Patents

Literature

61results about How to "Reasonable size design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

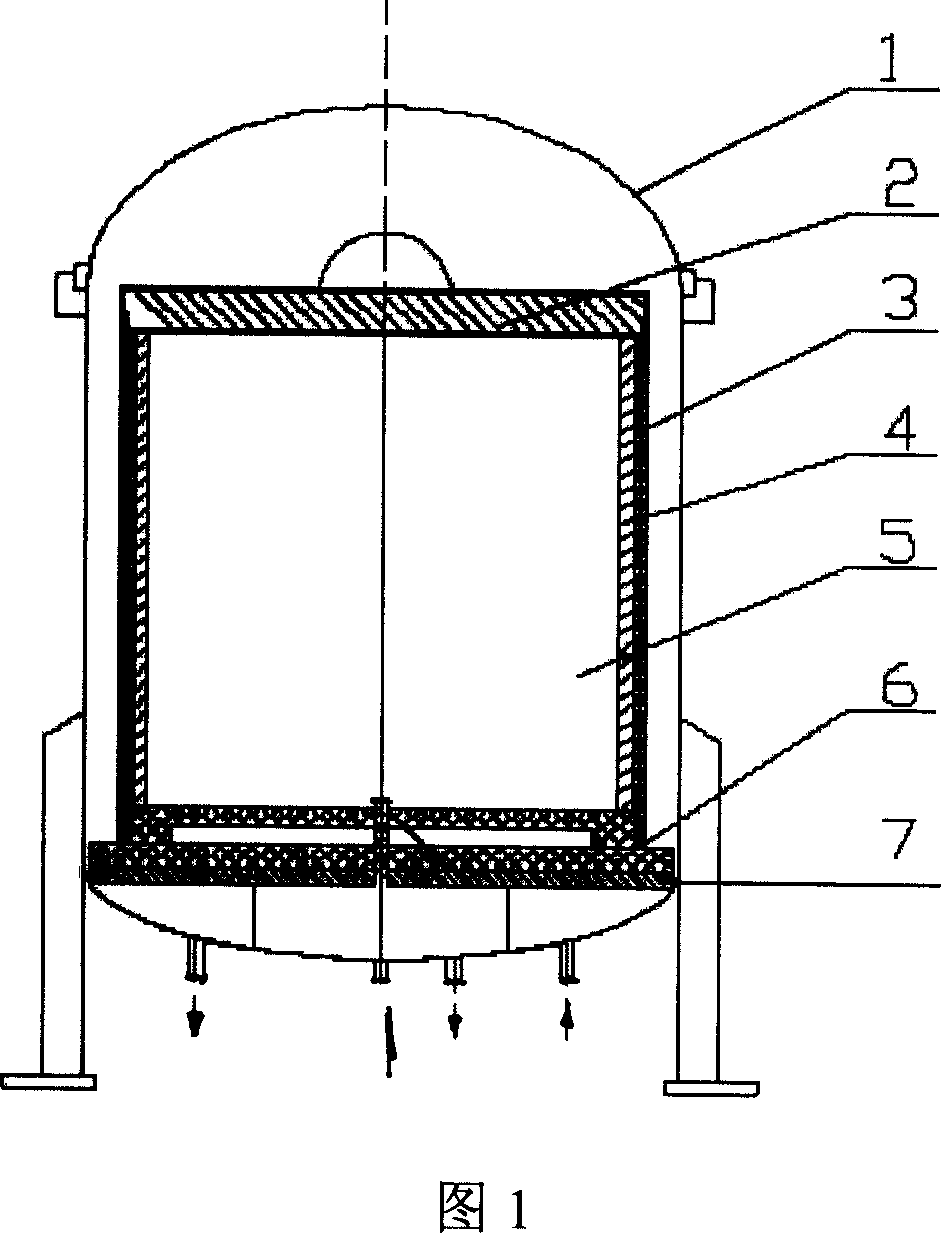

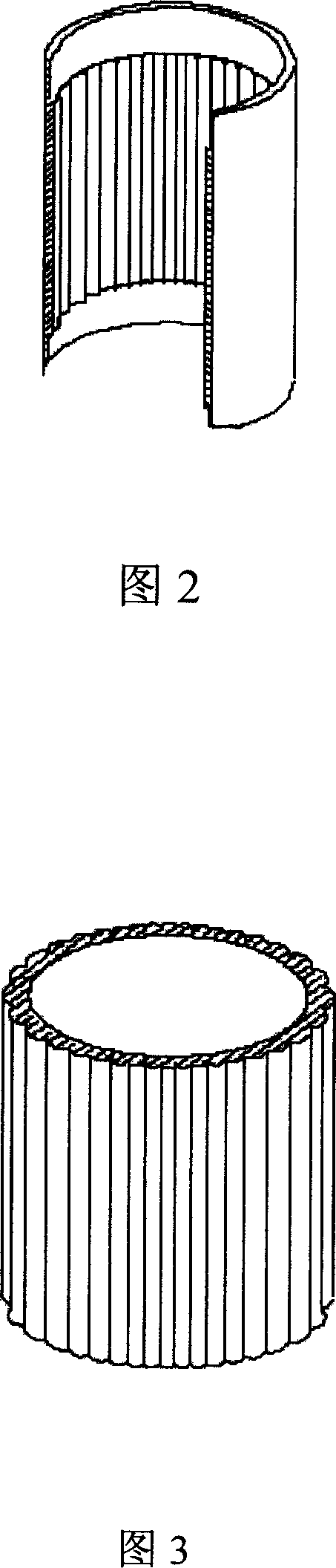

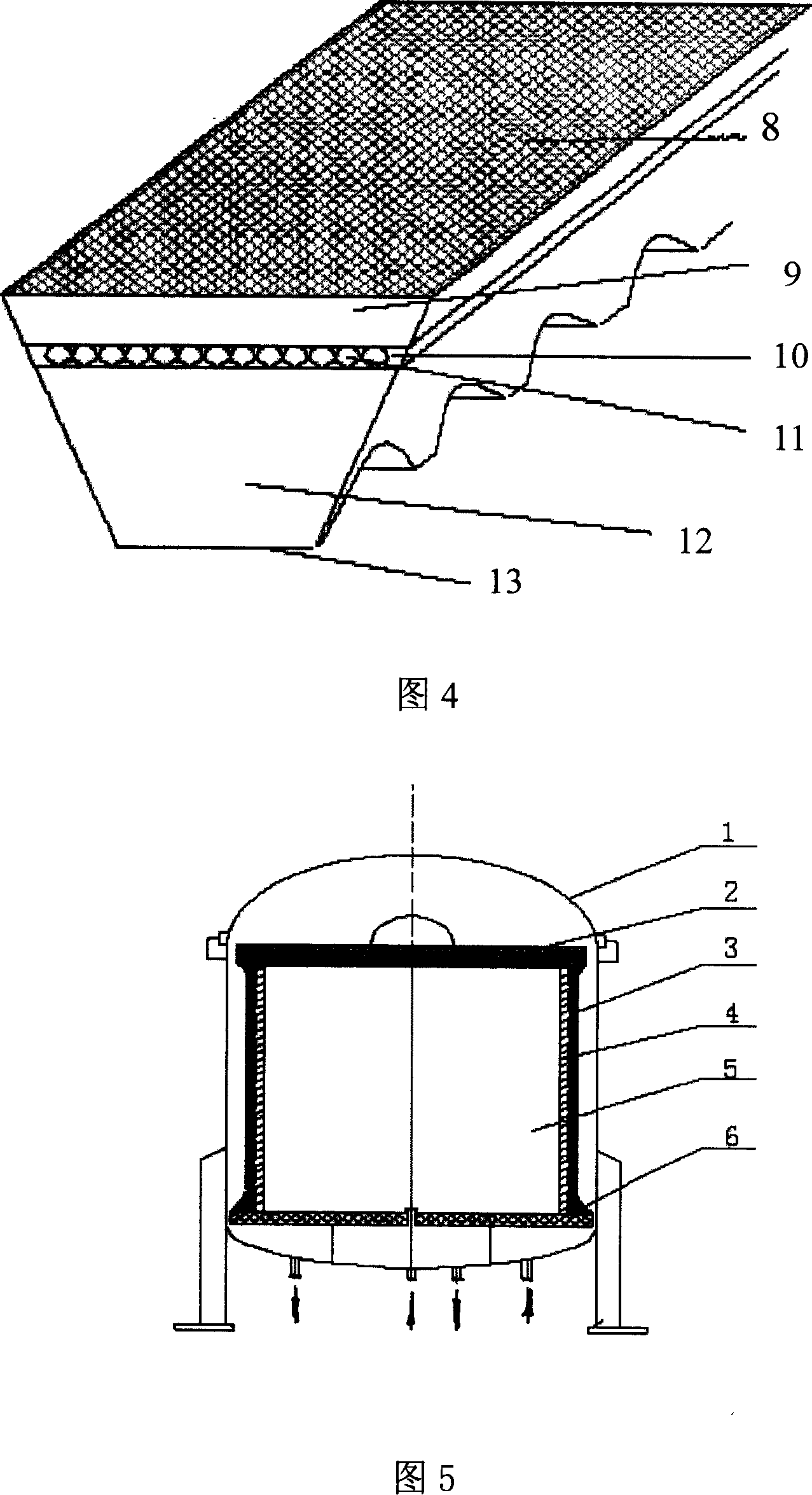

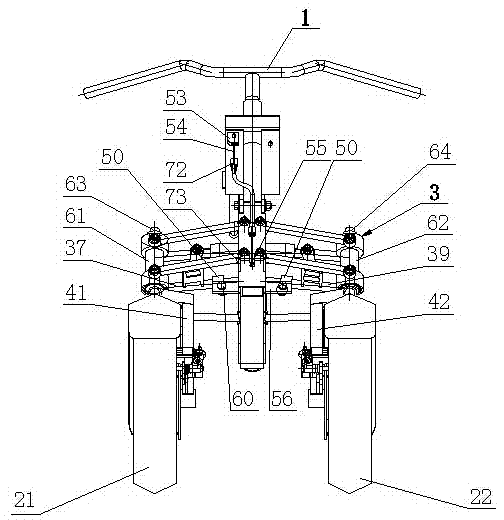

Reverse-forming sulfuration method for sealed type tooth-shaped edge V tape of rubber lagging

It relates to the glue sleeve seal teeth shape reversed V shape forming sulfuration. It makes belt blank at the inner mold, installs the round cylinder glue sleeve with teeth on the surface inside and smooth surface inside both ends on the glue sleeve base and fastened with shrouding rings, putting them into sulfur can, hanging belt blank into glue sleeve, covering the top cap and the cap of the sulfur can, sequentially opening the outside pressure and inner pressure steam for sulfuration, stripping the belt blank round cylinder with vertical rack outside and the cutting belt blank round cylinder, getting many teeth shape cutting V belt. It solves the sealing issue at both ends of the glue sleeve, eliminating the bubbling stratification defect of the product, increasing effective cutting 2-4 lines, reducing material consumption and cost.

Owner:ZHEJIANG ZIJINGANG RUBBER BELT

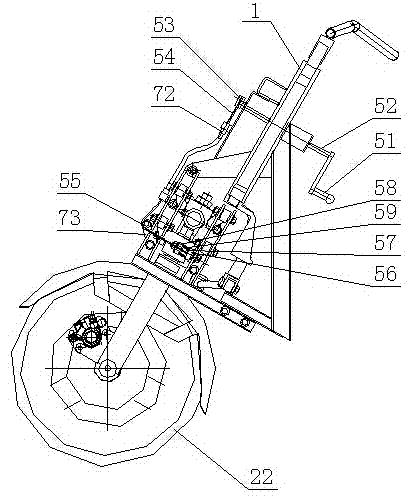

Side tilting three-wheel motor vehicle

The invention discloses a side tilting three-wheel motor vehicle. The motor vehicle comprises a frame and left and right front wheels, wherein the frame is connected with the left and right front wheels through a suspension mechanism respectively; the suspension mechanism is arranged on the upper side of the left and right front wheels and is connected with the wheels through a steering arm component; the frame is provided with a rocker arm and a rocker rod; the rocker rod is arranged on the frame in a rotating manner; the rocker rod is fixedly provided with a guy wire mounting block; the guy wire mounting block is connected with a side tilting guy wire; the side tilting guy wire is guided by a guy wire roller to change direction and then is connected with a side tilting slide block; the side tilting slide block sleeves a side tilting guide column; the side tilting guide column is provided with a guide column mounting plate and a side tilting lock spring; a side tilting stop block is also connected to one side of the side tilting slide block; an end head of the side tilting stop block is clamped with the suspension mechanism when the side tilting slide block is pulled by the side tilting guy wire. According to the vehicle, the wheel distance between the front wheels is shortened, miniaturization of the motor vehicle is realized, the side tilting control is more flexible, and the vehicle also has a wheel locking function.

Owner:重庆汉雪科技有限公司

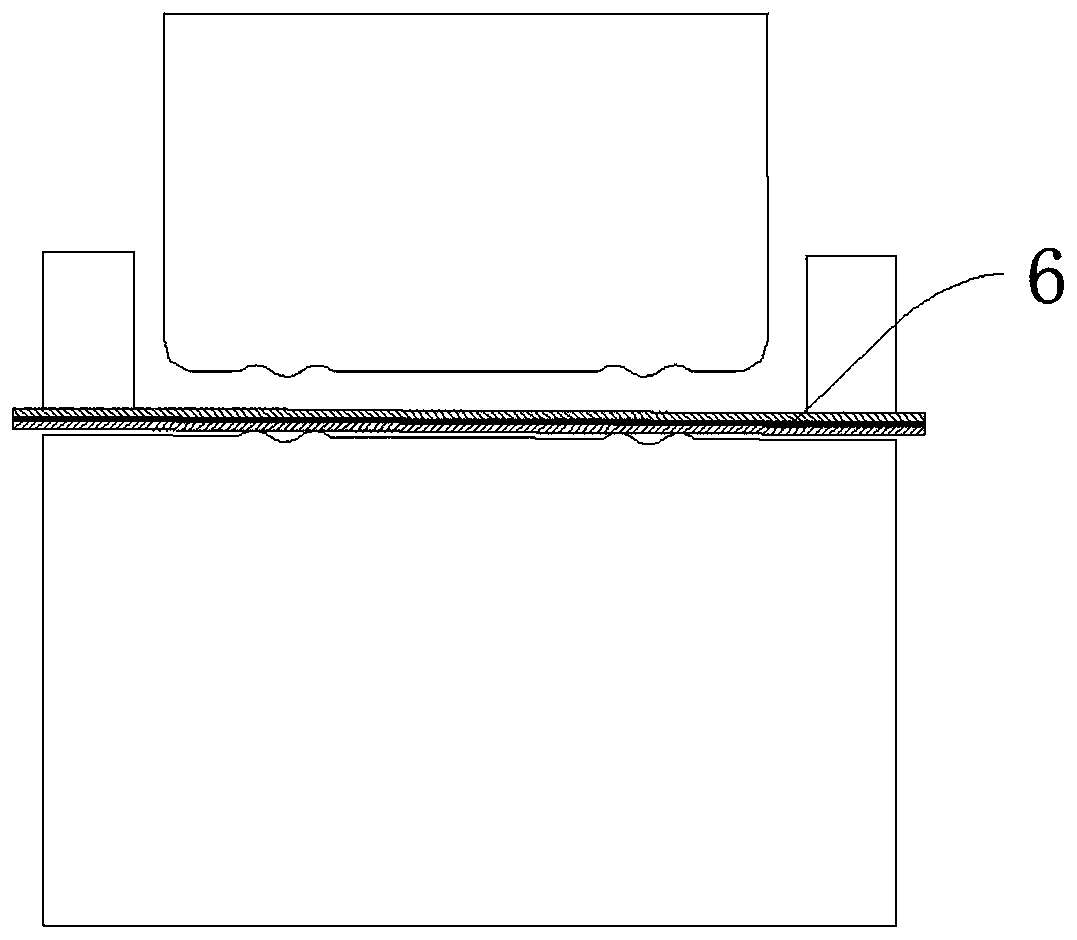

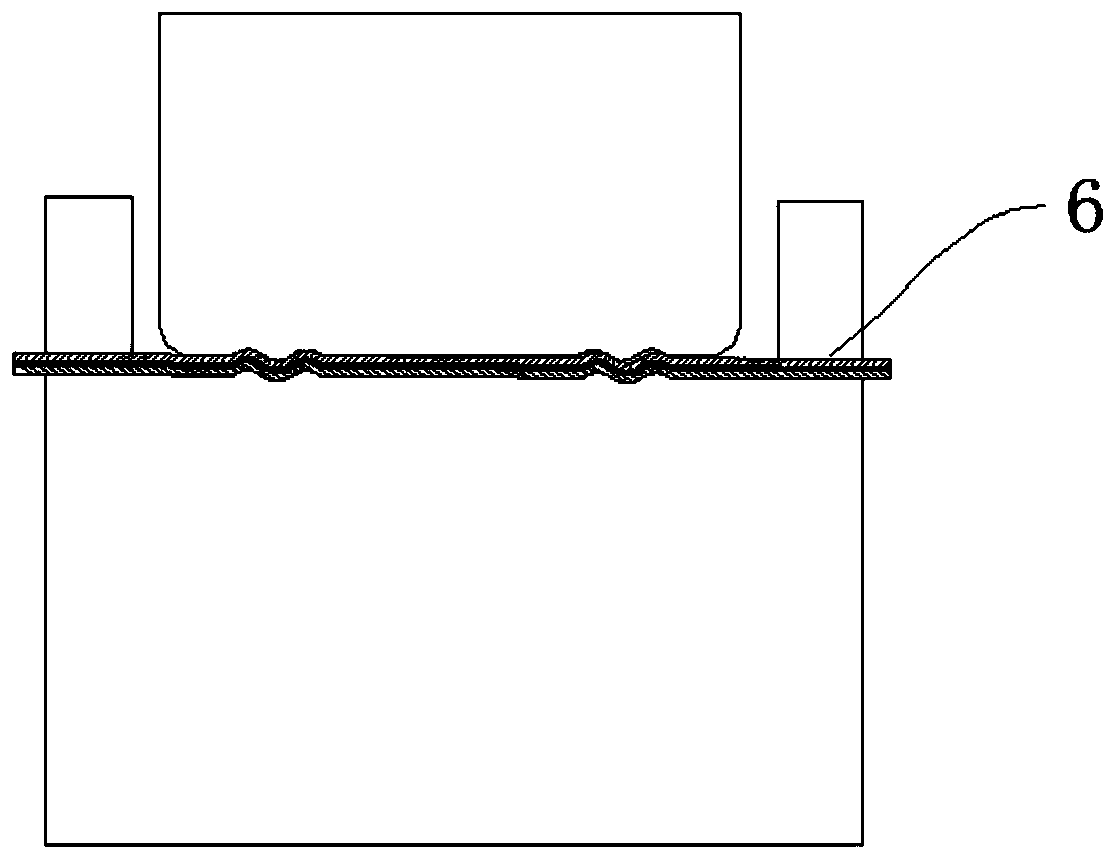

Method of forming fiber-aluminum alloy composite part

ActiveCN110143034AExtrude in timeOut in time, fromLamination ancillary operationsLaminationEpoxyFiber

The invention provides a method of forming a fiber-aluminum alloy composite part. The method comprises the following steps: 1, cutting an aluminum alloy plate and a fiber cloth according to a shape ofthe part; 2, subjecting the aluminum alloy plate to solid solution treatment, and immediately subjecting the aluminum alloy plate from the solid solution treatment to pre-pressing treatment, allowingfor uniform distribution of gridded grooves on a surface, glued to the fiber cloth, of the aluminum alloy plate, and then subjecting the pre-pressed aluminum alloy plate to quenching treatment; 3, subjecting the quenched aluminum alloy plate to degreasing treatment, and subjecting the fiber cloth to pre-impregnation treatment in an epoxy resin glue solution; 4, forming a sandwich plate in the order of aluminum alloy plate, fiber prepreg and aluminum alloy plate, and pre-pressing the sandwich plate; and 5, putting the obtained sandwich plate into a stamping die, closing the die and holding thetemperature, and then carrying out solidification to obtain the fiber-aluminum alloy composite part. The method overcomes the shortcoming of low elongation rate during the formation of a fiber material and improves the strength of the composite material part.

