Copying fixing tooling for automotive parts

A technology for auto parts and fixed tooling, which is applied to workpiece clamping devices, manufacturing tools, etc., can solve the problems of high production costs, achieve the effects of improving efficiency, reducing manufacturing cycles, shortening research and development cycles and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

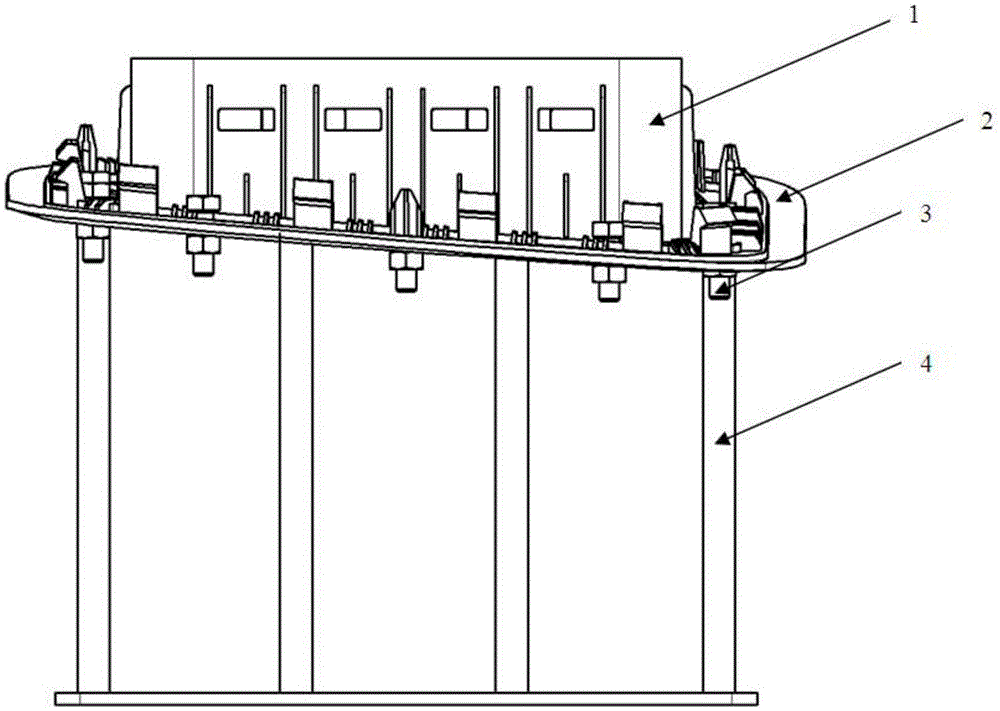

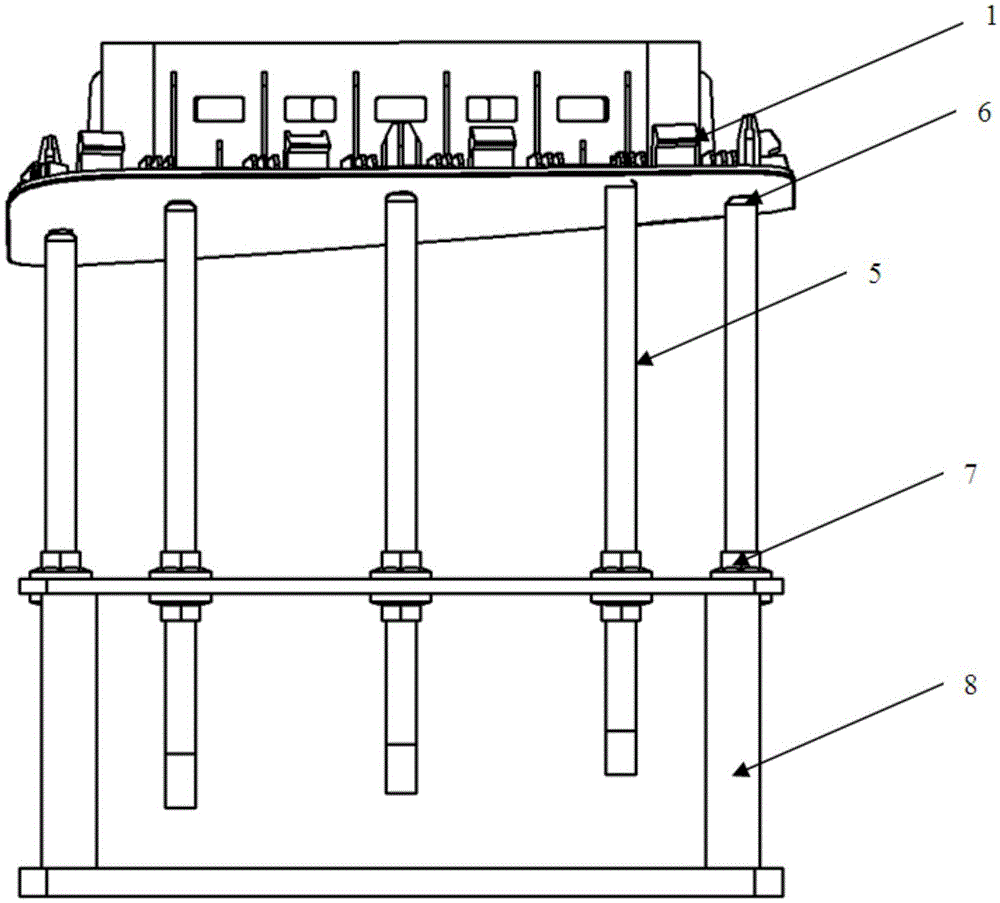

[0029] see figure 2 , this example takes a kind of smaller automobile interior and exterior trim as an example, the invented profiling fixed tooling includes a needle bar and a fixed tooling body, the fixing tooling body 8 is provided with several pin bars 5, through each pin bar 5 to adjust the height of the ends of each pin bar 5, the ends of several pin bars 5 form a profile that matches the smaller interior and exterior trims to support the interior and exterior trims.

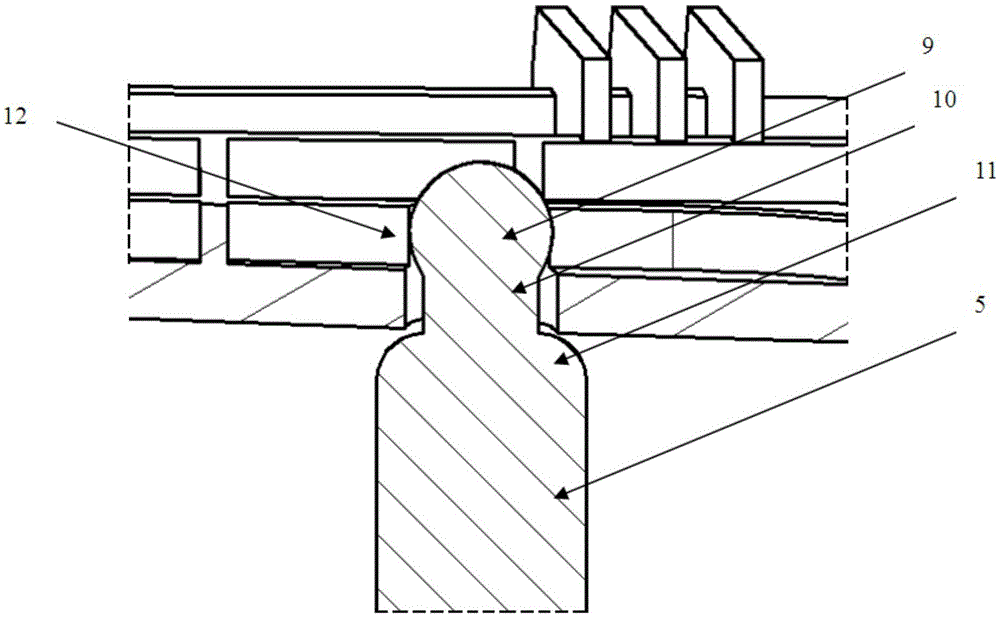

[0030] The needle bar 5 is connected with the fixed tool body 8 by a height adjustment fixture 7, and the needle bar 5 moves up and down in the height adjustment fixture 7 and is fixed. The surface of the pin bar 5 is provided with a threaded structure, see Figure 5 , the height adjustment fixture 7 includes a nut 13 and a tool support device 14, two paired nuts 13 are fixed on the tool support device 14, and the thread structure of the needle bar 5 matches the inner thread of the nut 13.

[0031] The ...

Embodiment 2

[0036] This example only illustrates the differences from Example 1, and the same parts as Example 1 will not be repeated.

