Device and method for assembling steelwire snap ring in piston

A steel wire clip and piston technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as affecting the assembly quality, scratching the inner wall of the piston hole by the wire port, and only staying on the top of the piston hole. Low, high-quality press-fit, practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

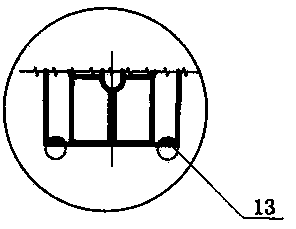

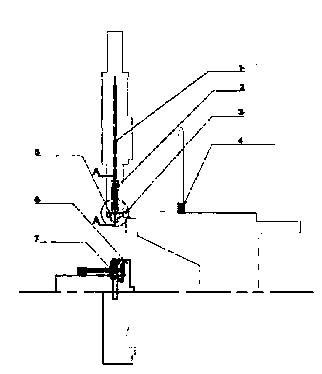

[0033] Such as figure 1 As shown, it is a schematic structural diagram of the device for assembling the piston steel wire circlip. The described device for assembling the piston steel wire circlip includes a taper sleeve 5 and a feeding mechanism 3 capable of sending the steel wire circlip 4 to the taper sleeve 5, above the taper sleeve 5 There is a center pin 1 and an elastic pressure head 2, the center pin 1 and the elastic pressure head 2 are independent, and can slide up and down relative to each other, and a fixed seat 6 for placing the piston and supporting the piston connecting rod is provided under the taper sleeve 5, such as figure 2 As shown, the fixed seat 6 is provided with a lower ejector rod 7 that can move up and down and can hold the steel wire clamp together with the piston pin. When the piston is placed on the fixed seat 6, the piston is positioned by the lower push rod 7.

[0034] Such as Figure 4 As shown, there is a gap between the taper sleeve 5 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com