Automatic assembling mechanism for special-shaped sealing ring

A special-shaped sealing ring, automatic assembly technology, applied in the direction of measuring device, transportation and packaging, conveyor objects, etc., can solve the problems of difficult to control product quality, increase the probability of errors, increase labor intensity, etc., to achieve convenient operation and improve work. Efficiency, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

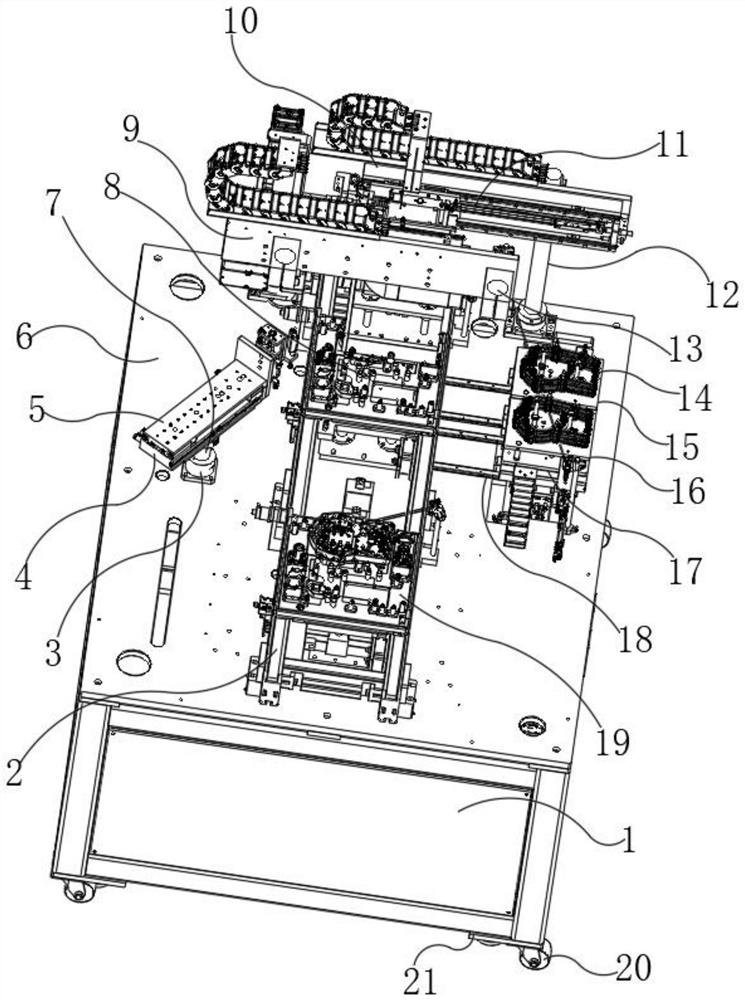

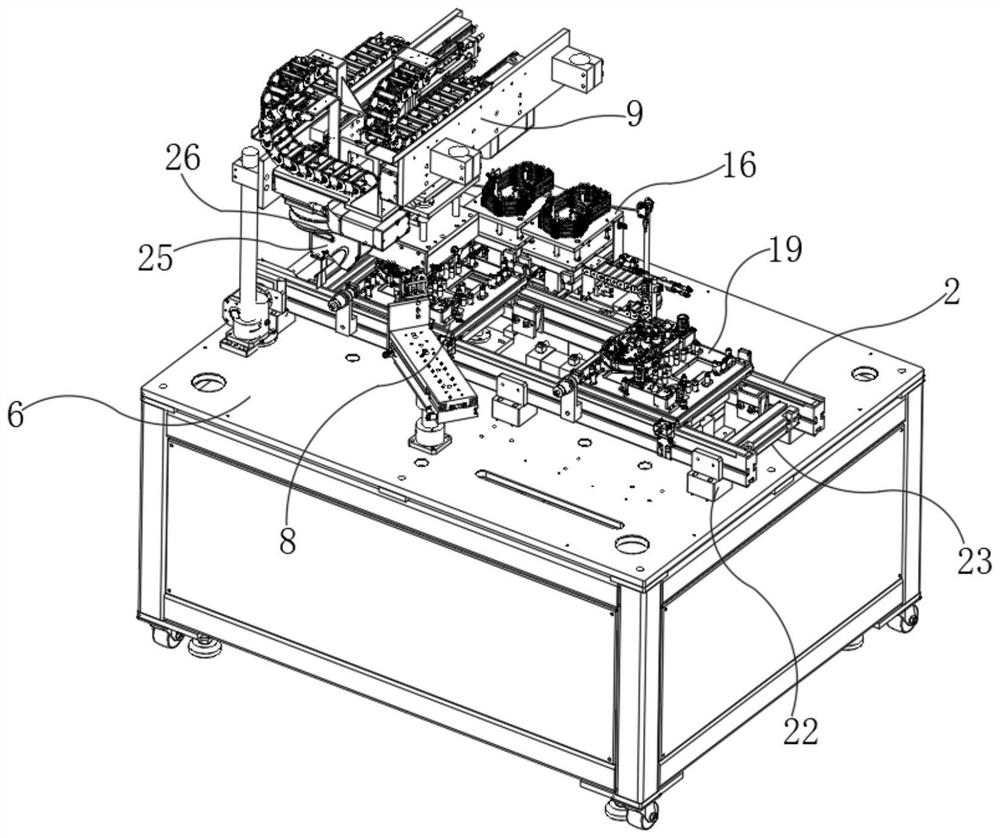

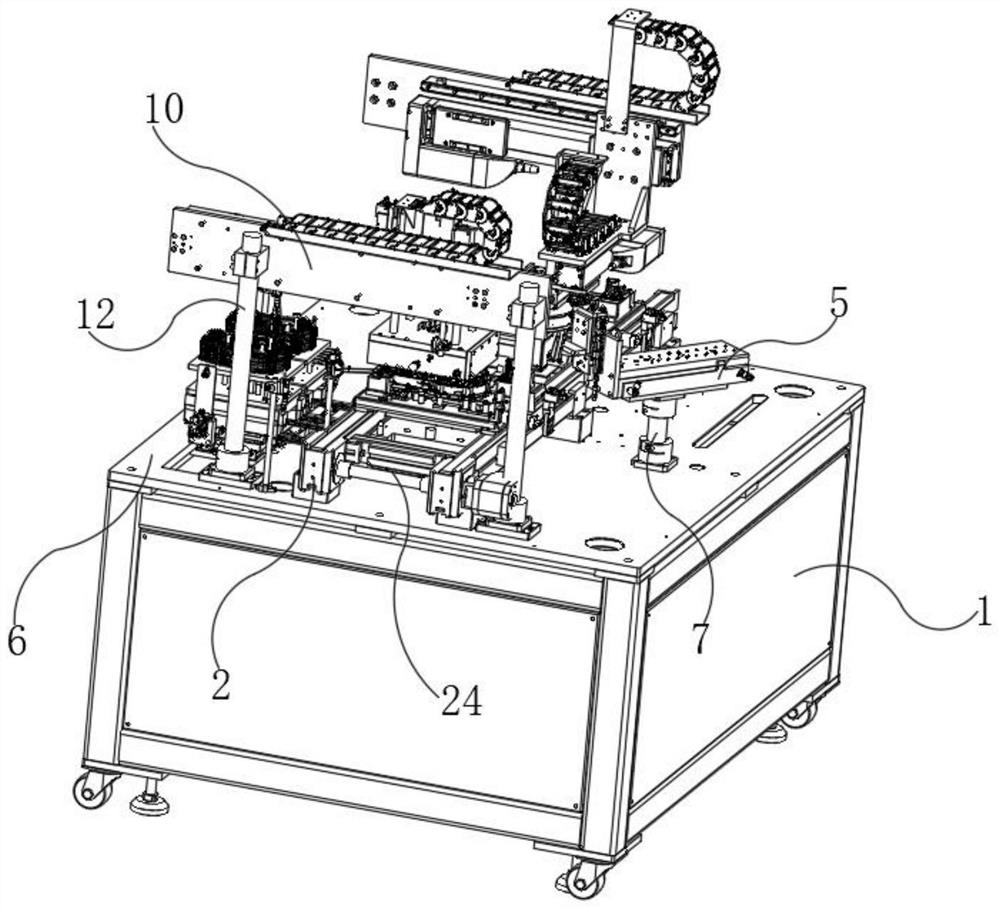

[0026] Such as Figure 1-4 As shown, a special-shaped sealing ring automatic assembly mechanism includes a processing table 1, a processing station 6 is installed on the upper end of the processing table 1, and an installation connection block 21 is installed on the bottom of the processing table 1, and the bottom of the installation connection block 21 is provided with a movable Roller 20, positioning support 3, column 12, drawer-type quick-change fixture 17 and servo module 2 are installed on processing station 6, and No. 1 feed bin 16 and No. 2 feed bin 15 are installed on drawer-type quick-change fixture 17.

[0027] Further, the upper end of the column 12 is equipped with a transport module 10, the transport module 10 is equipped with a slideway 11, the front end of the slideway 11 is equipped with a transport mechanism 9, and the front end of the transport mechanism 9 is equipped with a transport material folder 13, the servo mold The upper end of the group 2 is provided...

Embodiment 2

