Wrong-inserting preventing speed sensor

A speed sensor and anti-insertion technology, which is applied to devices using electric/magnetic methods, etc., can solve the problem of lack of anti-insertion function, etc., and achieve the effect of low manufacturing cost and satisfying use requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

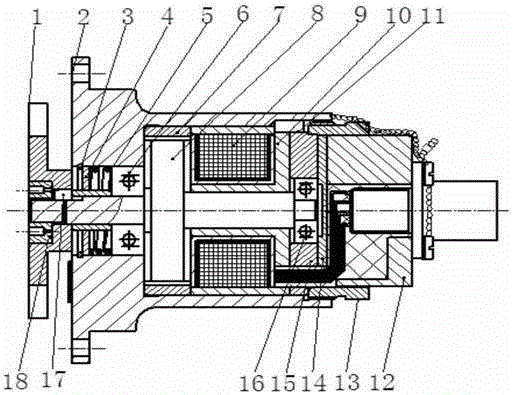

[0021] This embodiment is an anti-misplug speed sensor.

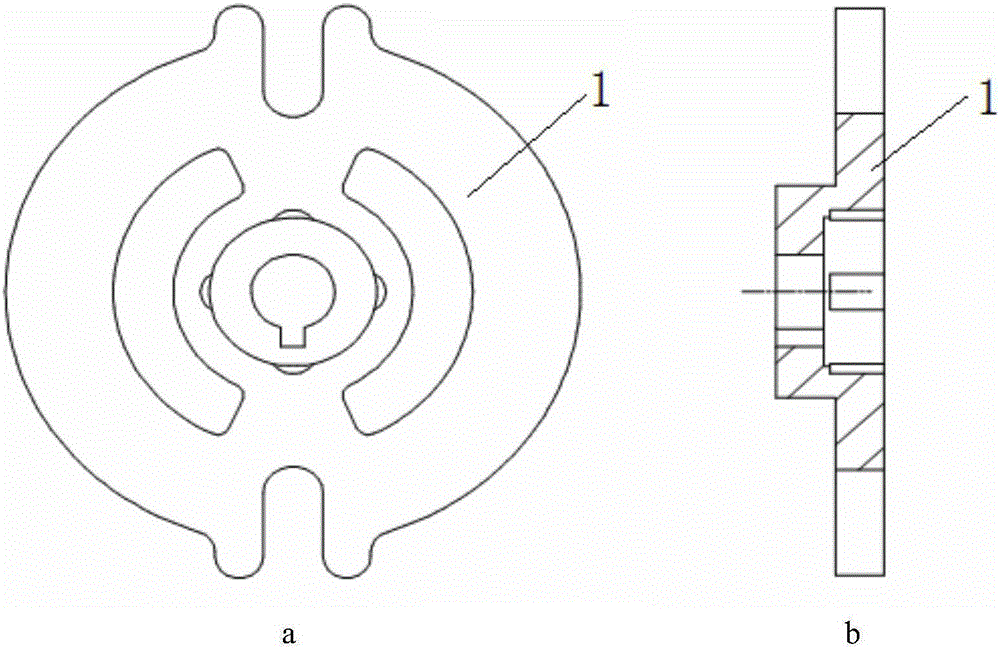

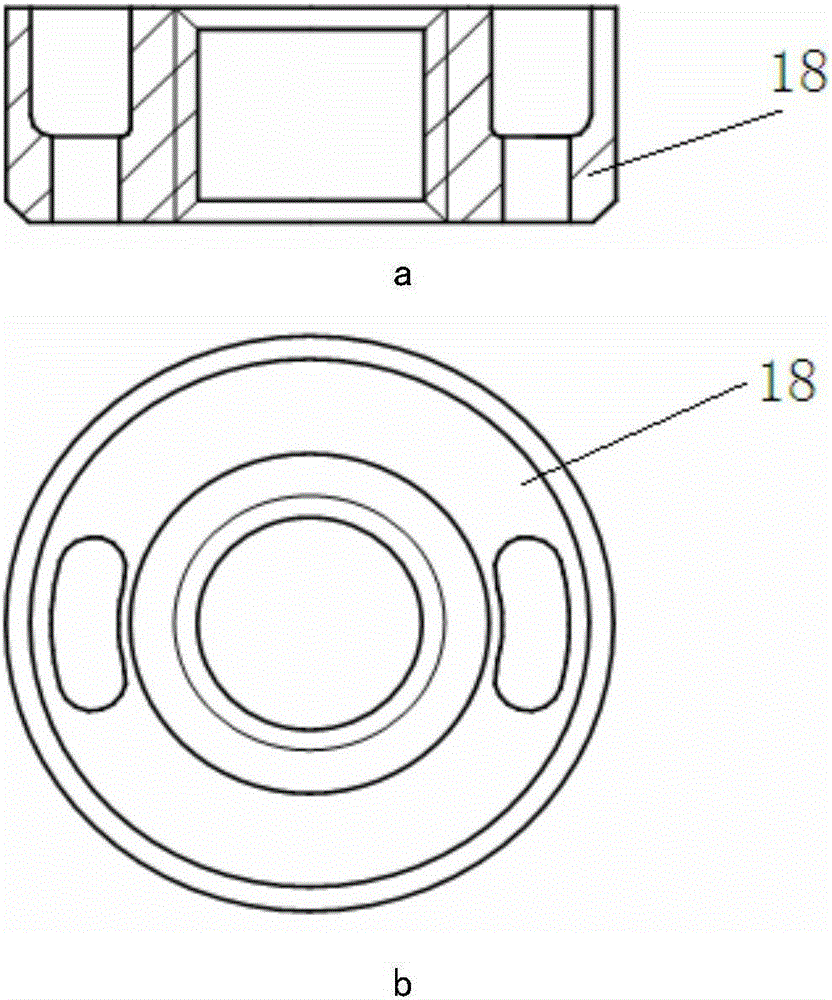

[0022] This embodiment includes an anti-wrong insertion fork 1, a housing 2, a circlip 3 for holes, a dustproof ring 4, a spring 5, a large bearing 6, a gear ring 7, a rotor assembly 8, a coil assembly 9, a magnetizer 10, Straight pin 11, base 12, screw sleeve 13, compression cover 14, bearing seat 15, small bearing 16, key 17, lock nut 18.

[0023] In this embodiment: the large bearing 6 is pressed into the positioning boss in the middle of the rotor assembly 8, the coil assembly 9 and the magnetizer 10 are installed on the rotor assembly 8, and the small bearing 16 is pressed into the runner located in the rotor assembly 8 Install the shaft on the end face, put the gear ring 7 and the rotor assembly 8 equipped with the coil assembly 9, the magnetizer 10, the large bearing 6 and the small bearing 16 into the housing 2, and then put it into the bearing seat 15, and at the same time press the Cover 14 compresses bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com