High-efficiency water tank for heat pump water heater

A heat pump water heater, high-efficiency technology, used in fluid heaters, heat recovery systems, energy-saving heating/cooling, etc., can solve the problems of adverse effects, energy efficiency decline, and low energy efficiency of heat pump systems, shortening inefficient heating time, and improving operation. working conditions, the effect of improving the energy efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

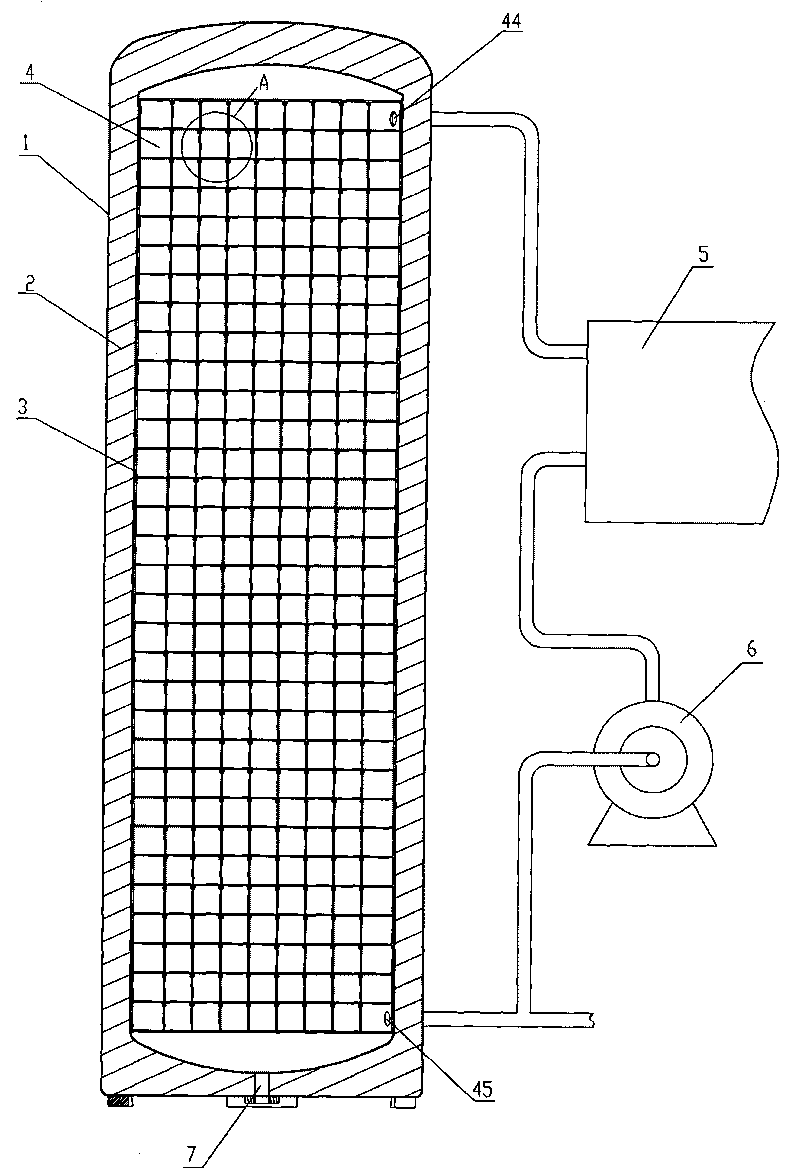

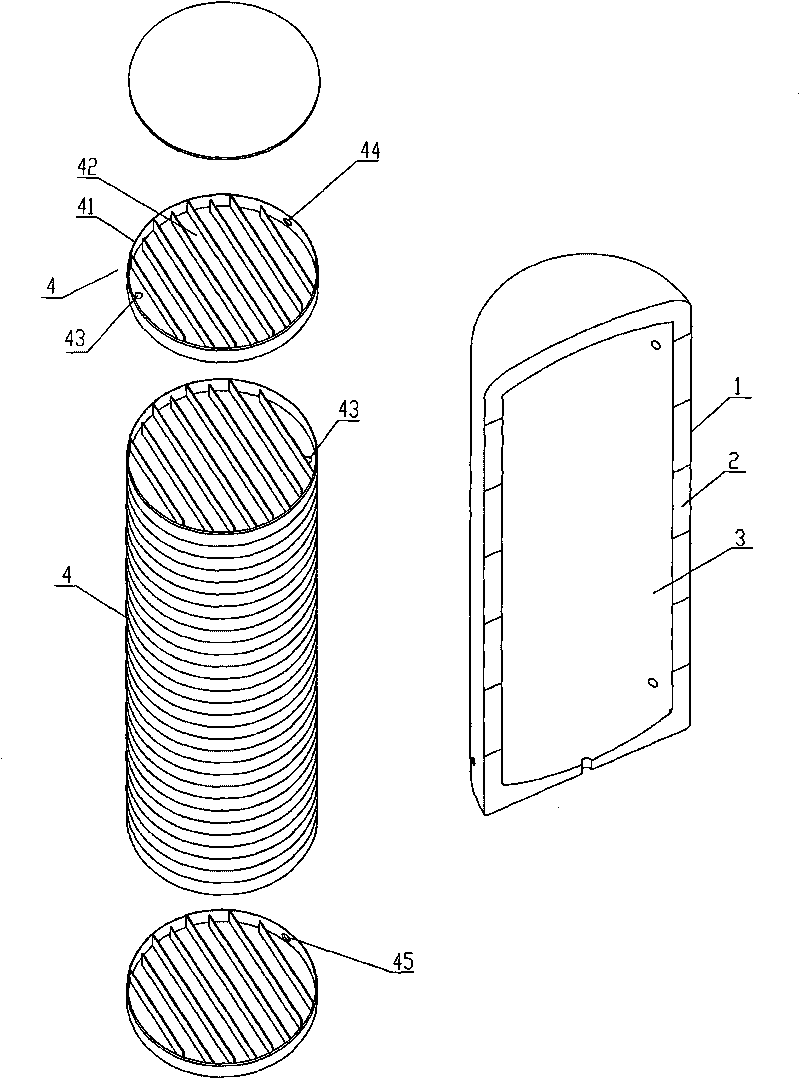

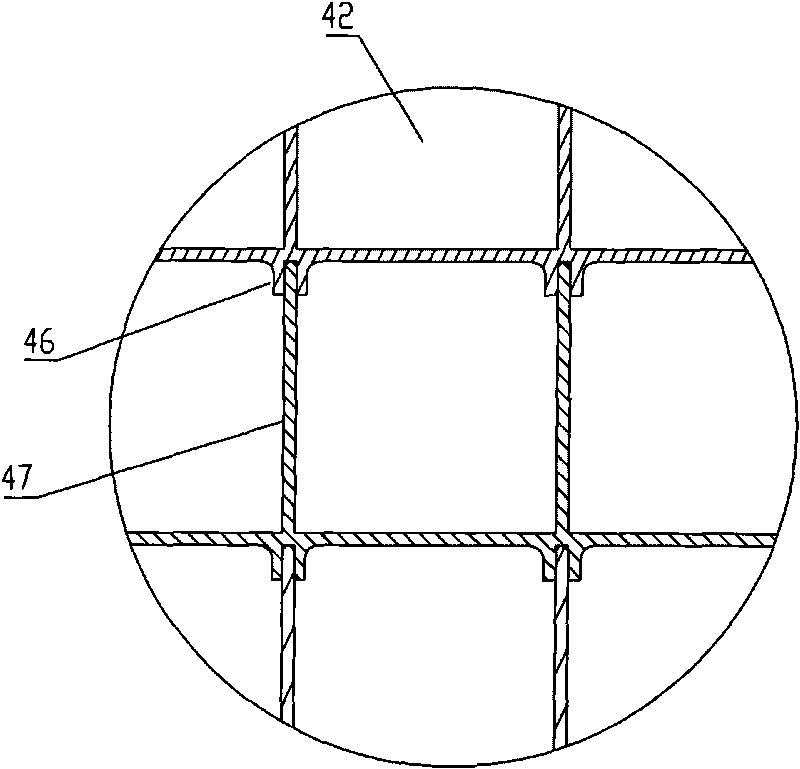

[0015] refer to Figure 1 to Figure 4 As shown, a high-efficiency water tank for a heat pump water heater includes an outer shell 1, an insulation layer 2 and an inner tank 3. The inner tank 3 is stacked with a multi-layer water flow unit 4 from top to bottom. The water flow unit 4 includes a surrounding edge 41 and a surrounding edge 41 The inner slender groove-shaped water flow channel 42, the end of the water flow channel 42 of each layer of water flow unit 4 is provided with an opening 43 communicating with the head end of the lower layer of water flow unit 4, and the head end of the water flow channel of the top water flow unit 4 is provided with an external device. The upper opening 44 of the bottom water flow unit 4 is provided with a lower opening 45 connected to external equipment at the end of the water flow channel 42. The external equipment includes the heat exchanger 5 and the circulating water pump 6 of the heat pump water heater. The design of the cross-sectional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com