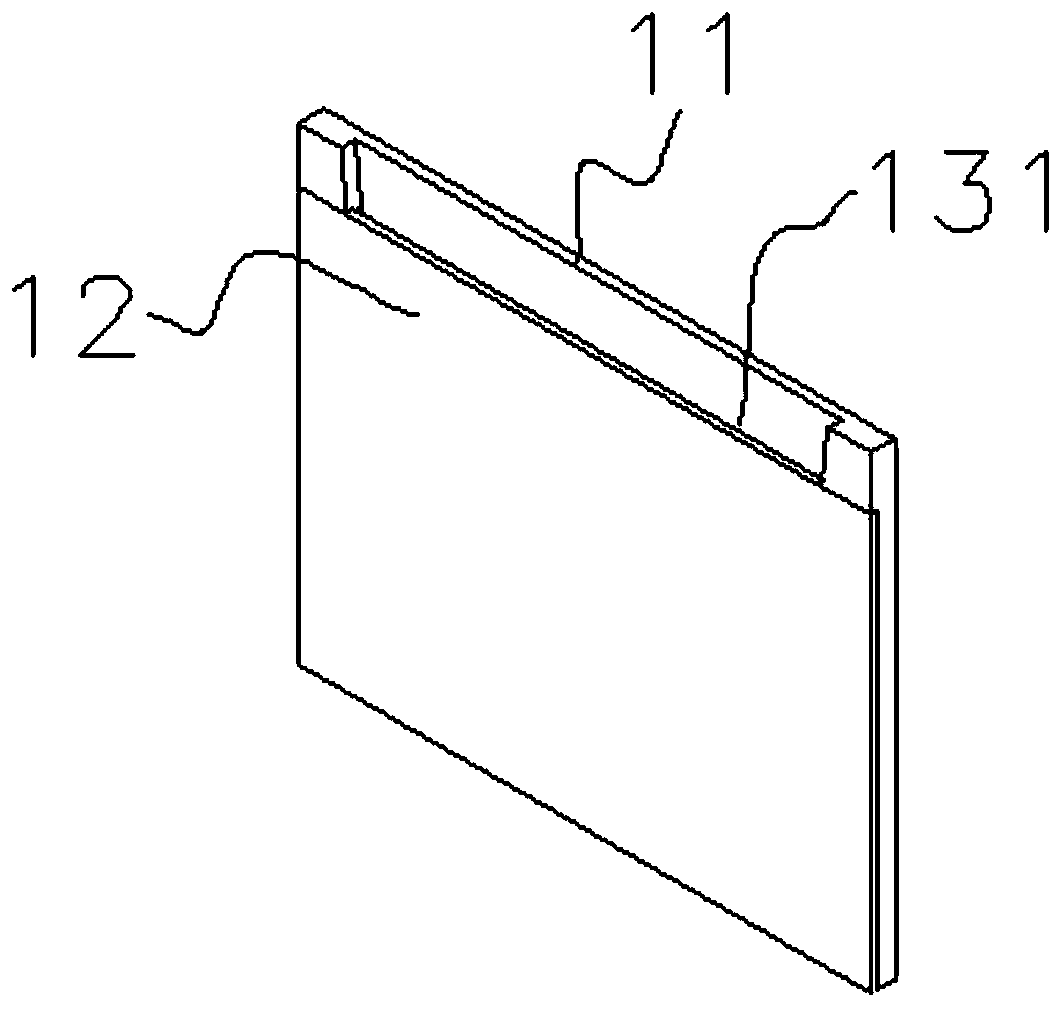

Vertical electrophoresis tank and electrophoresis apparatus

ActiveCN108490059ASmall footprintImprove cleanlinessMaterial analysis by electric/magnetic meansElectricityElectrophoresis

The invention provides a vertical electrophoresis tank and an electrophoresis apparatus. The vertical electrophoresis tank comprises a slide assembly, a gel frame assembly and a groove body assembly,wherein the slide assembly comprises a large slide and a small slide used for forming a gel preparing cavity, and a lateral opening groove communicated with the bottom of the gel preparing cavity is formed in the large slide; the gel frame assembly comprises a gel frame, a concave sealing member, a first negative electrode conduction member and a first positive electrode conduction member; the groove body assembly comprises a groove body, a pressing mechanism, a second negative electrode conduction member and a second positive electrode conduction member. The conduction of an electrode and thepressing of the slide assembly are synchronously completed by the pressing mechanism to eliminate the single operation of locking and inserting positive and negative electrodes sequentially in the slide assembly of traditional electrophoresis equipment to prevent the leakage of electricity and electric shocks; gel preparing and electrophoresis are completed in the vertical electrophoresis tank, additional gel preparing auxiliary devices are not needed, occupied space of electrophoresis testing equipment is saved, the operation is easier, and externally dripping gel liquid in the gel preparingprocess is accumulated in the groove body, so that the cleanliness of a testing tabletop is improved.

Owner:莫纳(武汉)生物科技有限公司

Method for processing eels

The invention belongs to the field of food processing, and particularly relates to a method for processing eels. The method comprises the following steps: firstly, breeding eels with empty stomach forat least 24 hours so as to clean eel intestines; secondly, keeping the eels unconscious with ice water so as to reduce activity; thirdly, killing the eels, removing bones and viscera so as to form eel slices, and cutting fish meat along the length direction of eel meat surface, wherein cutting depth is only less than that of fish meat part so as to guarantee the integrity of fish skin; fourthly,flush the eel slices with clear water; fifthly, punching the eel slices, rolling and massaging the punched eel slices with a rubber bar, then placing the rolled eel slices into a filter screen frame,and conducting filtration; and sixthly, conducting baking, firstly putting skin surface upwards and meat surface downwards, baking the slices by infrared rays positioned above the eels, then turning over the eel slices, and also baking the meat surface by the infrared ray. Eel slices with different specifications are selected according to different weight sizes, and then the eel slices are packaged according to the specifications. Through the combination of the process steps, the eel slices with good presentation, high yield, good flavoring by baking and good fishy smell removal can be obtained.

