A direct drive turning device

A slewing device and direct drive technology, applied in the direction of electromechanical devices, mechanical energy control, electrical components, etc., can solve the problems of structure and size mismatch, complicated and complicated drive system design, etc., to reduce the manufacturing cycle and production cost, and achieve superior performance , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

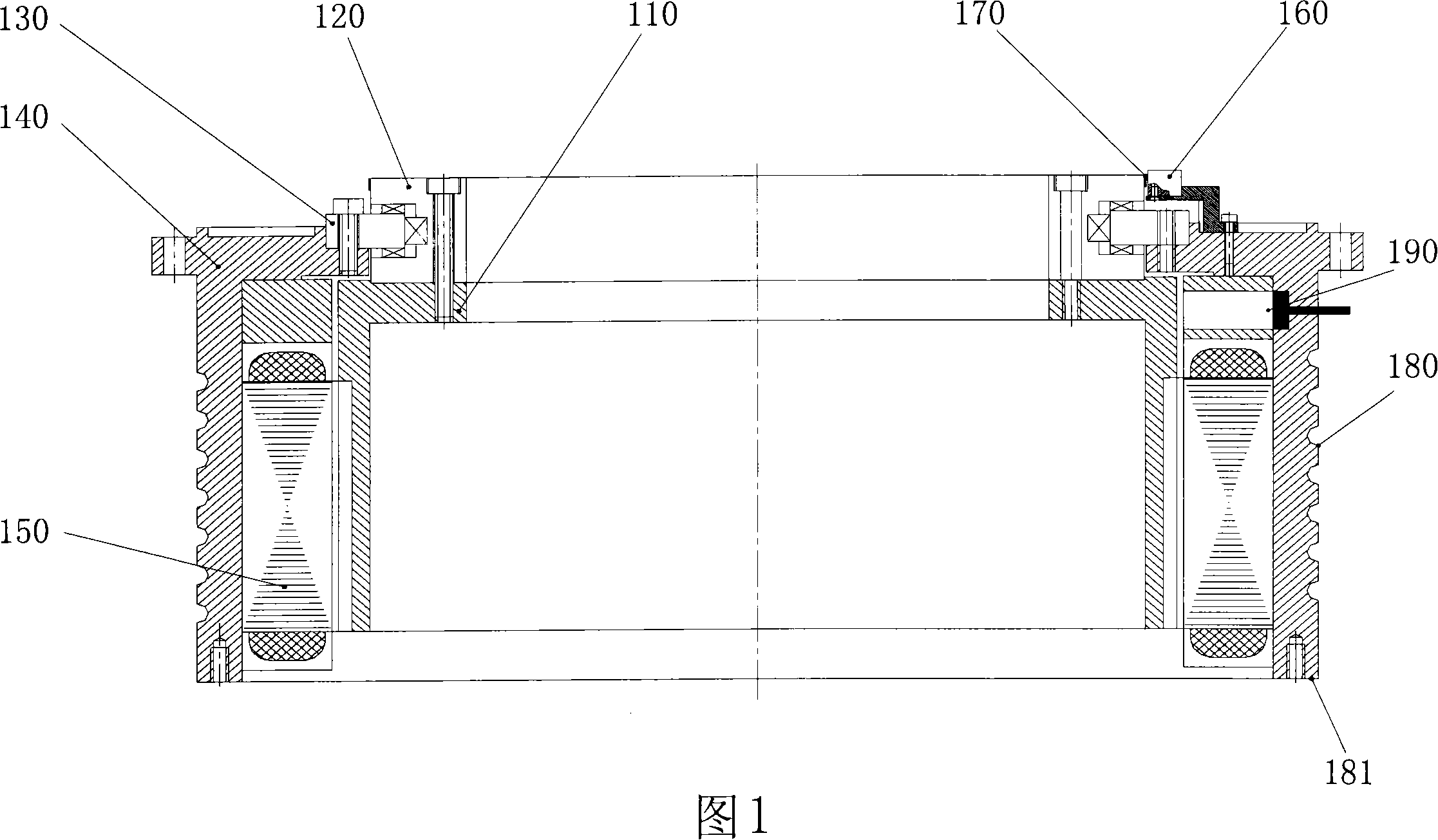

