Multifunctional food processor

A food processor and multi-functional technology, which can be applied to household appliances, applications, kitchen appliances, etc., can solve the problems of trouble, easy misuse by users, falling off and smashing items, etc. The effect of the knife

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

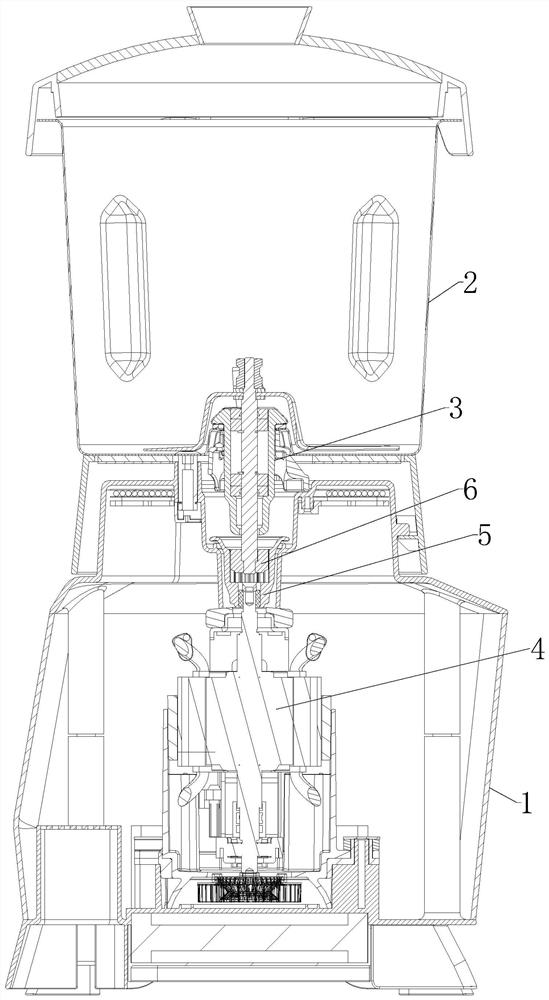

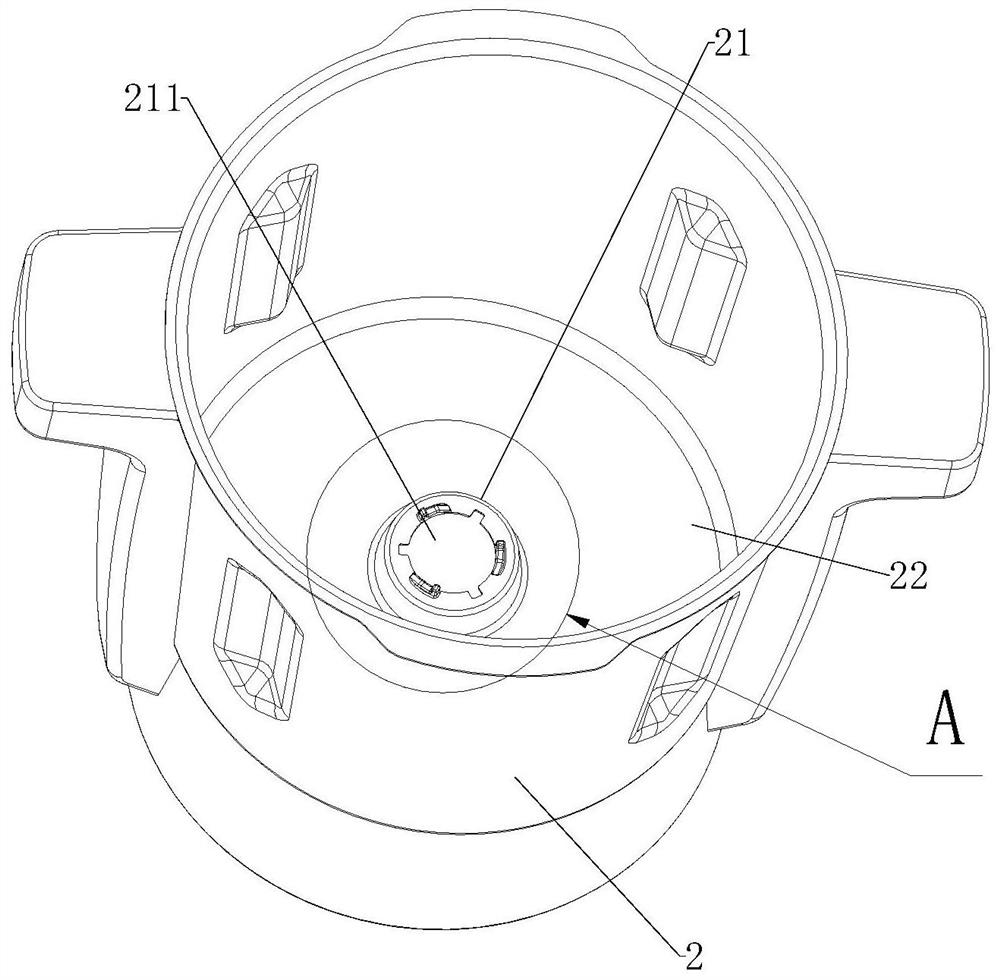

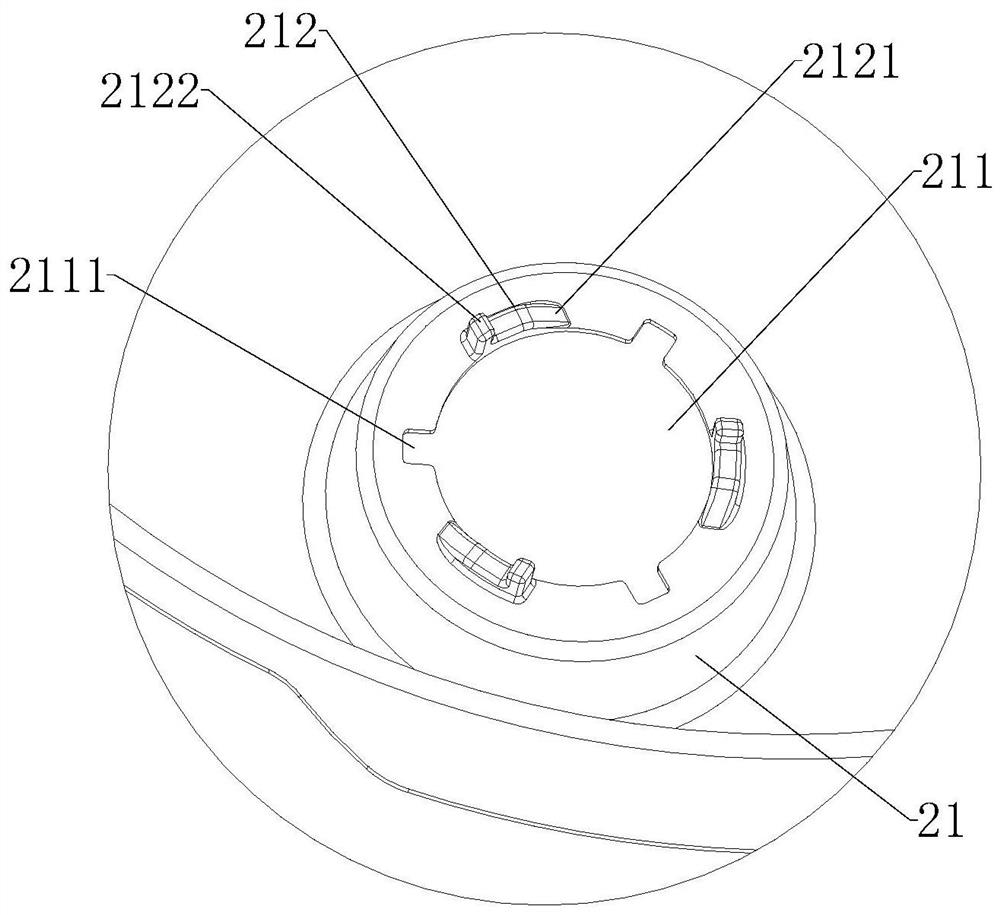

[0042] Embodiment one: if figure 1 — Figure 10 As shown, a multifunctional food processor includes a main base 1, a stirring cup 2 and a stirring knife assembly 3, the stirring cup 2 is installed on the upper end of the main base 1, the stirring knife assembly 3 is installed in the stirring cup 2, and the stirring knife assembly 3 is connected to the motor assembly in the main base 1. There is a round hole 211 that penetrates up and down in the stirring cup 2. There are multiple positioning structures evenly distributed on the edge of the round hole 211. The round hole 211 is used for the mixing knife assembly 3 to pass through. The stirring knife assembly 3 is provided with a fixing structure that matches the positioning structure and is used to connect the positioning structure.

[0043] Such as figure 1 As shown, the motor assembly includes a motor 4 and a lower clutch 5 , the output shaft at the upper end of the motor 4 is connected to the lower clutch 5 , and the lower...

Embodiment 2

[0051] Embodiment two: if Figure 11 — Figure 23 shown. Embodiment 2 is the same as Embodiment 1 in that the main base 1 and the stirring cup 2 have the same structure, and the difference is:

[0052] Such as Figure 11 , Figure 18 and Figure 19 As shown, the fixed structure is three positioning claws 34 evenly distributed on the outer wall of the upper end of the mixing knife assembly 3. The groove 2111 is for the positioning claws 34 to pass through. 2122 blocks the positioning claw 34, and the side of the positioning claw 34 fits together with the protrusion 2122, preventing the motor 4 from rotating and causing the processed food to be unable to be processed. During installation, the mixing knife assembly 3 passes through the round hole 211 of the mixing cup 2 from the outside to the inside, and the positioning claw 34 passes through the groove 2111; then, when the knife assembly 31 is rotated, the positioning claw 34 moves to the On the top of the positioning blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com