Owner:福清福荣食品有限公司

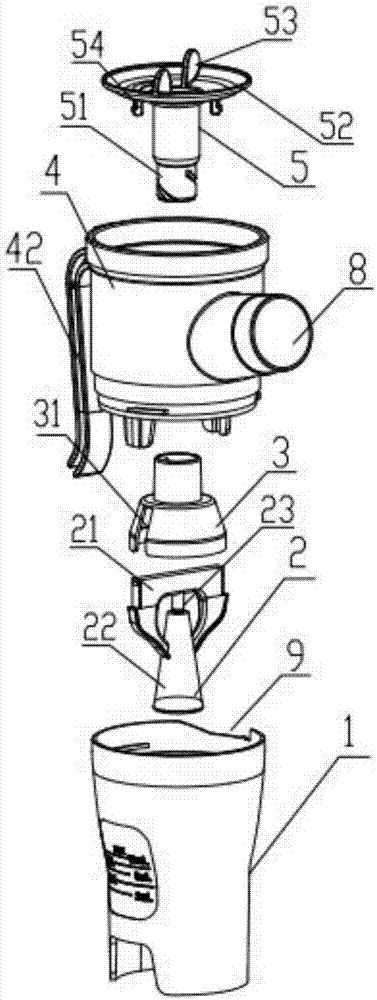

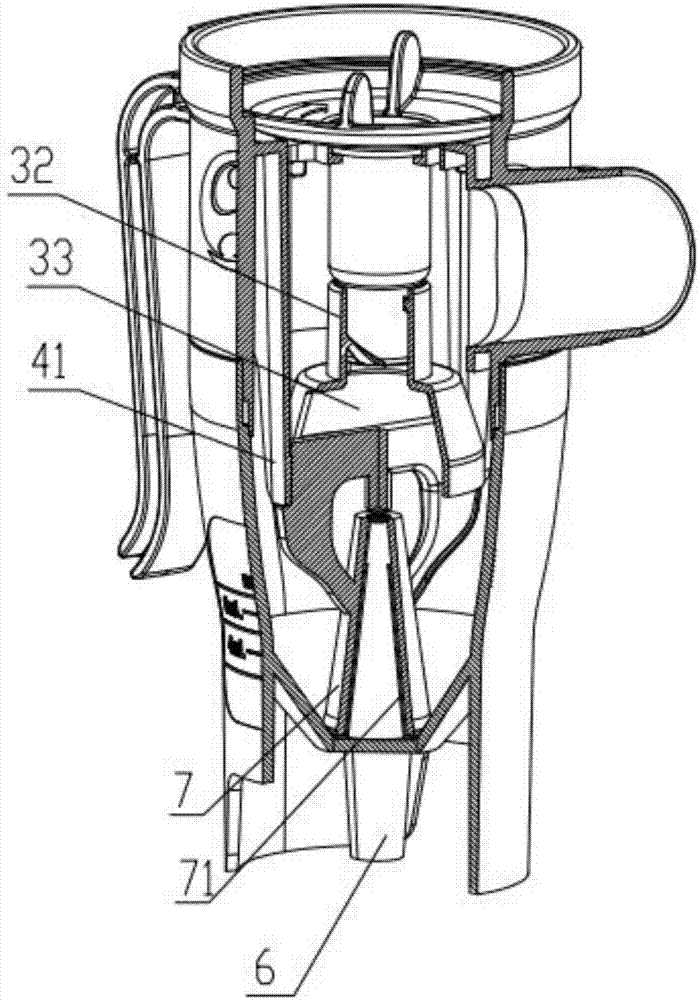

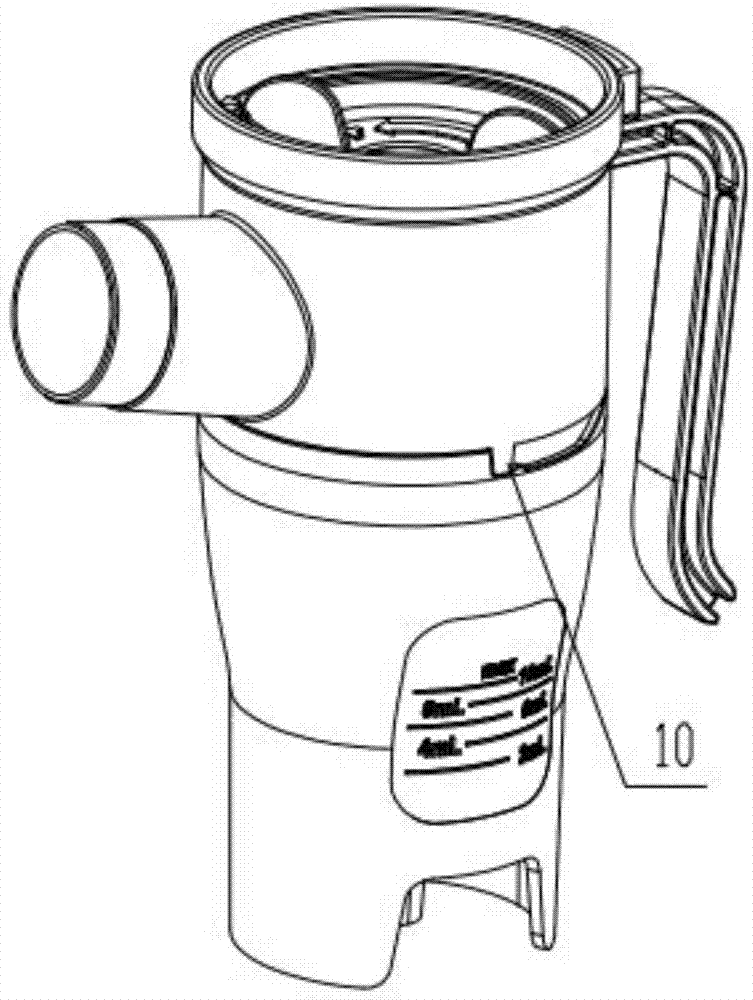

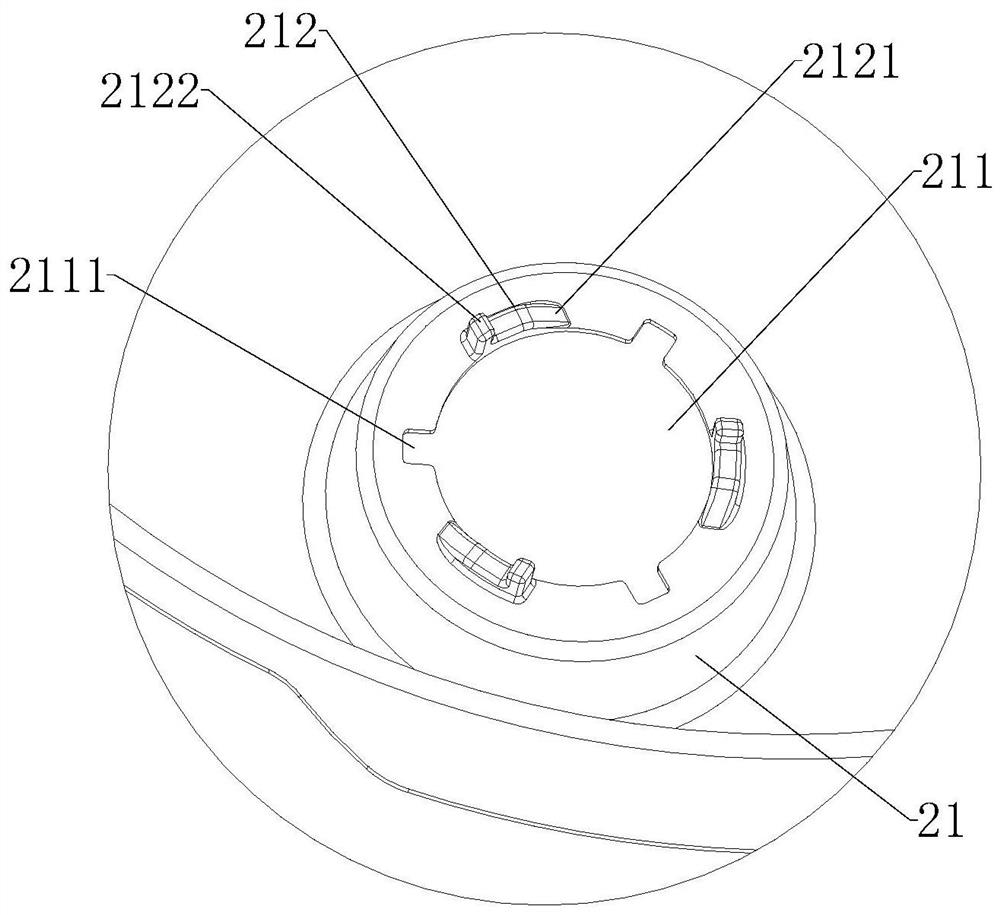

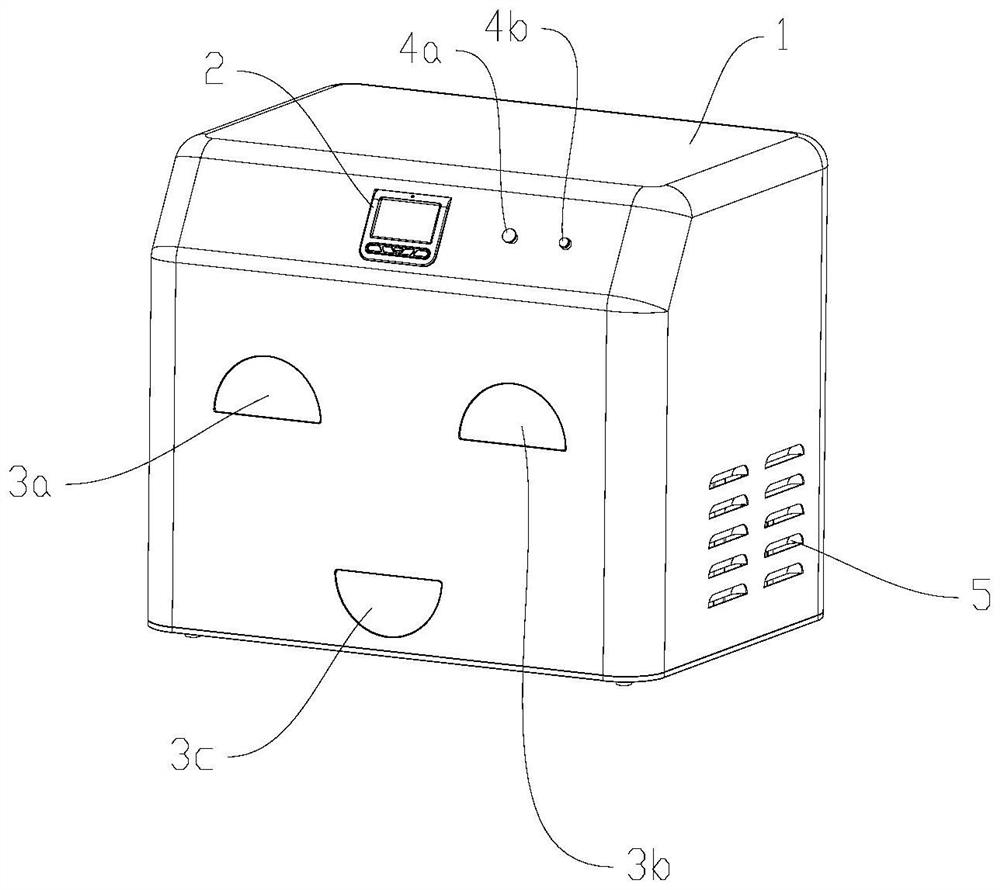

Multifunctional food processor

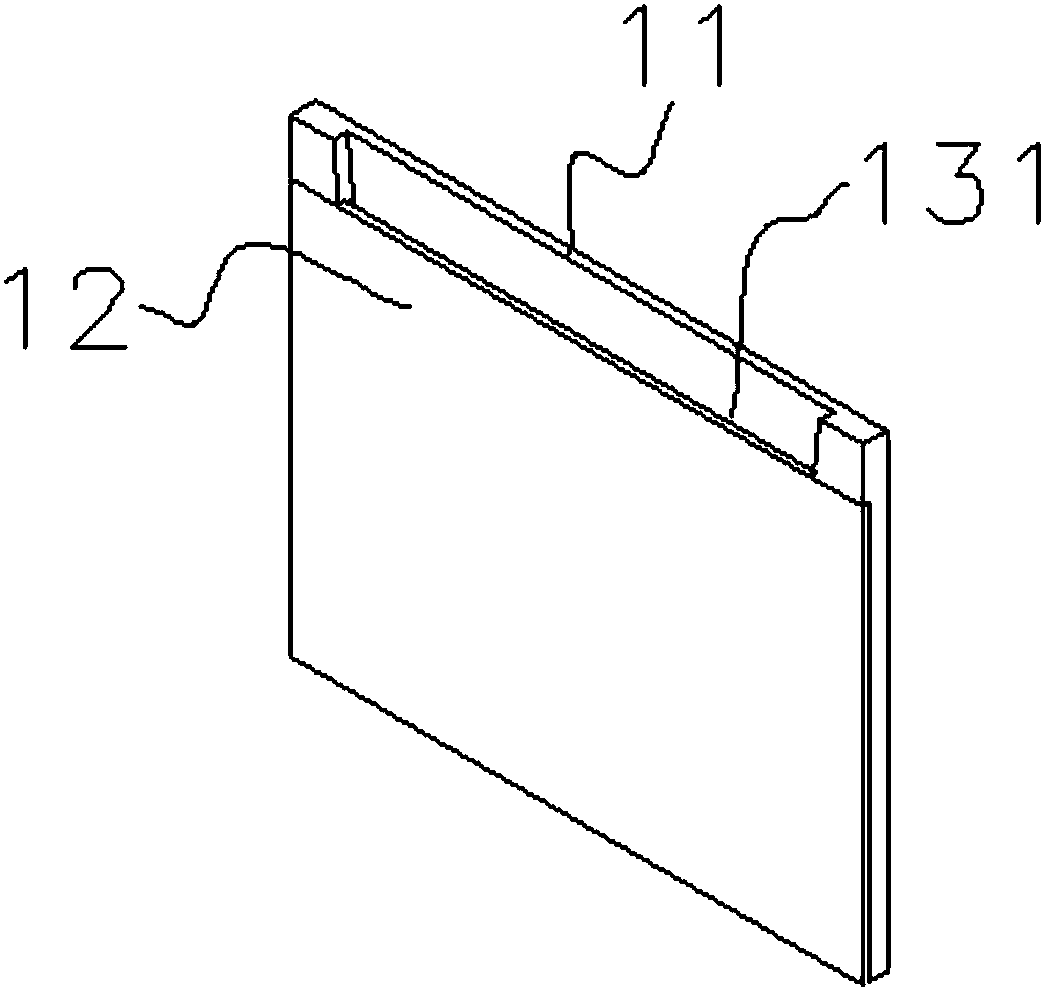

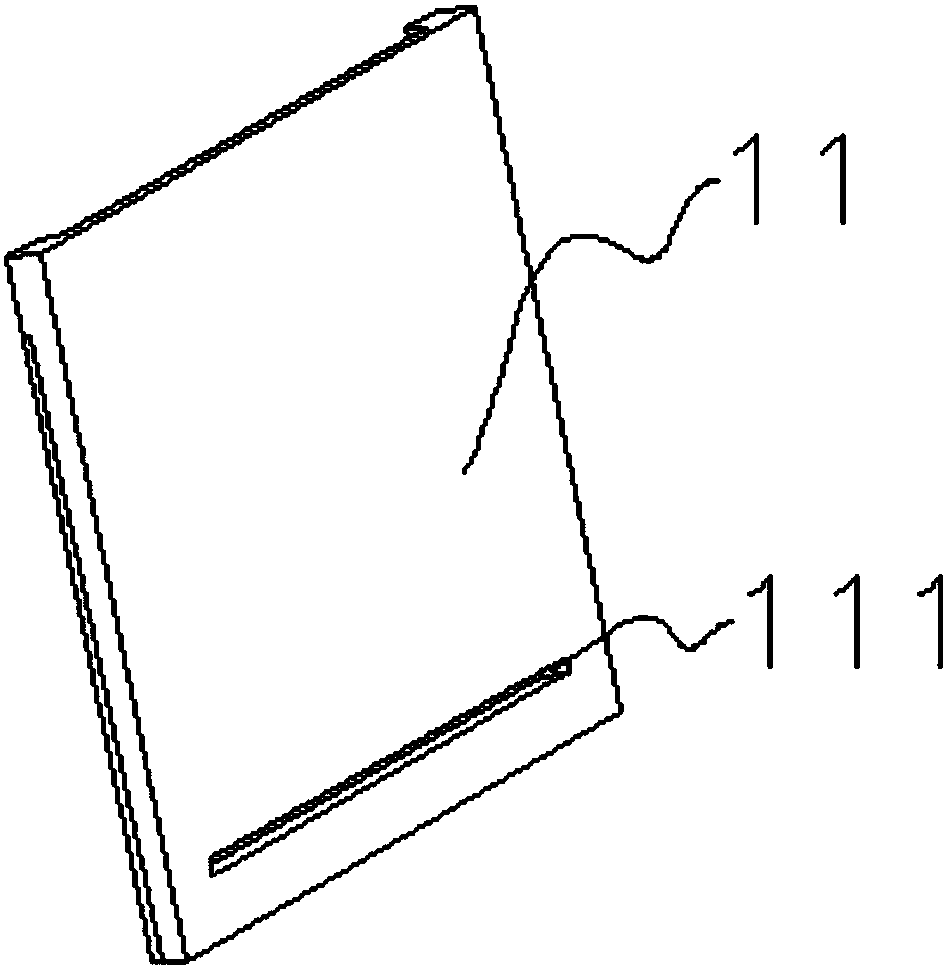

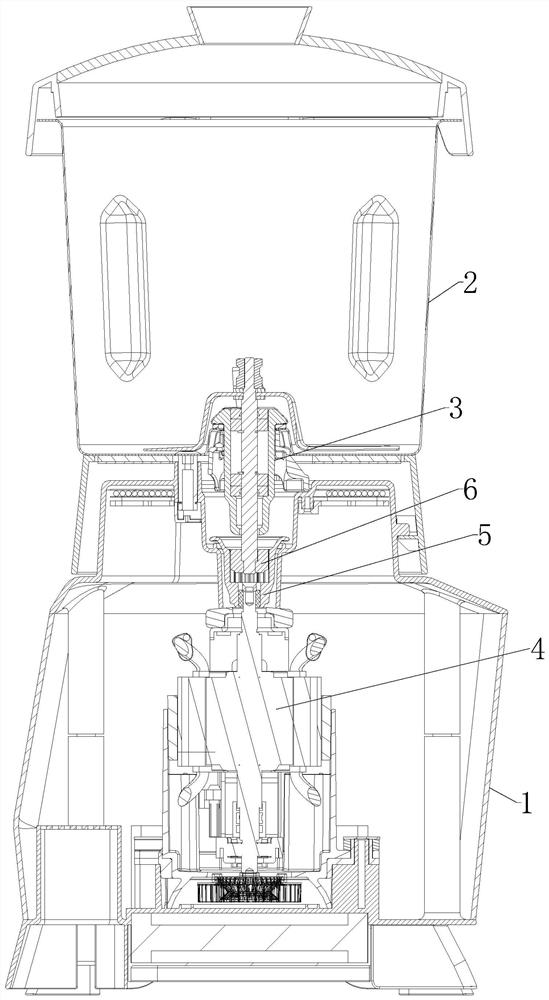

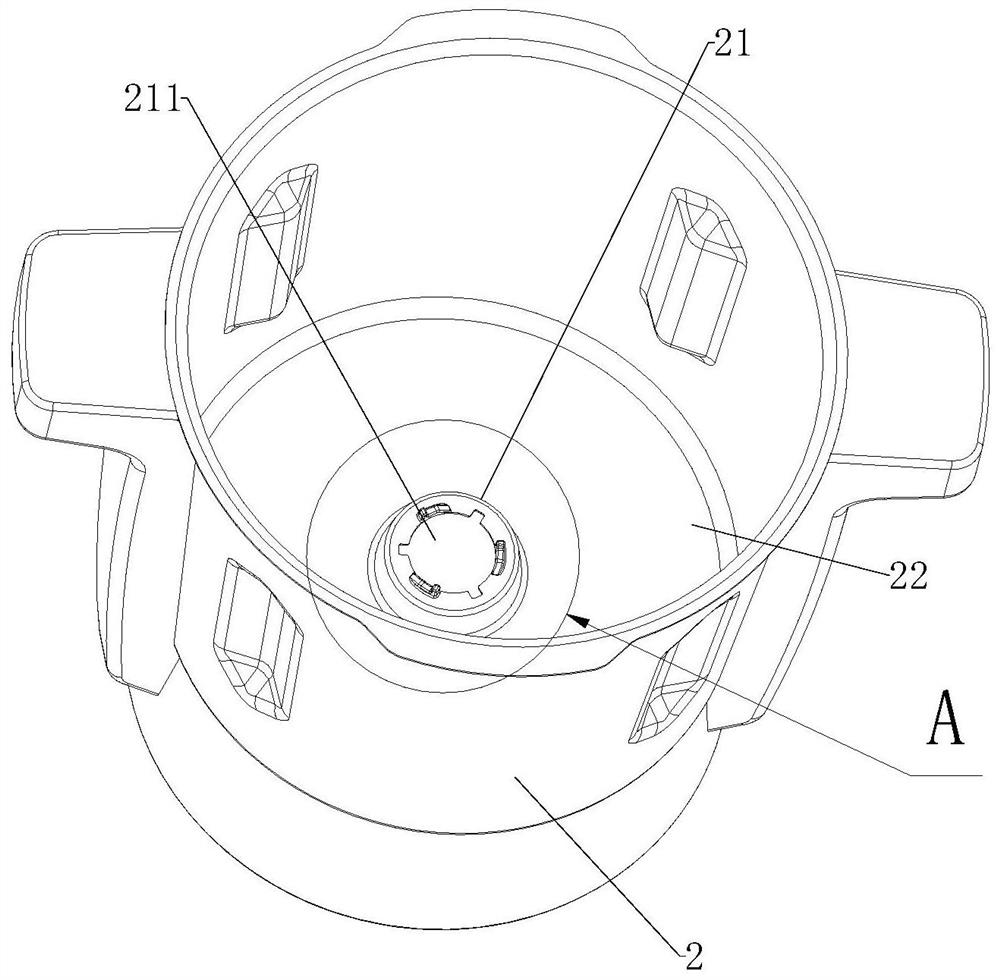

PendingCN113498989AFirmly connectedPrevent misinstallationKitchen equipmentProcess engineeringMechanical engineering

The invention discloses a multifunctional food processor. The multifunctional food processor comprises a main machine base, a stirring cup and a stirring knife assembly, wherein the stirring cup is installed at an upper end of the main machine base, the stirring knife assembly is installed in the stirring cup, the stirring knife assembly is connected with a motor assembly in the main machine base, a round hole is formed in the stirring cup, and a plurality of positioning structures are evenly distributed on an edge of the round hole; the stirring cutter assembly penetrates through the round hole and is provided with a fixing structure matched with the positioning structures and used for being connected with the positioning structures. The food processor is simple in structure and convenient to maintain and assemble, and the stirring knife assembly can be designed to be detachable and is convenient to clean and install; the stirring cup and the stirring knife assembly can be conveniently and stably connected together, and the stirring knife assembly does not lose the food processing function; various low-speed large-torsion food processing functions such as beating, dough kneading, cooking, meat mincing, slicing and shredding can be realized, and the function of identifying different cutters can be indirectly realized; whether a user neglects the installation of the stirring knife assembly or does not install the stirring knife assembly in place or not can be recognized.