Owner:WUHAN UNIV OF TECH

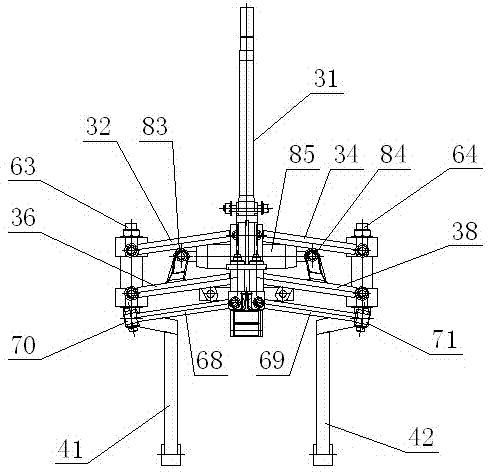

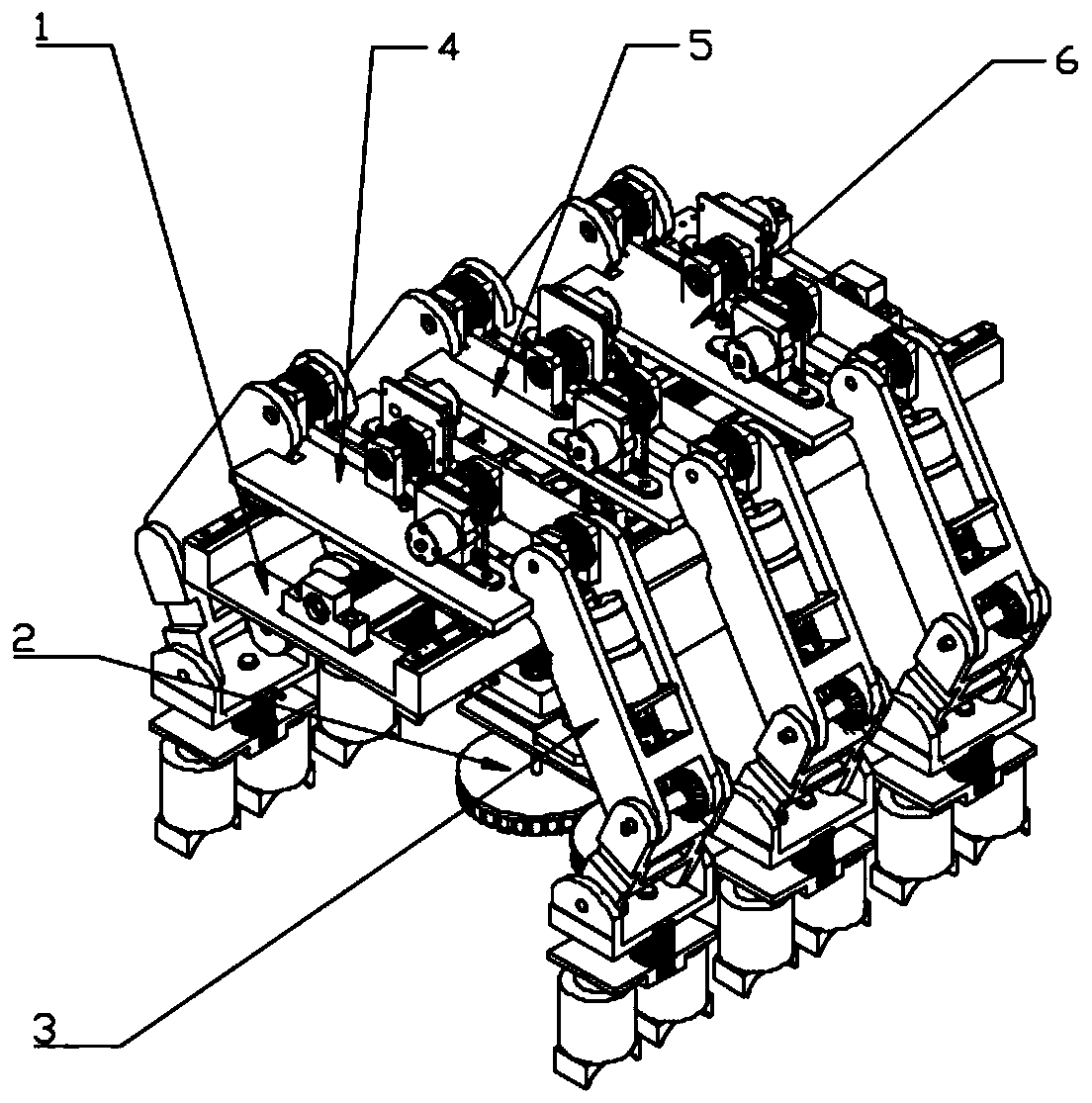

Novel hexapod boiler water wall maintenance robot

ActiveCN110901785ARealize the adsorption functionRealize the function of overcoming obstaclesVehiclesLow noiseHexapod

The invention provides a novel hexapod boiler water wall maintenance robot. The novel hexapod boiler water wall maintenance robot comprises: a main transmission system for realizing longitudinal linear movement of the robot on a vertical wall surface; a three-degree-of-freedom mechanical leg transverse movement mechanism which is used for realizing an adsorption function, an obstacle crossing function and crossing in different working intervals of the robot; and a maintenance mechanism which achieves the functions of accumulated dust cleaning and camera shooting. The electromagnetic wall-climbing robot is high in load capacity, flexible in movement, high in wall surface adaptive capacity and good in application prospect, almost realizes full coverage of the interior of a boiler without dead angles, and has good application prospect. According to the scheme, low noise, no pollution, low cost and light weight are achieved, and sustainable development of the environment and the society isfacilitated.

Owner:HARBIN ENG UNIV

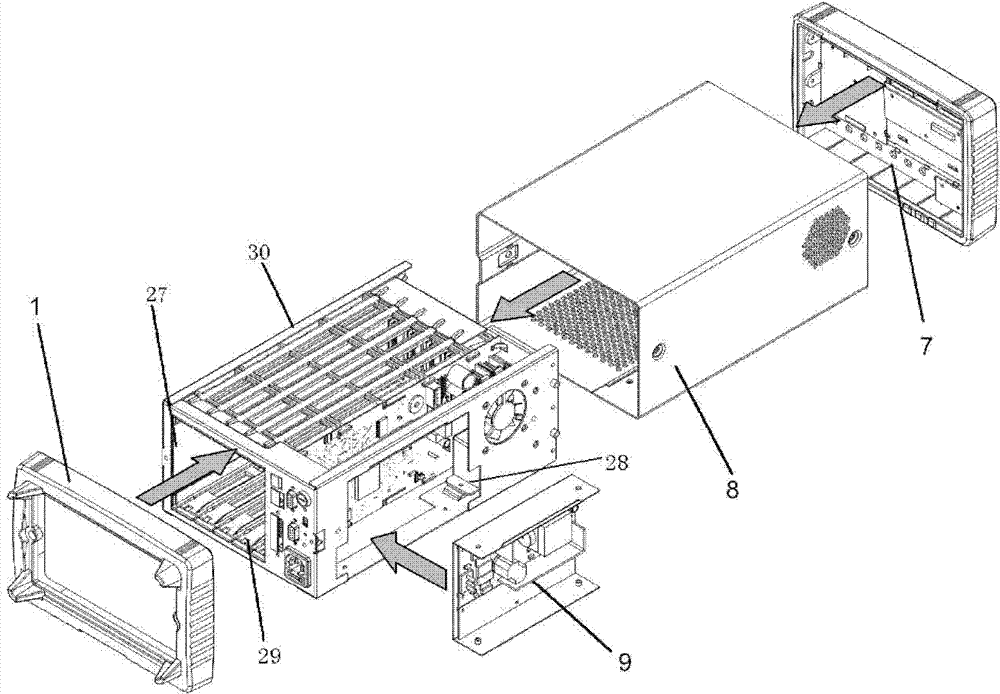

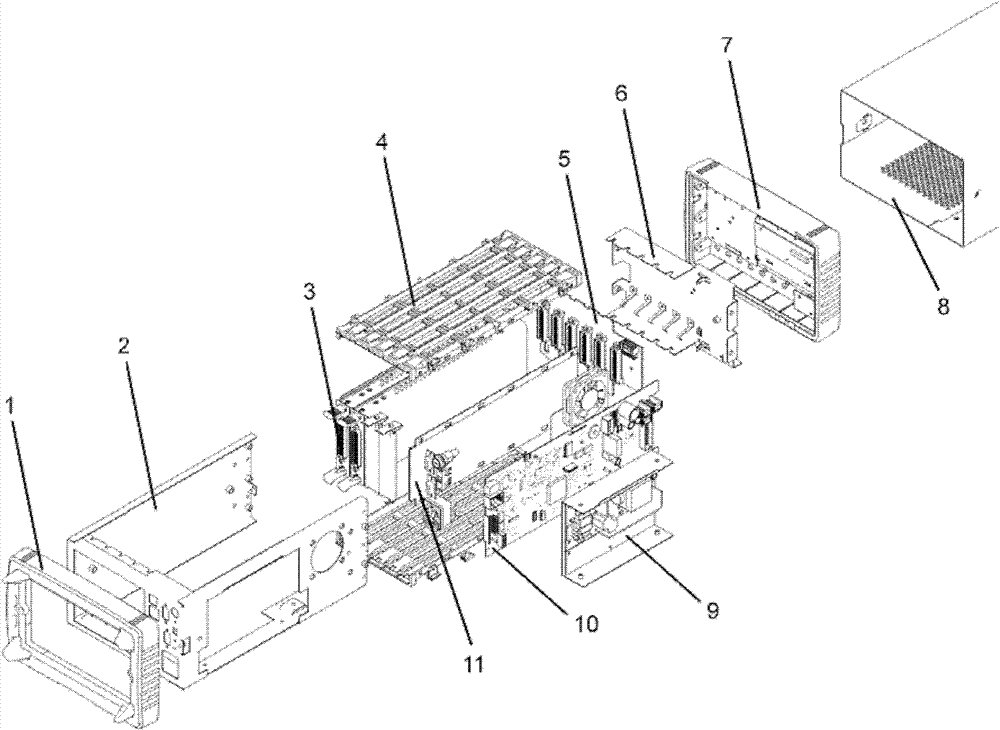

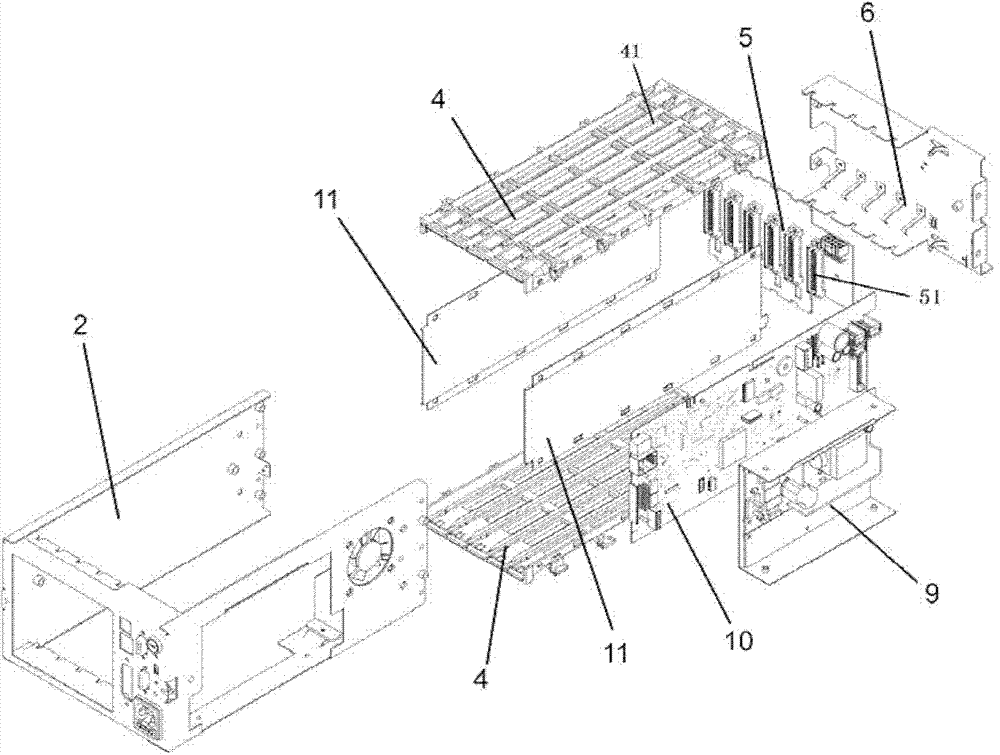

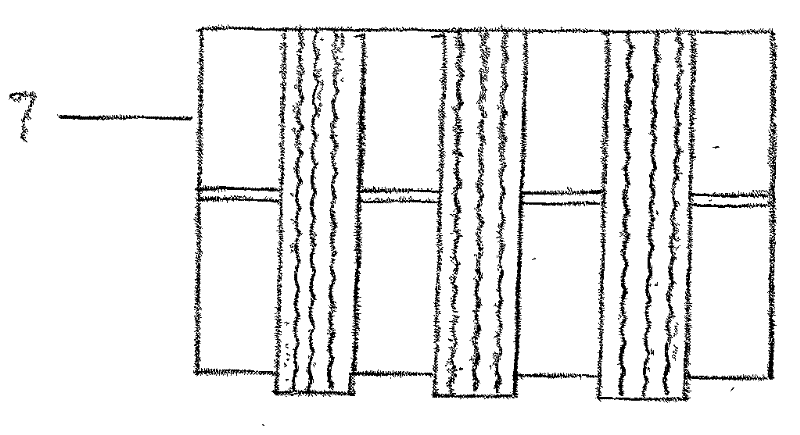

Chassis with bus structure

ActiveCN102770002AAvoid assemblyAvoid connectivitySupport structure mountingSelf lockingEmbedded system

The invention relates to a chassis with a bus structure. The chassis comprises a sleeve, an instrument frame and a main control panel, wherein the instrument frame is arranged in the sleeve; a module card entrance is arranged at the rear end wall of the instrument frame; a power-supply module socket is arranged on the side wall of the instrument frame; a module card guide rail and the main control panel are arranged in the instrument frame; the main control panel is arranged on the side wall of the module card guide rail and is connected with the power-supply module which is arranged on the power-supply module socket; the instrument frame is fixedly connected by inserting a front frame and a rear frame; a bus rear panel is longitudinally arranged in the front frame; the module card is inserted into the module card guide rail through the module card entrance and is socketed with the bus rear panel; and the module card guide rail is connected with the rear frame and the front frame respectively in a clamping and hooking way. According to the chassis with the bus structure, the design difficult point of an instrument in a compact space is solved, as the internal main structures and the main control panel are all assembled by self-locking structure assembles such as plugging, clamping and hooking, the chassis is high in assembling efficiency, compact in structure and high in installation reliability.

