Thrust wheel floating oil seal press-fitting machine

A floating oil seal and press machine technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor intensity and low efficiency of workers, and achieve the effect of convenient and accurate positioning, improved assembly efficiency, and stable clamping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

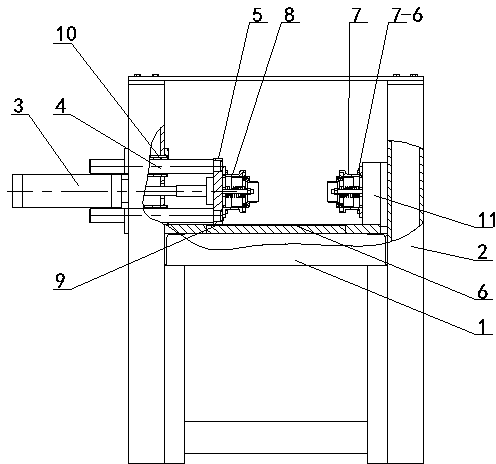

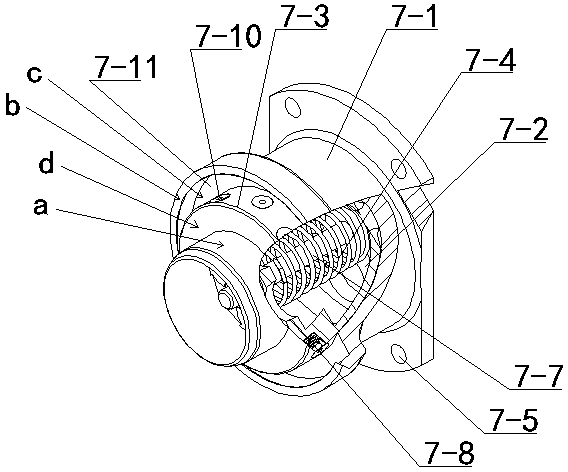

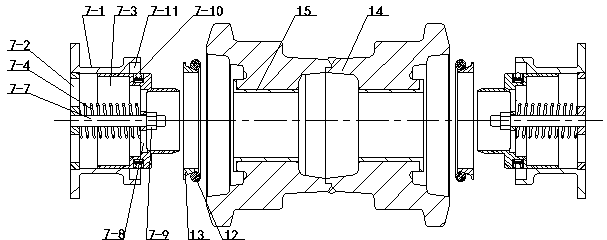

[0032] as attached figure 1 , 2 As shown, the roller floating oil seal pressing machine of the present invention is mainly composed of a workbench 1, a frame 2, a cylinder 3, a guide rod 4, a top plate 5, an arc positioning plate 6, a fixed pressure head 7 and a movable pressure head 8.

[0033] Described frame 2 is " 冂 " shape frame.

[0034] Workbench 1 is fixedly arranged on the lower part of frame 2 inner side. Cylinder 3 cylinder body is fixed on frame 2 one side, and cylinder rod extends to the upper side of workbench 1 in frame 2. The top plate 5 is vertically arranged on the workbench 1, and is fixedly connected with the end of the cylinder rod. The top plate 5 is slidingly fitted with the workbench 1 through the bearing 9 arranged at the lower end. One end of the guide rod 4 is fixedly connected with the top plate 5 , and the other end passes through the frame 2 , and is slidably matched with the frame 2 through the guide rod sleeve 10 .

[0035] The movable pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com