Driving gear shaft for gearbox

A technology for driving gear shafts and gearboxes, which is applied in the directions of gear lubrication/cooling, shafts, shafts, and bearings, and can solve problems such as uneven pressure distribution in oil grooves, and achieve the effect of improving press-fit quality and avoiding relaxation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

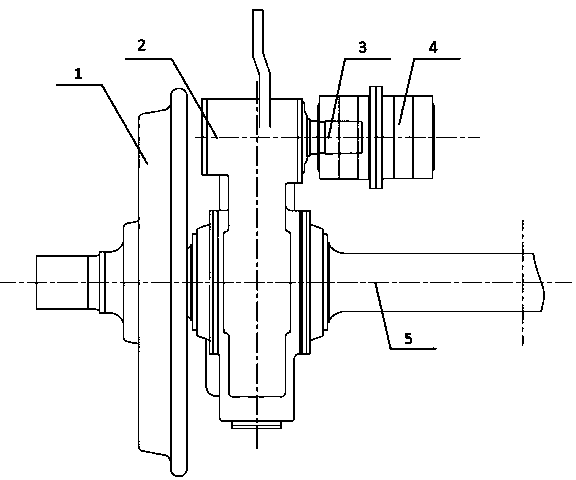

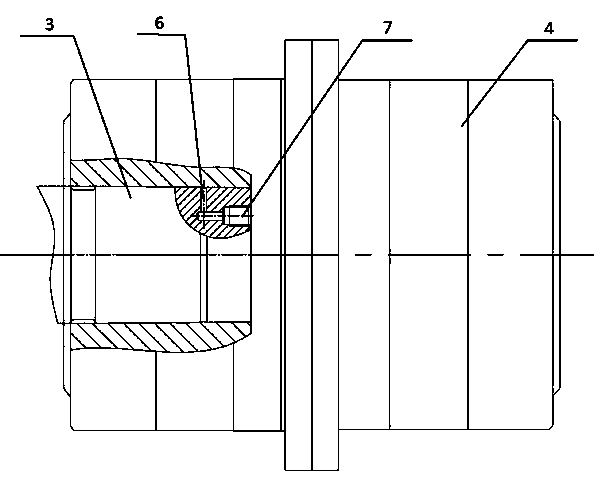

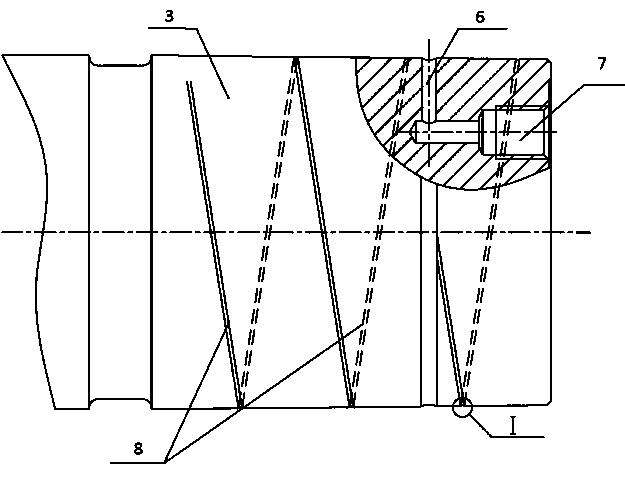

[0026] A gearbox driving gear shaft, such as image 3 As shown, it includes a driving gear shaft 3 connected with an interference fit with the coupling 4; the outer circular surface of the driving gear shaft 3 is provided with a U-shaped spiral oil groove 8 in section, as figure 2 As shown, the outer circular surface of the driving gear shaft 3 is used to cooperate with the inner surface of the shaft coupling 4 . Such as image 3 As shown, the spiral oil groove 8 communicates with the oil groove 6 and is distributed at equal intervals in the axial direction. Such as Figure 4 As shown, the helical oil groove 8 is continuous on the surface of the driving gear shaft 3, and the helical oil groove 8 is chamfered in order to avoid stress concentration at sharp corners.

[0027] The pitch of the helical oil groove 8 is 1 / 3 of the mating length of the coupling 4 and the driving gear shaft, because the pitch is too large, the processing technology is complicated, and it is not con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com