Owner:RIGOL

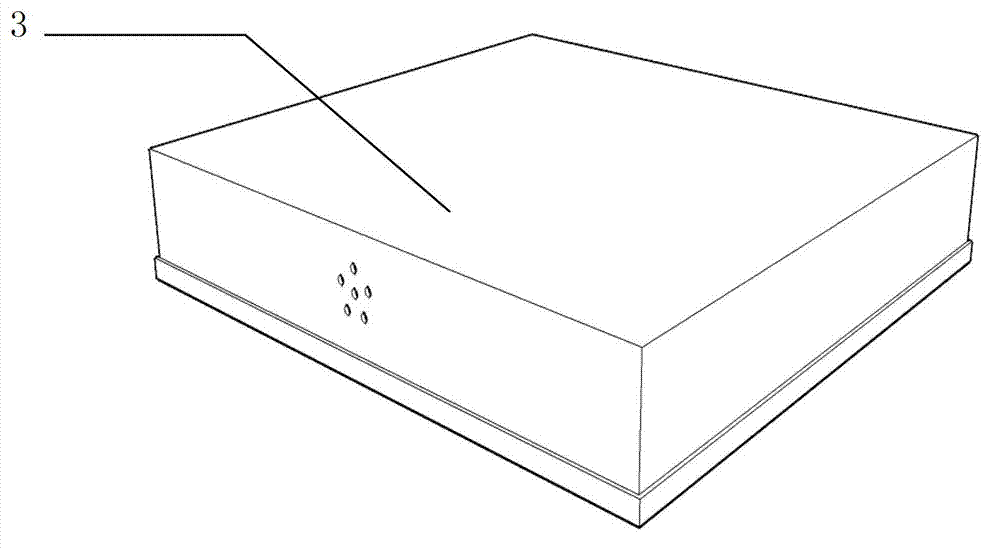

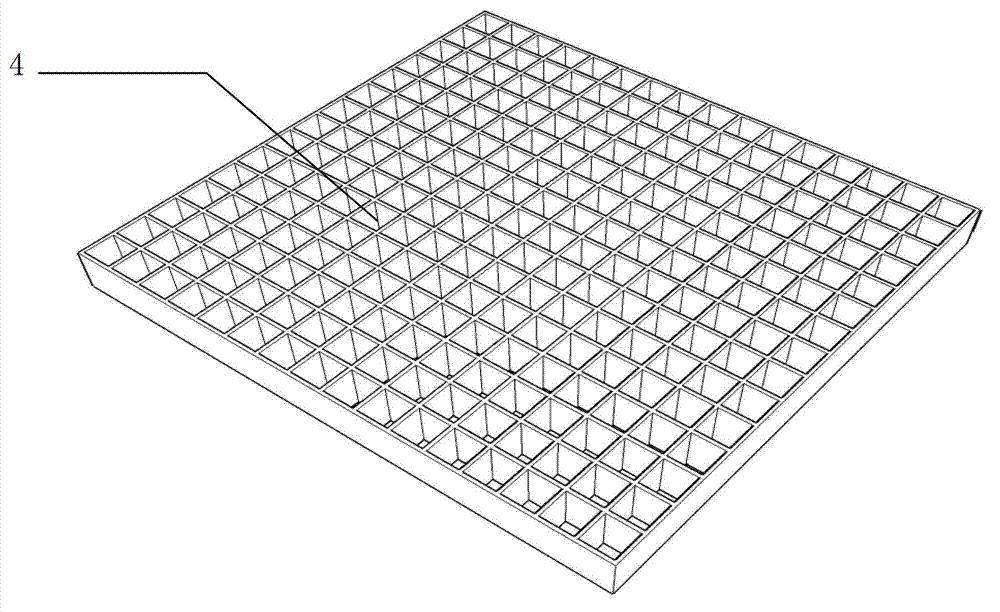

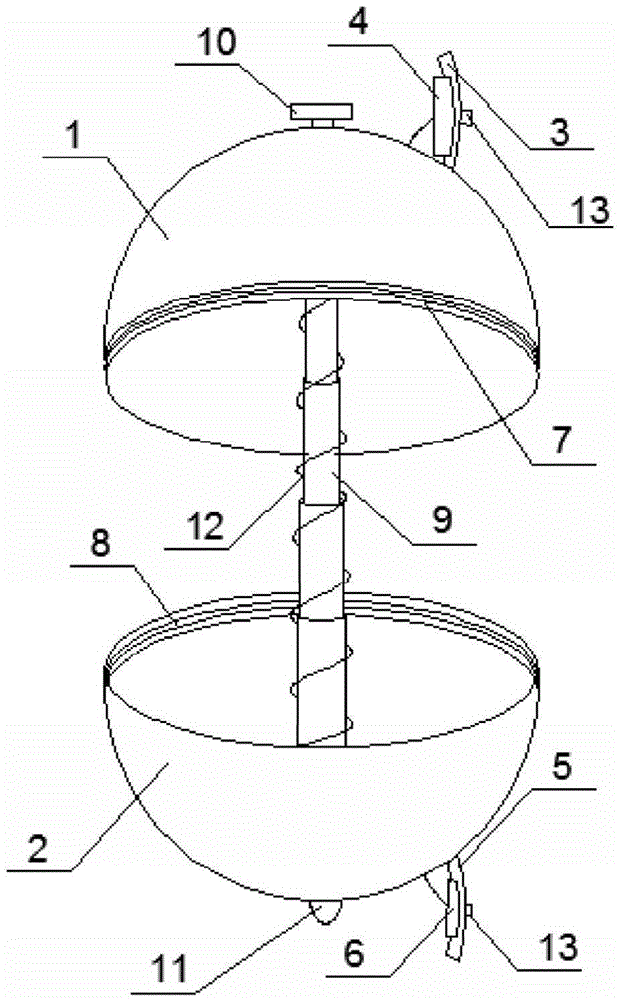

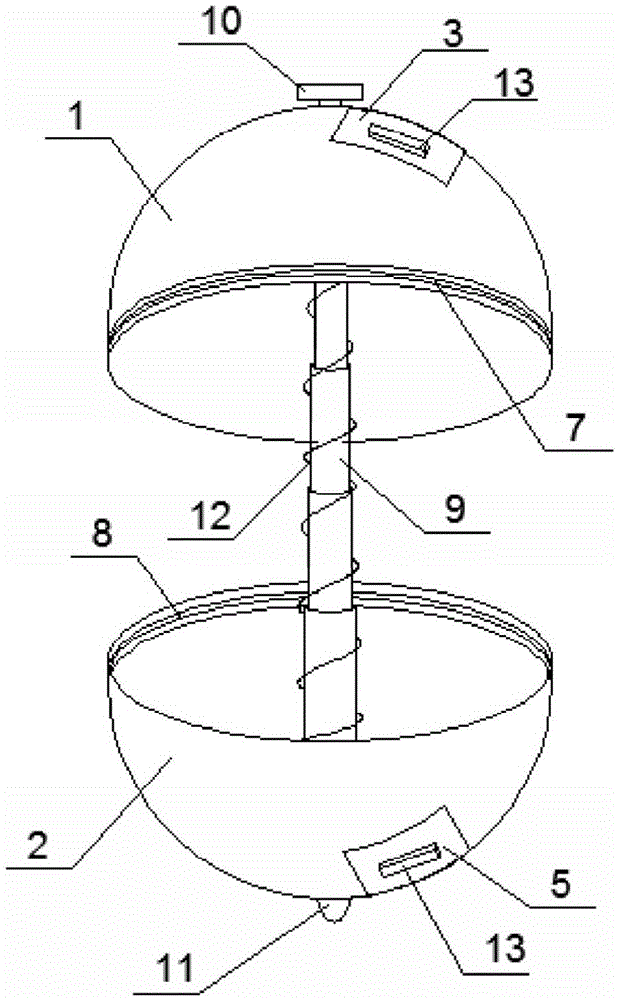

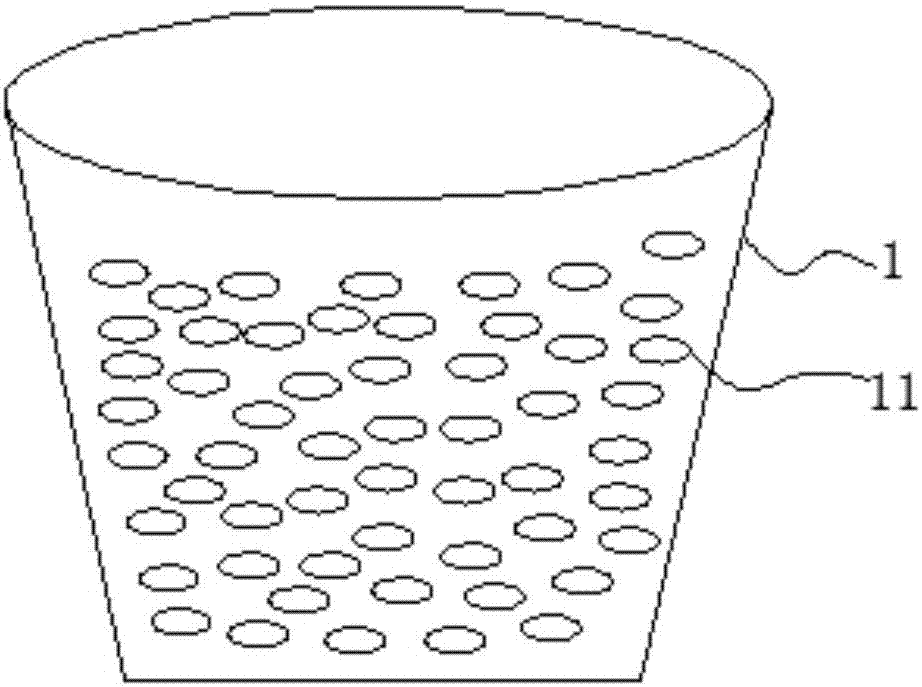

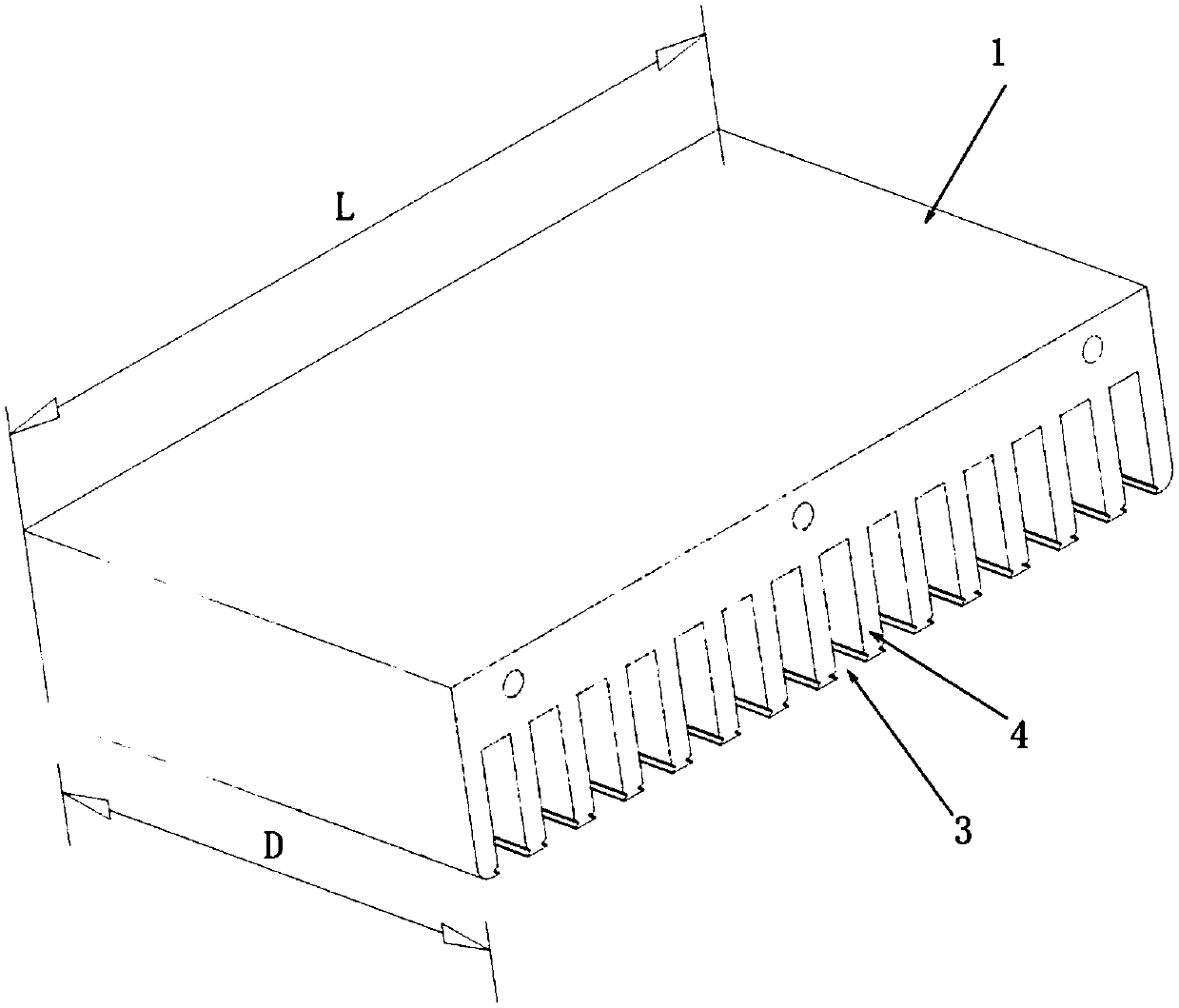

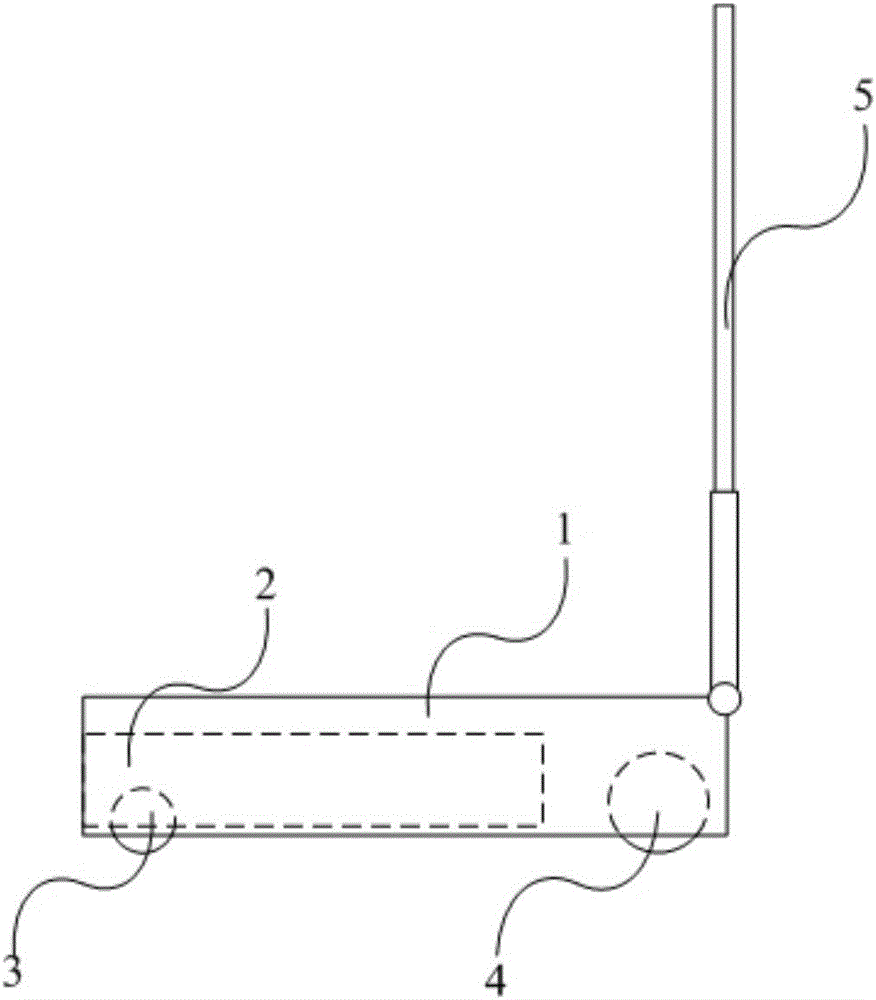

Pteridophyte seedling raising device

ActiveCN103081745AReasonable size designMake full use of spaceReceptacle cultivationSporePteridophyte

The invention discloses a pteridophyte seedling raising device. The pteridophyte seedling raising device comprises a seedling raising basin, a sowing clapboard, and a culture medium pushout constructional element. The seedling raising basin comprises a basin body (2) and a cover body (3) which is matched with the basin body. The basin body is composed of a bottom wall and side walls. Through-holes are formed in the bottom wall. The cover body is composed of a top wall and side walls. Convection holes are formed in the side wall of the cover body. The sowing clapboard (4) is arranged in the basin body and is composed of clapboard side walls and side walls of griddings arranged inside the clapboard side walls. The culture medium pushout constructional element (5) comprises a base seat and a convex circular cylinder which is arranged on the base seat and matched with the shape of gridding cavities. The pteridophyte seedling raising device can improve efficiency of seedling and transplanting, reduce cross infection probability between sporophytes, reduce damage of gametophytes and sporophytes in transplanting process, and has the advantages that cultivating room is made full use of, stability of development environment of spores and seeding transplanting process standardization are guaranteed, management cost is reduced and the pteridophyte seedling raising device is suitable for pteridophyte seedling standardization and large-scale production.

Owner:INST OF BOTANY CHINESE ACAD OF SCI

Data wire storage box

The invention discloses a data wire storage box. The data wire storage box comprises a shell, a wire winding rod and a detecting device, wherein the shell comprises an upper shell and a lower shell which are detachably connected with each other; a first opening is formed in the curve surface of the upper shell; one side of the first opening is articulated with a first cover body; the inner wall of the first cover body is provided with a USB (Universal Serial Bus) plug socket; a second opening is formed in the curve surface of the lower shell; one side of the second opening is articulated with a second cover body; the inner wall of the second cover body is provided with a charging plug socket; the wire winding rod is formed from at least two segments of connecting rods which are sleeved mutually; the uppermost connecting rod is connected with the upper shell through a bearing; the lowermost connecting rod is in threaded connection with a screw cap; the detecting device comprises a first electric wire and a second electric wire; the second electric wire is connected with a battery and a display lamp. The data wire storage box disclosed by the invention can be used for storing a data wire inside a closed shell, is convenient to carry and provides convenience for use of the data wire without opening the shell; moreover, the detecting device for detecting the data wire is arranged on the shell; the data wire storage box disclosed by the invention has the advantages of being simple in structure, safe, reliable, economical, practical and the like.

Owner:靳职雄

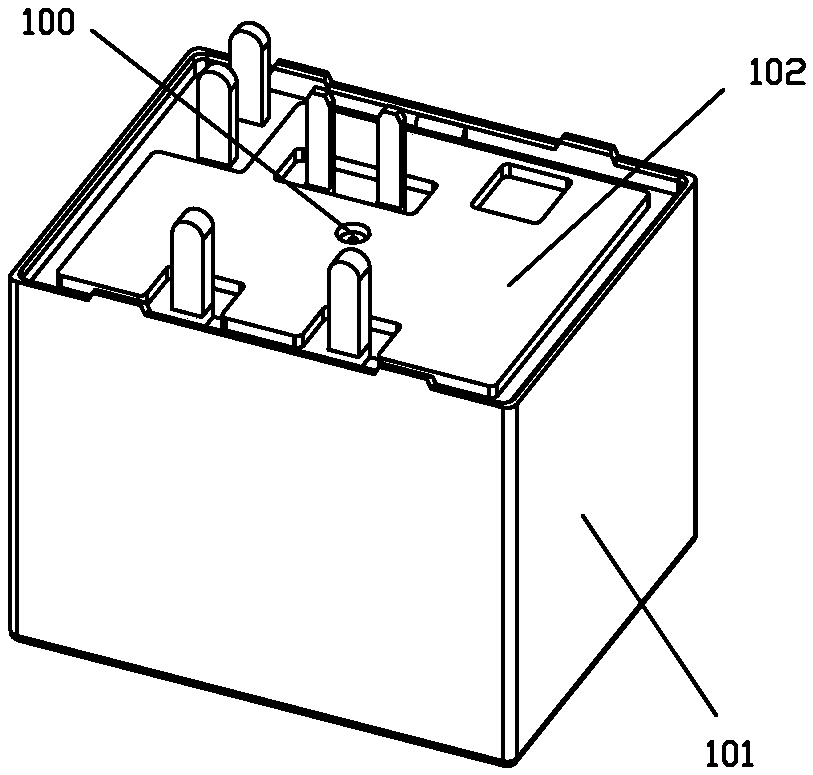

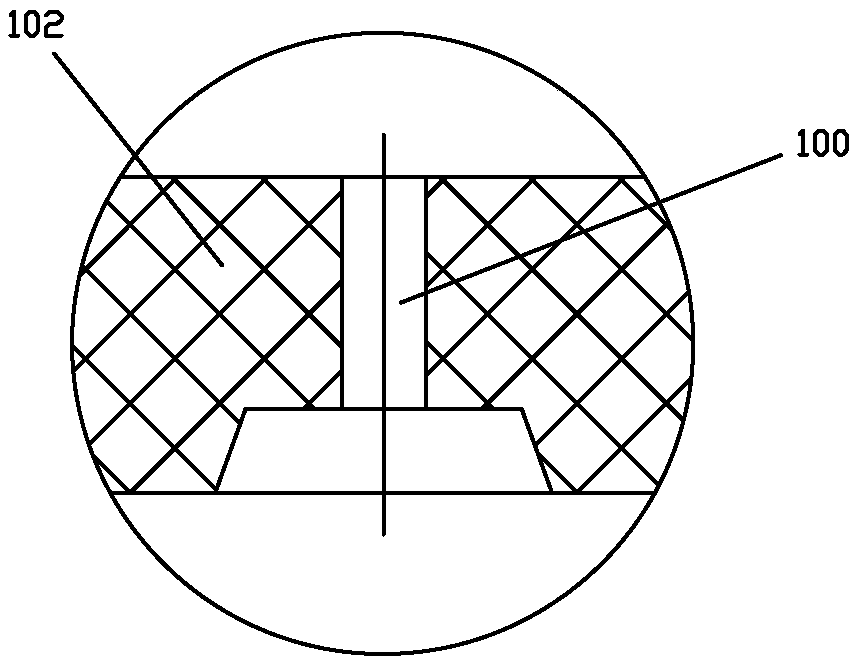

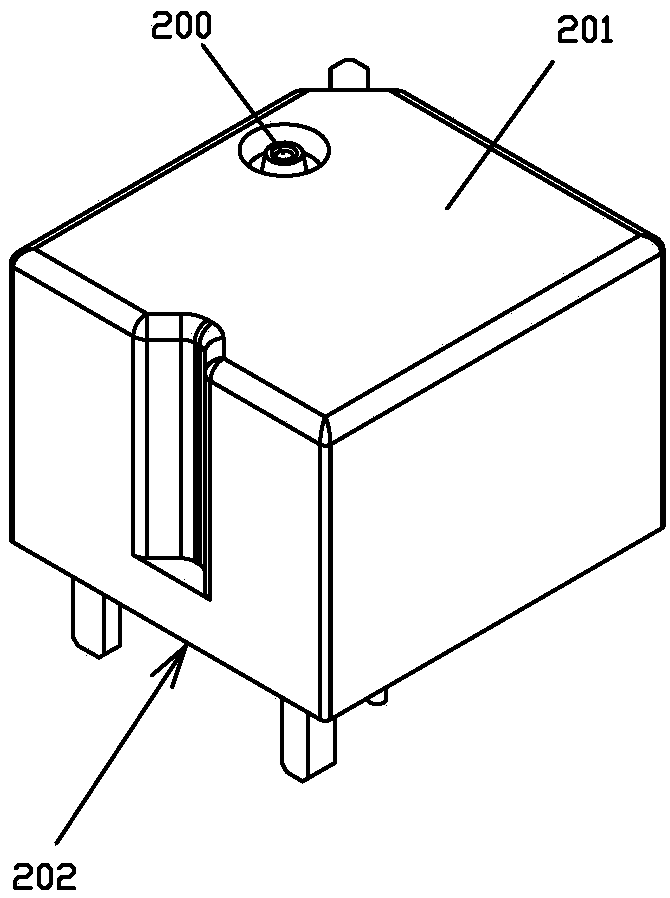

Ventilation hole structure for rainproof type relay

ActiveCN107946140AImprove the effect of rain protectionSimple designElectromagnetic relay detailsLarge mouthEngineering

The invention discloses a ventilation hole structure for a rainproof type relay. The ventilation hole structure for the rainproof type relay comprises a shell and a base; the shell is provided with acavity having a downward opening, so that internal parts of the relay are contained; the base is embedded at the bottom of the shell; a vertical raised rib downwardly extending along the top is arranged outside one side wall of the shell; a groove having a downward opening is arranged on the bottom end face of the raised rib; a through hole is arranged in one side wall of the shell; the through hole is communicated with the groove; furthermore, the groove is set to a structure having a large mouth and a small internal part; and the through hole and the groove form the ventilation hole of the relay. According to the ventilation hole structure for the rainproof type relay disclosed by the invention, the structure of the ventilation hole is improved; therefore, the structure is simple; a module can be conveniently released when a part is produced; furthermore, optical cement can be prevented from flowing into the interior of the relay from the small hole at the broadside of the shell; andthus, the use performance of the relay is ensured.

