Forming mould and stamping technology for n-shaped automobile cross beam

A technology of forming molds and zigzags, applied in the directions of forming tools, beams, manufacturing tools, etc., can solve the problems of long mold production and manufacturing cycle, increased equipment loss, low material utilization rate, etc., to reduce the number of use, reduce equipment loss, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation process of the present invention is described in detail below with the stamping die and technology of producing double-row light truck automobile-the rear floor front beam, but protection scope of the present invention should not be limited.

[0031] The same can also be used for such as: rear floor front beams of multiple double-row truck cabs, rear floor beams of various cars, rear floor beams of multiple electric vehicles, front floor rear beams of some electric vehicles, etc. similar to those of the present invention Production of stamping parts in the shape of the product.

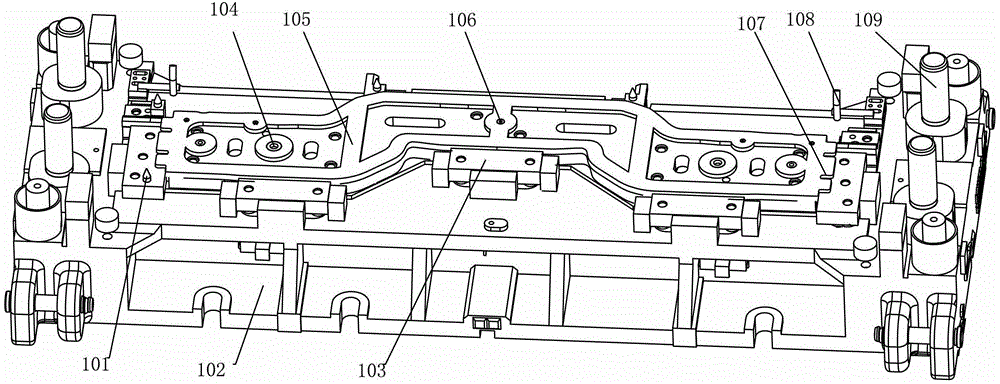

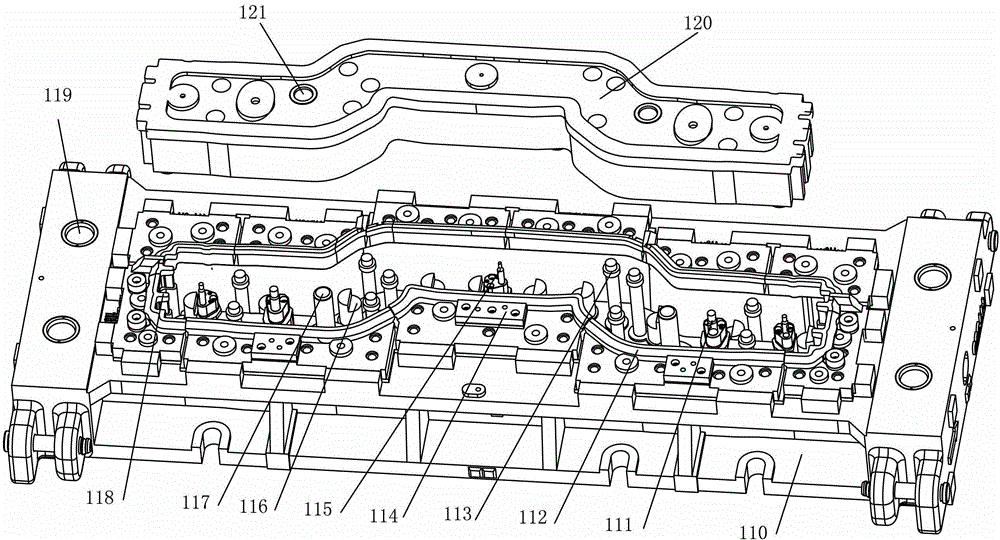

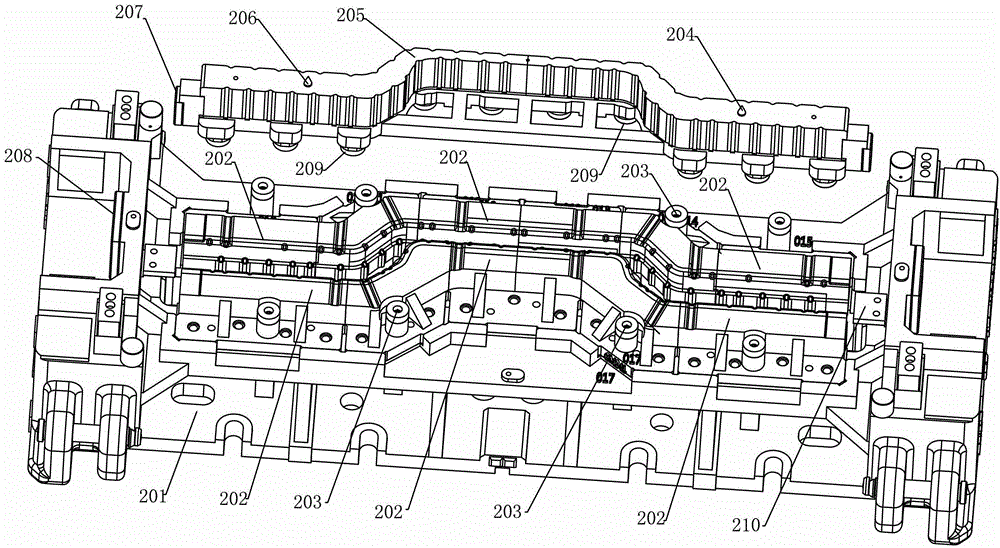

[0032] The first process: Picture 1-1 and Figure 1-2 The mold in the picture is the first process mold of the double-row light truck--rear floor and front beam mold: drop die, Picture 1-1 For the lower mold assembly, Figure 1-2 For the upper mold assembly. The mold in this process mainly includes positioning pin 101, lower die base body 102, lower die small sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com