Press fitting tool for thin-walled cylinder sleeve

A technology for press-fitting tools and cylinder liners, applied in the field of press-fitting tools, can solve the problems of cylinder pulling failure, affecting work efficiency, heavy work, etc., and achieve the effects of small deformation of the cylinder liners, improving work efficiency, and convenient operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

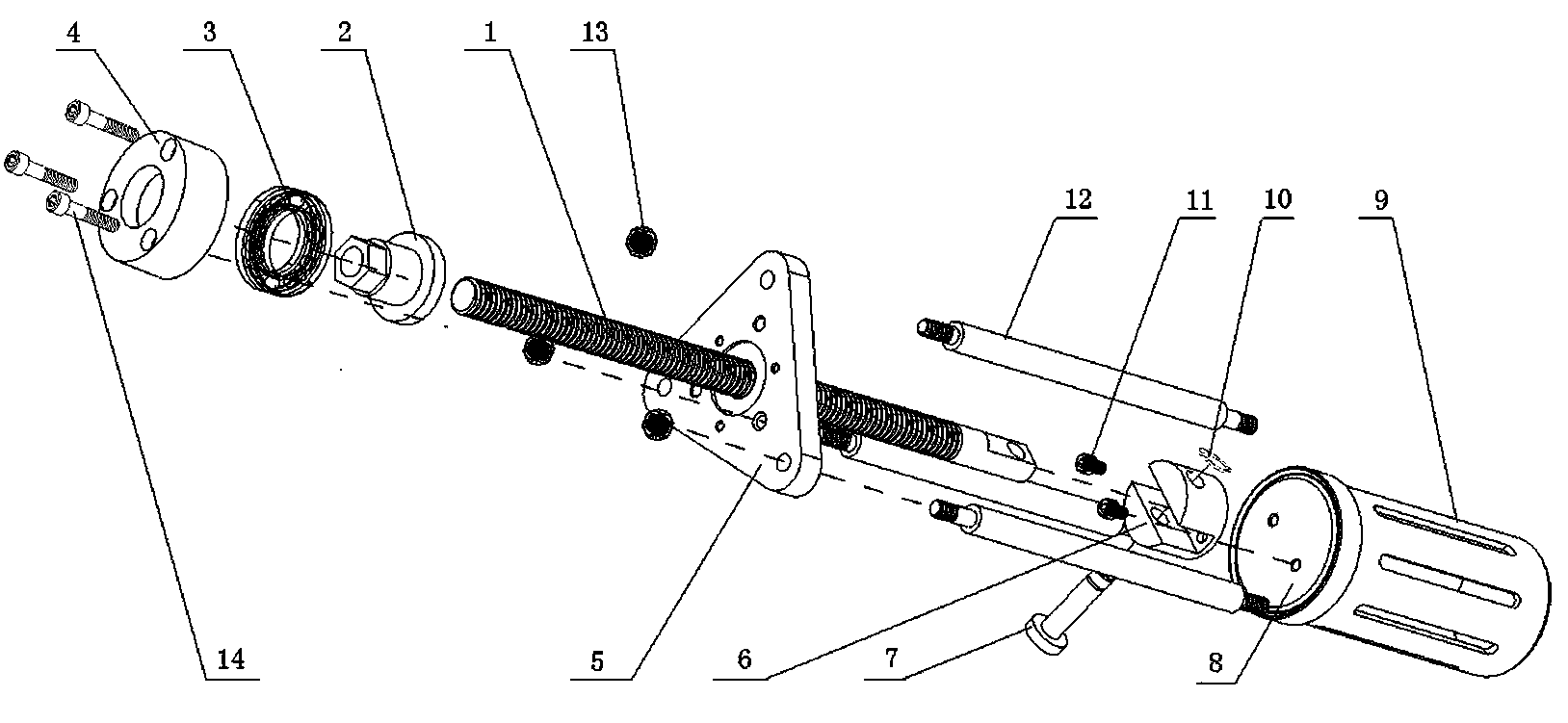

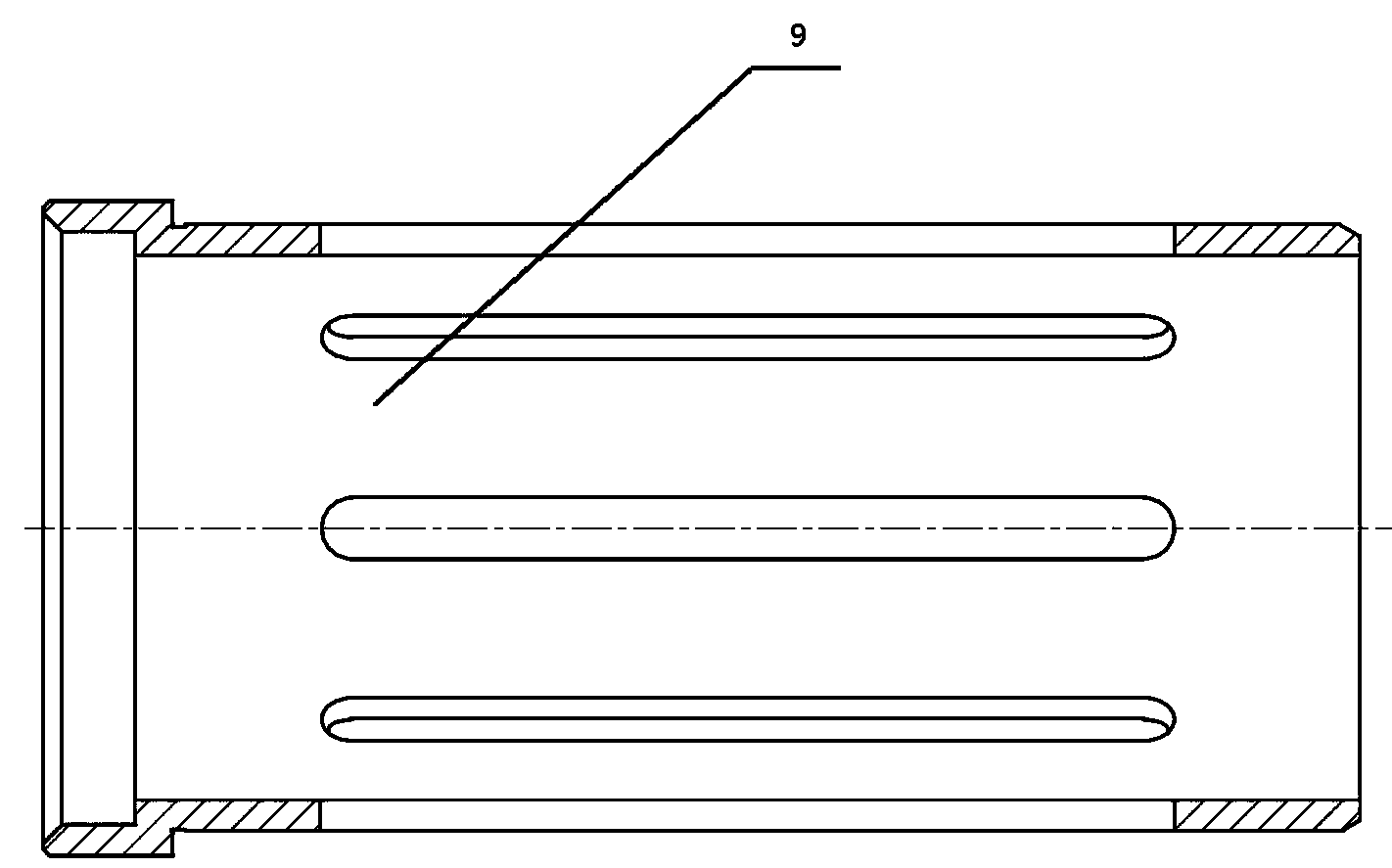

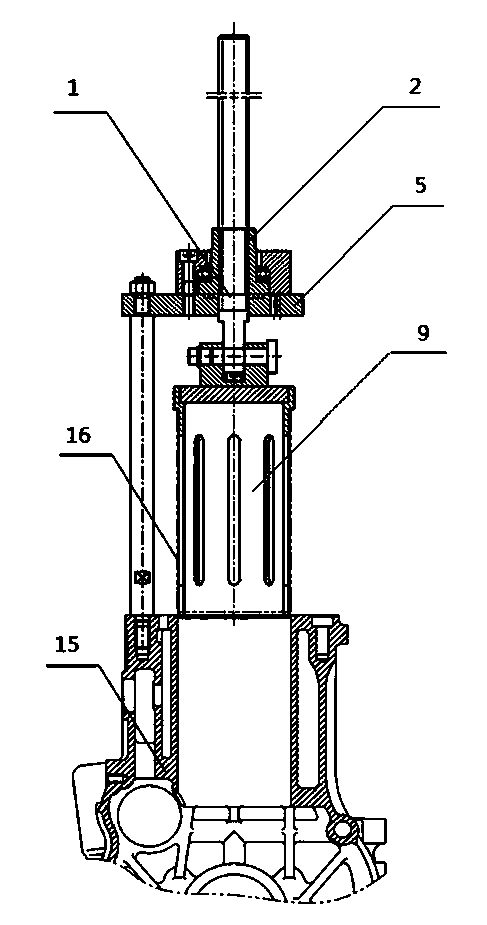

[0023] Such as figure 1 As shown, a press-fitting tool for thin-walled cylinder liners is used to press-fit a thin-walled cylinder liner of an engine, including a press rod 1, a support plate assembly, three support rods 12, and a press head sleeve Components.

[0024] The pressure rod 1 is in the shape of a trapezoidal threaded shaft. The trapezoidal thread has high strength, good neutrality and good process performance. Therefore, the trapezoidal thread is used for transmission, and the optimal solution is to use the Tr26×5 trapezoidal thread. The pressure head sleeve assembly is in the shape of a cylinder with one end closed and one end open. The support plate assembly is sleeved on the pressure rod 1, and one end of the pressure rod 1 is fixedly connected with the closed end of the pressure head sleeve assembly.

[0025] The supporting plate assembly includes a bearing plate 4, a thrust ball bearing 3, a bearing nut 2 and a supporting plate 5. The bearing plate 4 is a cover wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com