Metal mold for vulcanizing tire treads

A tire tread and mold technology, applied to tires, household appliances, and other household appliances, can solve problems such as time required and achieve the effect of preventing misinstallation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] An embodiment of the present invention will be described below with reference to the drawings.

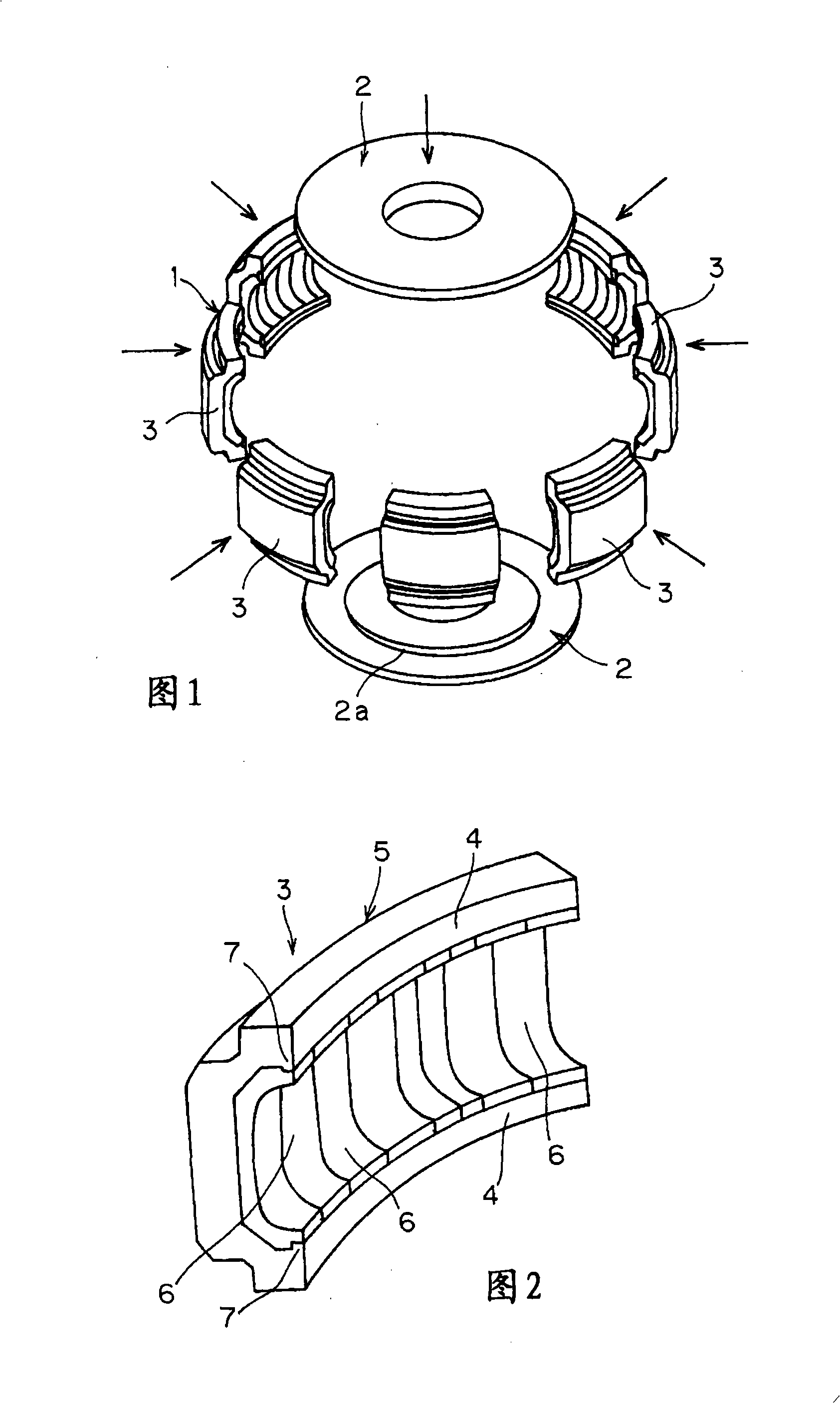

[0018] FIG. 1 is a schematic perspective view showing a tire tread vulcanizing mold according to an embodiment of the present invention together with a pair of side vulcanizing molds. Reference numeral 1 denotes the tire tread vulcanizing mold according to the present invention, and 2 denotes a pair of side vulcanizing molds. Add sulfur mold.