[0031] On the basis of Example 1, as Figure 1-4 As shown, a special-shaped sealing ring automatic assembly mechanism includes a processing table 1, a processing station 6 is installed on the upper end of the processing table 1, and an installation connection block 21 is installed on the bottom of the processing table 1, and the bottom of the installation connection block 21 is provided with a movable Roller 20, positioning support 3, column 12, drawer-type quick-change fixture 17 and servo module 2 are installed on processing station 6, and No. 1 feed bin 16 and No. 2 feed bin 15 are installed on drawer-type quick-change fixture 17.

[0032] Further, the upper end of the positioning support 3 is provided with a rotating shaft 7, the upper end of the rotating shaft 7 is equipped with a vacuum suction cup seat 5, and the outer side of the vacuum suction cup seat 5 is equipped with a positioning frame 4, and the servo module 2 and the drawer type quick-change fixture 17 Telescop...

Embodiment 3

[0035] On the basis of embodiment one and embodiment two, such as Figure 1-4As shown, a special-shaped sealing ring automatic assembly mechanism includes a processing table 1, a processing station 6 is installed on the upper end of the processing table 1, and an installation connection block 21 is installed on the bottom of the processing table 1, and the bottom of the installation connection block 21 is provided with a movable Roller 20, positioning support 3, column 12, drawer-type quick-change fixture 17 and servo module 2 are installed on processing station 6, and No. 1 feed bin 16 and No. 2 feed bin 15 are installed on drawer-type quick-change fixture 17.

[0036] Further, a connecting frame 23 is installed on the inner side of the servo module 2, a positioning connection card seat 22 is installed between the servo module 2 and the processing station 6, and a driving rod 24 is provided at both ends of the servo module 2, A camera detection mechanism 26 is installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com