Wiring terminal contact pin press-fitting device and method

A technology of terminal and press-fitting device, which is applied in the direction of connection, circuit/collector parts, electrical components, etc., can solve the inaccurate distance of the downward movement of the pin row, reduce the quality of pin press-fitting, and affect the pin problems such as the accuracy of material selection to achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

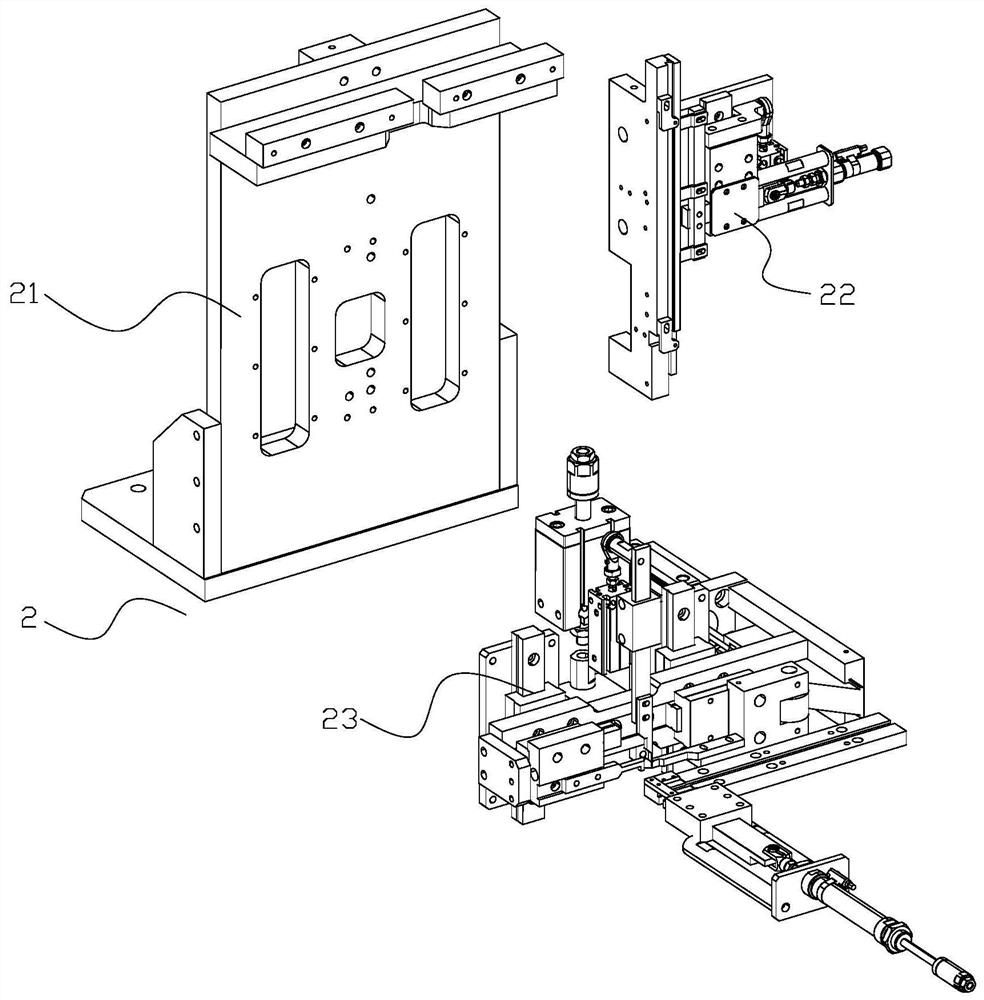

[0033] Such as figure 1 The shown pin press-fitting device 2 includes a press-fit base plate 21 and a pin-pushing mechanism 22 and a pin-pressing mechanism 23 fixed on the press-fit base plate 21; The outlet of the material bending device is connected, and the output end of the pin pushing mechanism 22 is connected with the input end of the pin pressing mechanism 23; the output end of the pin pressing mechanism 23 is connected with the feeding port of the blanking device; The feeding mechanism 22 is used to move the pins connected side by side to move down; the pin depressing mechanism 23 is used to press down a single pin into the corresponding hole of the cartridge.

[0034] The product flow direction of the connection terminal is: the pin pushing mechanism 22 to the pin pressing mechanism 23 .

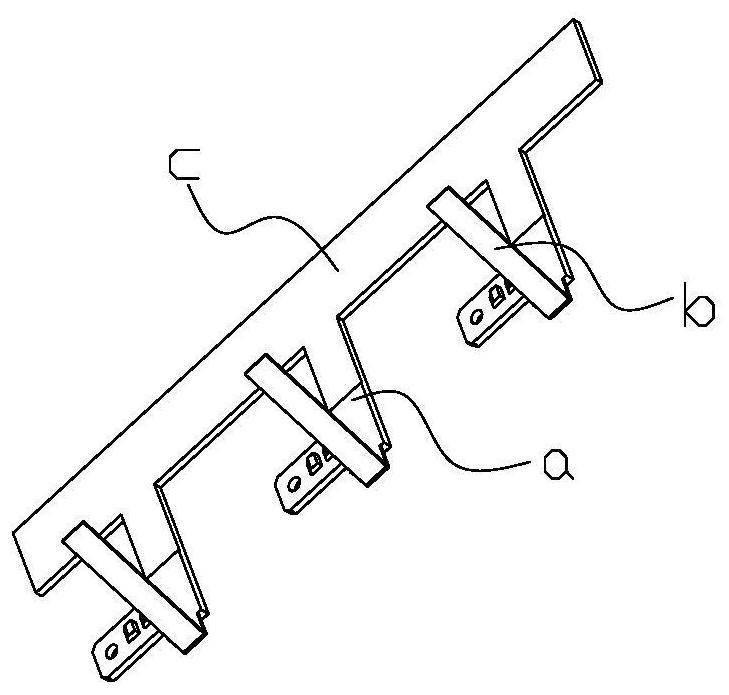

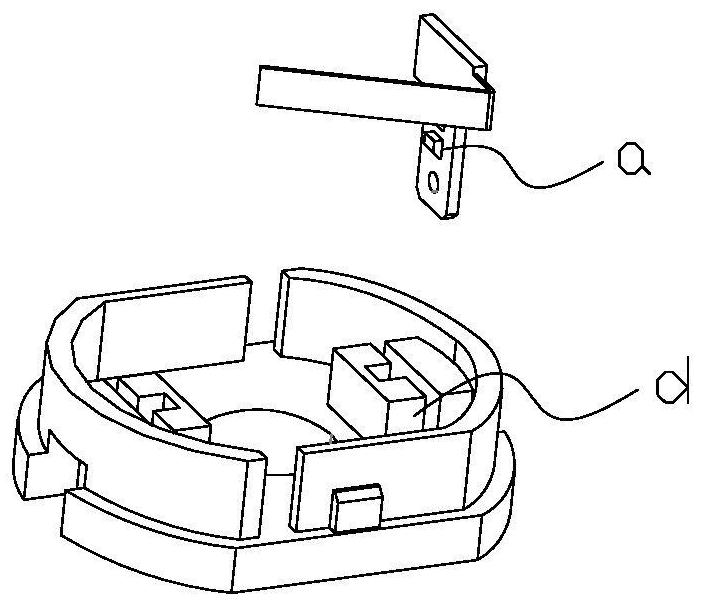

[0035] Such as figure 2 , image 3 Shown is a schematic diagram of the structure of terminal blocks. The terminal block is composed of a pin a and a card seat d: a single pin a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com