Owner:XIAMEN HONGFA AUTOMOTIVE ELECTRONICS

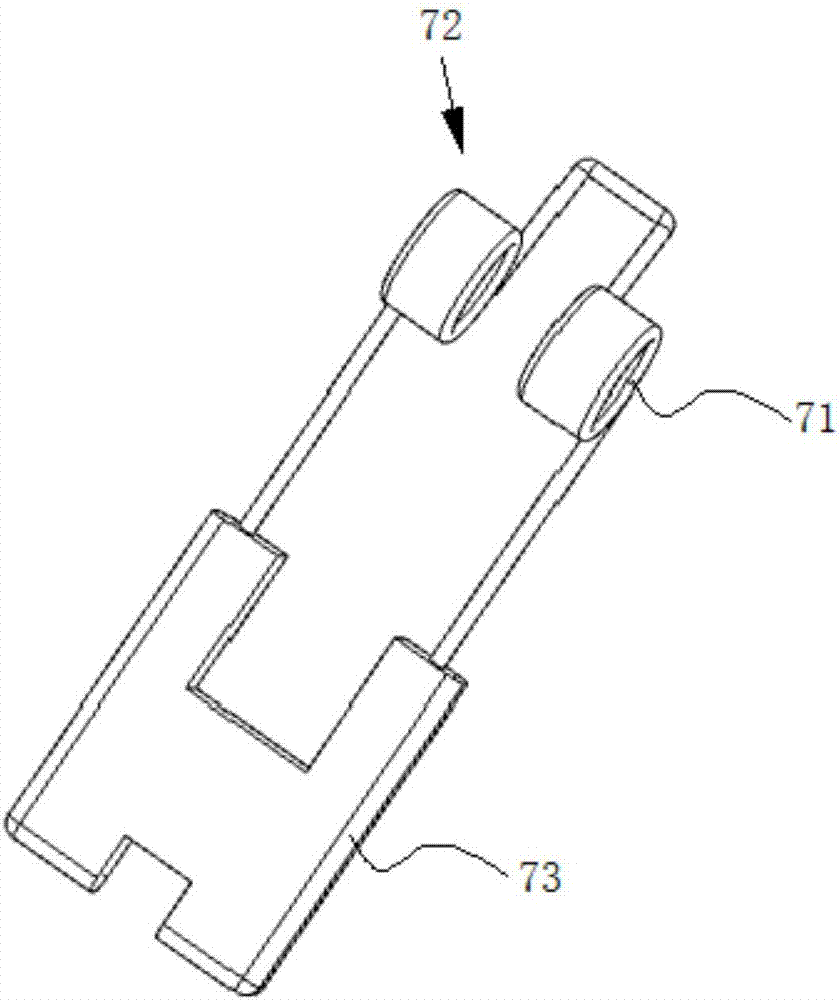

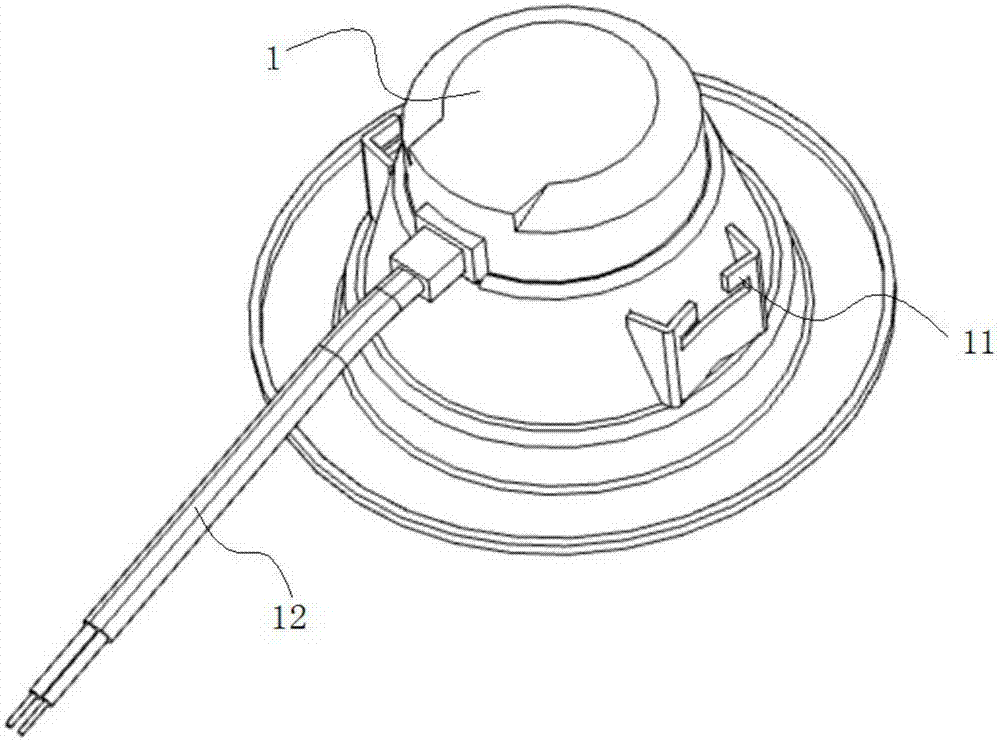

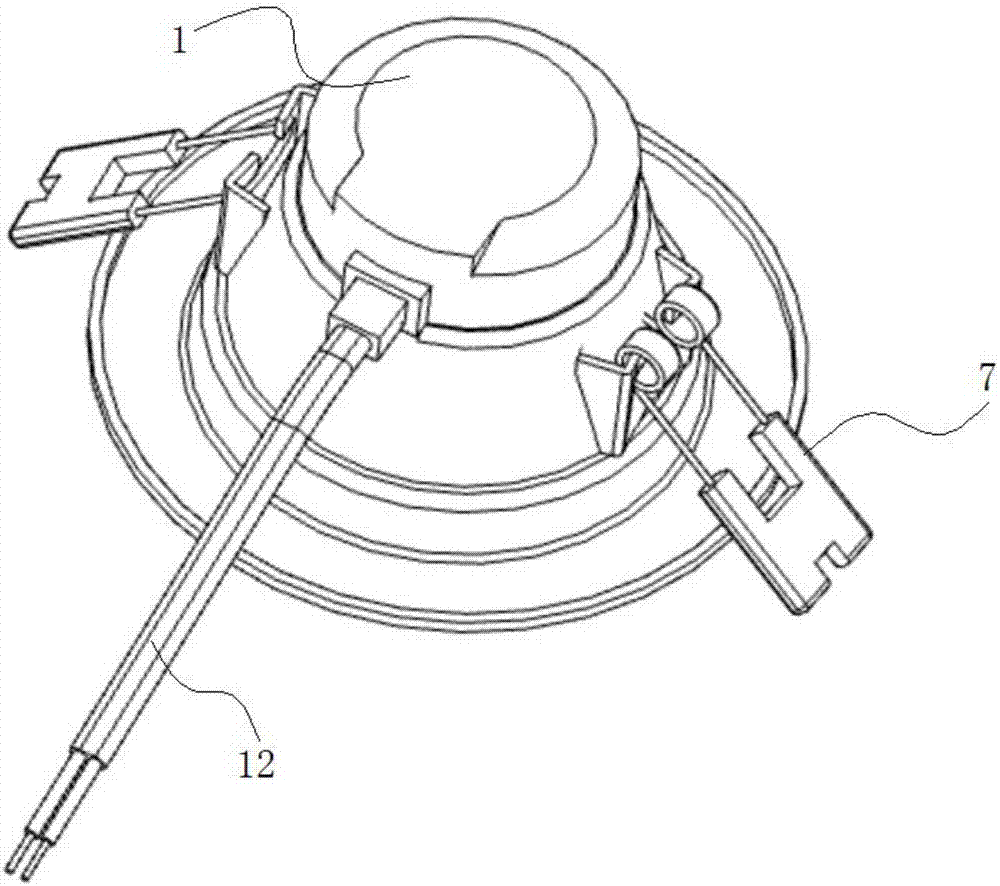

Downlight spring automatic assembling equipment

PendingCN107263069AEasy to adjustEasy to replaceMetal working apparatusControl systemStructural engineering

The invention discloses downlight spring automatic assembling equipment which can be used for automatically assembling a downlight spring. The downlight spring automatic assembling equipment comprises a spring left and right automatic clamping device, a spring front and back automatic forking device and a control system. The spring left and right automatic clamping device comprises a spring clamping mechanism which clamps the spring, a spring attaching mechanism which attaches the spring to spring slots and a spring pushing mechanism which pushes the spring into the spring slots; both the spring clamping mechanism and the spring pushing mechanism are arranged on the spring attaching mechanism, and a pressure block for extruding the spring is arranged on the tail end of the spring pushing mechanism; the spring front and back automatic forking device comprises a lifting fork, the end portion of the lifting fork comprises left and right spring lifting fork portions, the left and right spring lifting fork portions are separately aligned to the spring slots on two sides of the downlight, and the left and right spring lifting fork portions share a power unit. According to the downlight spring automatic assembling equipment disclosed by the invention, as the spring is automatically pushed and forked and the like, the spring is automatically mounted on the downlight, and the mechanisms can automatically return, so that the labor is saved; the downlight spring automatic assembling equipment is efficient, stable in quality, convenient to replace light types, high in universality and etc.

Owner:KUNSHAN TUOYU AUTOMATION TECH CO LTD

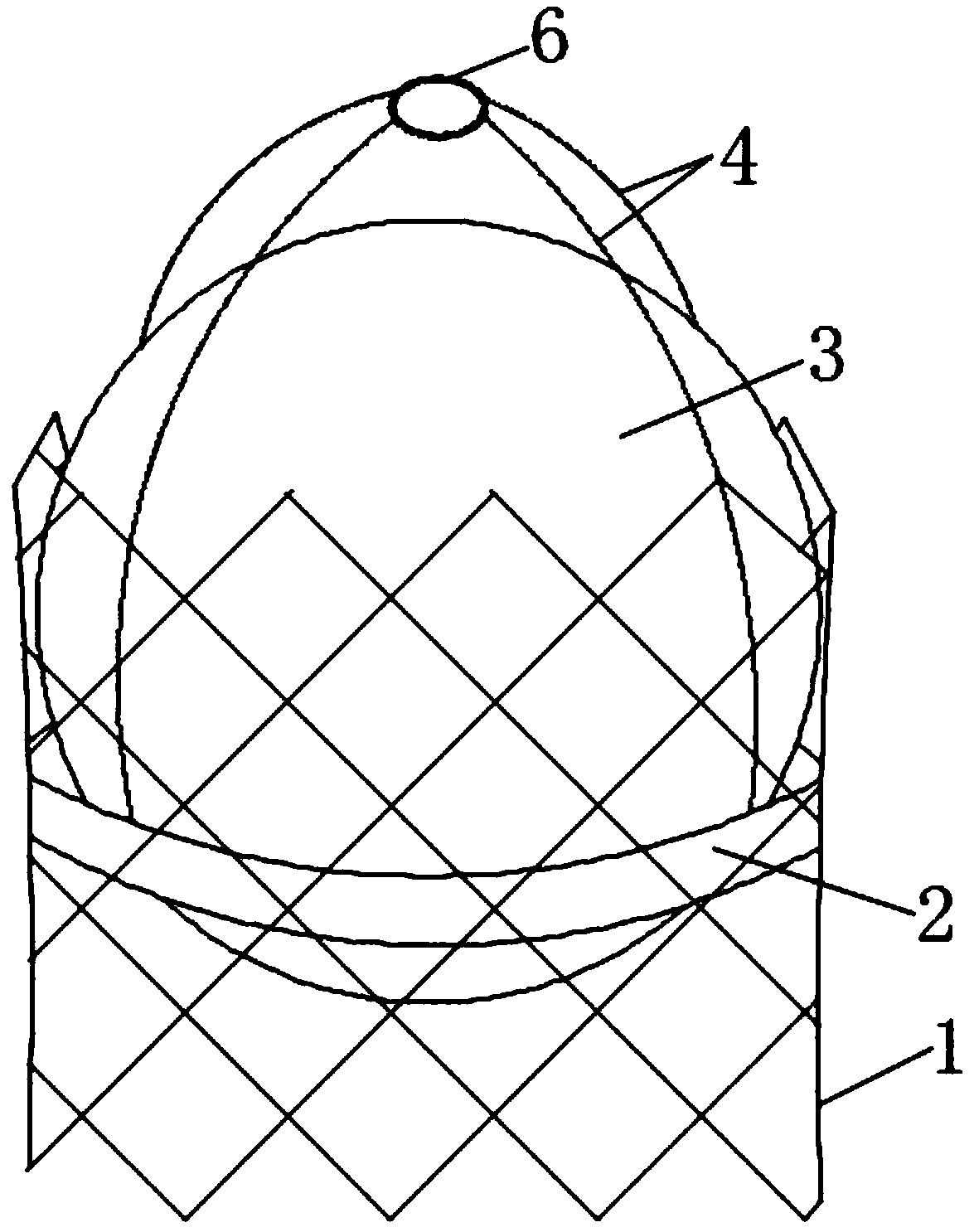

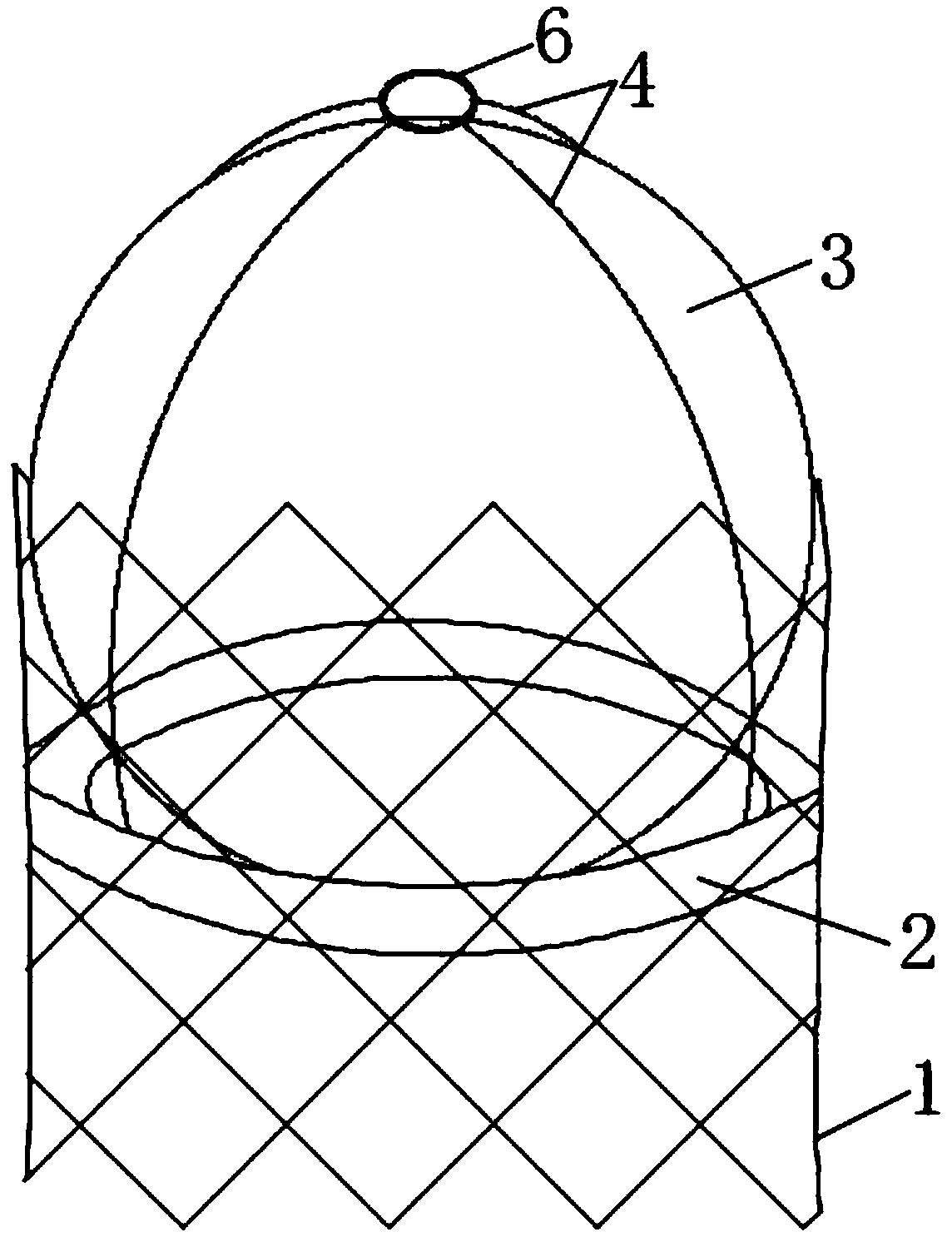

Interventional aortic valve stent system with inflating type ball bag

The invention relates to an interventional aortic valve stent system with an inflating type ball bag. The interventional aortic valve stent system with the inflating type ball bag comprises a flexiblecylindrical aortic valve stent, a ring-shaped valve ring and the ball bag; the aortic valve stent is anchored on the inner wall of an aorta; the valve ring is arranged in the aortic valve stent, thecenter line of the valve ring and the center line of the aortic valve stent are superposed, and the outer wall of the valve ring is connected and fixed to the inner wall of the aortic valve stent; theend, which is away from the aortic valve, of the valve ring is connected with an elastic ball cage, and the ball bag is arranged in the ball cage; and under the effect of blood pressure difference, and the ball bag moves between the top of the ball cage and the valve ring until part of the ball bag extends into the valve ring and is attached to the inner wall of the valve ring or the ball bag moves towards the top of the ball cage and away from the valve ring. The interventional aortic valve stent system with the inflating type ball bag has the advantages that the ball bag replaces a traditional valve leaflet, disassembling and changing are facilitated, compared with a biological tissue valve leaflet, the ball bag does not have the 'chronic disease' of dysfunction of the valve, the risk of secondary surgical valve change of a patient is reduced, and the surgical safety is high.

Owner:武汉开阖同立医疗科技有限公司

Traditional Chinese medicine medical pillow used for treating cervical spondylosis

InactiveCN101721491AWide variety of sourcesReasonable pricePillowsHydroxy compound active ingredientsCervical spondylosisMyrrh

The invention relates to the technical field of traditional Chinese medicines, in particular to a traditional Chinese medicine medical pillow which is exclusively used for treating cervical spondylosis. The traditional Chinese medicine medical pillow comprises an external pillowslip with air permeability and traditional Chinese medicines filled into the pillowslip, wherein the traditional Chinese medicines comprise the following raw materials according to parts by weight: 10-30 parts of safflower, 10-30 parts of myrrh, 10-30 parts of mastic, 20-40 parts of lycopodium clavatum, 20-40 parts of garden balsam stem, 20-40 parts of radix sileris, 30-40 parts of pubescent angelica root, 30-40 parts of radix puerariae, 5-20 parts of tortoise plastron, 20-40 parts of salvia chinensis, 20-40 parts of borneol, 10-30 parts of red peony root, 10-40 parts of chrysanthemum and 10-30 parts of peppermint. The invention has obvious curative effect to the cervical spondylosis, and the cure rate can reach 95%. As the pillowslip of the traditional Chinese medicine medical pillow has reasonable size design and is matched with the size of the neck of a person, the traditional Chinese medicine medical pillow can also be used as a daily health-care pillow. The invention has stronger and very extensive market application prospect.

Owner:姜明洲

Engaged retaining pile and construction method and application thereof

The invention discloses an engaged retaining pile. The engaged retaining pile comprises a plurality of plain concrete piles laid from front to back and a plurality of reinforced concrete piles laid from front to back. The plain concrete piles and the reinforced concrete piles are laid in a staggered mode. A pile body of each reinforced concrete pile is engaged with pile bodies of two plain concrete piles located front and back, so that the retaining effect is good. The invention further discloses a construction method of the engaged retaining pile. The construction method comprises the steps that firstly, construction of the plain concrete piles is conducted, and the multiple plain concrete piles are constructed from front to back; and secondly, construction of the reinforced concrete piles is conducted, the multiple reinforced concrete piles are constructed from front to back in the construction process of the multiple plain concrete piles, drilled hole-forming construction processes of any one of the reinforced concrete piles are conducted after the construction of the two adjacent plain concrete piles front and back is completed. The construction method is simple; the design is reasonable and the construction is simple and convenient; the construction efficiency is high and the construction effect is good. In addition, the invention discloses an application of the engaged retaining piles, namely a foundation pit retaining structure is formed by fixedly connecting the multiple engaged retaining piles tightly.

Owner:SHAANXI ZHUANGXIN CONSTR ENG +1

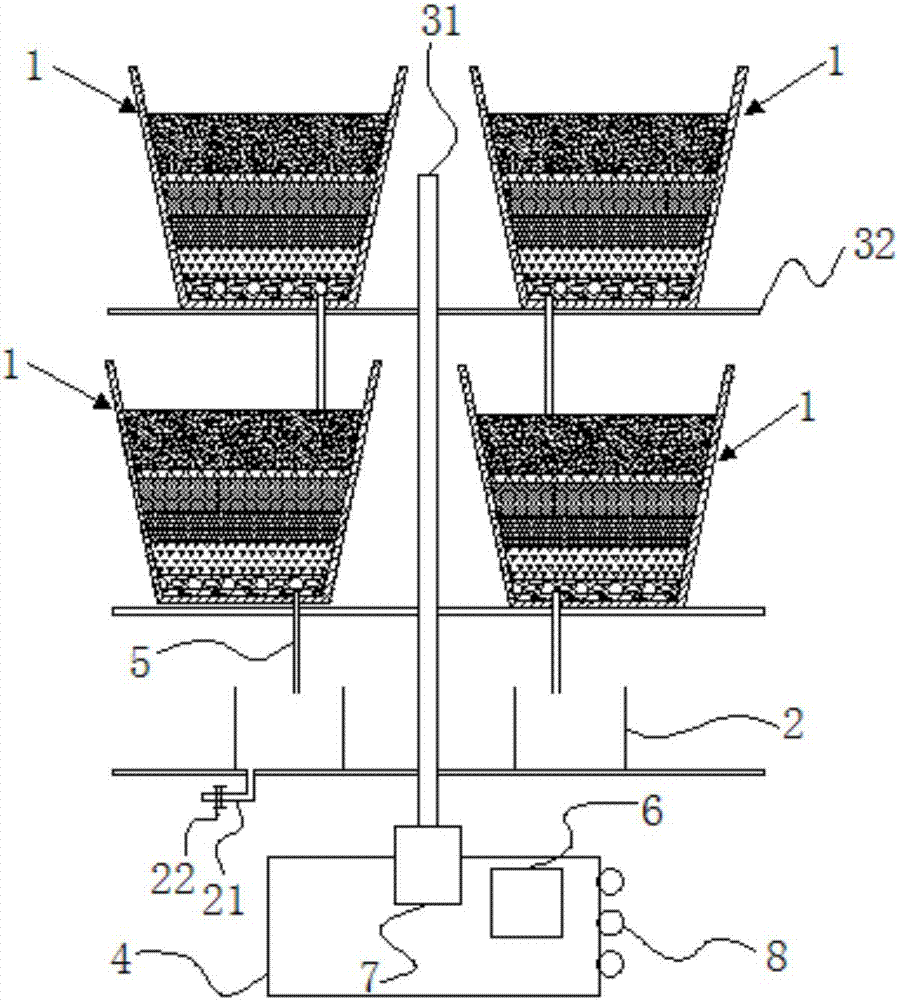

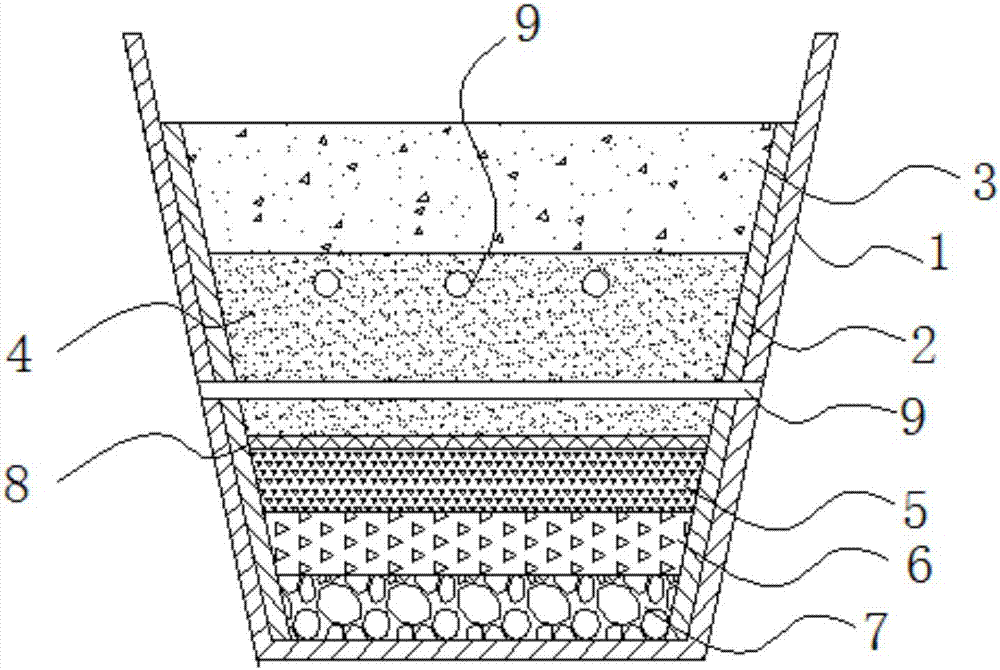

Multi-layer vertical potting green planting structure

PendingCN106973717APromote growthReasonable soil structureCultivating equipmentsReceptacle cultivationElectric machinerySoil horizon

The invention discloses a multi-layer vertical potting green planting structure. The structure comprises a potting, a green support arranged at the potting or a water-collecting pool and a base connected with the green support. The potting comprises a potting container and a soil layer. The soil layer is provided with a gravel layer, a coarse sand layer, a middle sand layer, a fine sand layer and a mixed garden soil layer sequentially from up to down. A drain pipe is arranged on the bottom of the gravel layer; a water outlet pipe is arranged on the bottom of the water-collecting pool; a water outlet valve is arranged on the water outlet pipe. A power supply device and a drive motor electrically connected with the power supply device are arranged in the base; an output shaft of the drive motor is connected with the lower end of the green support and can drive the green support to rotate. According to the multi-layer vertical potting green planting structure, the existing balcony space can be fully used; the potting in different positions can be irradiated by sun; a better environment is provided for the growth of the potting; water sources are fully used; the environment is not polluted, and is clean and attractive.