Owner:宁波智可电器科技有限公司

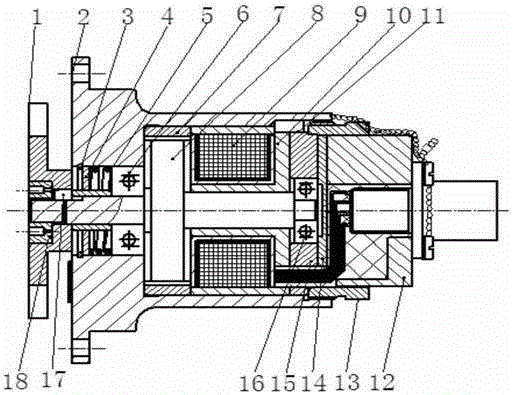

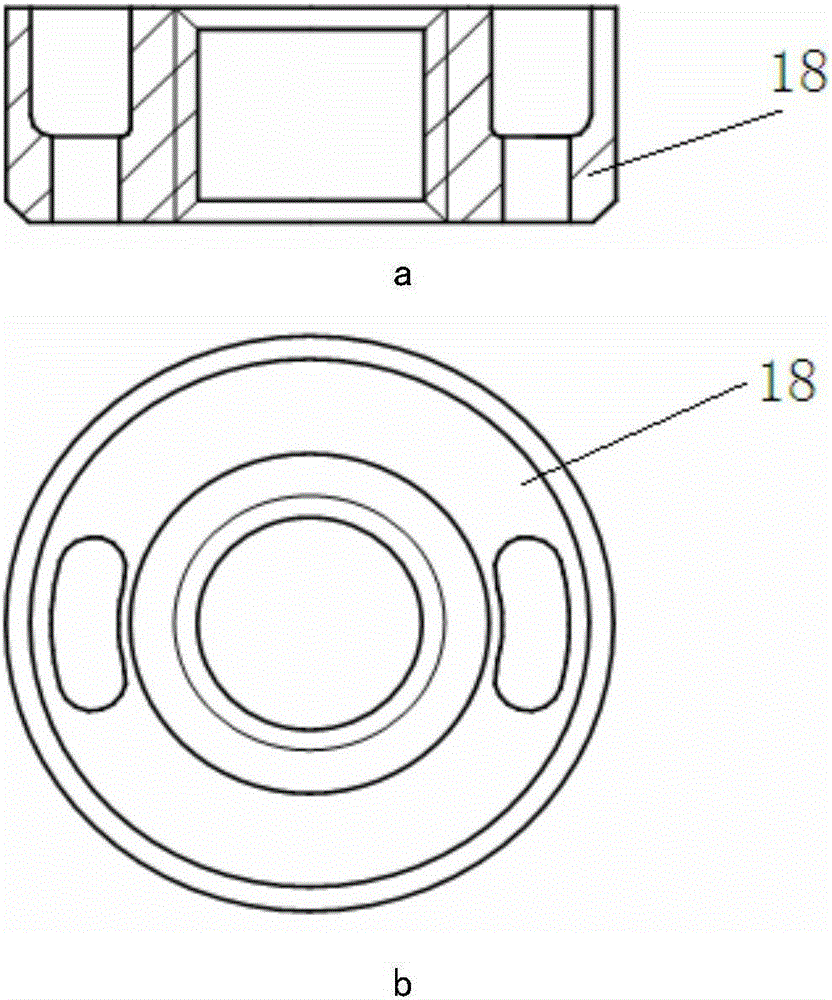

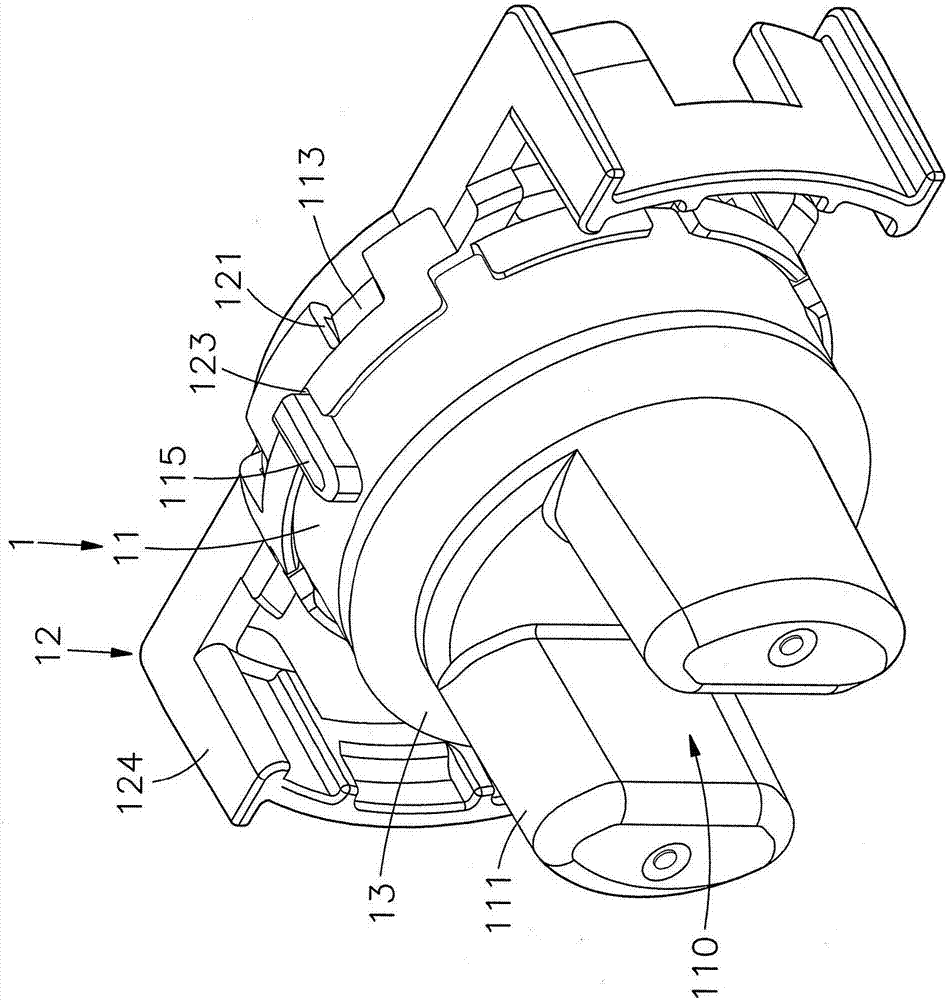

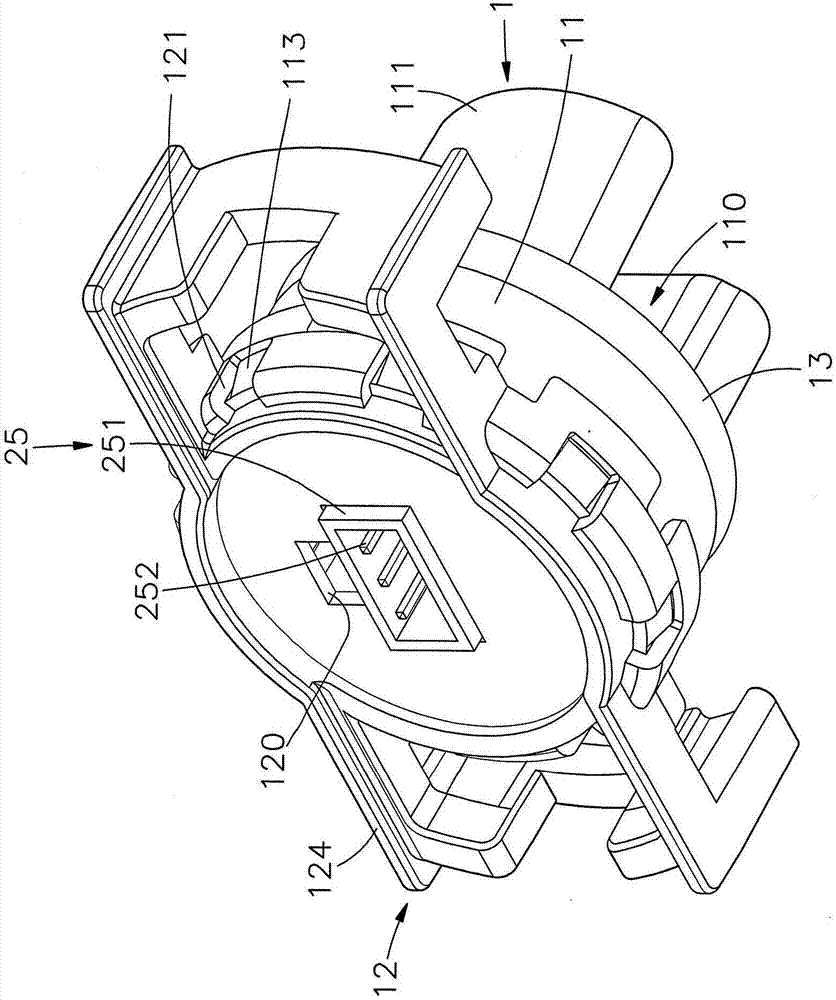

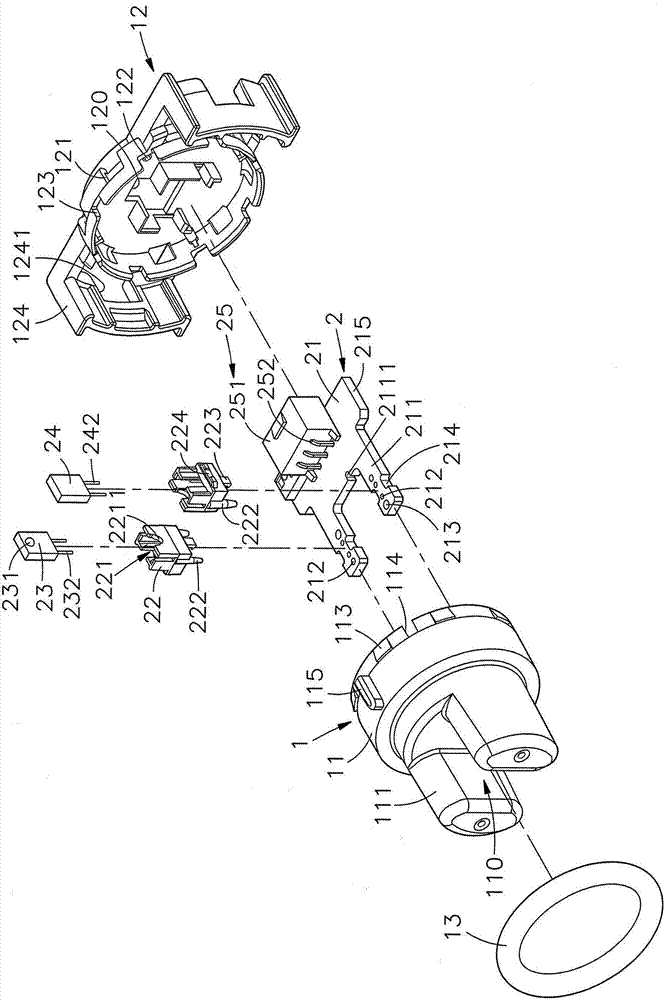

Wrong-inserting preventing speed sensor

InactiveCN105203791AThe installation is not in placeNo situationDevices using electric/magnetic meansEngineeringMechanical engineering

The invention discloses a wrong-inserting preventing speed sensor. A large bearing is located in the middle of a rotor assembly. A coil assembly and a magnetic conductor are installed on the rotor assembly. A small bearing is installed in an installation shaft of the rotor assembly. The magnetic conductor, a bearing pedestal, a gear ring and the rotor assembly are installed in a shell. A spring and a dust-proof ring are arranged on a rotating shaft of the rotor assembly in a sleeving mode and locate in a cavity in one end of the shell. A wrong-inserting preventing shifting fork is located on the outer side of the shell, fixed to the rotating shaft of the rotor assembly in a sleeving mode and located at the end provided with the spring. The end face of the rotating shaft is provided with a locking nut for fastening the wrong-inserting preventing shifting fork. The rotating shaft of the rotor assembly is in clearance fit with the wrong-inserting preventing shifting fork. A shifting rod carries out transmission in a shifting fork groove, and has the wrong-inserting preventing function. Installation test flight verifies that the shifting rod is installed free of displacement or disengagement in the test flight process.