[0037] see Figure 6 , this example takes a kind of smaller automobile interior and exterior trim as an example, the invented profiling fixing tool, wherein, the support and positioning mechanism at the top of the pin bar 5 is the anti-off mechanism 6, and the structure of the anti-off mechanism 6 is the same as that of embodiment 1 different.

[0038] The anti-off mechanism 6 includes an inverted tapered guide portion 15, a tapered support portion 17, and a connecting structure 10. The tapered support portion 17 is connected to the end of the needle bar 5, and between the tapered support portion 17 and the inverted tapered guide portion 15 The connecting structure 10 is used to connect. After the fitting hole 12 of the vehicle body or the interior and exterior trim and the inverted tapered guide part 15 are interference-fitted, the body or interior and...

Embodiment 3

[0041] This example only illustrates the differences from Embodiments 1 and 2, and the same parts as Embodiments 1 and 2 will not be repeated.

[0042] see Figure 7 and Figure 8 , this example is a larger car body profiling fixed tooling with an area, and the supporting positioning mechanism at the top of the needle bar 5 is a spherical mechanism 19 in this example. The pin bar 5 is distributed on the entire body profile, and is matched and supported by a point of the spherical mechanism 19, and the position of the pin bar 5 is limited by the height adjustment fixture 7 to match the profile.

[0043] After the interior and exterior trim parts with a large area are supported by profiling tooling, when measuring the interior and exterior trim parts, in order to prevent the interior and exterior trim parts from moving or falling out, several assembly points and studs for profiling tooling can be added to the exterior part of the interior and exterior trim Secured to avoid mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com