Owner:SUZHOU CHUNHE ENVIRONMENTAL TECH CO LTD

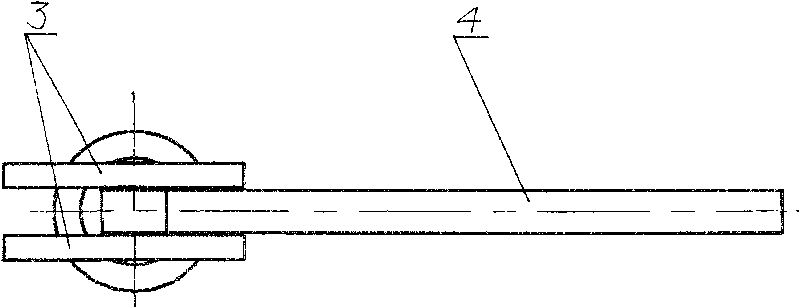

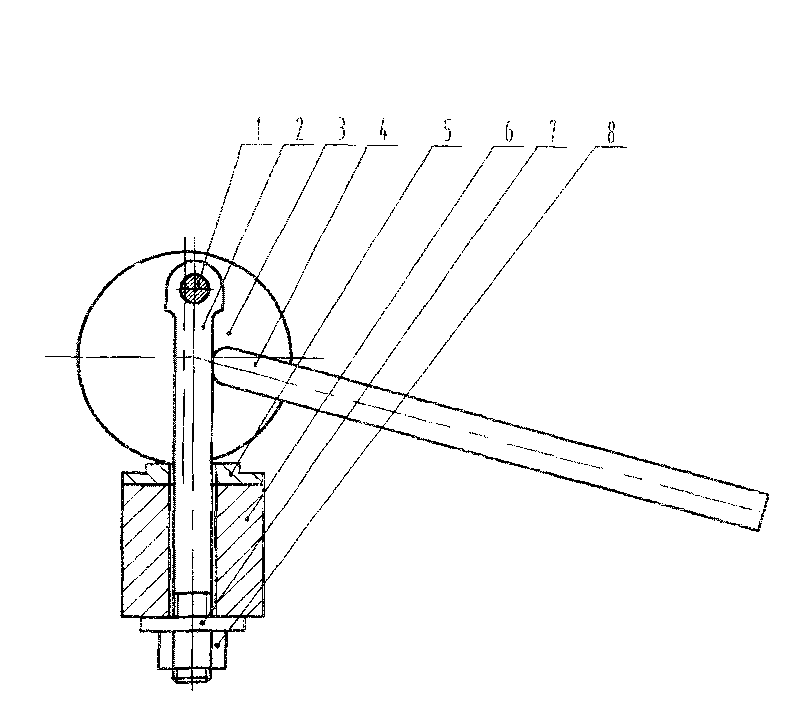

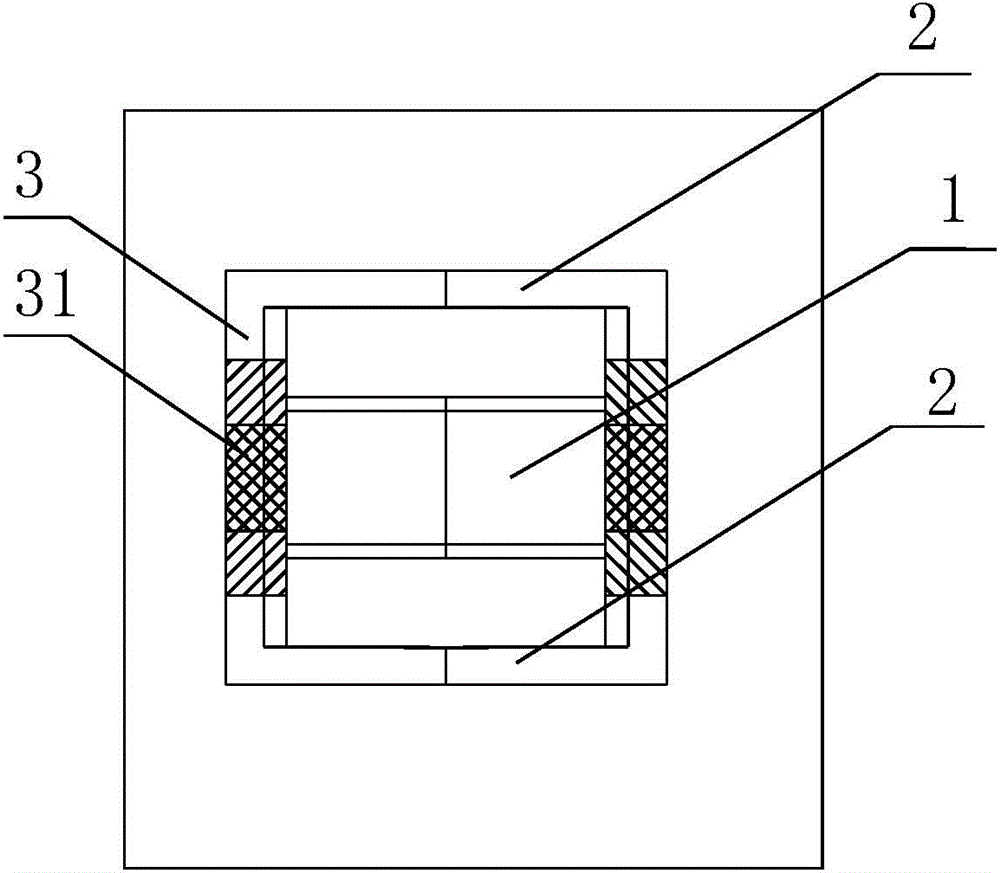

Orifice sealing device

The invention discloses an orifice sealing device, comprising a rubber part and a presser bar mechanism, wherein, the rubber part is a hollow rubber plug, the presser bar mechanism is composed of a screw stem and a pinch roller provided with a handle, one end of the screw stem penetrates through the inner hole of the rubber plug and then is connected with a nut, and the other end of the screw rod is rotationally connected with the pinch roller through a cylindrical pin. The pinch roller is a cam or a disc. The orifice sealing device is used for plugging a joint orifice when the tightness of the inner chamber of a member is tested in internal-combustion engine industry, has the advantages of simple, fast and laboring saving assembly and disassembly and good use effect, thereby deserving promotion and application.

Owner:YANGDONG CO LTD

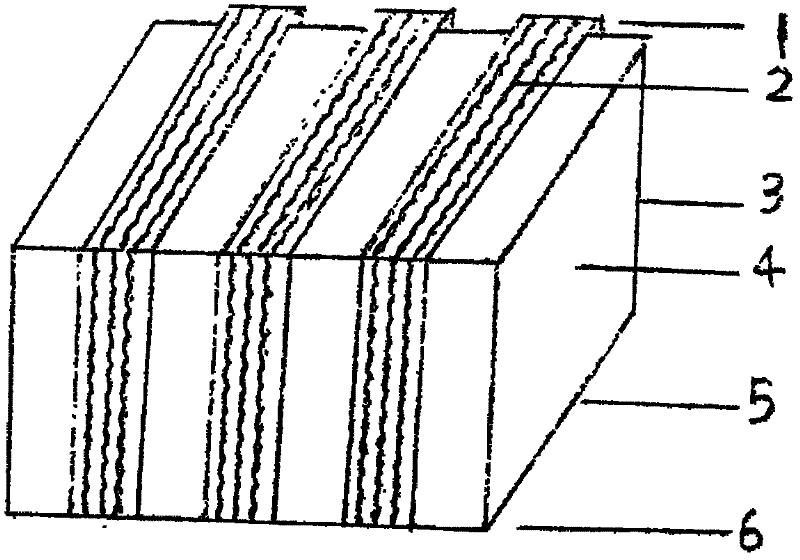

High-strength energy-saving concrete load-bearing block

InactiveCN102418397AReasonable size designImprove shear resistanceConstruction materialHigh strength concreteThermal insulation

A high-strength concrete load-bearing block provided by the invention is composed of insulation board layers and concrete. A plurality of the insulation board layers are arranged parallel with spacing in the concrete. A plurality of linking holes are disposed on each insulation board layer, which is fixed in the concrete through the linking holes. The linking holes on two adjacent layers of insulation board are staggered and don't communicate with each other. Each insulation board layer protrudes 1 cm on one surface of the block and the protruding parts form mortar joints for connecting with other blocks. During the laying process, the insulation board layers are laid parallel to the wall. Regardless of appearance change as well as big change of the internal structure of the block, compression resistance and thermal insulation performance are both improved a lot, thus solving deficiencies for building high buildings and the defect of poor thermal insulation capacity.

Owner:赵云良

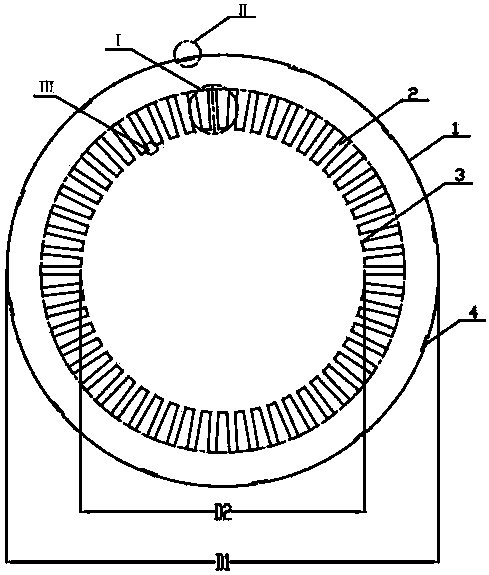

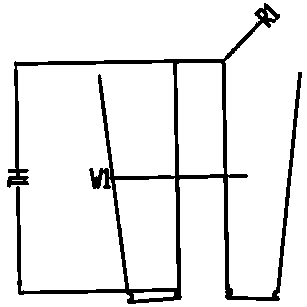

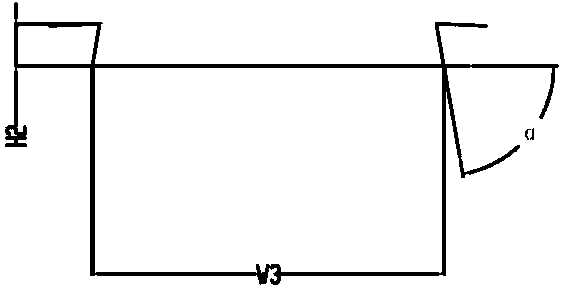

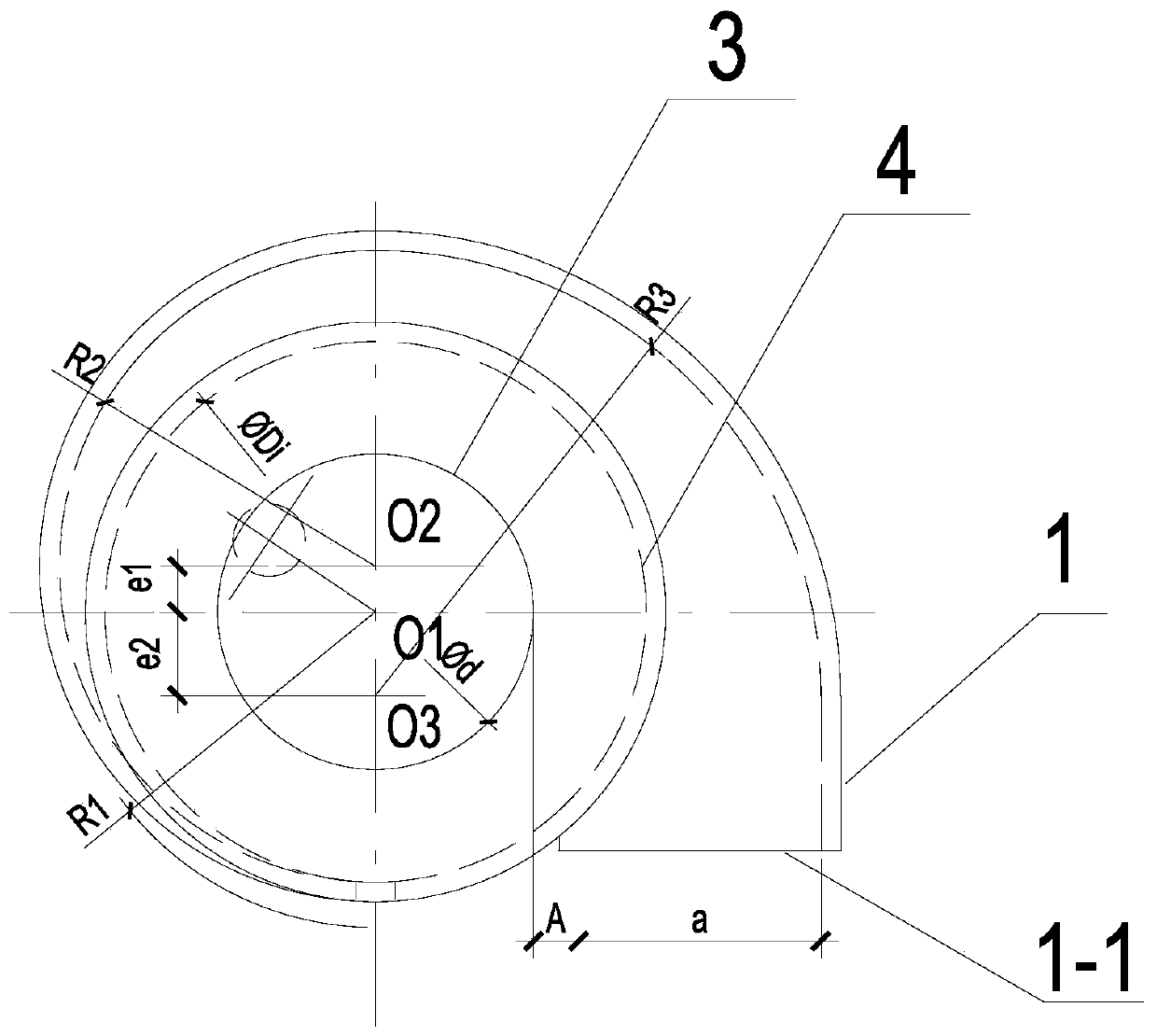

Stator punching sheet of high-voltage permanent-magnet synchronous motor, winding stator and motor

InactiveCN109638991AGuaranteed uptimeImprove performanceWindingsSynchronous machine detailsPunchingSynchronous motor

The invention discloses a stator punching sheet of a high-voltage permanent-magnet synchronous motor, a winding stator and the motor. A stator punching sheet body is in a round shape, 54 rectangular winding grooves are formed in the stator body and are uniformly distributed along a circumference, the widths W1 of the winding grooves are 13.7 millimeters, H1 of the winding grooves are 65 millimeters, a magnetic groove wedge slot is formed in a winding groove opening and is used for placing a magnetic groove wedge, 12 swallowtail positioning grooves are formed in an outer circle profile of the stator punching sheet body and are uniformly distributed along the circumference, the magnetic groove wedge slot is in a semi-circular shape, the radius R2 of the magnetic groove wedge slot is 1 millimeter, a fillet is arranged at a connection position of the magnetic groove wedge slot and the winding groove, the arc radius R3 is 0.2 millimeter, and the opening width W2 of the magnetic groove wedgeslot is 15.7 millimeters. The semi-circular magnetic groove wedge is employed, the air gap magnetic field distribution is improved, and the vibration and the noise of the motor are reduced; and an inner circle and an outer circle of the stator punching sheet and the winding groove are reasonable in design, the iron core loss of the motor is reduced, and the running performance of the motor is improved.