Owner:XIAN AVIATION BRAKE TECH

Device and method for installation of magnetic steel of loudspeaker

ActiveCN103731781APrevent misinstallationSimplified installation procedureElectrical transducersPush outLoudspeaker

The invention discloses a device and method for installation of magnetic steel of a loudspeaker. The device for installation of the magnetic steel of the loudspeaker comprises an installation platform face. A fixing cylinder base and a magnetic steel pushing mechanism are arranged on the installation platform face side by side, the upper end of the fixing cylinder base is connected with a vertical magnetizing sleeve in a threaded mode, the magnetic steel pushing mechanism comprises a pushing rod capable of transversely moving and a power source driving the pushing rod to move forwards and backwards, the pushing rod is provided with a starting position and a stopping position after forward-movement is conducted, the side, corresponding to the pushing rod, of the fixing cylinder base is provided with a pushing rod hole matched with the pushing rod, the other side of the fixing cylinder base is provided with a magnetic steel outlet opposite to the pushing rod hole, the magnetizing sleeve and the pushing rod are both made of a non-magnet material, and a magnetic steel blank is placed in the magnetizing sleeve for overall magnetization so that a magnetic steel string with the same magnetic pole direction can be obtained and the magnetic steel can be pushed out by the pushing rod one by one, and therefore automatic installation of the magnetic steel can be achieved. According to the device and method for installation of the magnetic steel of the loudspeaker, the production efficiency is high, automatic production is easy to achieve, and reverse installation of the magnetic steel can be avoided in the process of installation.

Owner:ZHEJIANG ANYALL AUDIO TECH CO LTD

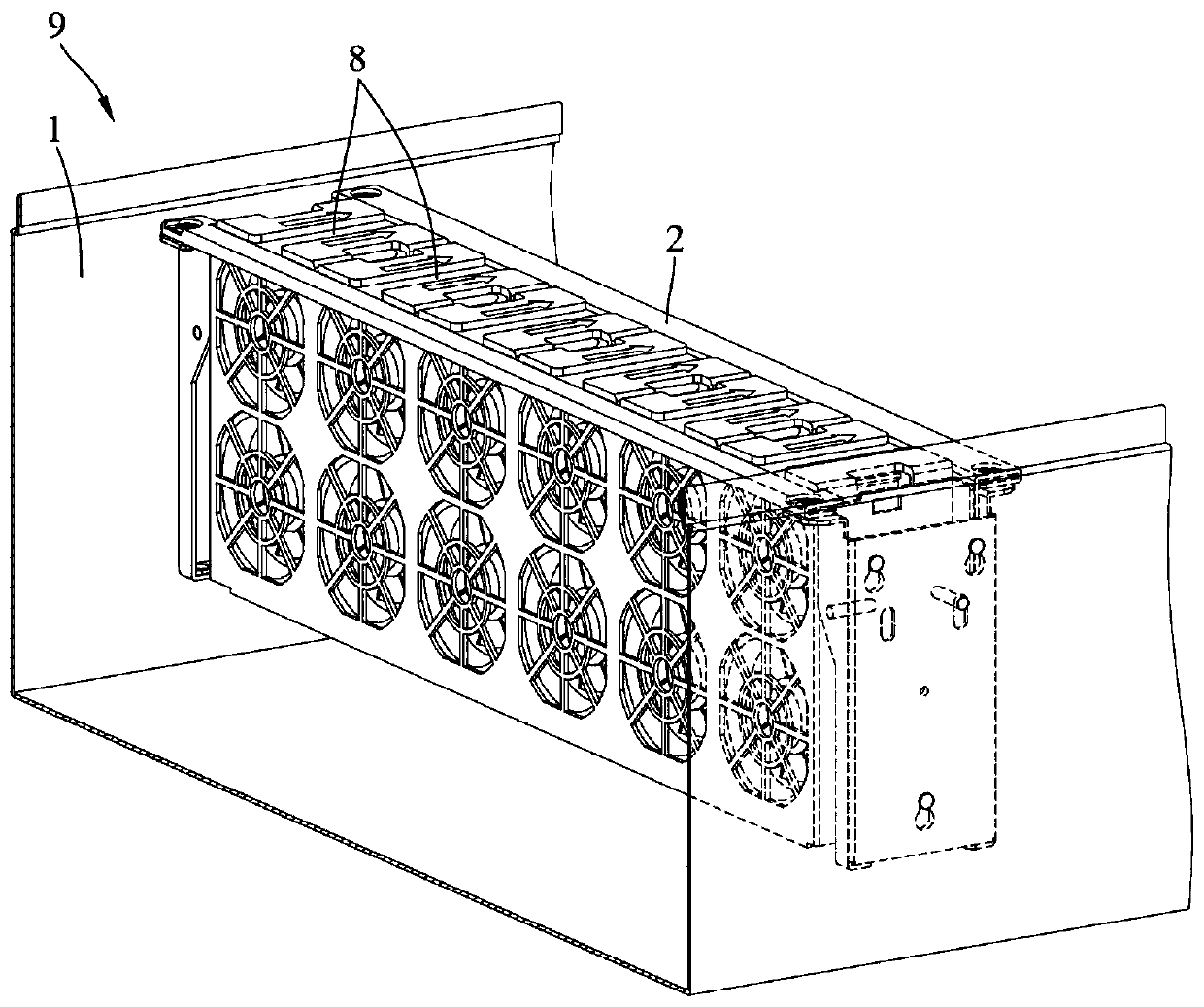

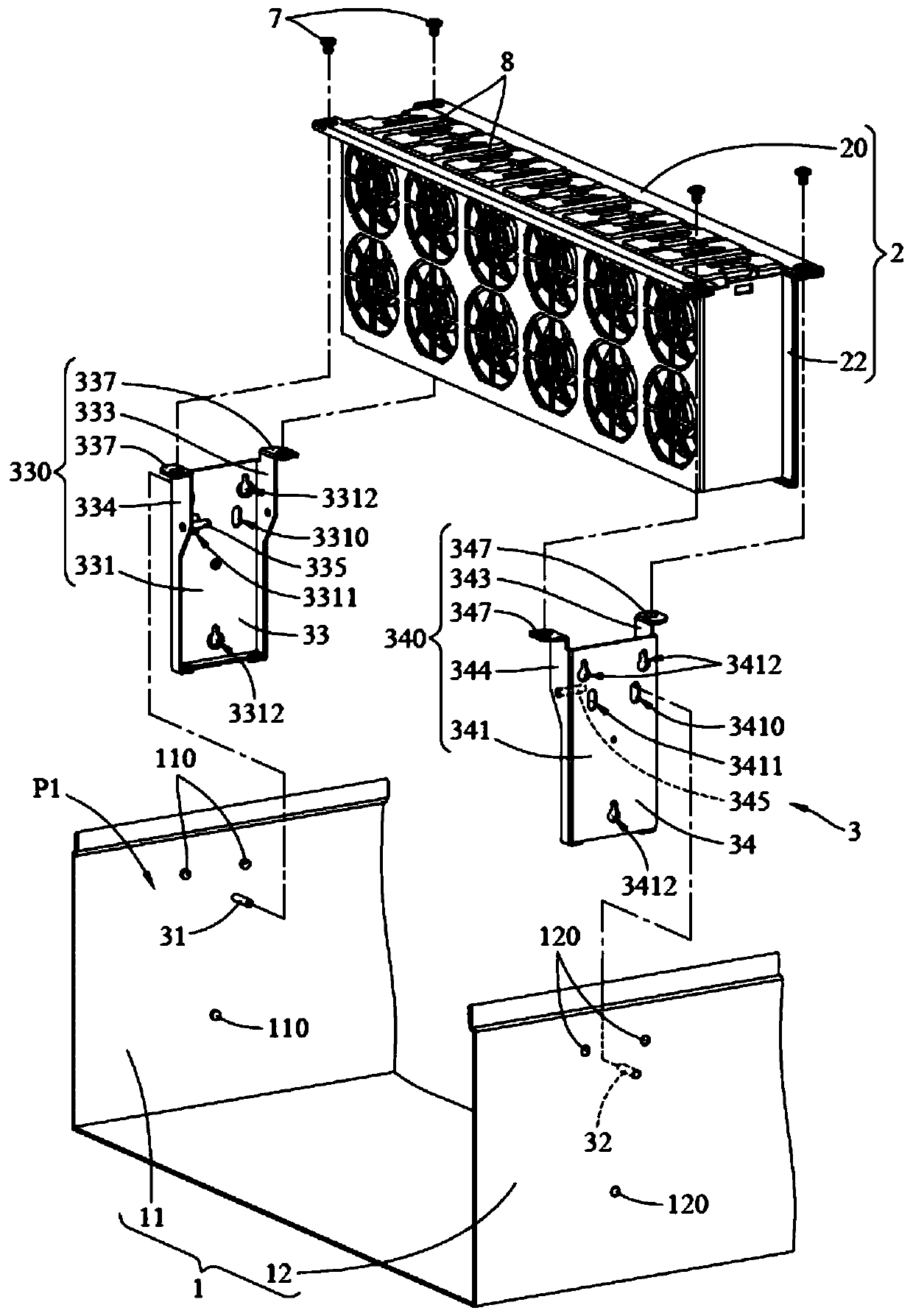

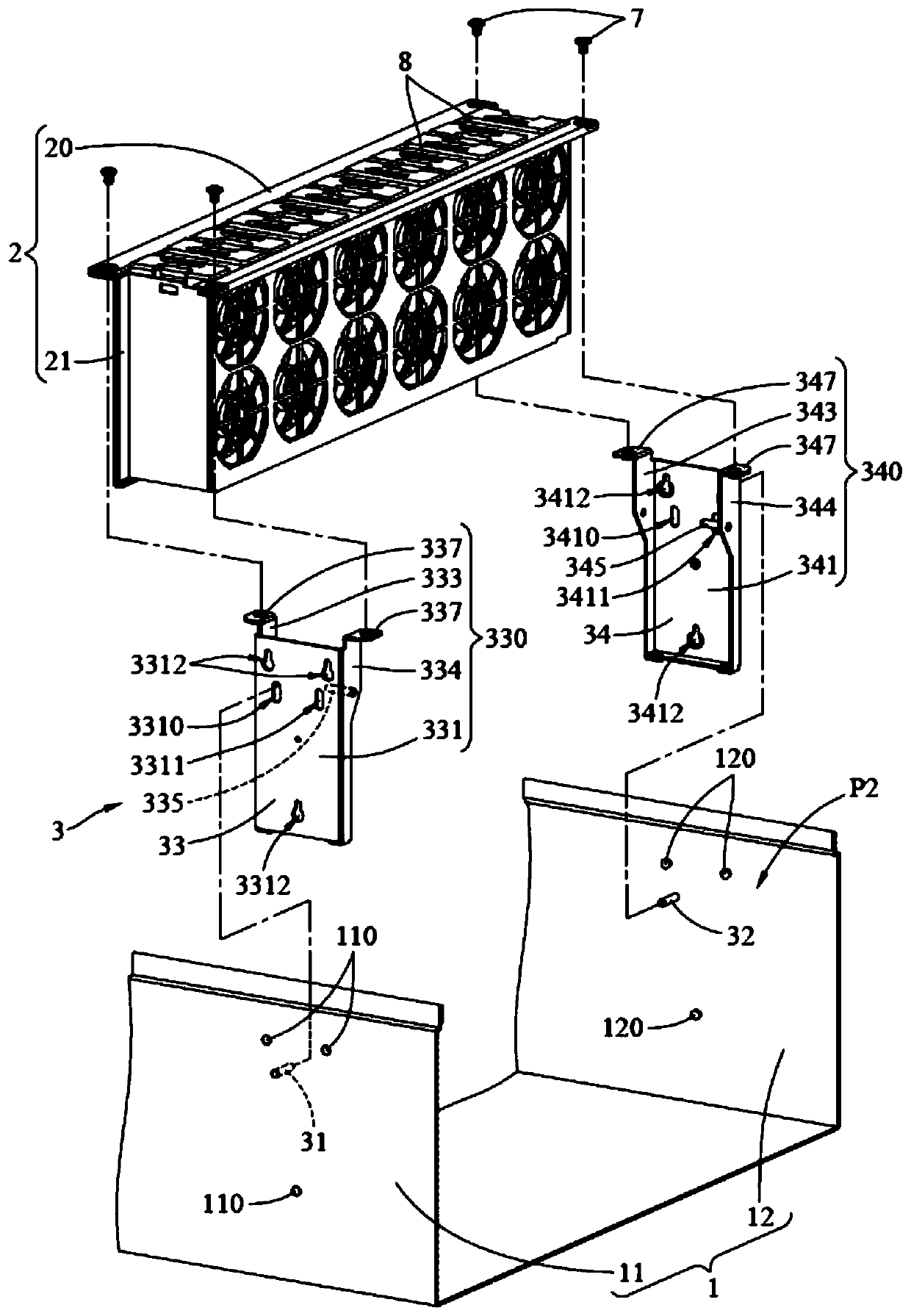

Fool-proof bracket group and server case

ActiveCN111596739AAvoid misdirectionGuaranteed heat dissipationServersDigital processing power distributionStructural engineeringMechanical engineering

The invention provides a fool-proof bracket group and a server case. The fool-proof bracket group comprises a stopping piece fixed to a shell, a first support and a second support, wherein the first support and the second support are arranged on the two sides of the shell. The fool-proof piece of the first support is fixed to the side plate of the first support and shields one of the through grooves of the bottom plate of the first support. When the first support is installed at the first installation position of the shell, the stop piece is arranged in the other through groove of the bottom plate in a penetrating mode, and a receding space for one fixed side plate of the assembly frame to penetrate through is formed between the stop piece and the other side plate of the first support. Thefool-proof piece of the second support is fixed on the side plate of the second support and shields one through groove of the bottom plate of the second support. When the second support is installedat the first installation position, the space occupied by the fool-proof piece is overlapped with the space occupied by the stop piece. When the first support and the second support are installed at the first installation position and the second installation position of the shell respectively, the fool-proof piece blocks the two fixing side plates of the assembly frame, and one fixing side plate is arranged in the receding space in a penetrating mode.

