Gear self-learning method of knob shifter

A self-learning method and shifter technology, applied to components with teeth, belts/chains/gears, mechanical equipment, etc., can solve problems such as gear angle range errors, eliminate installation errors and ensure accuracy , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

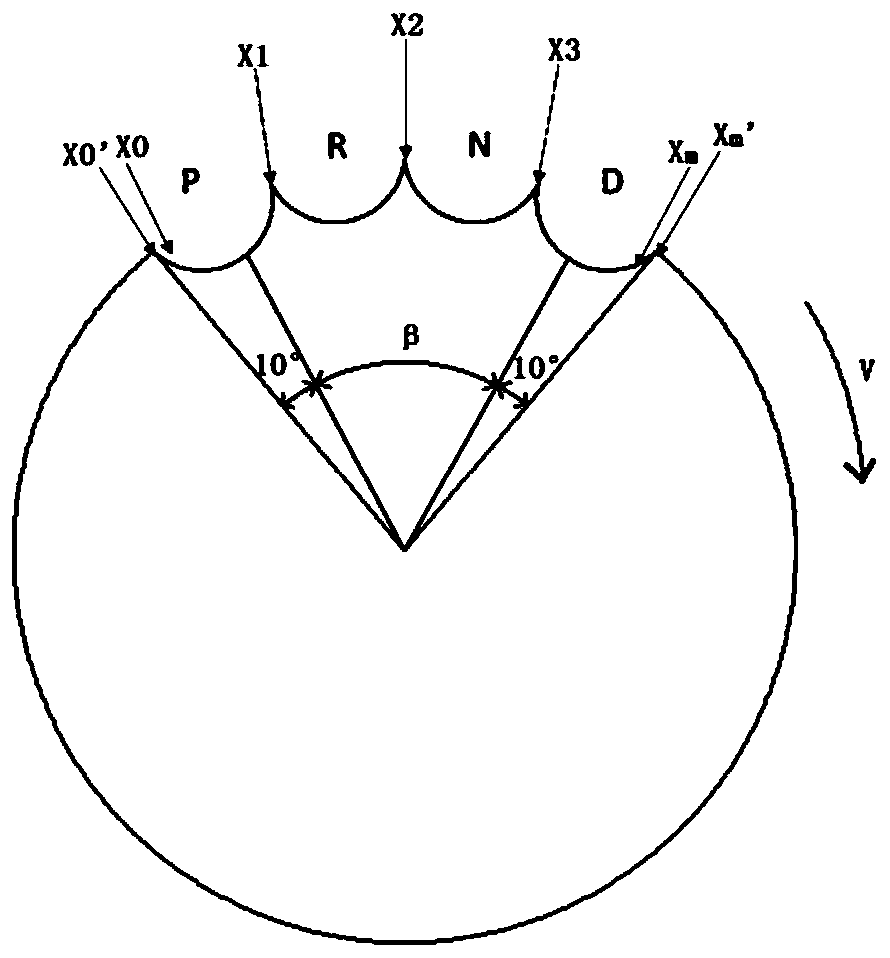

[0040] Such as Figure 1 to Figure 3 As shown, the present invention discloses a gear self-learning method for a knob shifter. The working method of the knob shifter is as follows: a gear angle is set for each gear of the knob shifter. Range, the rotation angle value of the knob is detected by the Hall sensor, and the detected rotation angle value is compared with the angle range of each gear position. The gear position corresponding to the gear angle range of the detected rotation angle value is the knob shifter Output gear information.

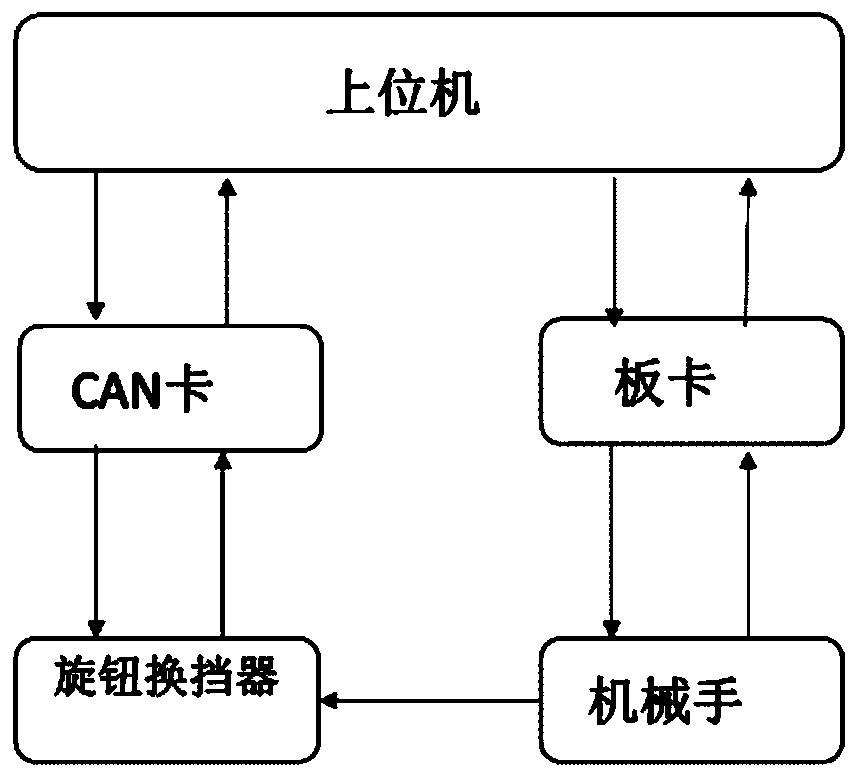

[0041]The gear self-learning method is used to determine an accurate gear angle range for each gear of the knob shifter, and it is implemented based on a host computer, a CAN card, a board and a manipulator, wherein the host computer can pass The board controls the manipulator so that the manipulator can rotate the knob shifter for gear self-learning to control the shifting knob, and the host computer can receive the knob shifter through th...