Owner:NANTONG UNIVERSITY

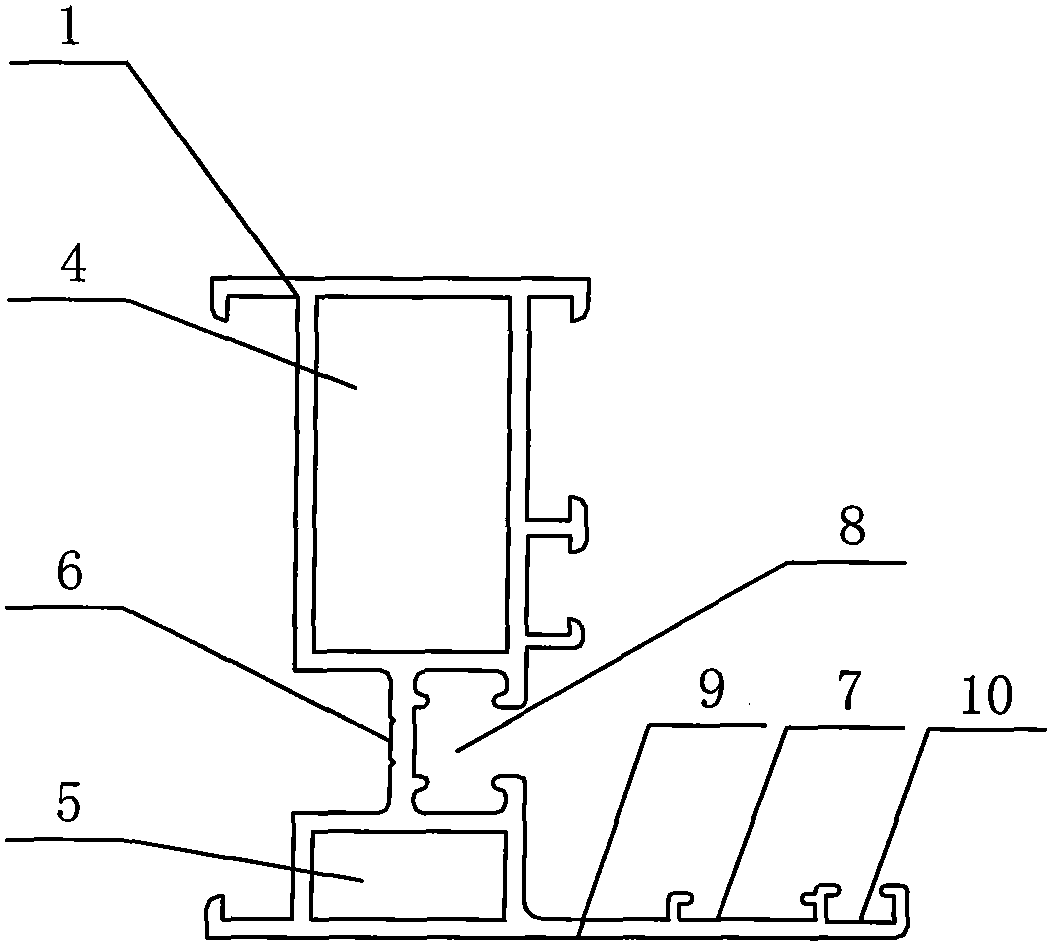

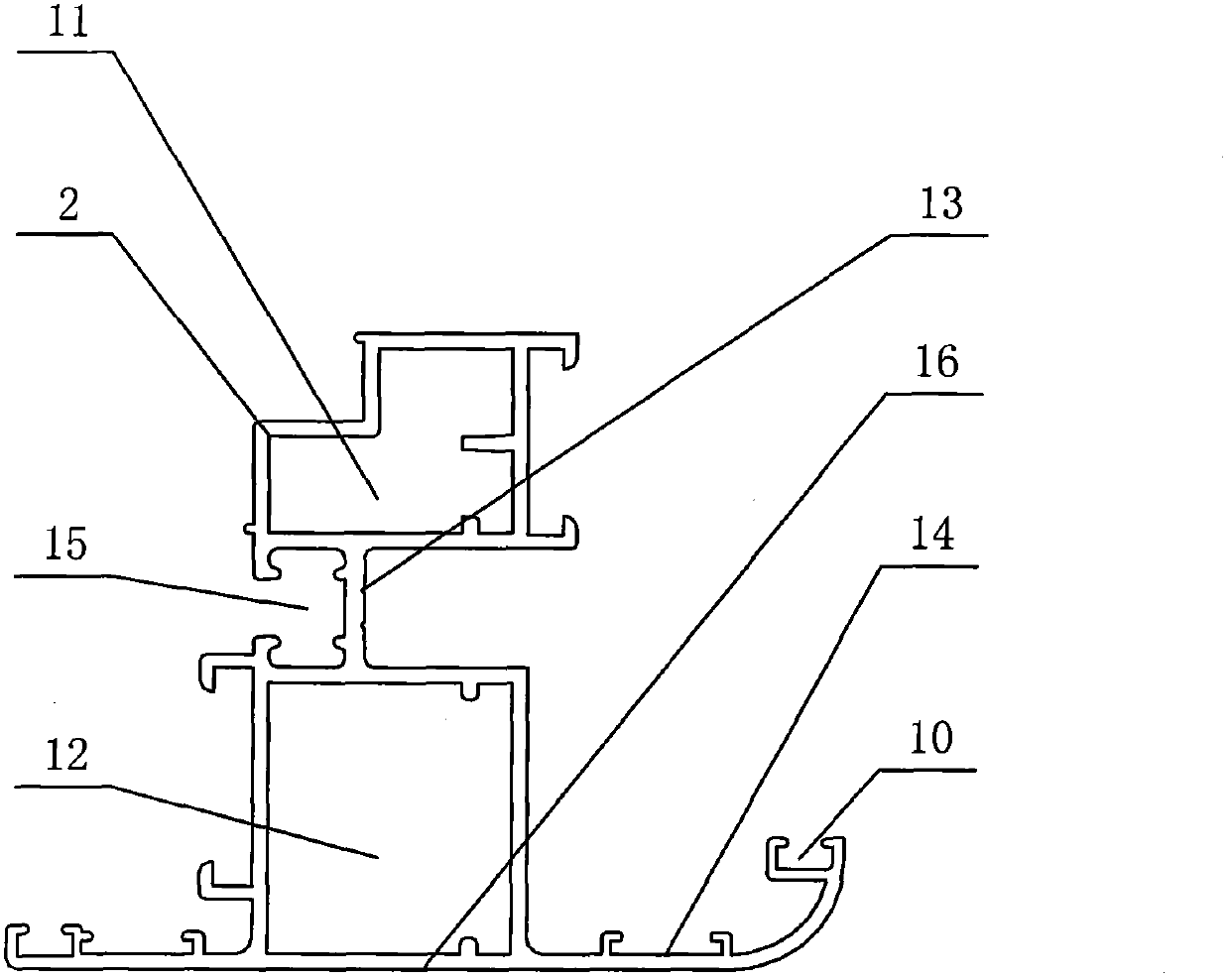

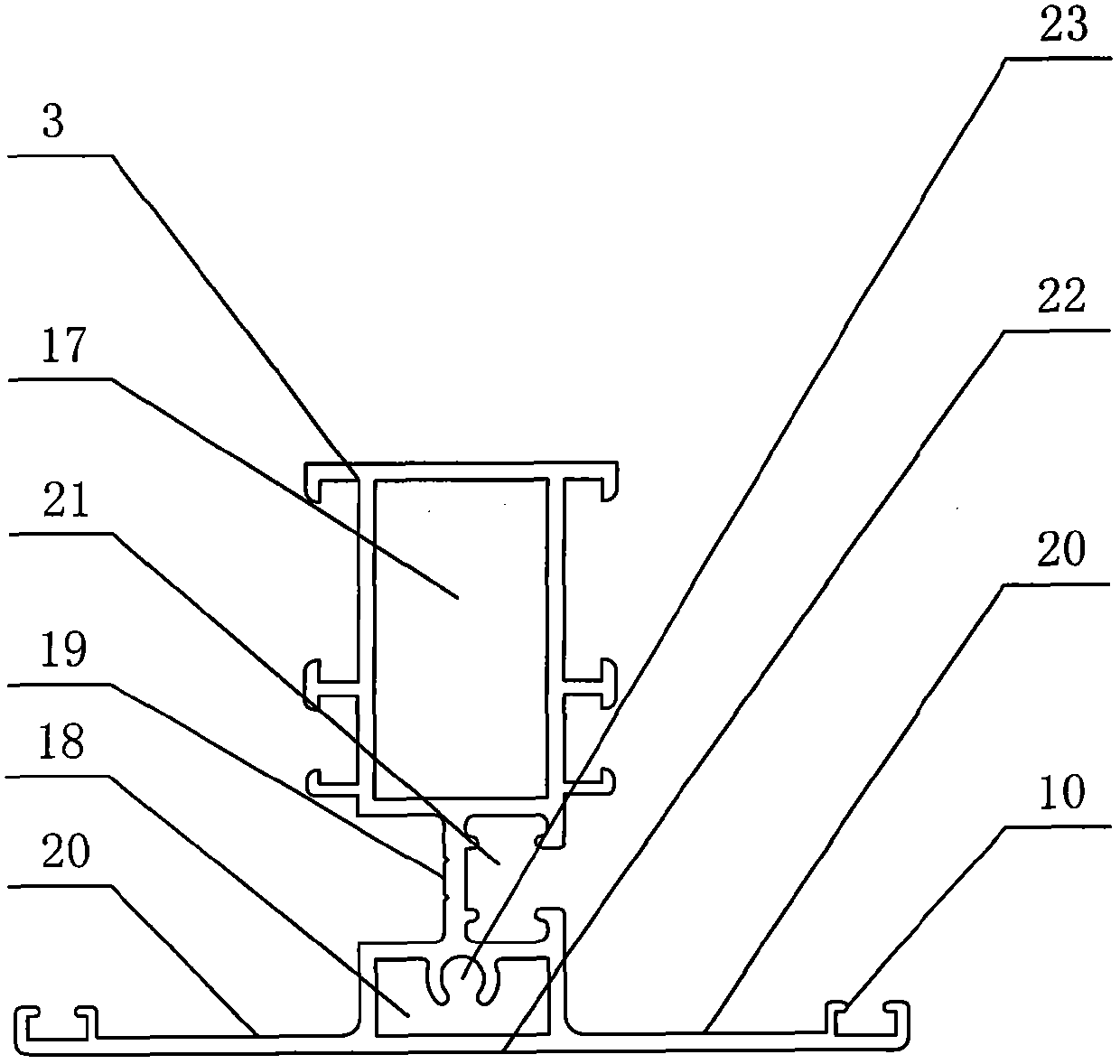

Injected bridge-cutoff aluminum profile used for inswinging casement window

InactiveCN102953632AReduce thicknessWill not affect the load-bearing strengthWing arrangementsWing framesThermal insulationEngineering

The invention discloses an injected bridge-cutoff aluminum profile used for inswinging a casement window, which comprises a window frame, a casement and a mullion. The window frame consists of a frame inner cavity, a frame outer cavity, a frame clapboard and a frame connecting plate. One end of the frame clapboard is connected with the middle part of the inner wall of the frame inner cavity, and the other end is connected with the middle part of the inner wall of the frame outer cavity. The frame clapboard, the inner wall of the frame inner cavity at one side of the frame clapboard, and the inner wall of the frame outer cavity make up a frame adhesive injection cavity. The frame connecting plate and the outer wall of the frame outer cavity are on the same plane, one end of the frame connecting plate is integrally molded with the end part of the outer wall of the frame outer cavity to form a frame outer decorative face, and the other end of the frame connecting plate extends outwards. The aluminum profile has the advantages that the wall thickness design of the side wall of the adhesive injection cavity is reasonable; the aluminum profile saves material while the original airtightness, watertightness, sound and heat insulation performances and thermal insulation properties are guaranteed; the percentage of outturn is improved; the weight per meter is reduced; and the production cost is reduced.

Owner:INNER MONGOLIA GUANGTAI INVESTMENT GRP

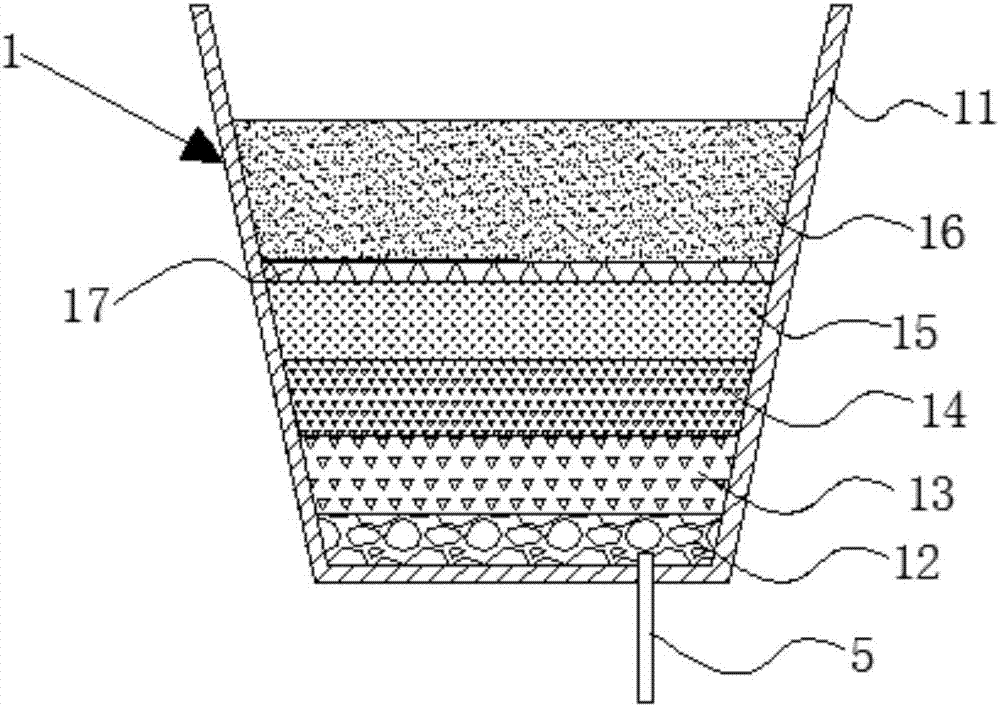

Breathable water-retaining potting structure

InactiveCN106888846AImprove breathabilityGuaranteed normal growthGrowth substratesCulture mediaEngineeringSoil horizon

The invention discloses a breathable water-retaining potting structure which comprises a potting container and a soil layer structure. A plurality of breathable through holes are formed in the wall of the potting container, a layer of waterproof breathable gauze is arranged on the inner wall of the potting container and positioned between the inner wall of the potting container and the soil layer structure, thickness of the waterproof breathable gauze is 0.5-1.5mm, size of the breathable through holes in the wall of the potting container is greater than that of micropores in the waterproof breathable gauze, and the size of the micropores in the waterproof breathable gauze is less than grain size of mixed garden soil; the soil layer structure comprises a mixed garden soil layer, a compound nutrient layer, a fine sand layer, a medium sand layer and a gravel layer, a horizontal screen plate is arranged between the compound nutrient layer and the fine sand layer, and transverse breathable pipes in up-down layers are arranged in the compound nutrient layer. The breathable water-retaining potting structure has breathable water-retaining performance, can be applied in bonsai planting, can maintain sufficient water during plant growing and has high breathability.

Owner:SUZHOU CHUNHE ENVIRONMENTAL TECH CO LTD

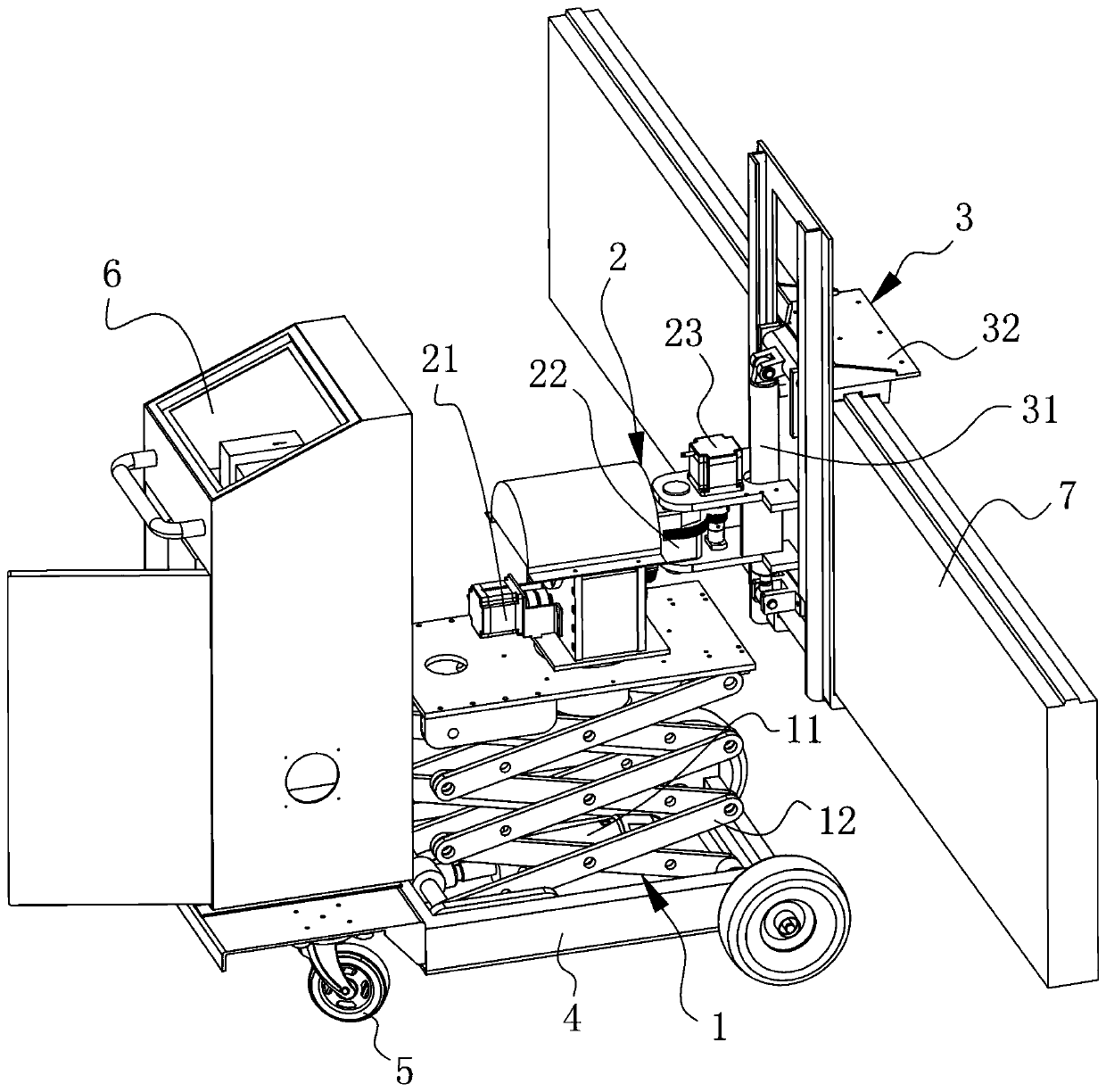

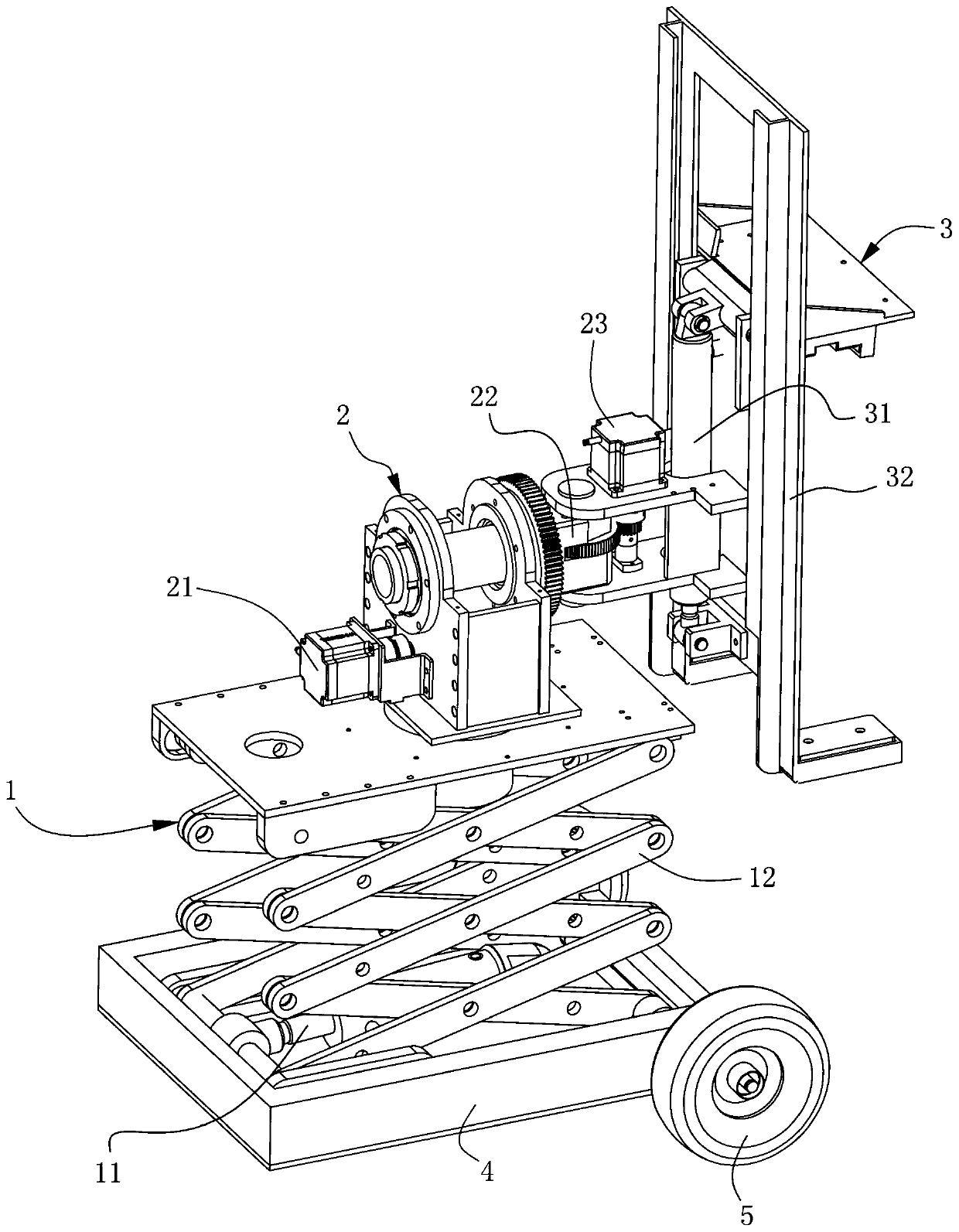

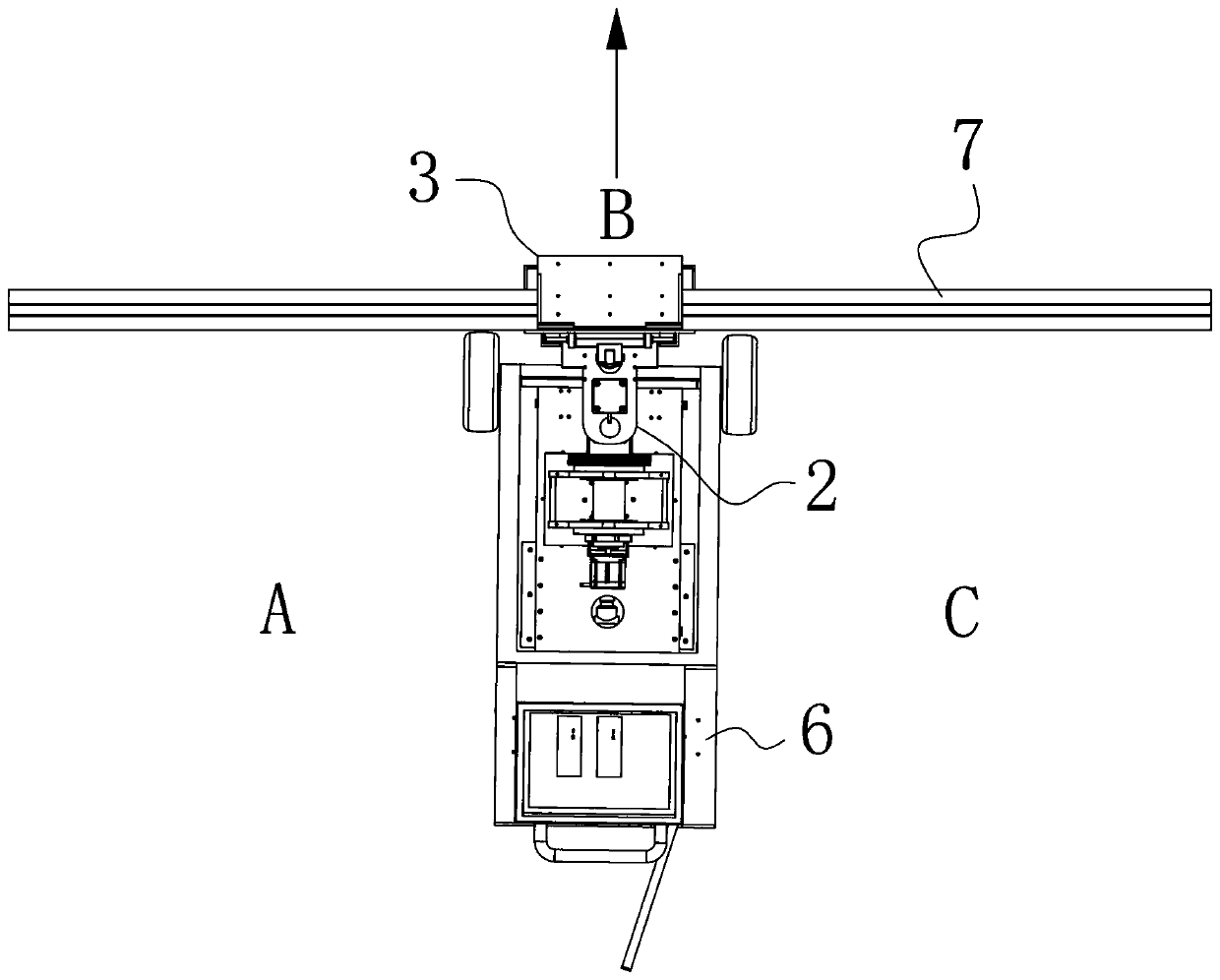

Wall building machine

PendingCN111119500AProvincial laborLabor savingBuilding material handlingConstruction engineeringMechanical engineering

The invention relates to the technical field of wallboard overturning, in particular to a wall building machine. The wall building machine comprises an oil pressure lifting device, a universal rotating device and an oil pressure board clamping device; the oil pressure board clamping device is used for clamping wallboards; the universal rotating device drives the oil pressure board clamping deviceclamping the wallboards to rotate universally; and the oil pressure lifting device drives the oil pressure board clamping device clamping the wallboards to move up or down. The wall building machine achieves that the wallboards are loaded in parallel, no labor force is needed for carrying or balance adjusting in the overturning and moving process of the wallboards, turning or reversing is not needed, and the wallboards can be installed in three directions; the oil pressure lifting device is used for lifting the wallboards, safety is achieved, labor is saved, parallel moving attached to the ground is achieved in the process that the wallboards are transported to the destination, turning over and porcelain colliding are not likely to be caused during transferring, the wallboards are overturned into a plane after reaching an assigned place, and the wall building machine is light and fast and flexible; and the whole wall building machine is reasonable in size design so that the whole wallbuilding machine can run smoothly in the construction site, and it can also be achieved that the wallboards are overturned and moved in one step at a narrow floor or in a height limited space.