Owner:INVENTEC PUDONG TECH CORPOARTION +1

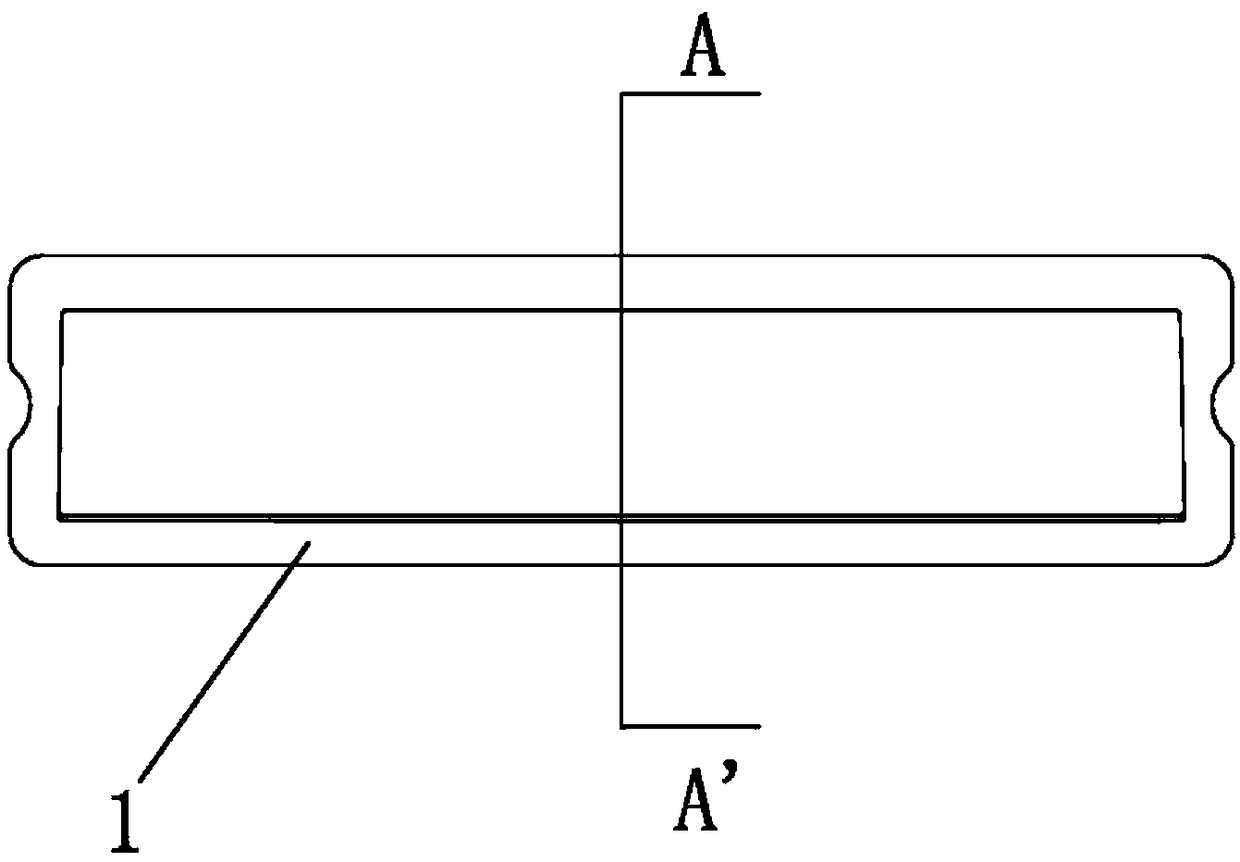

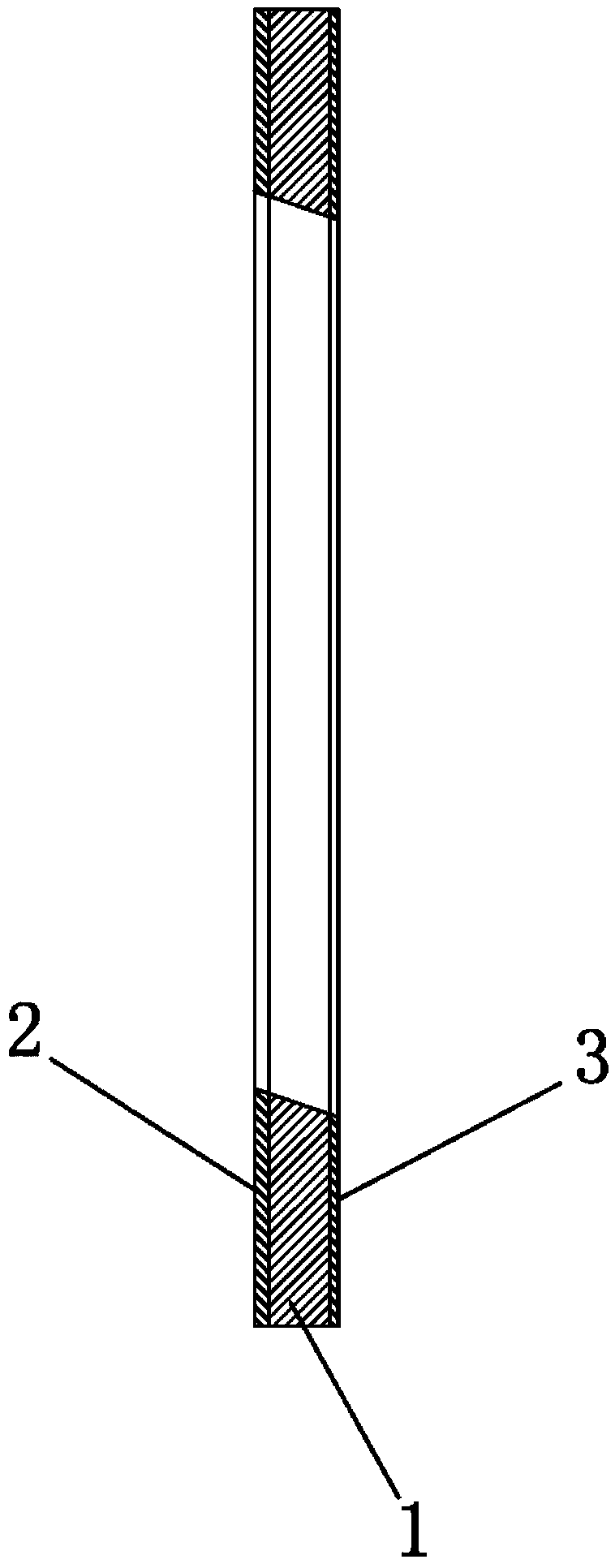

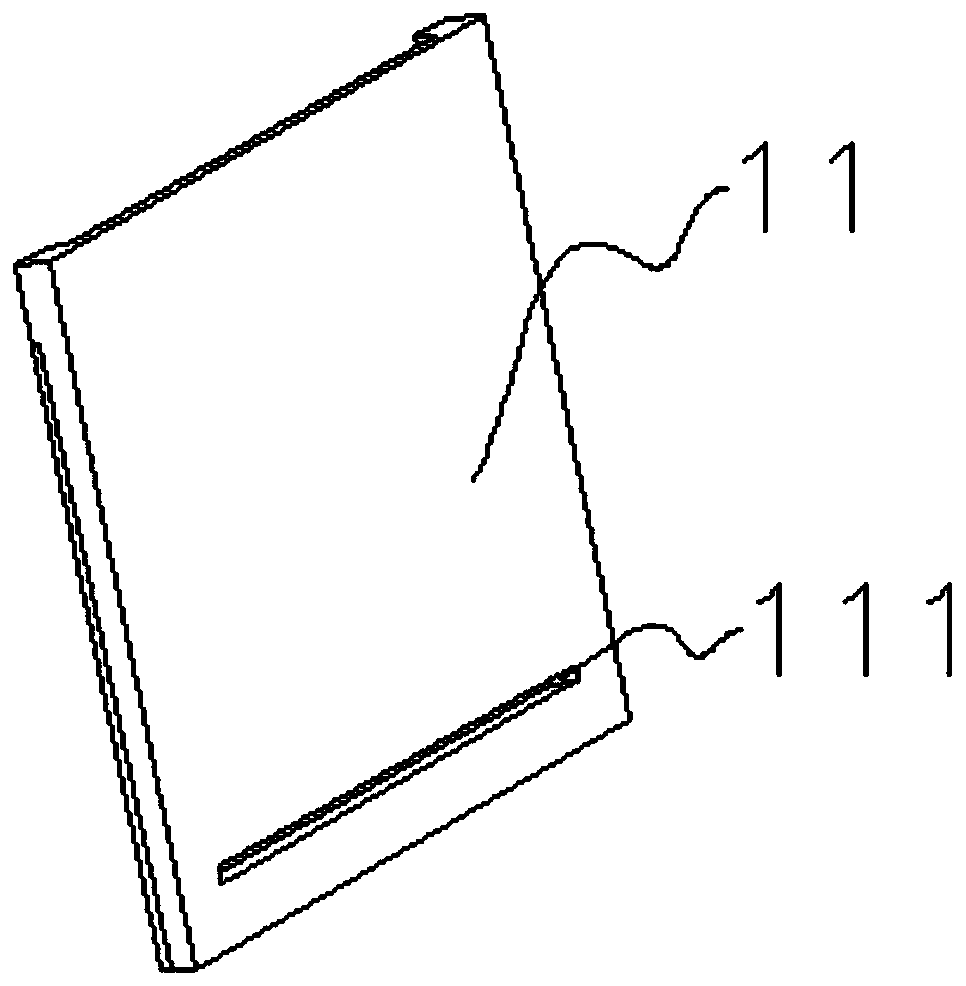

Beveled foam and production method thereof

PendingCN109370455AImprove punching effectImprove shock absorptionFilm/foil adhesivesEngineeringViscosity

The invention discloses beveled foam and a production method thereof. The beveled foam comprises a foam body, wherein the foam body is of a flaky rectangular frame structure; a hollow rectangular window hole is formed in the foam body; the end surfaces of the short edges of the two sides of the rectangular window hole are parallel to the thickness direction of the foam body; the end surfaces of the long edges of the two sides of the rectangular window hole are parallel to each other, and slantwise angles exist between the end surfaces of the long edges and the thickness direction of the foam body; a first adhesive layer and a second adhesive layer are respectively compounded on the two surfaces of the foam body in a stacking manner; the first adhesive layer is located on the back side of the foam body, and the second adhesive layer is located on the front side of the foam body; and the first adhesive layer and the second adhesive layer have different viscosities. The production methoddisclosed by the invention is simple and reasonable; and the produced beveled foam has good sealing and shock absorption effects and a good using effect and is convenient to install.

Owner:苏州萍升源电子科技有限公司

Water quality sensor with automatic production function

ActiveCN107233062AReduce poor assemblySave manpower and production costsTableware washing/rinsing machine detailsAutomatic washing/rinsing machine detectionHuman powerCost savings

The invention provides a water quality sensor with an automatic production function. The water quality sensor comprises a shell and a sensing module; convex and extension parts which extend toward the same direction are formed on the two sides of the shell; an accommodating space with an opening is formed in the interior of the base opposite to the other side of the two convex and extension parts, and an outer cover covers the opening in a combined manner; the sensing module is arranged in the accommodating space of the shell; the sensing module comprises a circuit board and at least one group of butt joint seats assembled on the circuit board; positioning plates which are embedded in the convex and extension parts are arranged on the two sides of the circuit board by extension in the same direction; the butt joint seats are the same in structure and can install both of a light transmitting body and a light receiving body; the installation direction difference of the two butt joint seats can be 180 degrees, and the seats can be assembled on the circuit board separately by adopting an automatic plug-in manner, so that automatic assembling can be realized to replace manpower assembling so as to reduce poor conditions caused by manpower assembling, and human power and production costs can be lowered; and in addition, the butt joint seats share modules, so that the die cost and quantity can be reduced, and automatic assembling, improvement of production efficiency and cost saving can be further realized.

