Device and method for installation of magnetic steel of loudspeaker

A technology for installing devices and speakers, applied to sensors, electrical components, etc., can solve the problem of low installation efficiency of magnetic steel, and achieve the effect of automatic production, high production efficiency, and avoiding wrong installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

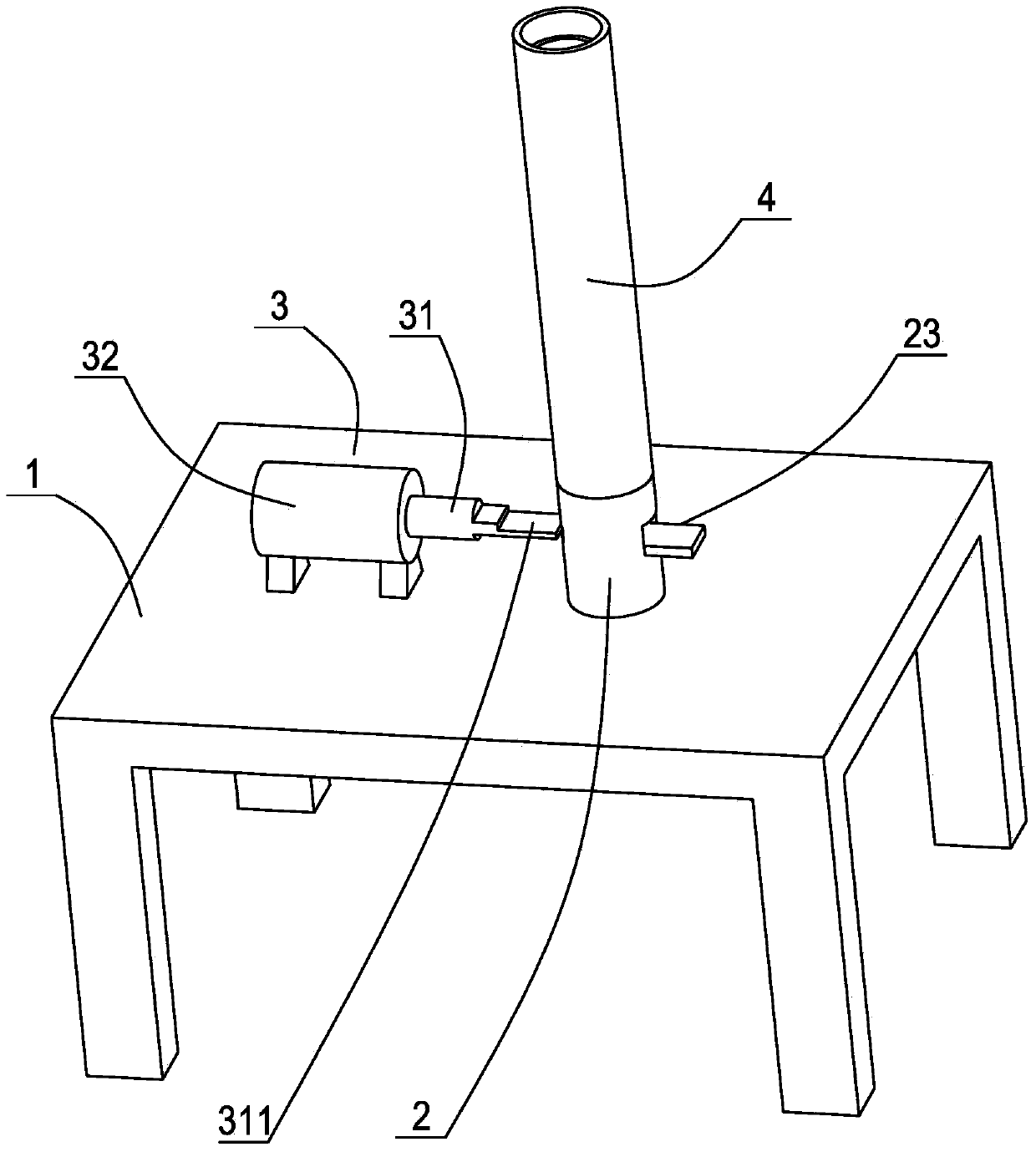

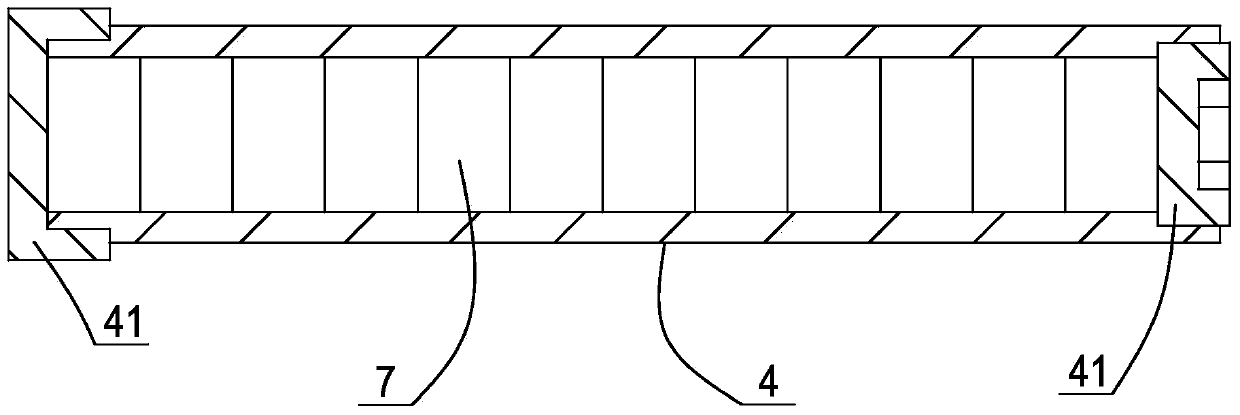

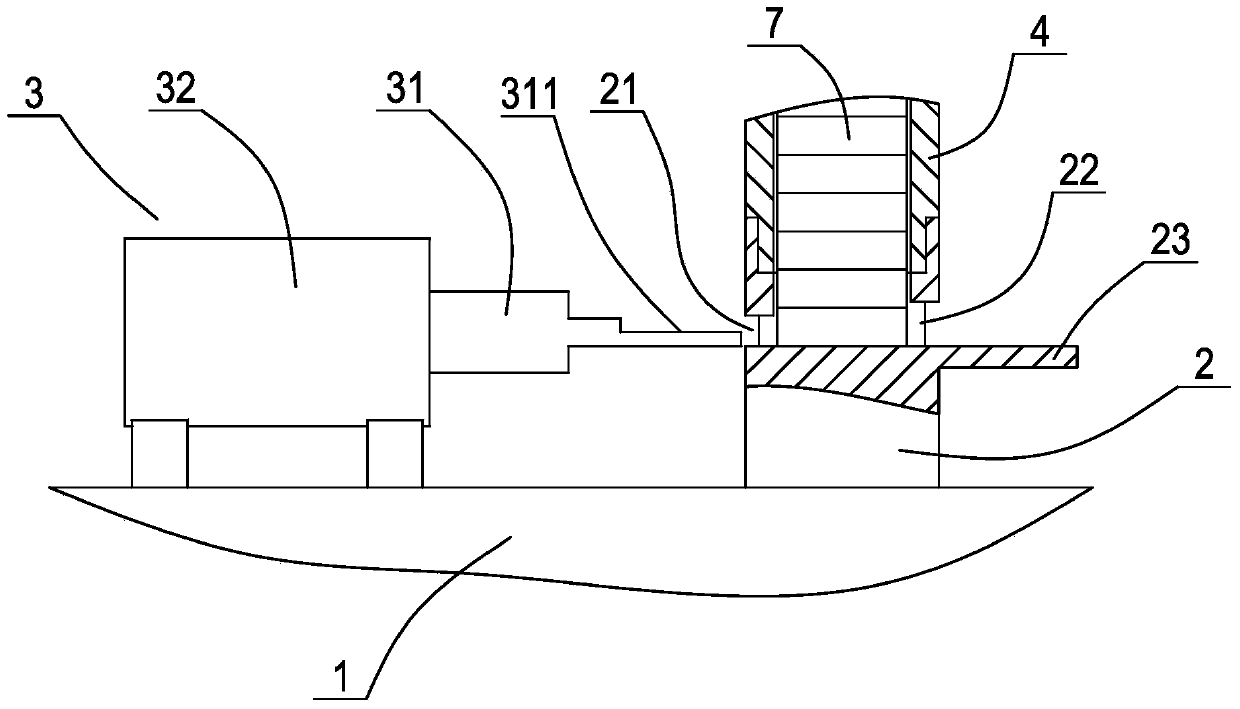

[0033] Embodiment 1: A magnetic steel mounting device for a loudspeaker, such as figure 1 As shown, it includes an installation platform 1, on which a fixed cylinder base 2 and a magnetic steel push mechanism 3 are arranged side by side, and a cylindrical magnetizing sleeve 4 is vertically screwed on the upper end of the fixed cylinder base to charge the cylinder. The magnetic sleeve is preferably made of aluminum alloy so as to be easily made by extrusion. like figure 2As shown, the magnetizing sleeve is provided with sealing caps 41 at both ends, and the lower end of the magnetizing sleeve is an external thread, and the upper end is an internal thread, and the corresponding lower end cap is an internal thread, and the upper end cap is an external thread. In this way, on the one hand, the cover and the magnetizing sleeve form a threaded connection; on the other hand, by setting the corresponding internal thread on the fixed sleeve, when the cover at the lower end of the mag...

Embodiment 2