Embodiment approach

[0062] In the step S1, the angle value X of the left dead center is measured 0 and right dead center angle value X m The method is:

[0063] Step S1.1, controlling the manipulator to rotate the knob of the knob shifter counterclockwise with a preset fixed torque until the angle value collected by the Hall sensor is maintained at For the same angle value, record the angle value, and repeat the step S1.1 multiple times;

[0064] Step S1.2, controlling the manipulator to rotate the knob of the knob shifter clockwise with a preset fixed torque until the angle value collected by the Hall sensor is maintained at For the same angle value, record the angle value, and repeat the step S1.2 multiple times;

[0065] Step S1.3, when the decreasing direction (V) of the angle value collected by the Hall sensor is the clockwise direction, if the maximum value among the multiple angle values recorded in the step S1.1 appears At least three times, then record the maximum value as the left...

Embodiment 3

[0070] On the basis of the above-mentioned embodiment 1 or embodiment 2, this embodiment 3 also adopts the following preferred implementation modes:

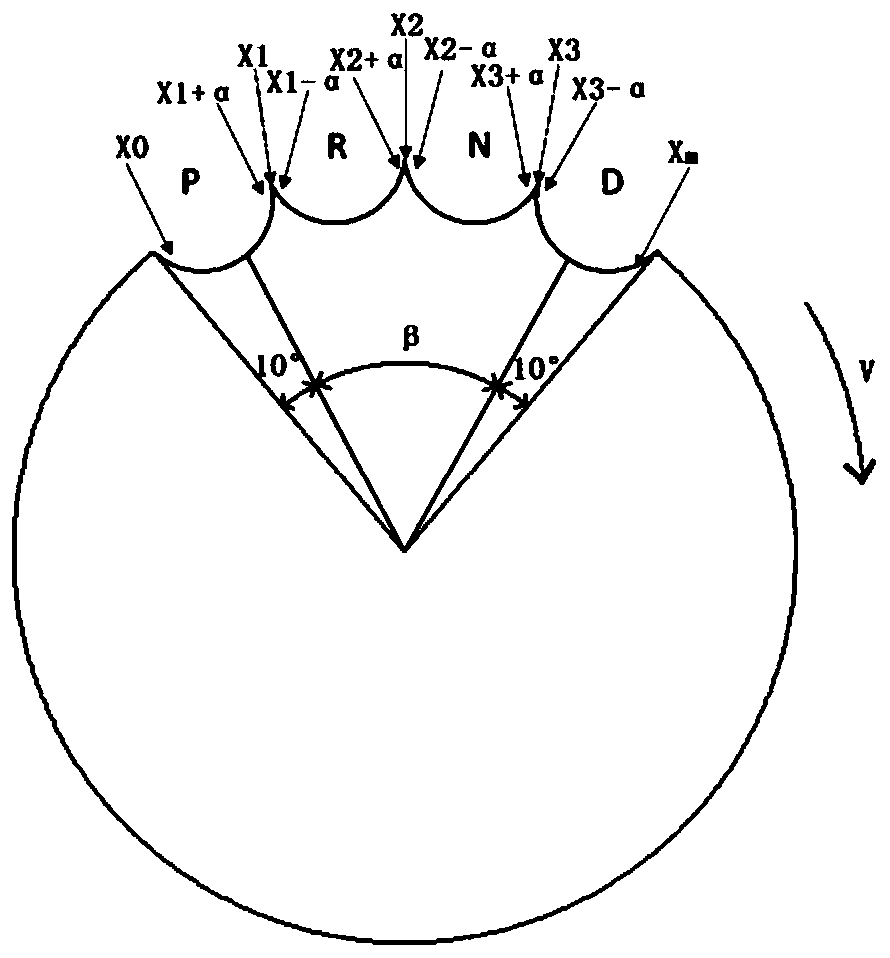

[0071] In the step S3, the value of the preset empty window angle α is between 0.2° and 0.5°.

[0072] Wherein, preferably: the value of the preset empty window angle α is 0.3°.

[0073] In order to better illustrate the advancement of the gear self-learning method of the present invention, a sample of a knob shifter is selected at random now (the parameters of the knob shifter are as described in the above-mentioned example 1), and two kinds of self-learning methods are used respectively. , a kind of existing gear self-learning method described in the background technology, that is: see Figure 4 , only self-study the P gear position, and then use the P gear position as a benchmark to calculate other gear positions according to the accumulation of the shifter stroke. The other is the gear self-learning method of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com