Owner:东莞市巨准自动化设备有限公司

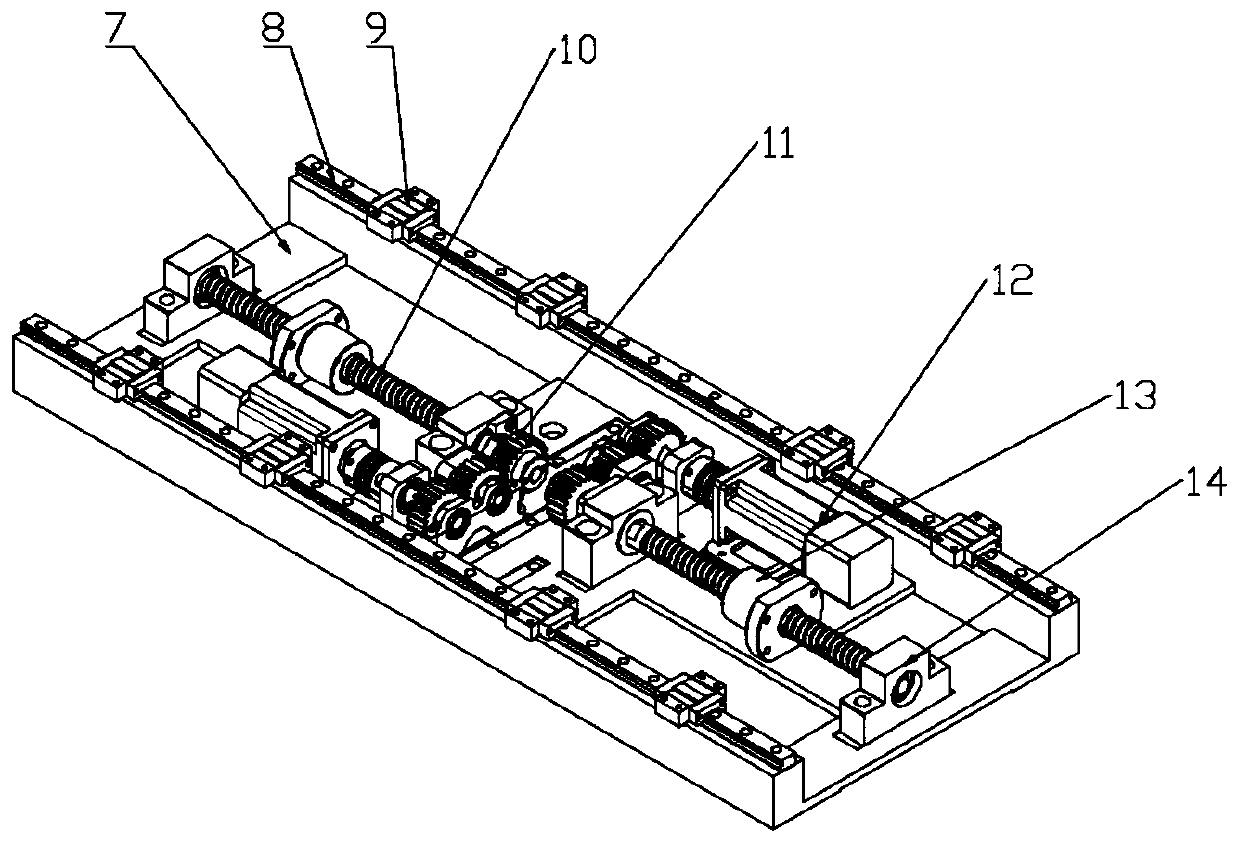

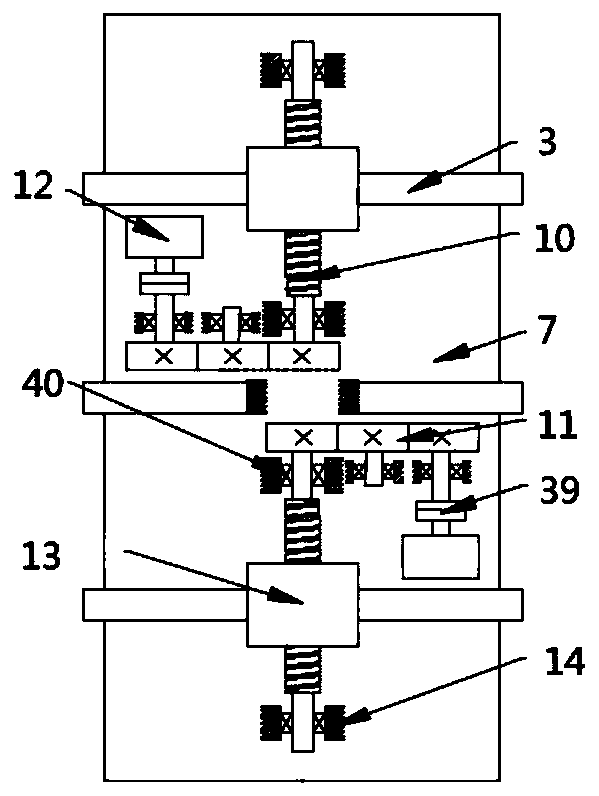

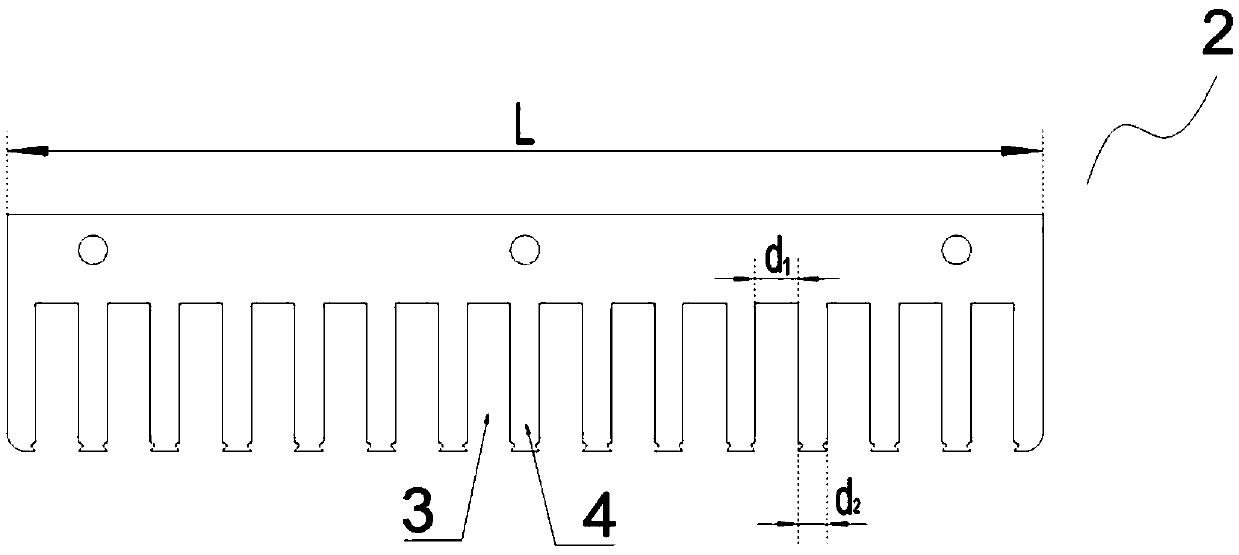

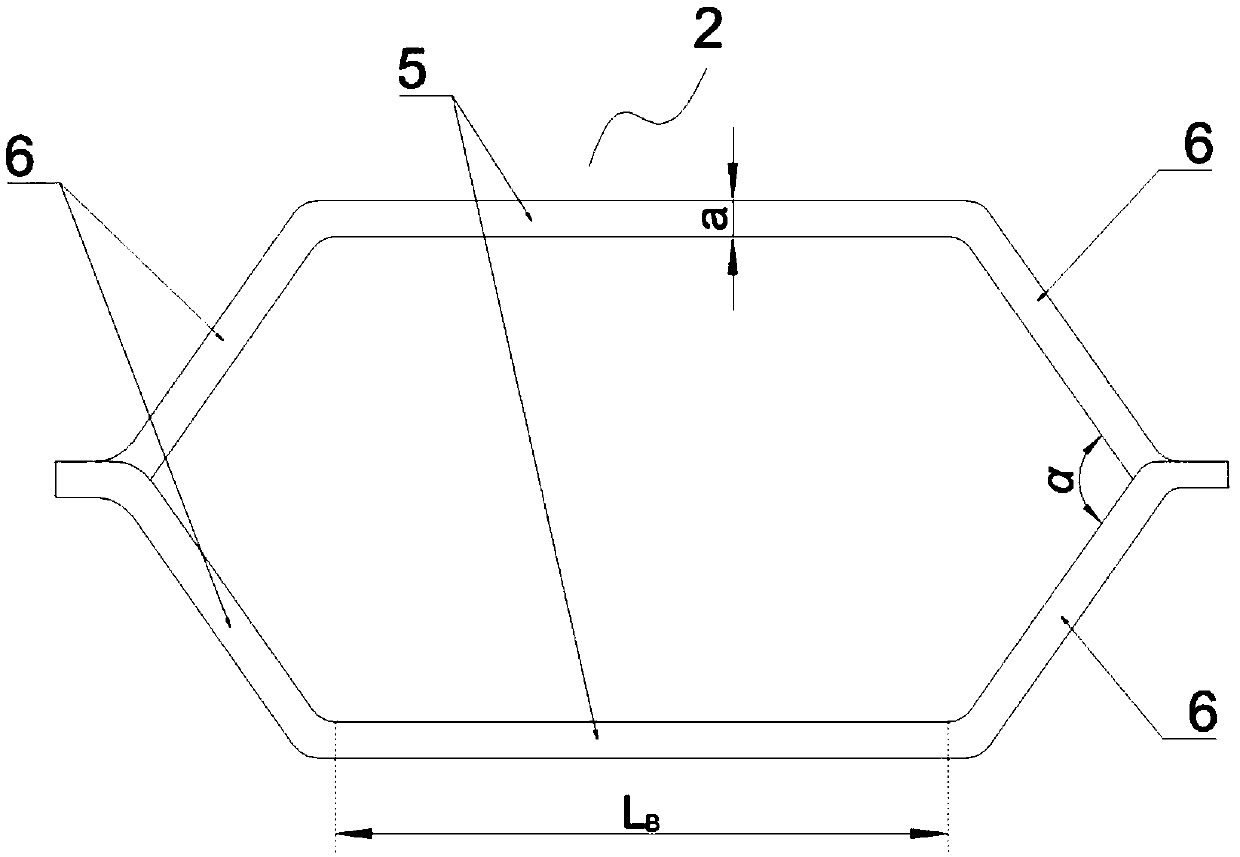

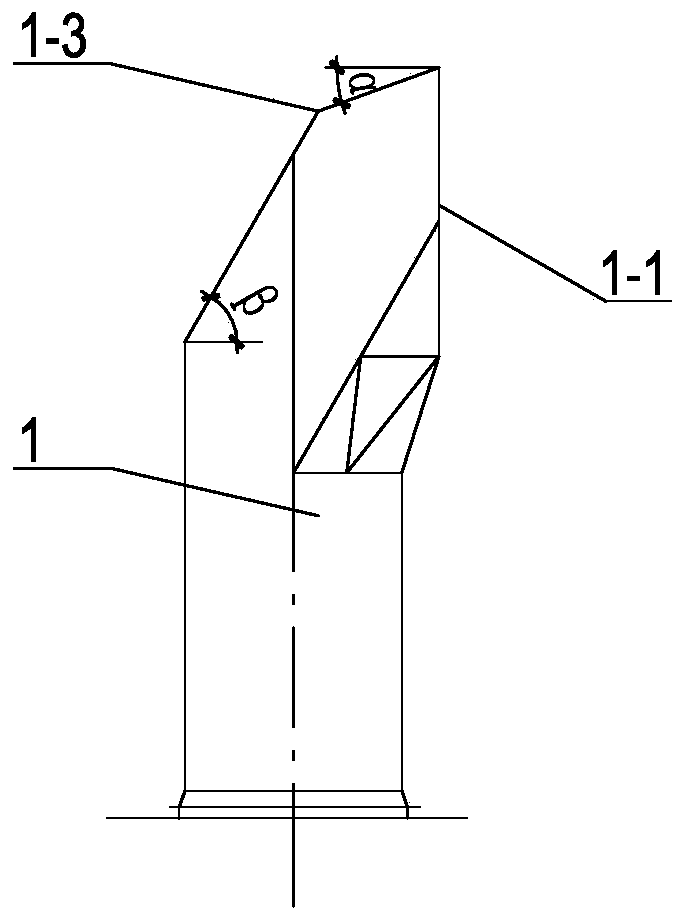

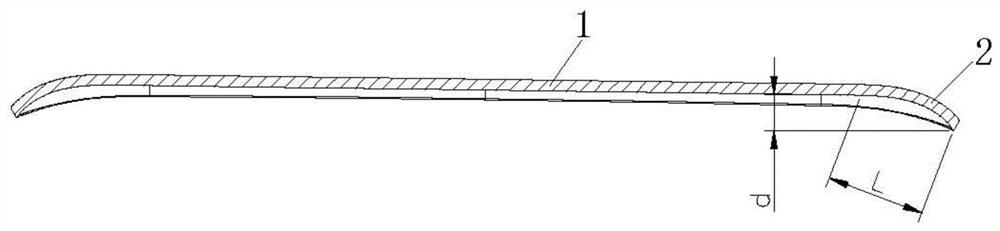

Design and verification method of winding coil of magnetic suspension linear motor

ActiveCN109687618AReasonable size designReduce manufacturing costWindings conductor shape/form/constructionProjection distanceStator

The invention provides a design and verification method of a winding coil of a magnetic suspension linear motor which can effectively solve the problem of long design and manufacturing cycle and highcost of the magnetic suspension linear motor caused by the existing design verification method. The method includes obtaining theoretical design values of a primary stator core and the winding coil according to the design speed of a maglev train and the design principle of the linear motor, comparing whether the linear distance b of the thickness a of the oblique portion of the isosceles trianglestructure at the end of the winding coil occupied on the length direction of the stator core is more than the sum of the stator slot width d1 of the stator core and the stator tooth portion width d2;determining whether the projection distance of the oblique portion of the isosceles triangle structure at the end of the winding coil in the width direction of the stator core is out of limit; whetherthe height h is out of limit after the whole isosceles triangle structure at the end of the winding coil is bent upward.

Owner:SUZHOU BETTER TECH

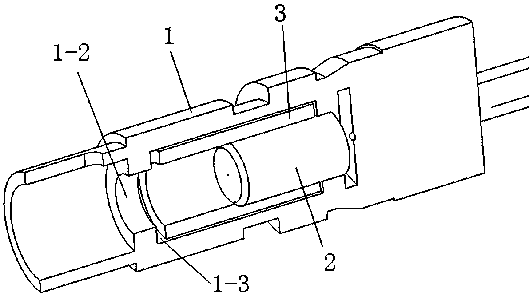

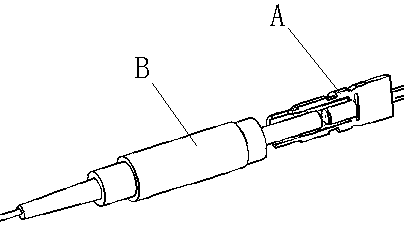

DIN type interface laser device

InactiveCN107800025ALittle room for movementImprove the limit effectOptical devices for laserUltrasound attenuationAngular deviation

The invention discloses a DIN type interface laser device. An optimal design is carried out on the structure parameters of the DIN type interface laser device through a simulation experiment. The DINtype interface laser device has the beneficial effects that according to the disclosed DIN type interface laser device, the dimensional design of the DIN type interface laser device is more reasonable, the lateral deviation and angular deviation of an inserting part and a ceramic core can be effectively reduced, and an optical signal output by the DINA type interface laser device can be conductedoutside in a low-attenuation manner.

Owner:THE 44TH INST OF CHINA ELECTRONICS TECH GROUP CORP

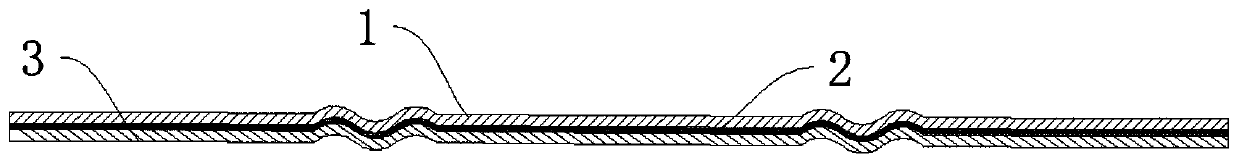

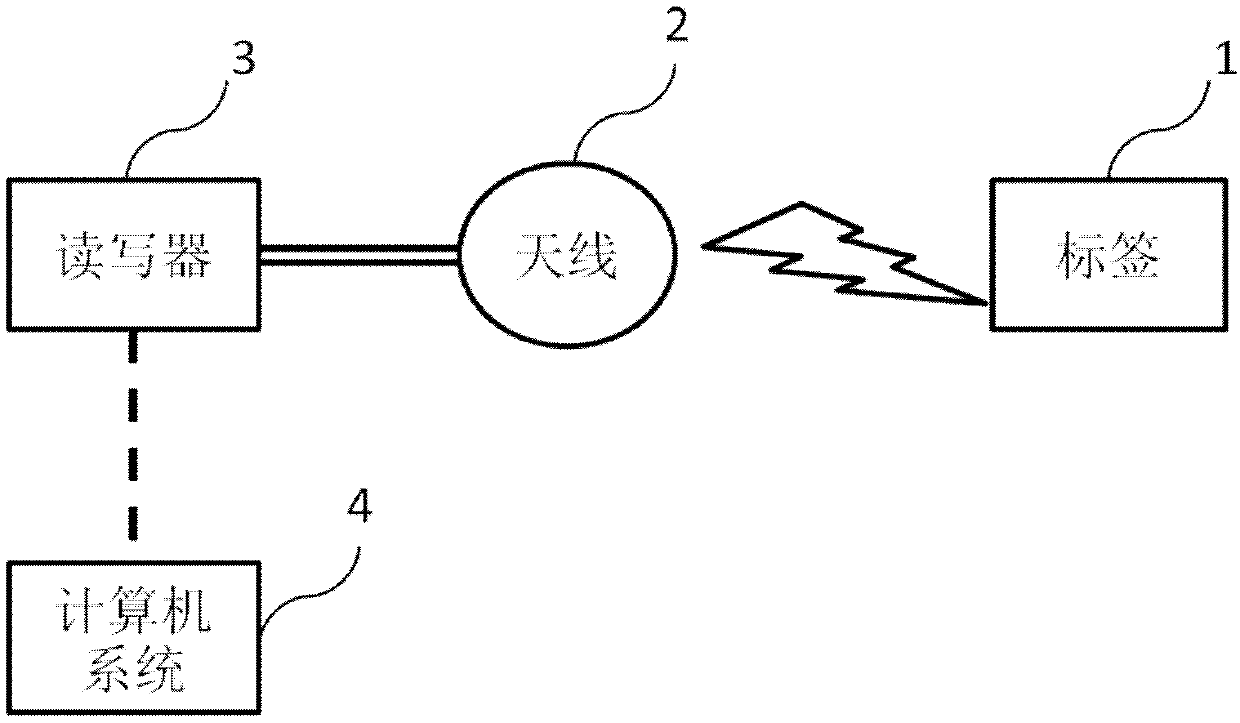

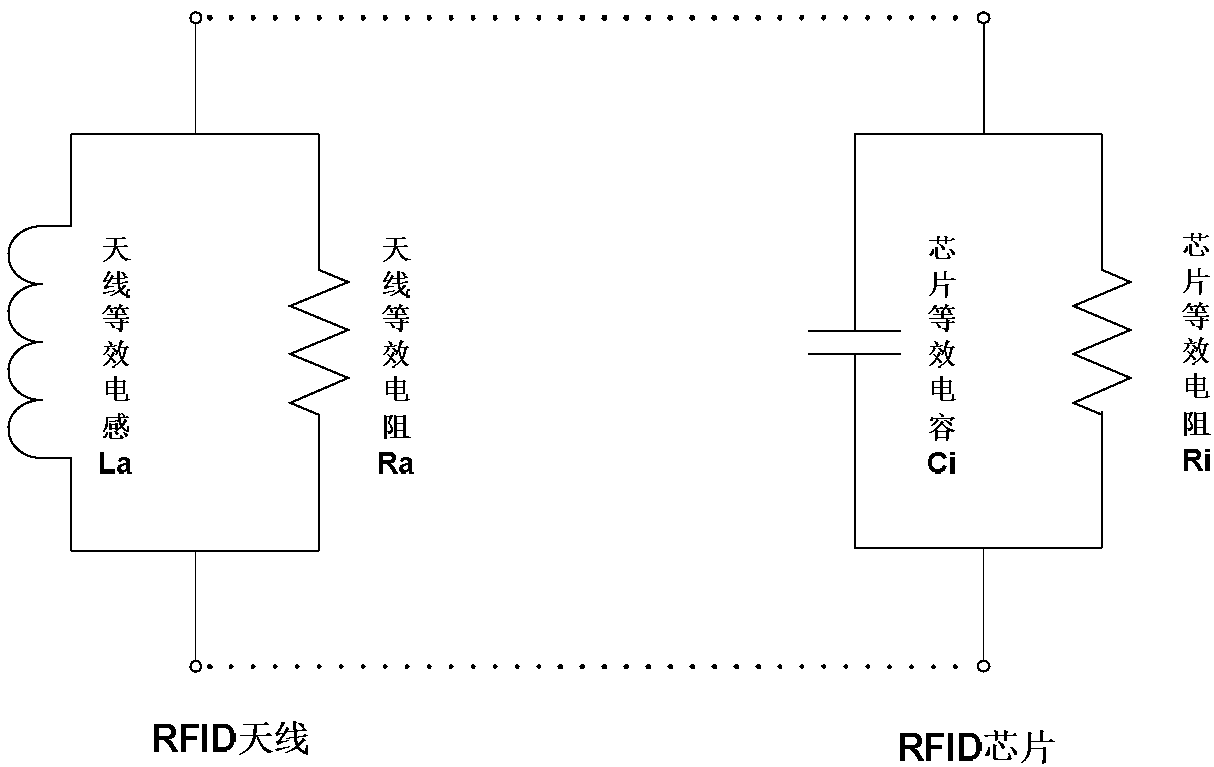

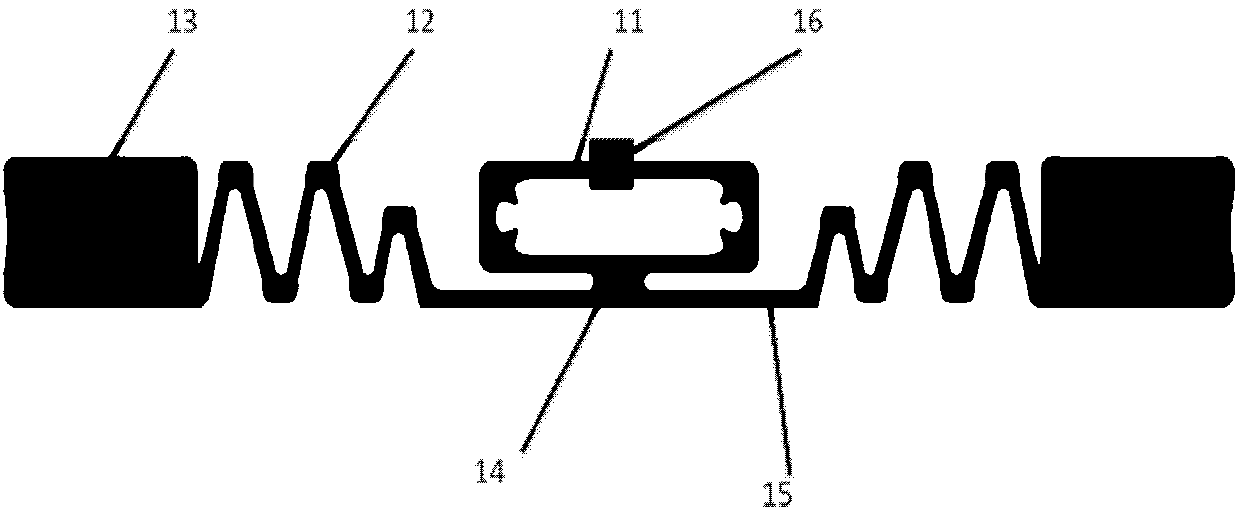

Broadband ultrahigh frequency electronic label and manufacturing method thereof

InactiveCN107633289AImpedance matchingImprove signal transmission efficiencyRecord carriers used with machinesMiniaturizationImpedance matching