[0038] Embodiment 2: A magnetic steel mounting device for a loudspeaker, such as Figure 4 , Figure 5 As shown, it also includes an installation platform 1, a fixed cylinder seat 2 and a magnetic steel pushing mechanism 3 arranged side by side on the installation platform. Unlike embodiment 1, there is no need to set a magnetic steel placement platform on the fixed cylinder base. In order to realize the automatic installation of the magnetic steel, we can set the magnetic steel installation mechanism 6 on the side away from the magnetic steel pushing mechanism of the fixed cylinder seat. The magnetic steel installation mechanism includes a delivery bracket 61 fixed on the installation table, and a The vertical conveying cylinder 62 corresponds to one of the loudspeaker skeleton positioning seats 51 of the conveying track 5 located at the lower part of the conveying bracket. The downward piston rod 621 of the conveying cylinder is made of non-ferromagnetic materials such as ...

Embodiment 3

[0042] Embodiment 3: A magnetic steel installation method for a loudspeaker, specifically comprising the following steps:

[0043] a. First put the magnetic steel blanks into a magnetizing sleeve made of non-ferromagnetic material. The magnetizing sleeve has a cover screwed to its open end, and then screw the magnetizing sleeve on Put the cover into the magnetizing machine to magnetize the magnet steel blank, so that the magnet steel blank in the magnetization sleeve becomes magnet steel. At this time, the magnetic steel in the magnetizing sleeve forms a magnetic steel string with the same polarity and is attracted to each other, and the magnetizing sleeve constitutes a storage container for the magnetic steel. Since the cross-section of the magnetic steel is usually circular, the magnetizing sleeve preferably adopts a matching cylindrical barrel structure. When the cross-section of the magnetic steel is in a rectangular shape, the inner cavity of the magnetizing sleeve The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com