Owner:SOLTEAM OPTO

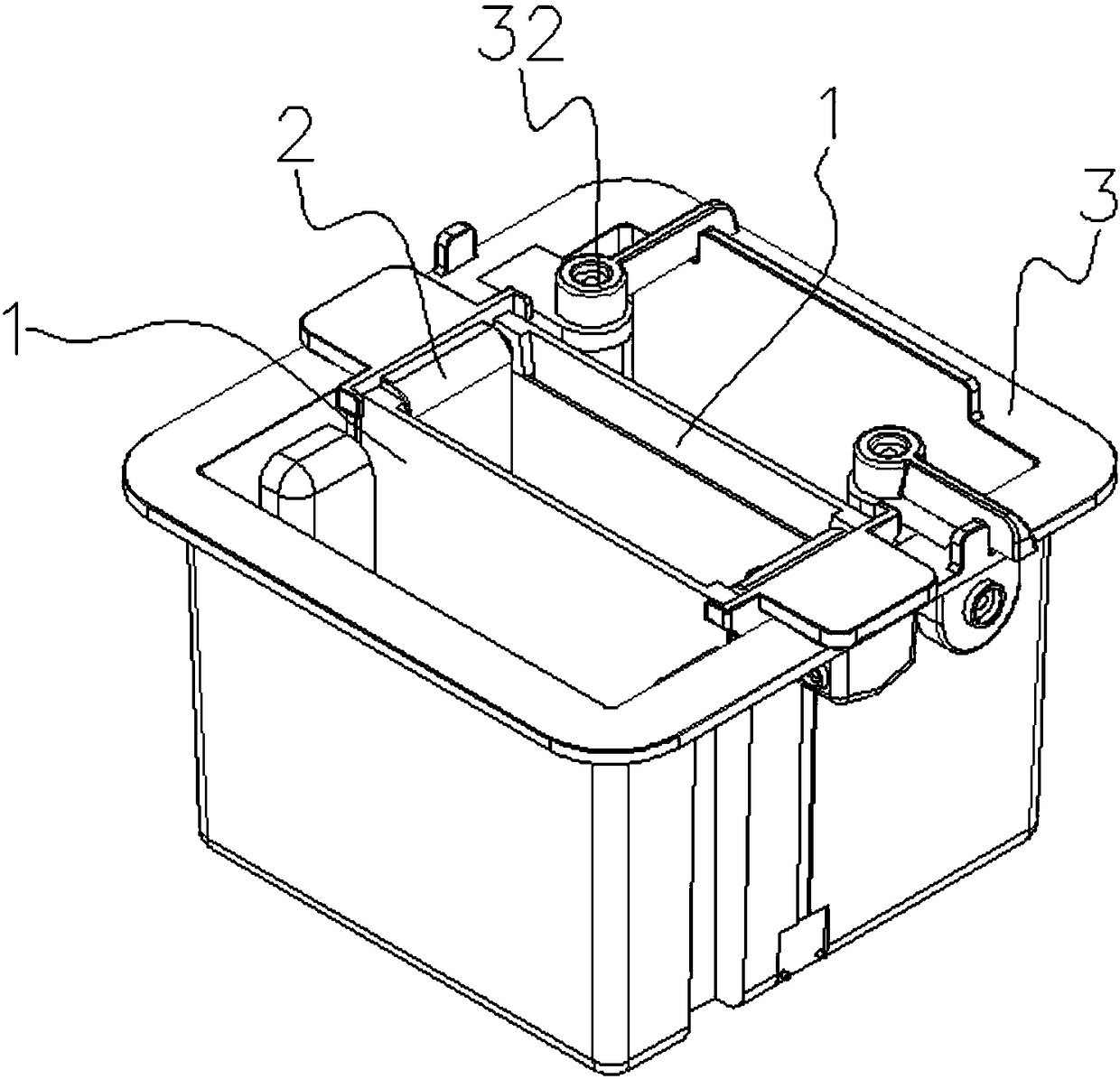

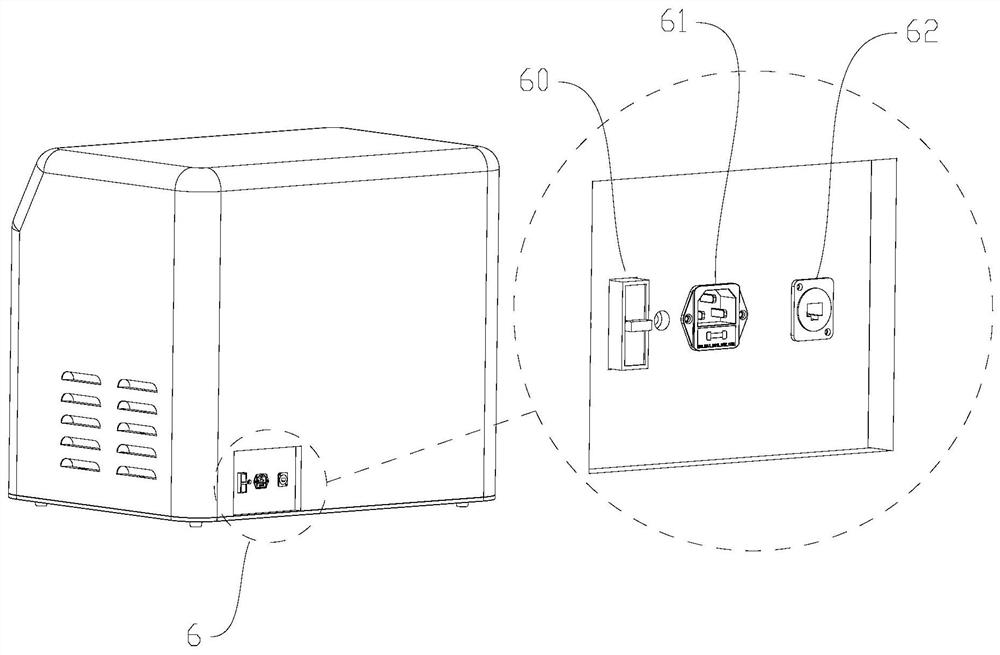

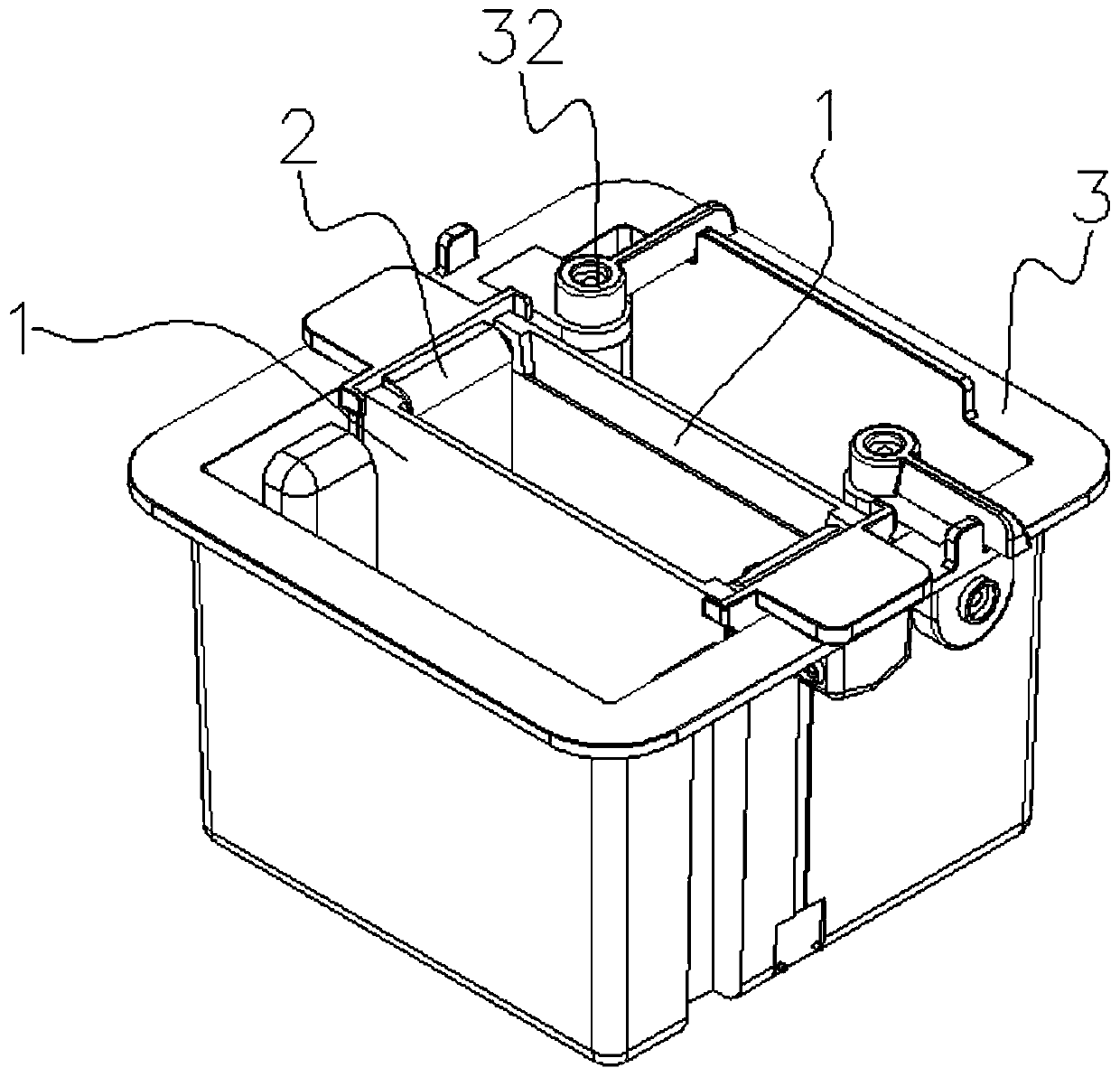

Consumable chip data rewriting equipment, paper box and rewriting method

The invention provides consumable chip data rewriting equipment, a paper box and a rewriting method. The rewriting equipment comprises a shell, a mounting drawer, a rewriting mechanism and a chip reset instrument; a drawer window is arranged on the shell; the mounting drawer is telescopically arranged in the drawer window and is used for mounting the paper box for accommodating an ink box; the rewriting mechanism is arranged in the shell, corresponds to the drawer window and is used for rewriting and upgrading data of the consumable chip on the ink box; and the chip reset instrument is arranged on the shell and used for identifying an identification code on the consumable chip. According to the consumable chip data rewriting equipment, the corresponding rewriting mechanism can be automatically identified and selected according to the type of the ink box or a packaging box, thereby preventing wrong installation when a plurality of rewriting mechanisms are arranged on one piece of equipment, and avoiding equipment damage and production safety problems caused by wrong operation.

Owner:ZHUHAI NINESTAR MANAGEMENT CO LTD

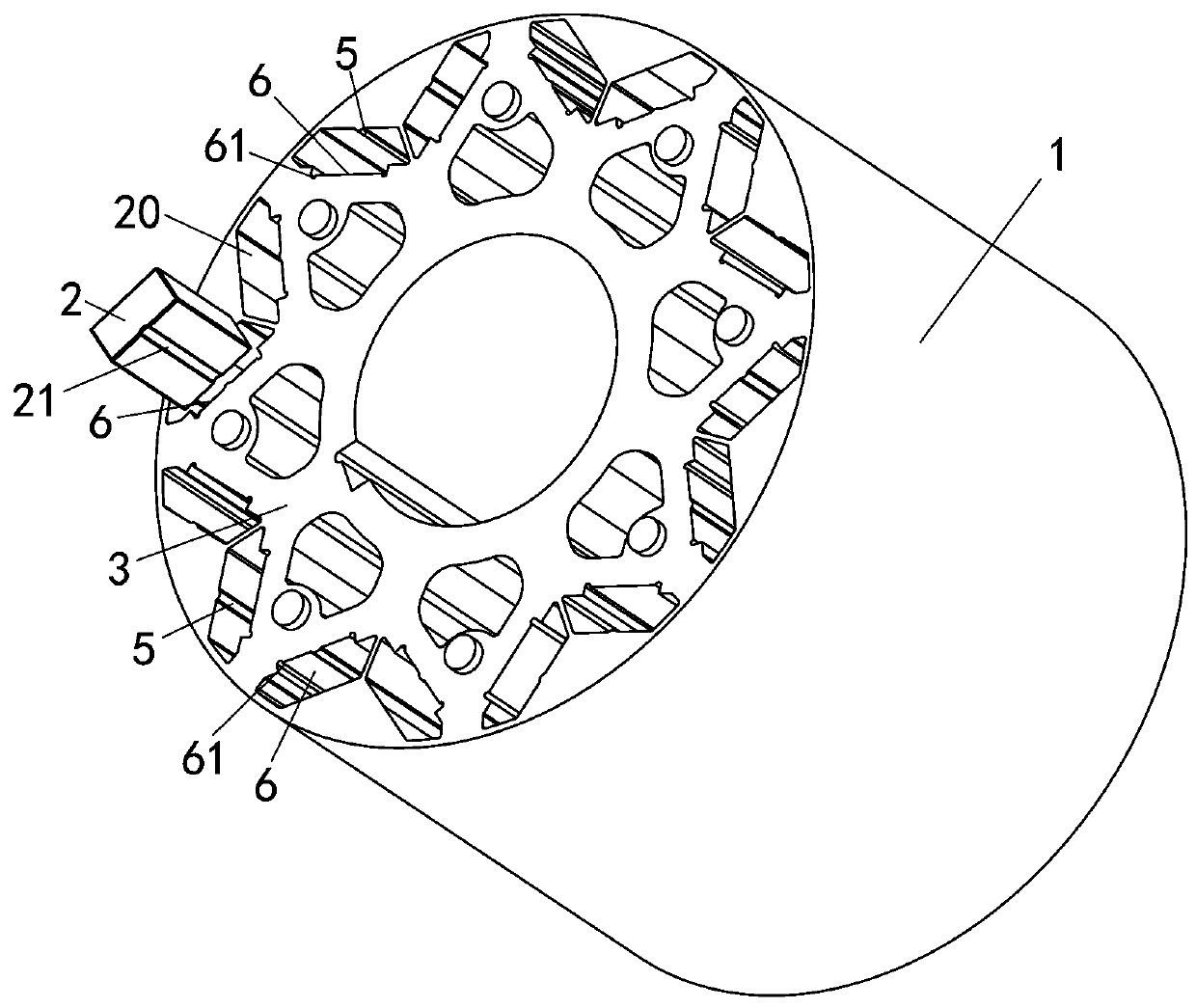

Mounting structure of rotor iron core and magnetic steel

PendingCN110224513AEasy to importImprove installation efficiencyMagnetic circuit rotating partsConvex structurePunching

The invention discloses a mounting structure of a rotor iron core and magnetic steel. The mounting structure comprises the magnetic steel and the rotor iron core formed by laminating a rotor punchingsheet, and is characterized in that through holes are uniformly distributed in the rotor punching sheet; after the rotor punching sheet is laminated into the rotor iron core, a magnetic steel mountinghole is formed by corresponding through holes; the magnetic steel is inserted into the magnetic steel mounting hole; and the side surface where the magnetic steel N pole / S pole is located and the side surface wherein the N pole / S pole of the magnetic steel mounting hole is located are matched through a concave-convex structure. The mounting structure is reasonable in design, and protruding blocksand opening grooves of the through holes are used for positioning and guiding the magnetic steel, so that the magnetic steel is conveniently guided into the magnetic steel mounting hole; meanwhile, the through holes are matched with the grooves of the magnetic steel through convex strips in a concave-convex mode, so that the mounting direction of the N pole / S pole of the magnetic steel is limited, the magnetic pole direction of the magnetic steel is prevented from being mounted incorrectly, the mounting efficiency of the magnetic steel is improved, and the cost of manufacturing a magnetic steel mounting tool is also saved; and the convex blocks and the grooves adopt arc design, so that assembling can be facilitated, and the operation is safer.

