Wax pattern mold for impeller investment casting

A technology of investment casting and wax mold, which is applied in the field of impeller investment casting and investment casting, can solve the problems of long cycle time and high manufacturing cost, achieve the effect of reducing equipment cost, reducing material cost, and preventing bump damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

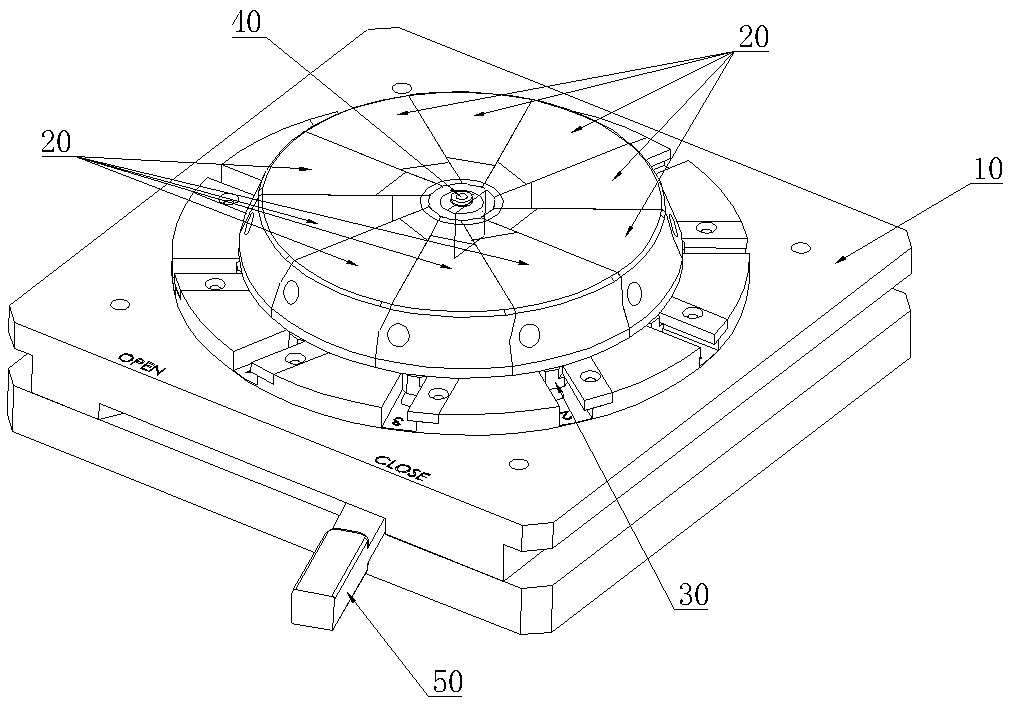

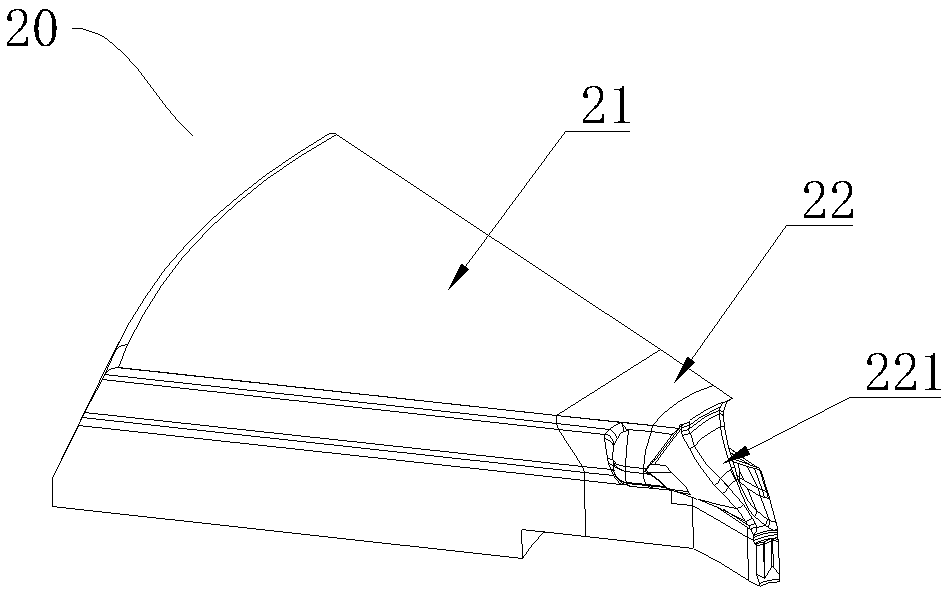

[0017] See figure 1 with figure 2 , the present invention includes a base 10 and a plurality of sliders 20, and the base 10 is evenly distributed along the circumference of a plurality of slide rails 30 extending radially. In this embodiment, there are ten sliders 20 and ten slide rails 30. , ten sliders 20 are respectively slidably installed between two adjacent slide rails 30; each slider includes a slider base 21 and a forming head 22, and the forming head 22 is provided with a wax mold forming cavity surface 221, The forming head 22 is removably mounted on the front end of the slider base 21 . The number of sliders 20 is determined according to different structural shapes of the impellers.

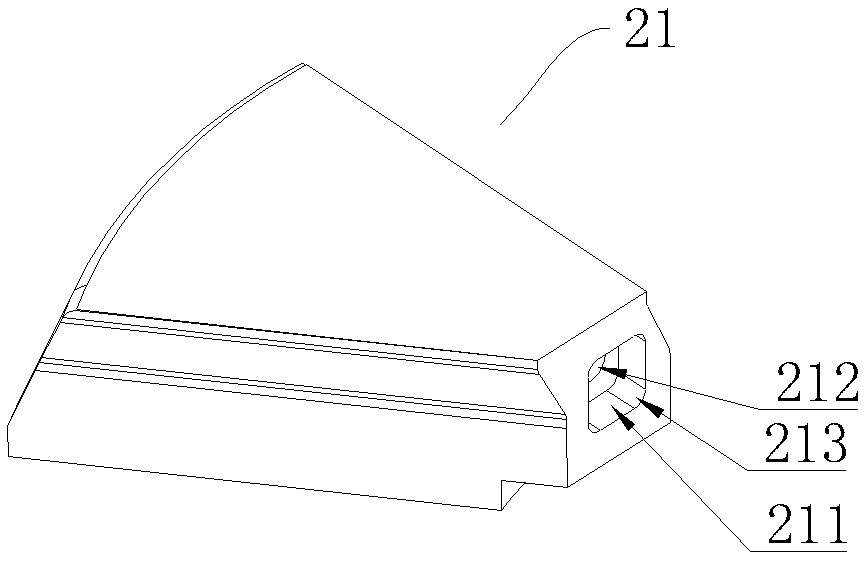

[0018] The front end of the slider base 21 and the rear end of the forming head 22 are connected and installed by positioning pins; the front end of the slider base 21 is provided with a positioning groove 211, and the rear end of the forming head 22 is provided with a positioning b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com