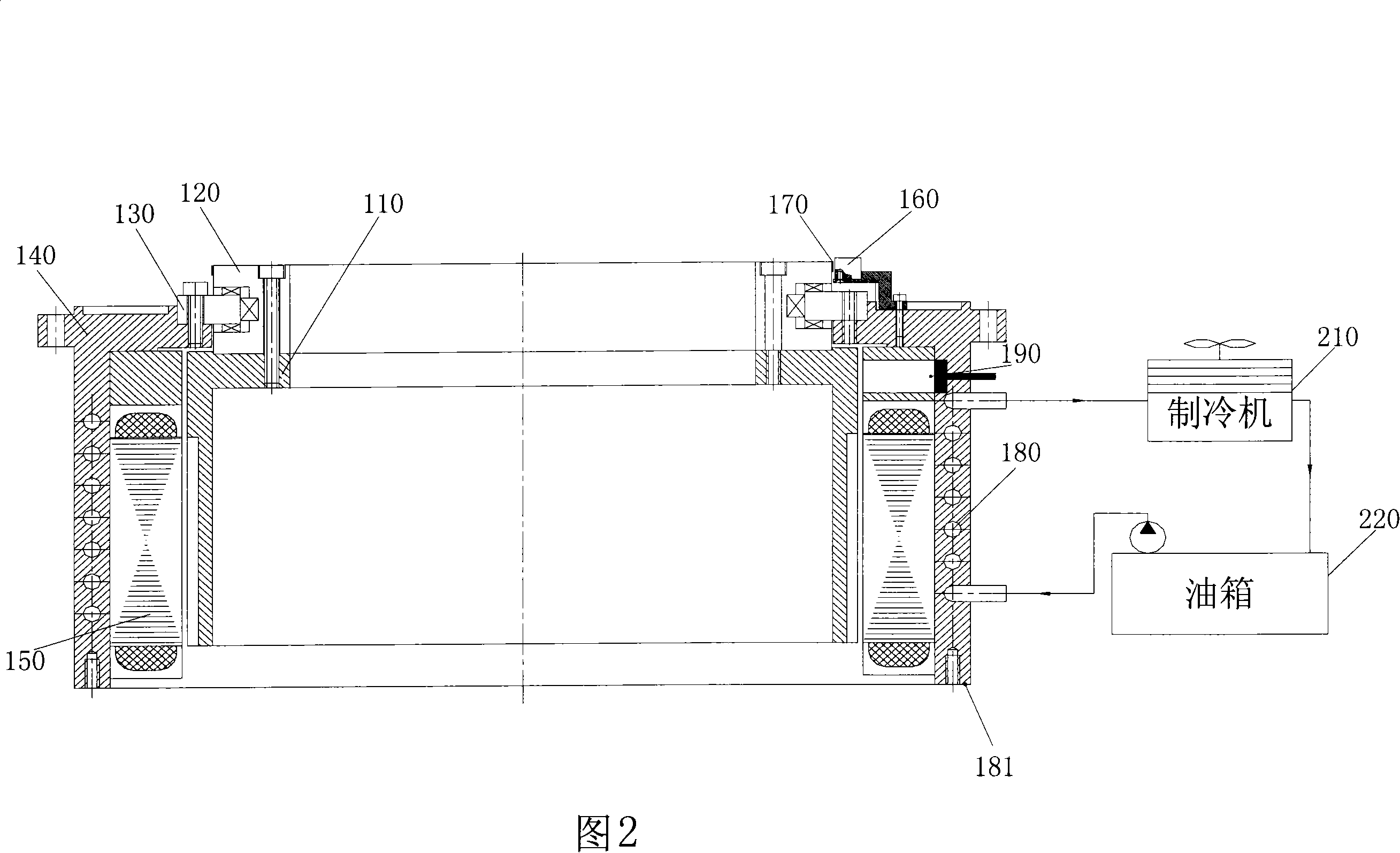

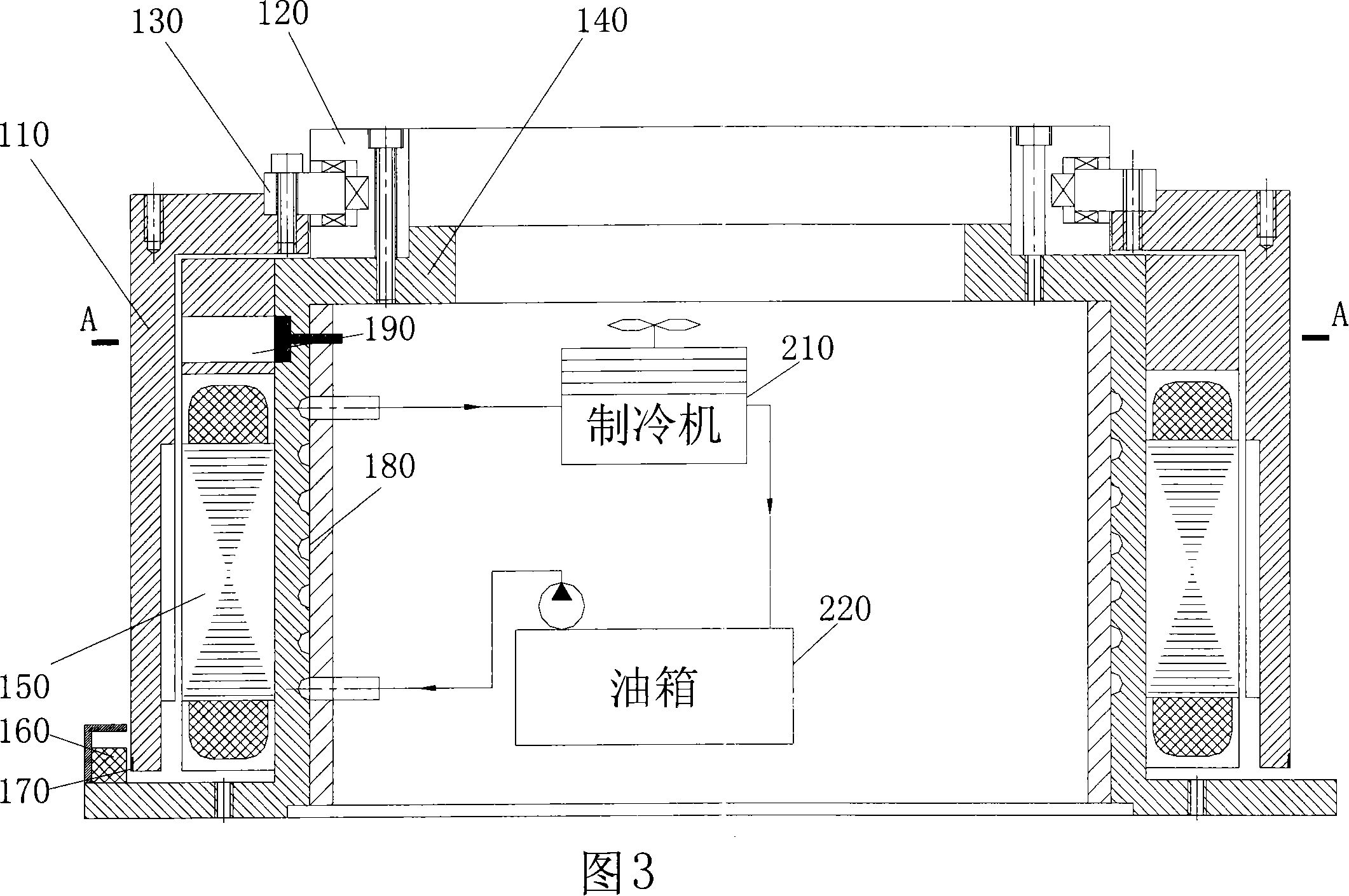

[0032] As shown in FIG. 1 , the structure schematic diagram of the direct drive rotary device of the present invention. A direct-drive rotary device provided by the present invention includes: a casing, a direct-drive motor, a bearing and a non-contact grating.

[0033] Among them, the direct drive motor (direct drive motor rotor 110 and direct drive motor stator 150) is connected with the casing 140 to enable the direct drive rotary device to obtain the best driving performance with the most simplified structure; the bearing adopts a high-precision, high-rigidity three-row The cylindrical combined bearing (including: bearing inner ring 120 and bearing outer ring 130) is connected with the casing 140 and the direct drive motor, which ensures the accuracy, stiffness and sensitivity of the output end of the direct drive rotary device; the non-contact grat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com