Owner:KINETEK DE SHENG SHUNDE MOTOR CO LTD

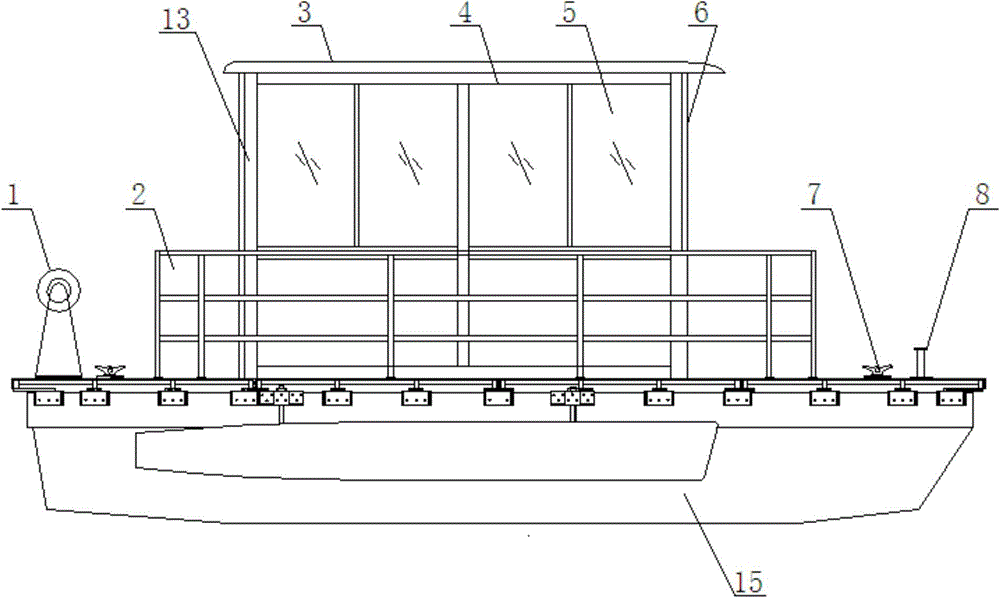

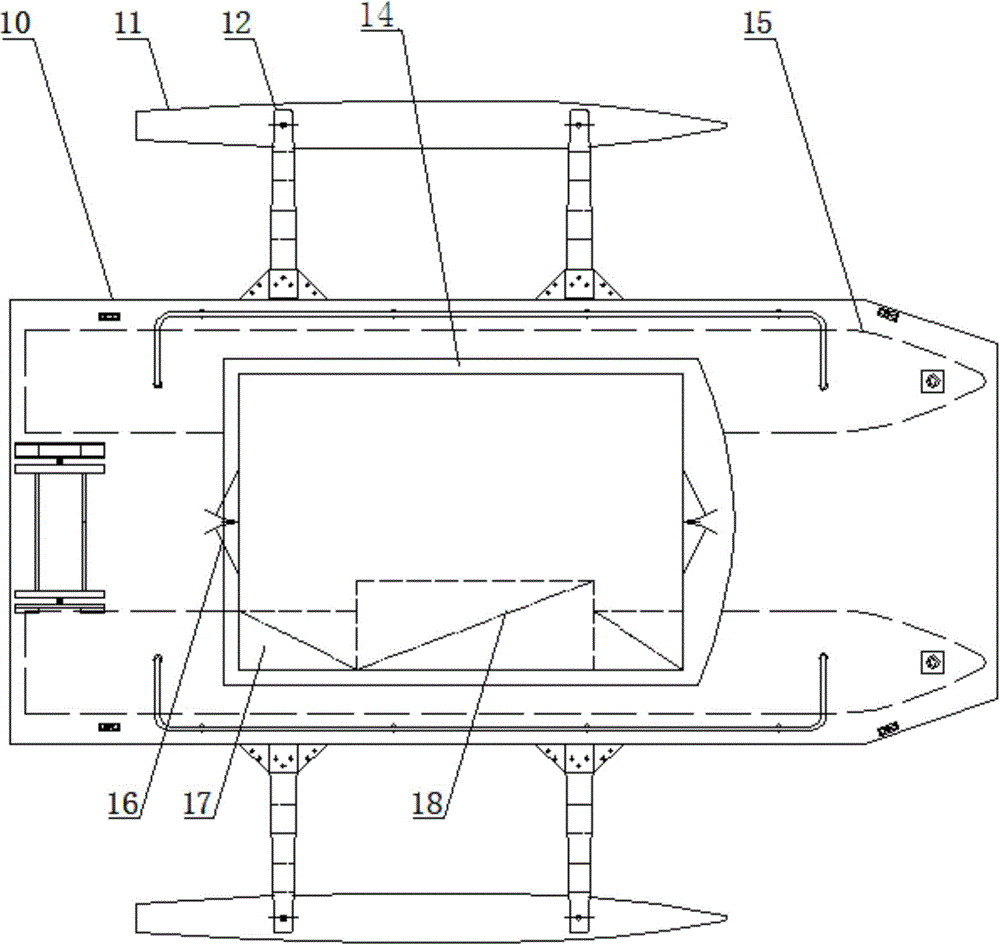

a detection vessel

ActiveCN103448876BSmooth sailingIncreased auxiliary buoyancyHull decksHull bulkheadsChemical weaponWinch

The invention belongs to the technical field of ship design and research, and in particular relates to a working ship for detecting chemical weapons left over from Japan, which can work in inland waterways and offshore waters. It includes a deck body, two floating bodies, a cabin, a hand winch, two lockers and a workbench; the deck body is mainly composed of deck a, deck b, deck c and deck d, and the cabin is a detachable structure; The invention has the following advantages: the new design of the auxiliary floating body increases the wind and wave resistance of the working boat; the whole structure adopts a modular assembly structure, which is convenient for transportation and convenient and quick to assemble; in addition to the detection of Japanese abandoned chemical weapons in the waters, it can also be widely used for other purposes work boat.

Owner:中国人民解放军防化学院

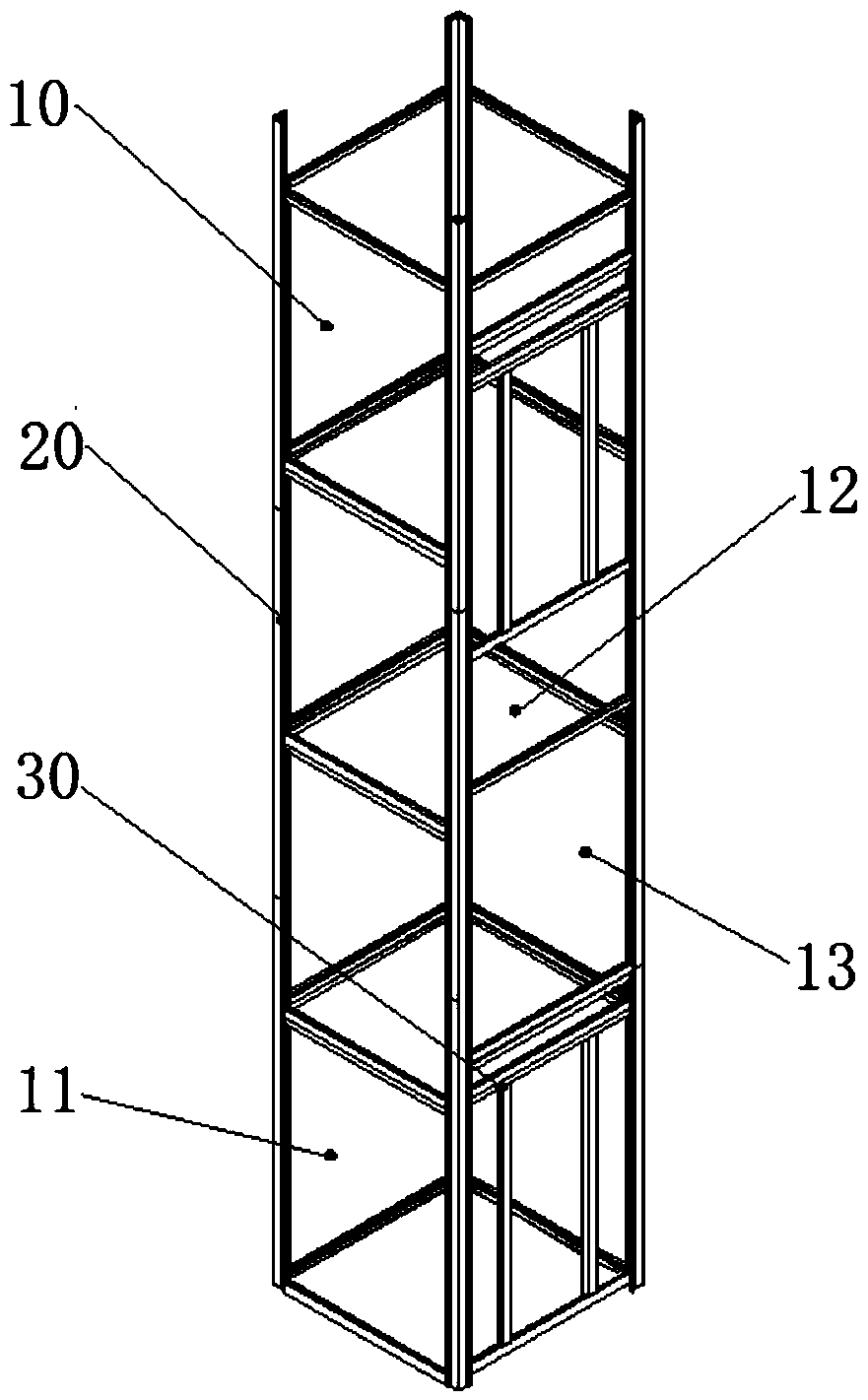

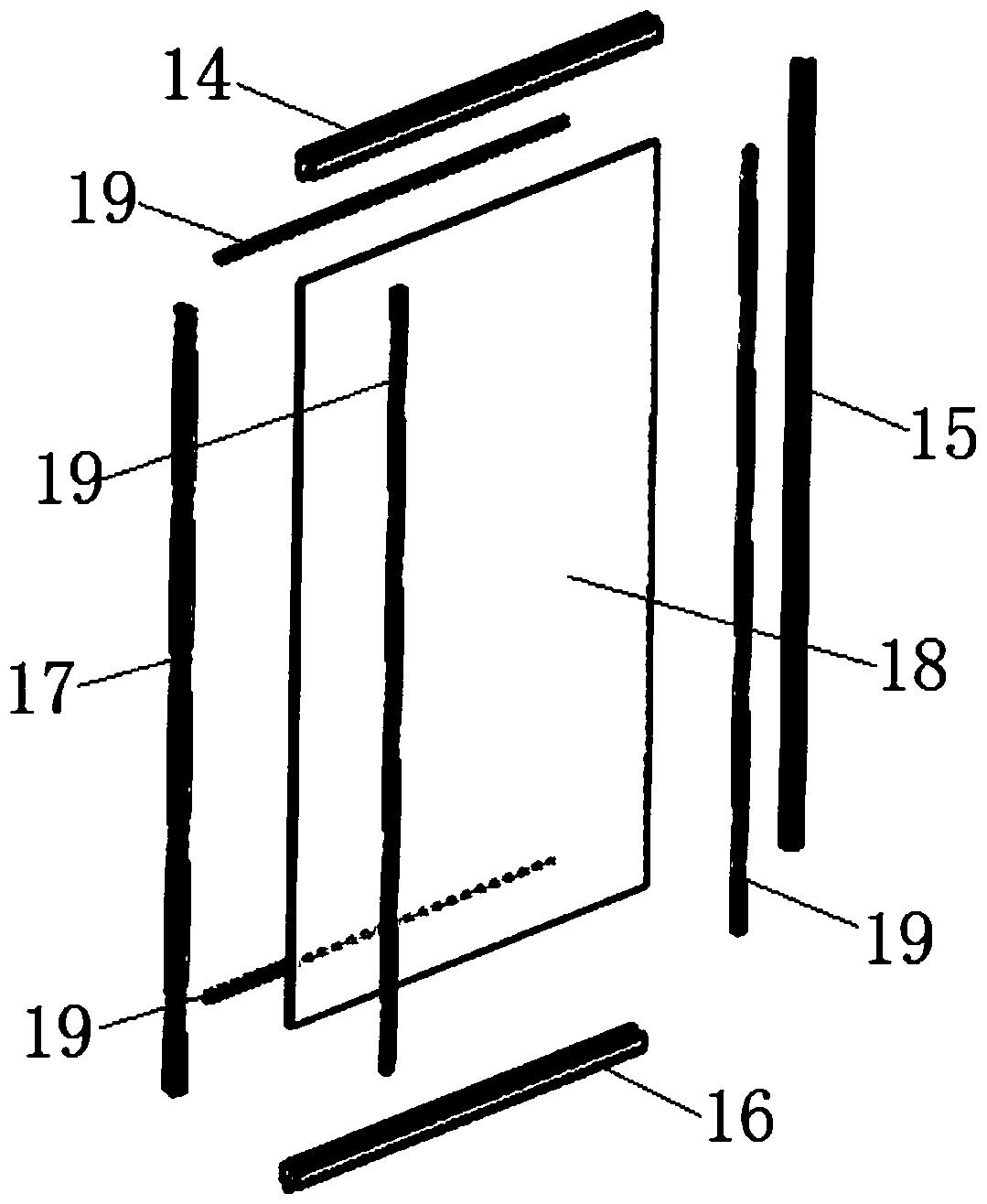

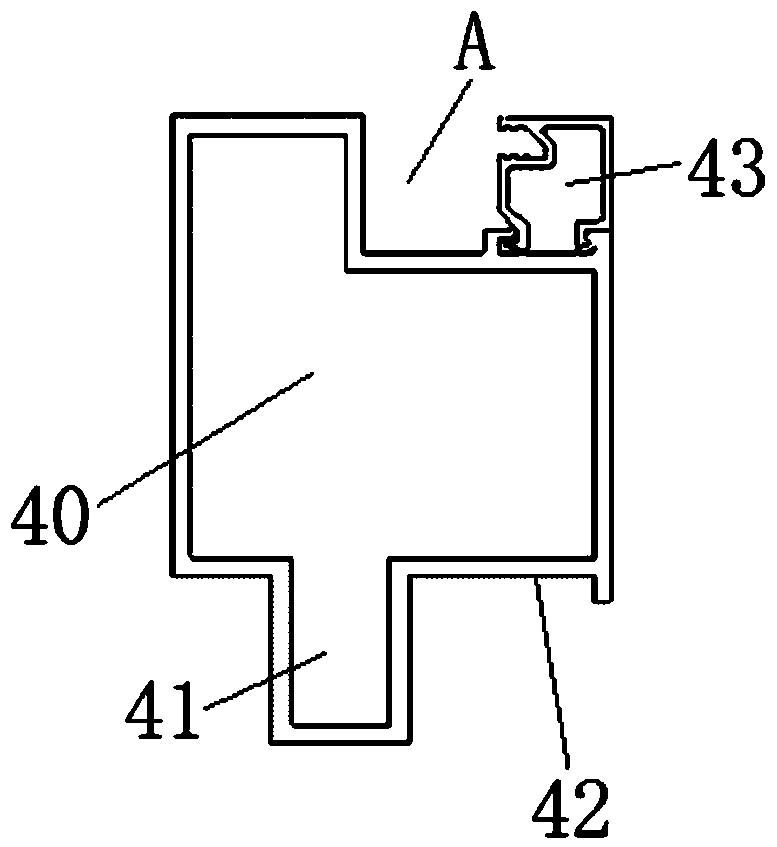

An elevator shaft frame and its installation method

ActiveCN107697765BReduce installation difficultyReduce installation costsElevatorsBuilding liftsStructural engineeringAlloy

