Pressing-assembling device for force-transmitting steel balls of universal joint

A press-fitting device and universal joint technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as difficult assembly of steel balls, achieve more neutral product alignment, ensure assembly accuracy, and high movement accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

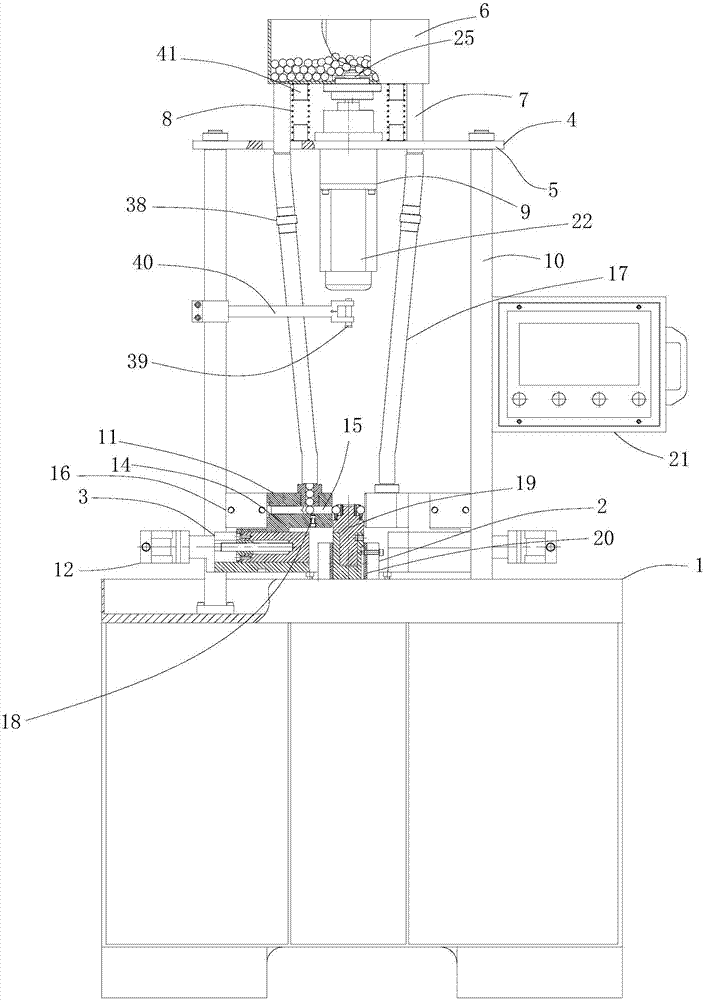

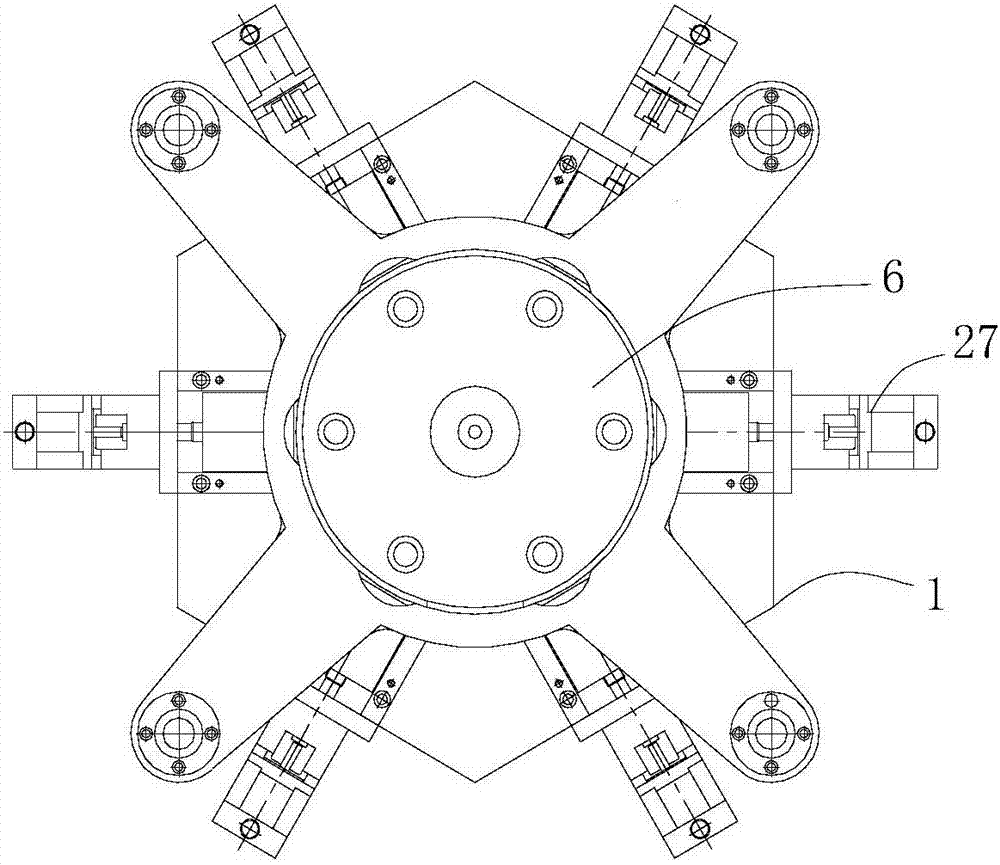

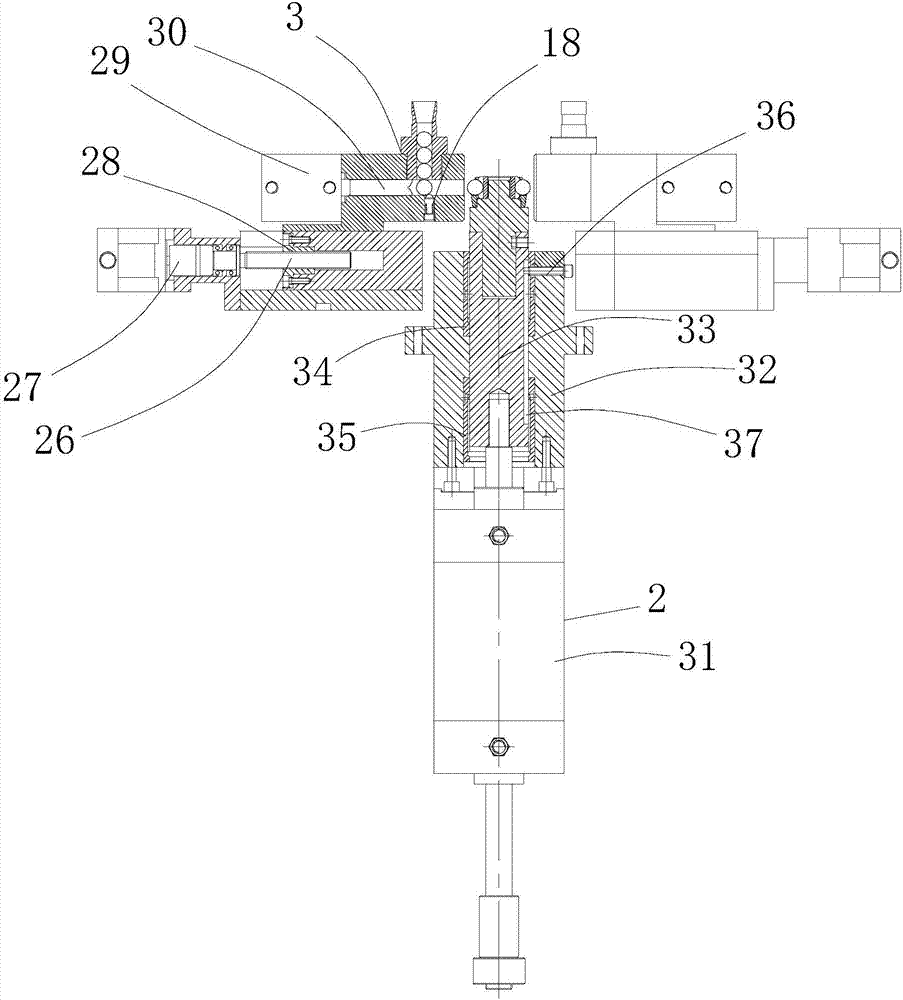

[0042] A universal joint force transmission steel ball press-fitting device of the present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to help those skilled in the art understand the present invention, and are not intended to limit the present invention.

[0043] The invention provides a universal joint force transmission steel ball press-fitting device, which is mainly used for pressing the steel ball into a workpiece to replace the manual assembly in the prior art. A plurality of steel balls should be pressed into each workpiece, and these steel balls are evenly distributed on the circumference of the workpiece. Each steel ball on the workpiece is pressed by an independent steel ball pressing mechanism 3. The loading mechanism 3 can act synchronously and press all the steel balls into the workpiece at the same time;

[0044] Each steel ball pressing mechanism 3 can also act independently, that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com