Transverse high-efficiency press fitting machine for automotive heat dissipator

A technology for automotive radiators and press-fitting machines, which is applied to assembly machines, metal processing equipment, manufacturing tools, etc. It can solve problems such as bumps caused by taking out and flipping radiator cores, product compression quality degradation, and affecting normal use. Improve the press-fitting accuracy and product quality, ensure stable fixation, and have a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

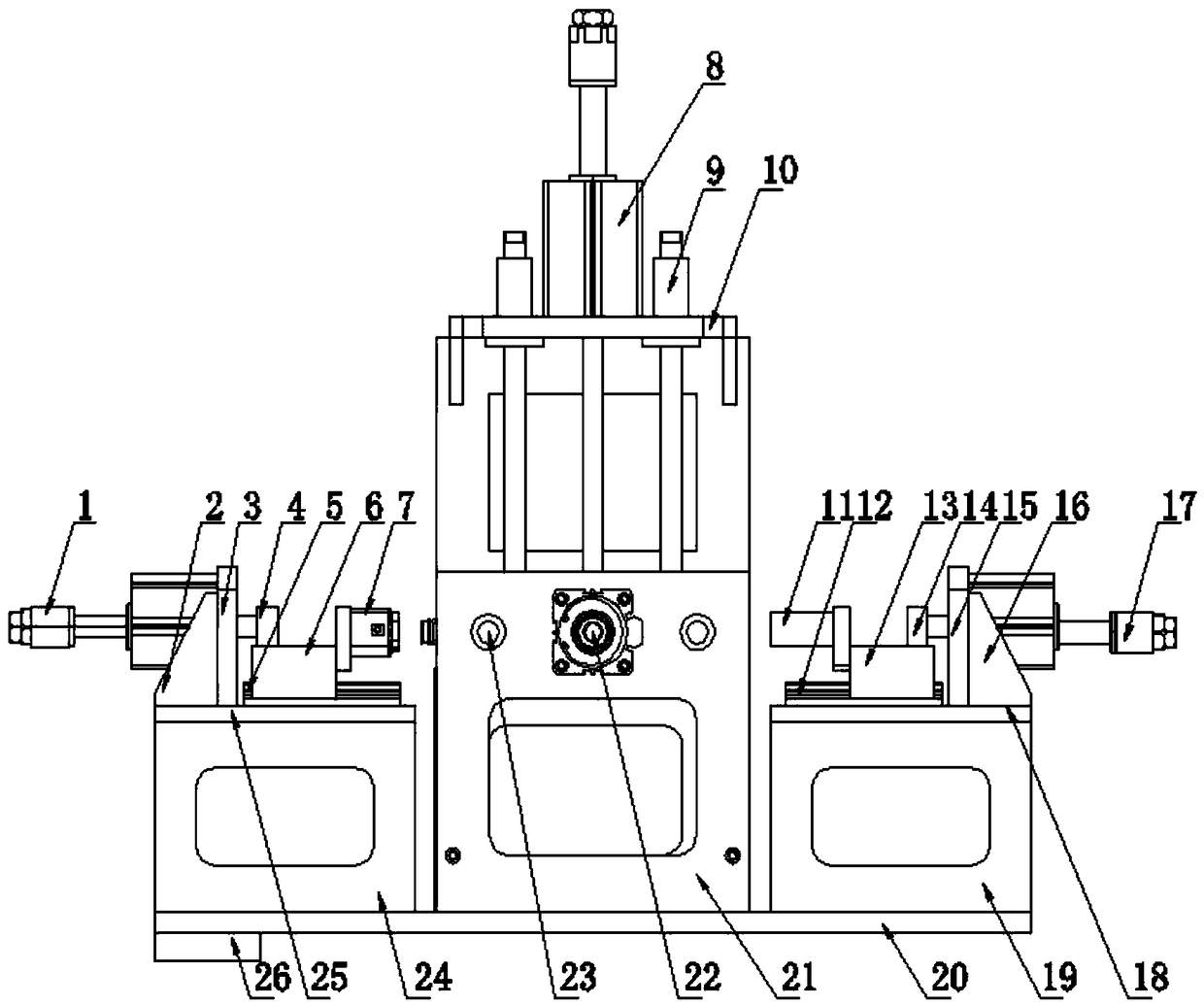

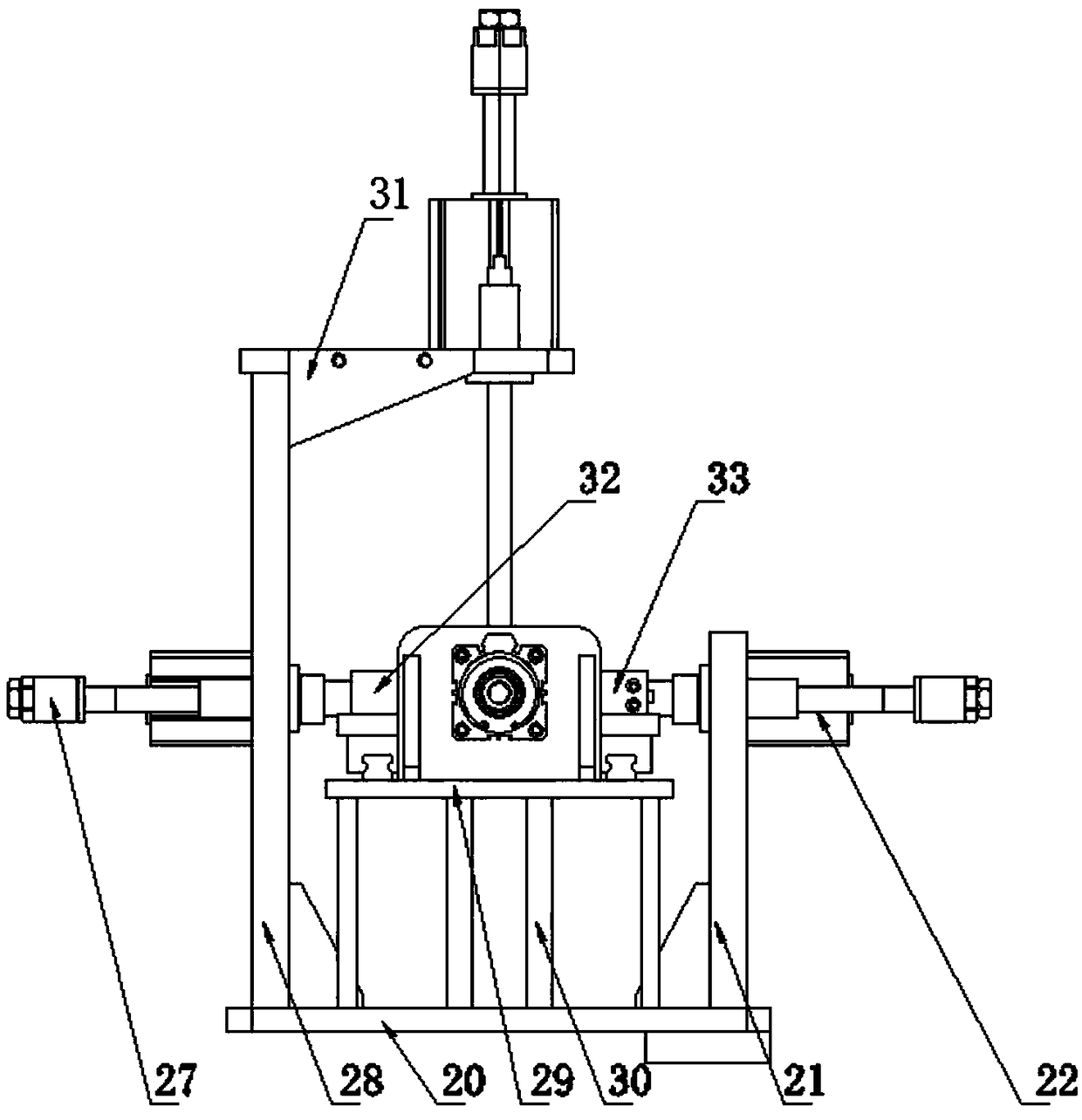

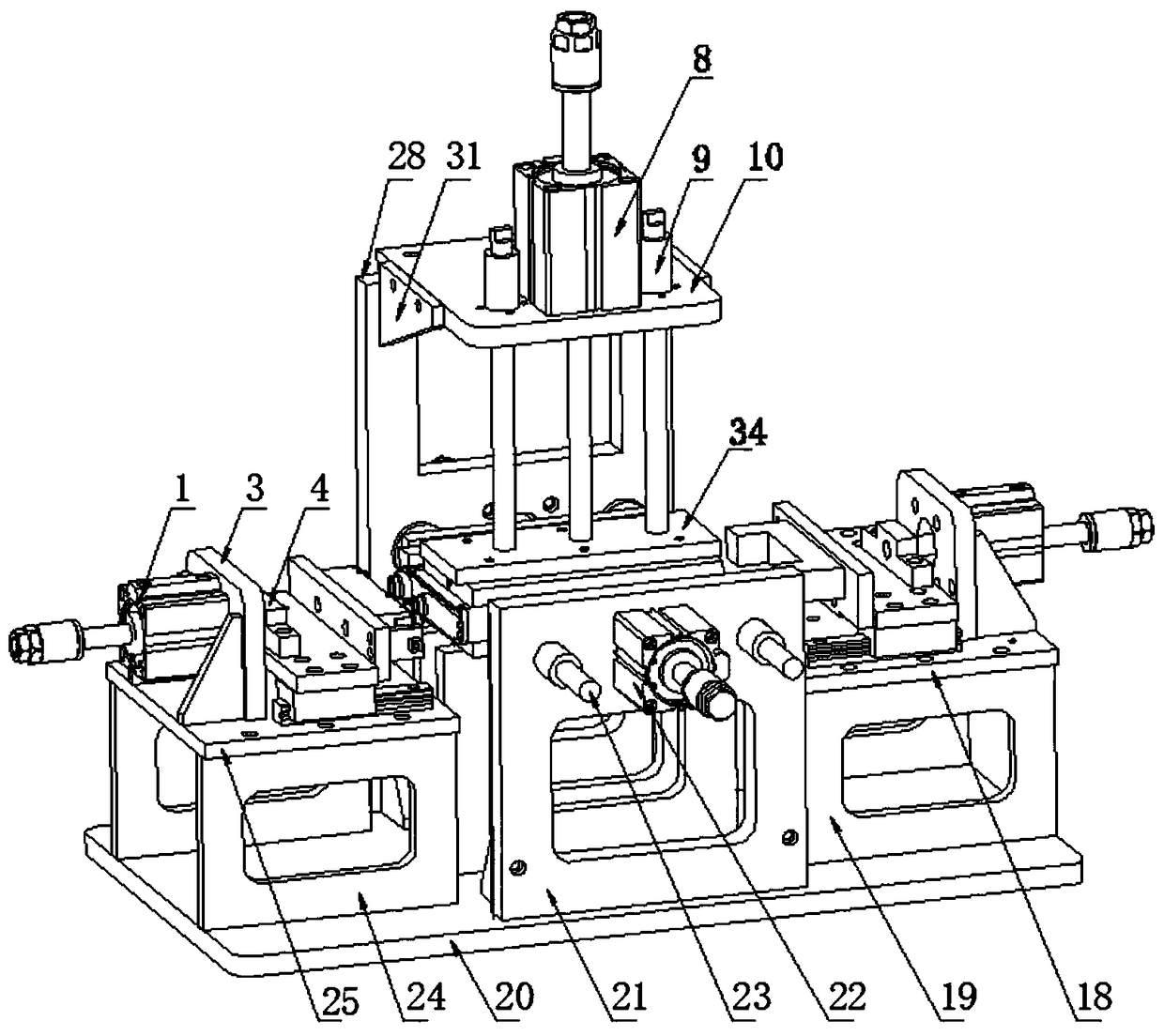

[0031] A horizontal high-efficiency press-fitting machine for automobile radiators, including a bottom plate 20, the innovation of which is: a radiator core support frame, a left press-fit mechanism mounting frame, a right press-fit mechanism mounting frame, and a front positioning plate 21 are installed on the bottom plate , the rear positioning plate 28 and the control unit 26, the radiator core support frame includes two parallel support vertical plates 30 and a support horizontal plate 29 connected to the two support vertical plates, and the left press mounting mechanism mounting frame includes two parallel support vertical plates 29 Left press-fit vertical plate 24 and the left installation horizontal plate 25 that is connected on two le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com