Owner:NINGBO HONGDA ELEVATOR

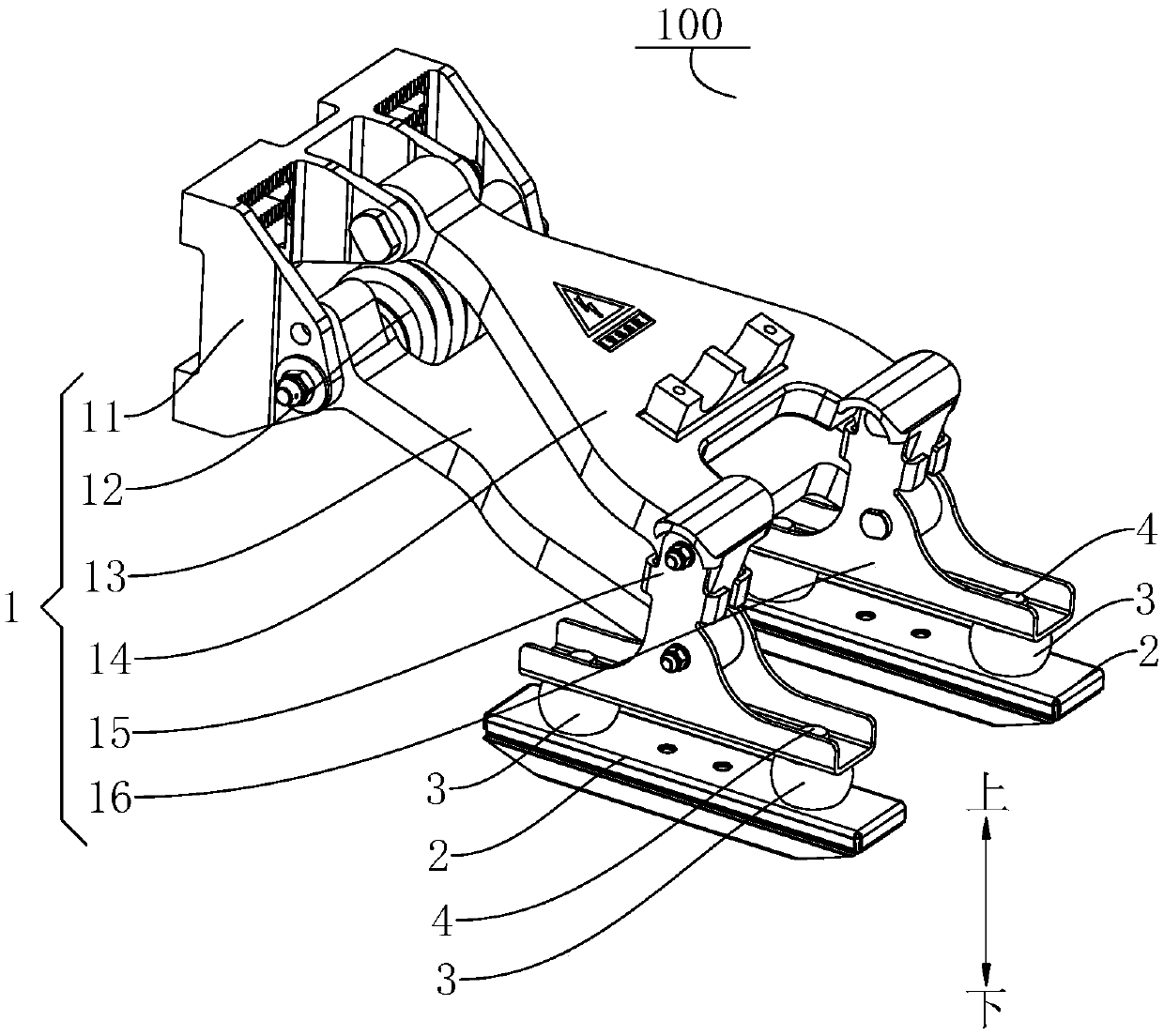

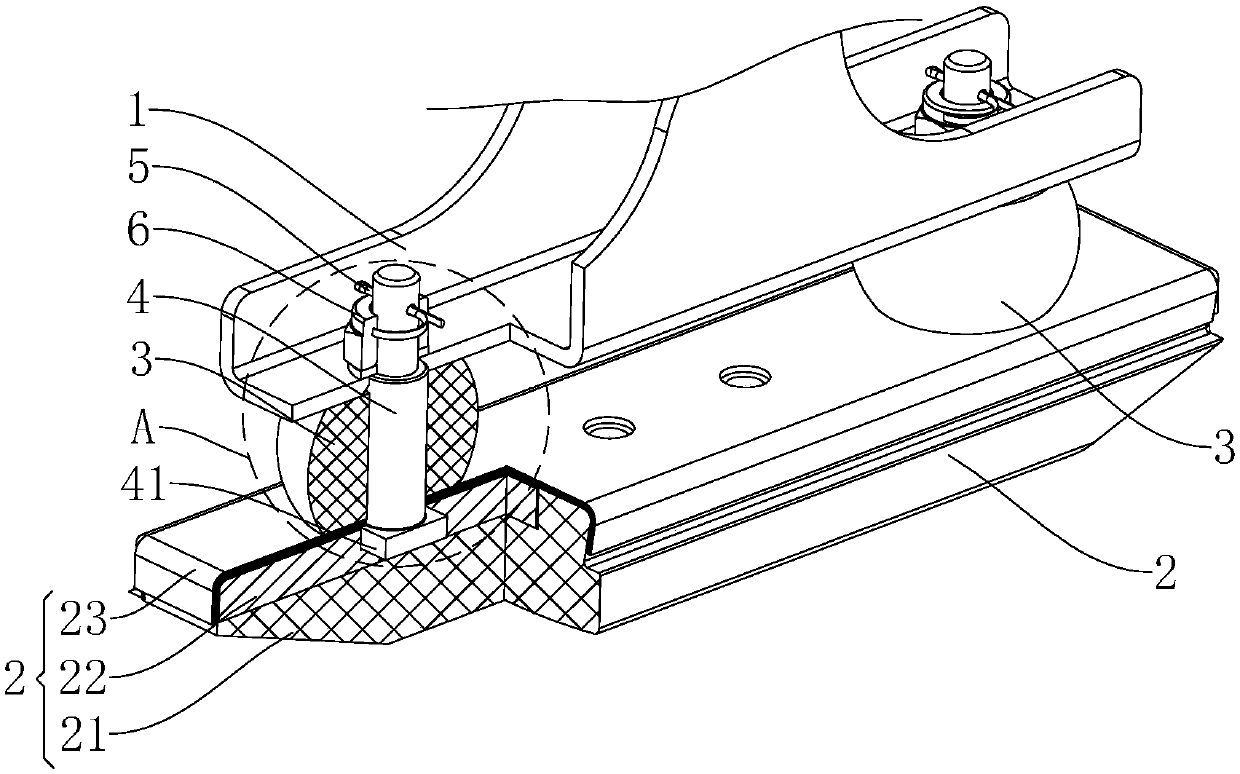

Current collector for railway vehicle and railway vehicle

PendingCN110962612AEnsure structural stabilityEasy assemblyRailway vehiclesPower current collectorsMechanical engineeringElectrical and Electronics engineering

The invention discloses a current collector for a railway vehicle and the railway vehicle. The current collector comprises a mounting bracket, a carbon contact strip, a buffer piece, a connecting piece and a matching piece, wherein one end of the mounting bracket is fixed on a vehicle body of the railway vehicle; a mounting hole is formed in the mounting bracket; the carbon contact strip is positioned at the other end of the mounting bracket; the buffer piece is arranged between the carbon contact strip and the mounting bracket; the connecting piece comprises a first rod body and a second rodbody; the first rod body penetrates through the buffer piece; one end of the first rod body is connected with the carbon contact strip; the other end of the first rod body is connected with the secondrod body, the outer diameter of the first rod body is larger than that of the second rod body; and the second rod body penetrates through the mounting hole. According to the current collector, the matching piece is matched with the second rod body to limit the buffer piece, the upper end of the first rod body extends into the mounting hole, the matching piece abuts against the top end of the first rod body, the assembling mode is simple, the assembling efficiency can be improved, and the situation of mistaken assembling can be avoided.

Owner:BYD CO LTD

A vertical electrophoresis tank and electrophoresis apparatus

ActiveCN108490059BImprove versatilityReduce configuration costsMaterial analysis by electric/magnetic meansElectrophoresesEngineering

The invention provides a vertical electrophoresis tank and an electrophoresis apparatus. The vertical electrophoresis tank comprises a slide assembly, a gel frame assembly and a groove body assembly,wherein the slide assembly comprises a large slide and a small slide used for forming a gel preparing cavity, and a lateral opening groove communicated with the bottom of the gel preparing cavity is formed in the large slide; the gel frame assembly comprises a gel frame, a concave sealing member, a first negative electrode conduction member and a first positive electrode conduction member; the groove body assembly comprises a groove body, a pressing mechanism, a second negative electrode conduction member and a second positive electrode conduction member. The conduction of an electrode and thepressing of the slide assembly are synchronously completed by the pressing mechanism to eliminate the single operation of locking and inserting positive and negative electrodes sequentially in the slide assembly of traditional electrophoresis equipment to prevent the leakage of electricity and electric shocks; gel preparing and electrophoresis are completed in the vertical electrophoresis tank, additional gel preparing auxiliary devices are not needed, occupied space of electrophoresis testing equipment is saved, the operation is easier, and externally dripping gel liquid in the gel preparingprocess is accumulated in the groove body, so that the cleanliness of a testing tabletop is improved.

Owner:莫纳(武汉)生物科技有限公司

Intelligent bolt specification identification system

ActiveCN114367456AReduce the difficulty of distinguishingPrevent misinstallationSortingElectrical connectionEngineering

The invention relates to an intelligent bolt specification identification system which comprises a detection device, a bolt movement device and a control device. The detection device comprises a base and a detection piece, and a channel is formed in the base; the channel is provided with a feeding section, a detection section and a discharging section which are communicated in sequence, the feeding section is provided with a feeding port in the length direction, the discharging section is provided with a discharging port and a wrong material outlet in the length direction, and the feeding port and the discharging port are arranged in a one-to-one correspondence mode; the detection piece is installed on the detection section and used for detecting actual specification information of the bolt. The bolt moving device is used for driving the bolt of any feeding hole to move along the channel; the control device at least comprises a storage module, a comparison module and a control module which are electrically connected. After the system is used, the specification of the bolt does not need to be distinguished, mistaken assembly is prevented, the distinguishing difficulty of online assembly workers is reduced, time is saved, working efficiency is improved, and various economic losses caused by mistaken assembly of the bolt are avoided.

Owner:VOYAH AUTOMOBILE TECH CO LTD

A three-phase conductor commutation joint

ActiveCN111129890BAchieve connectionRealize phase sequence interchangeSwitchgear arrangementsCoupling device detailsElectrical conductorEngineering

The invention relates to a three-phase conductor commutation joint, which comprises a sealing cylinder body and sealing flanges installed at both ends of the sealing cylinder body. The two sealing flanges are respectively provided with three transfer inserts, and the transfer inserts on the two sealing flanges are The inserts are arranged along the straight line with the same extension direction; there are three-phase conductors in the sealing cylinder, and the two ends of the three-phase conductors are respectively connected to the three transfer inserts on the two sealing flanges; the three-phase conductors are located on both sides Each of the two-phase conductors has a bent section, so that the two ends of each phase conductor in the two phase conductors are respectively connected to two transfer inserts on the two sealing flanges on both sides of the axis of the sealing cylinder. Such setting can realize the phase sequence interchange of A and C phases under the condition that the three-phase arrangement at both ends of the three-phase conductor commutation connector is the same. In actual use, the three-phase conductor reversing connector can be directly installed on the equipment. At the three-phase interface, the phase sequence exchange of A and C phases is realized, so as to realize the connection of three-phase equipment with different phase sequences.

Owner:PINGGAO GRP +2

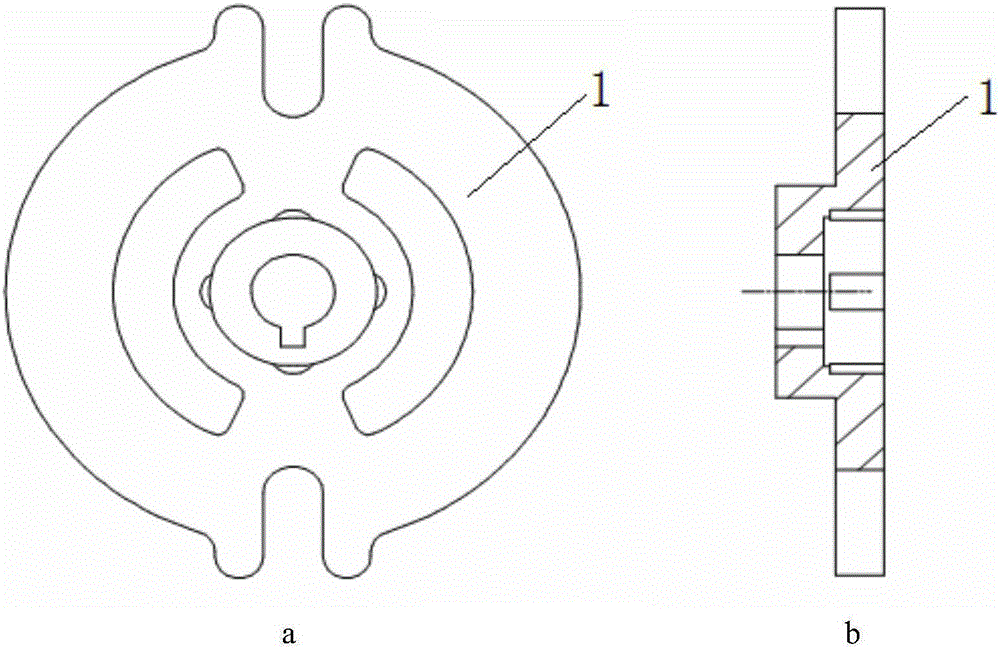

Press-fitting equipment for pointers of stepper motor combined instrument

ActiveCN105397711BThe zero line is consistentPrevent misinstallationMetal-working hand toolsElectrical resistance and conductanceDashboard

Owner:DONGFENG AUTOMOBILE ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com