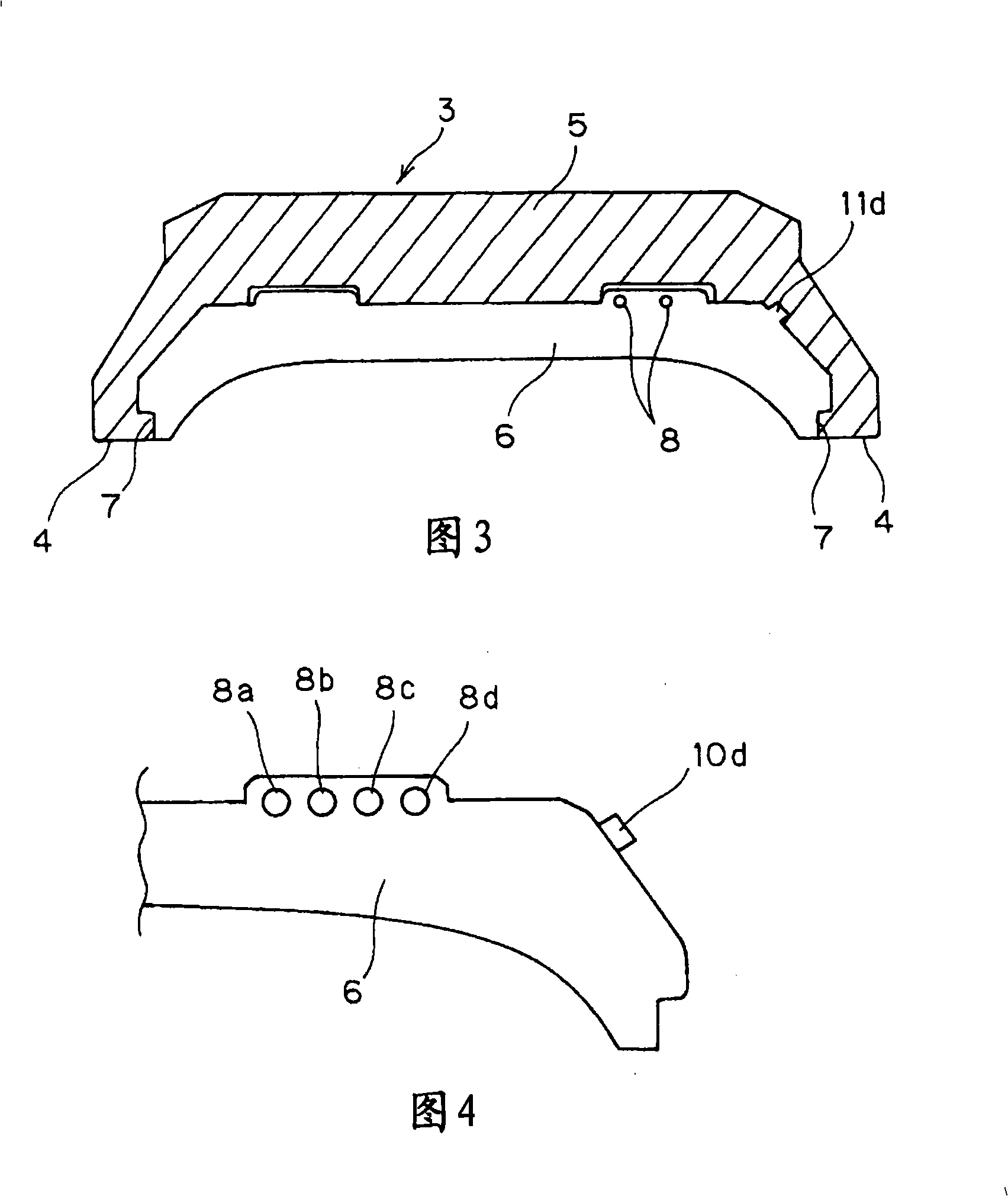

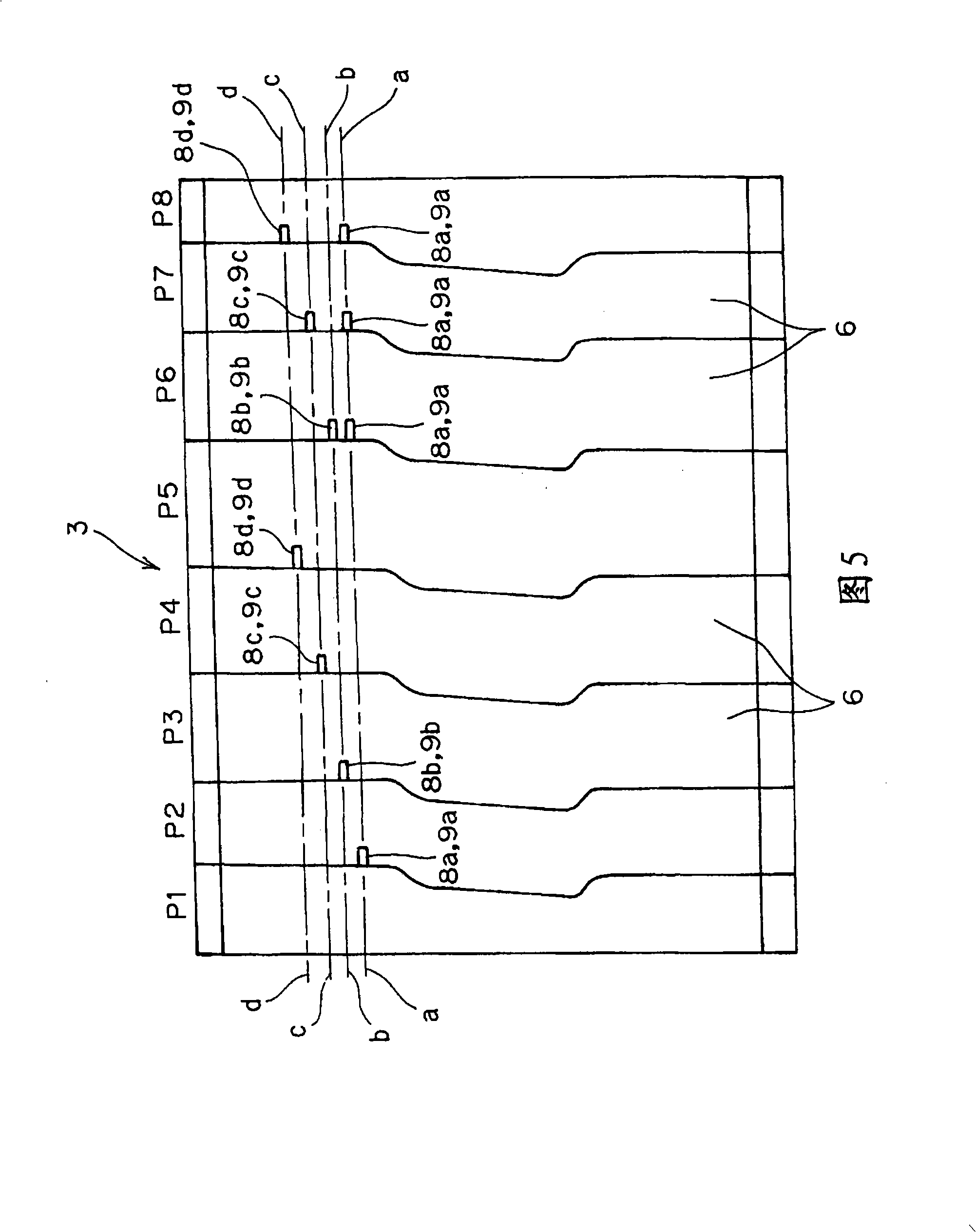

[0019] Here, the tire tread vulcanizing mold 1 is composed of a plurality of (eight are shown in the figure) sector molds 3 capable of expanding and contracting horizontally in the radial direction, and these sector molds 3 are separated by adjacent sector molds 3 . The postures that are in close contact with each other and whose diameter is reduced form a ring shape as a whole. In the figure, they are used together with a pair of upper and lower side vulcanization molds 2 to vulcanize a green tire to form the tread portion of a finis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com