The invention relates to a broadband ultrahigh frequency electronic label. The broadband ultrahigh frequency electronic label comprises a chip and antenna portion, wherein the antenna portion comprises a short cut ring, two bending radiators and two radiation arrays, the short cut ring is a rectangular ring structure, one ends of the two bending radiators are connected with the short cut ring, theother ends of the two bending radiators are connected with the two radiation arrays, the two bending radiators are multiple bending portions composed of multiple V-shaped structures with different heights, the two radiation arrays are arranged at the outer-most side of the antenna portion, the vertical dimension of each radiation array is not smaller than the vertical dimension of the bending radiator, the transverse dimension is greater than the transverse dimension of the single V-shaped structure, and the short cut ring is connected with a ground end and a radio frequency end of a radio frequency chip and is further taken as a feed end of the label antenna. The electronic label is advantaged in that difference of writing data power and reading data power is reduced, impedance matchingis realized, signal gain is improved, miniaturization is realized, and mechanical performance and service life are further improved.

Owner:BEIJING YISIDE LOGISTICS TECH

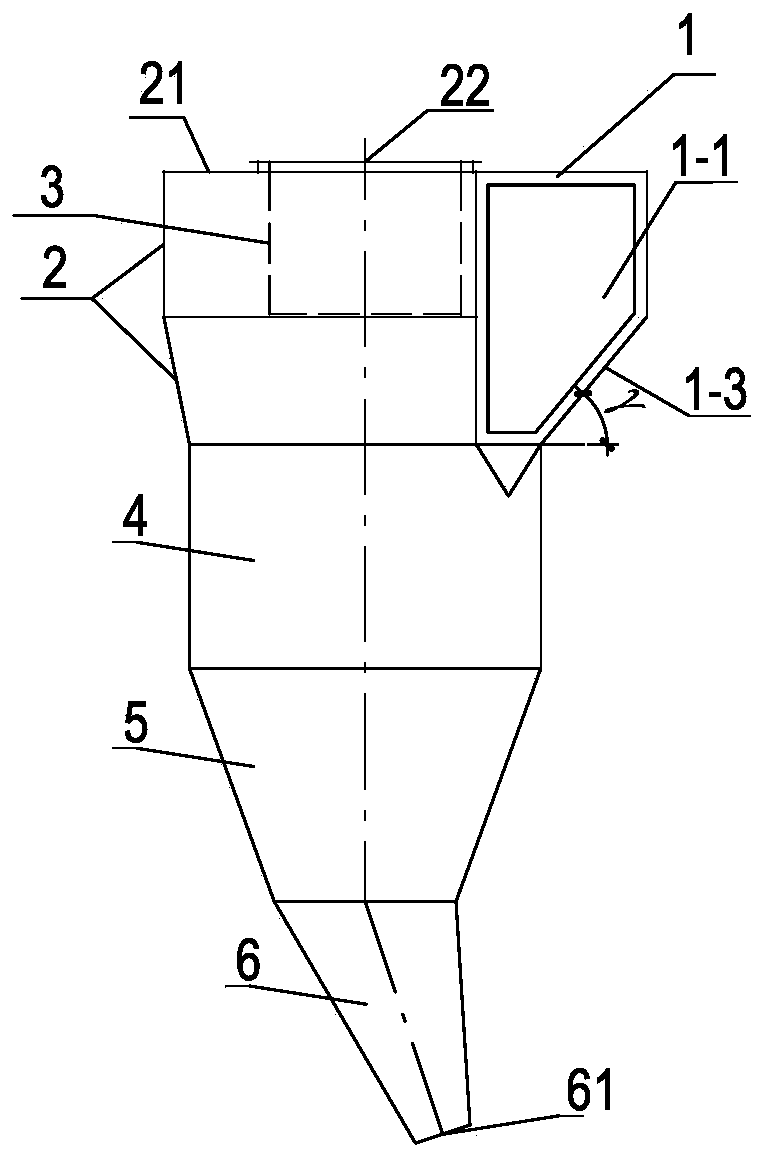

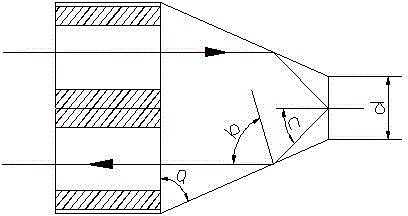

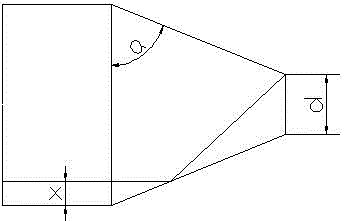

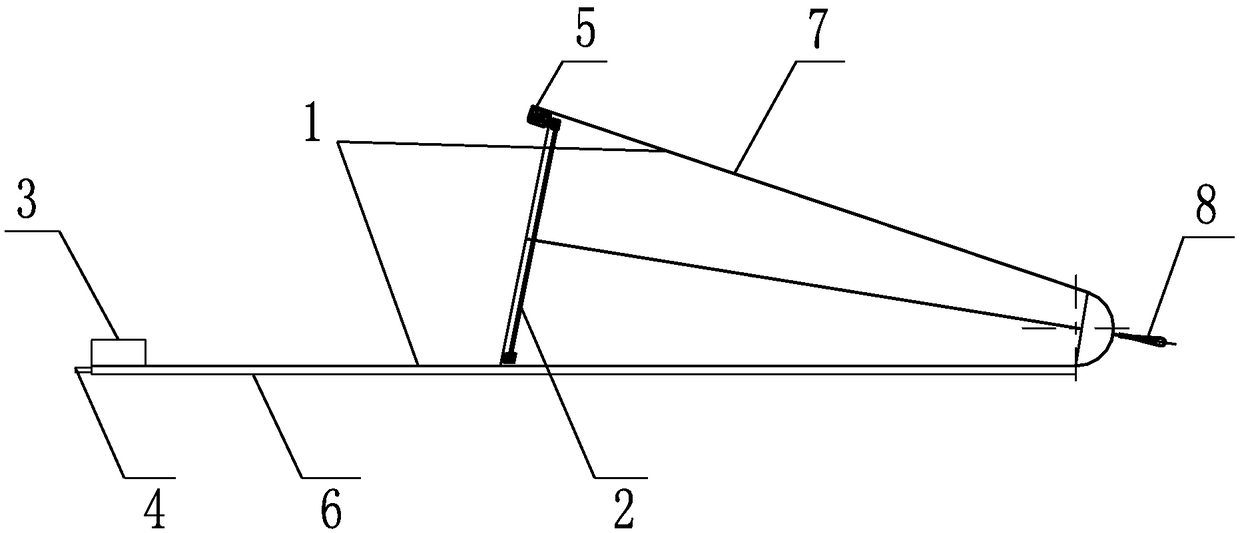

Efficient low-resistance cyclone and working method

PendingCN111167620AReduce resistanceImprove separation efficiencyReversed direction vortexStructural engineeringPipe

The invention belongs to the technical field of cement industrial production, and particularly relates to an efficient low-resistance cyclone and a working method thereof. The efficient low-resistancecyclone comprises an inlet air pipe, a volute body, an inner barrel, a cylinder body, an upper cone body and a lower cone body, wherein the inlet air pipe is arranged at an inlet of the volute body;the inlet air pipe is provided with an airflow inlet; the inner barrel is cylindrical, and the inner barrel and an airflow outlet are integrally welded in the volute body in a sleeved mode; the volutebody is of a three-center equal-height variable-angle volute structure formed by welding three arcs with different radii; a top cover is arranged at the top of the volute body; the airflow outlet isformed in the center of the top cover; the upper cone body and the lower cone body are sequentially connected below the cylinder body; and an outlet of the lower cone body is a discharging port. The efficient low-resistance cyclone and the working method thereof achieve the purpose that the resistance of the cyclone in a cement production line pre-decomposition system can still be greatly reducedon the premise that the separation efficiency is ensured, so that energy saving and consumption reduction are realized, and the resistance loss is lower than a common cyclone.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

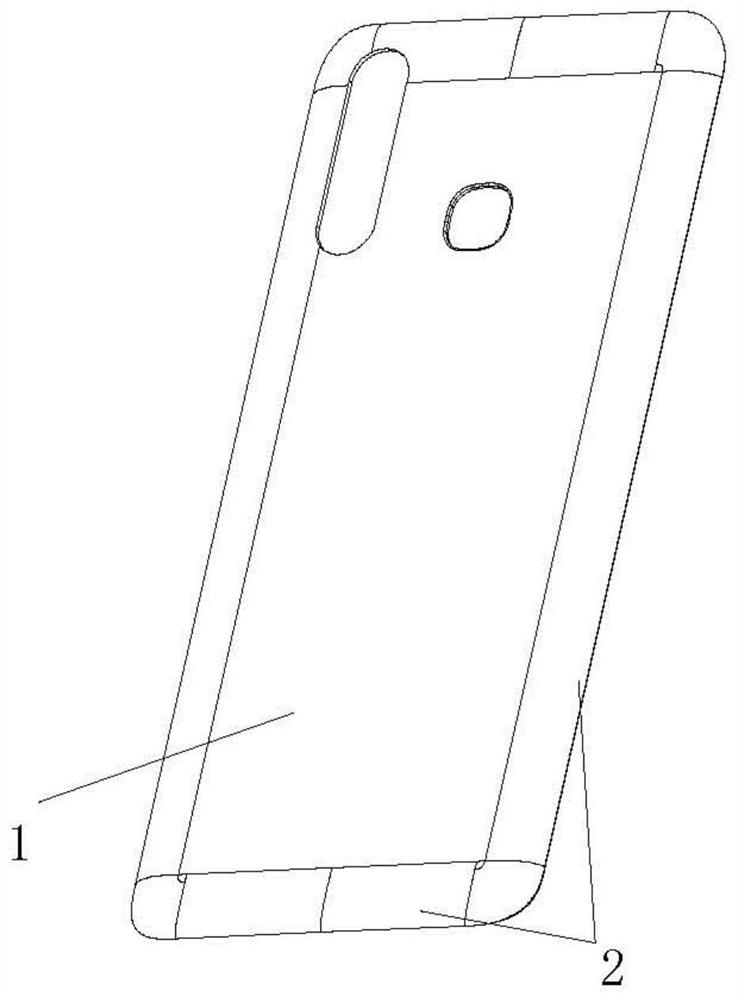

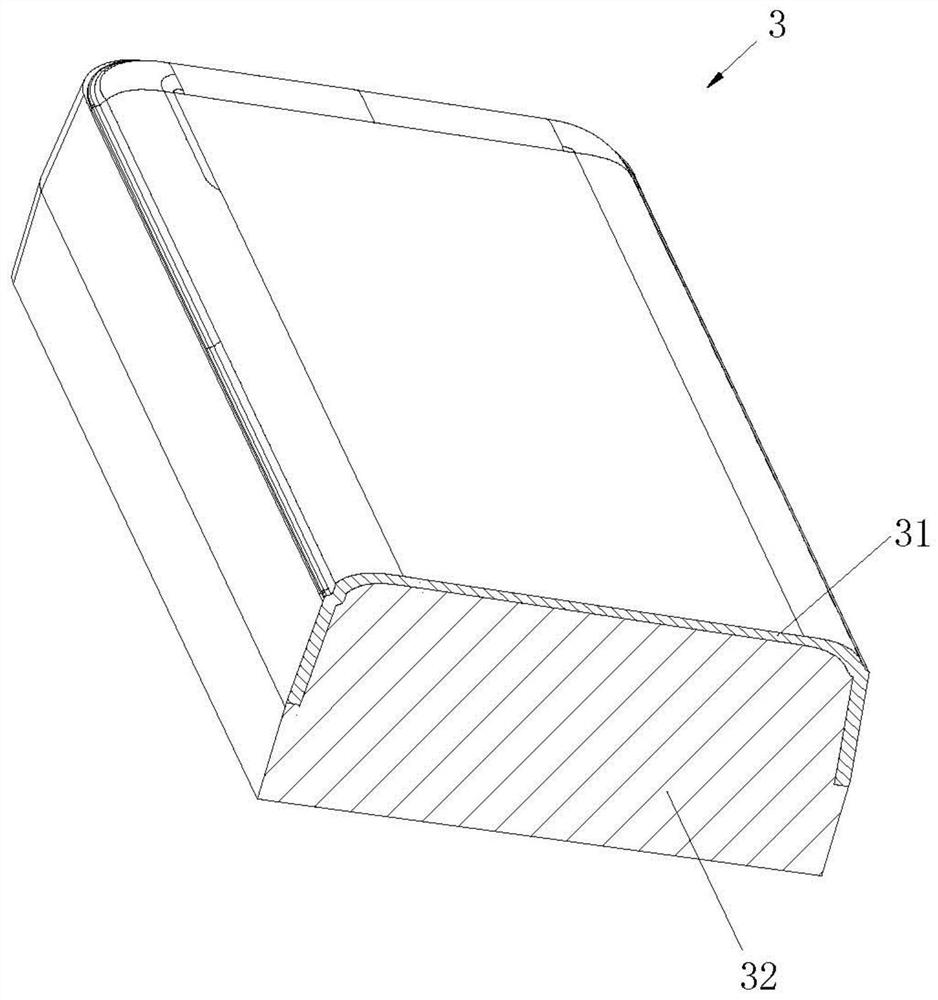

3D texture electroforming reprinting injection molding part, mold and process

PendingCN111873328AReasonable sizeReasonable designDomestic articlesTelephone set constructionsEngineeringLaser burn

The invention relates to the technical field of mobile phone back shells, in particular to a 3D texture electroforming reprinting injection molding part, mold and process. The mold comprises a front mold core and a rear mold core, a cavity used for forming the 3D texture electroforming reprinting injection molding part is formed between the front mold core and the rear mold core, and the rear moldcore comprises a base plate body and a texture forming plate body formed through electroforming reprinting. A convex part is formed on the surface of the texture forming plate body through electroforming reprinting, and the convex part is located in the cavity and used for forming an optical texture groove during injection molding. The base plate body is made of mold core steel, the texture forming plate body is made of nickel, and the texture forming plate body is connected to the surface of the base plate body. According to the 3D texture electroforming reprinting injection molding part, mold and process, the bottleneck of injection molding offset of a mold manufactured through a machining technology is broken through, the size precision of the optical texture groove of the injection molding part obtained through injection molding is improved, and meanwhile the problem of laser burning residues occurring when laser engraving is conducted on the texture groove is solved.

Owner:DONGGUAN TOPVIEW PLASTIC MFG

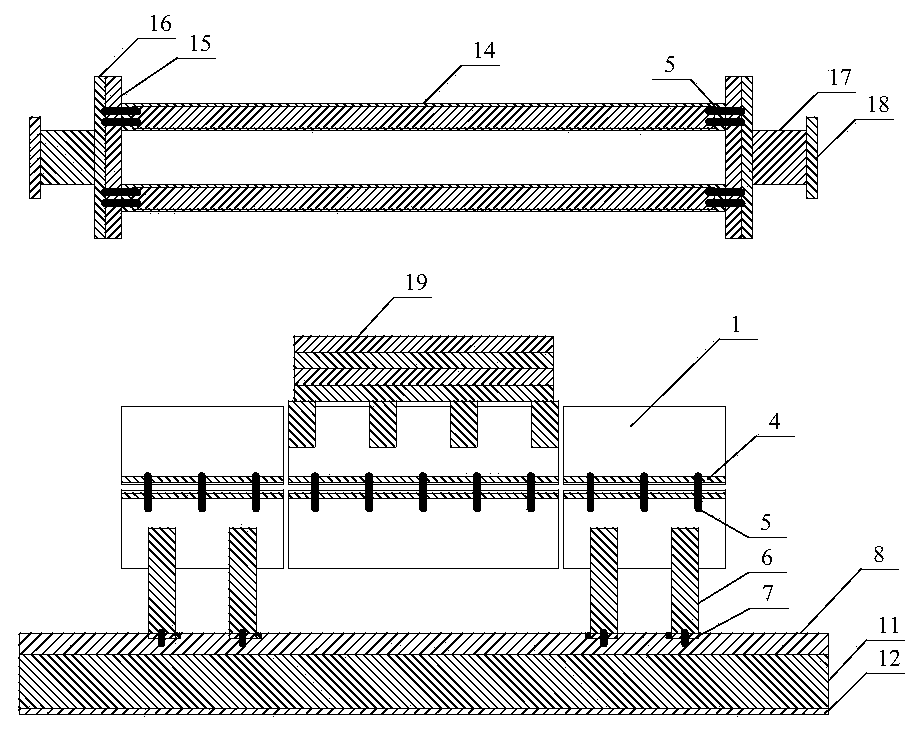

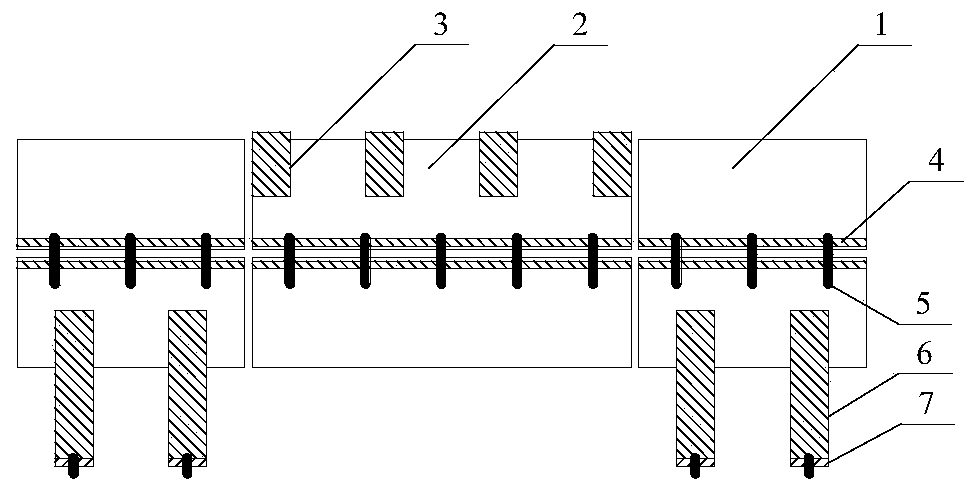

An anchor rod and anchor cable shear performance testing device and testing method

ActiveCN108387459BAvoid False Shear Strength ResultsLost or severely weakened tethering effectMaterial strength using steady shearing forcesEngineeringRock bolt

Owner:CHINA UNIV OF MINING & TECH +1

Multifunctional man-carrying intelligent luggage case

InactiveCN105935187AStrong handlingImprove portabilityLuggageOther accessoriesShortest distanceSubway station

The invention discloses a multifunctional man-carrying intelligent luggage case. The multifunctional man-carrying intelligent luggage case comprises a case body, a roller group and a pull bar; the box body comprises a top part, a bottom part and a lateral part, and the area of the top part and the area of the lateral part are respectively greater than or equal to the area of the lateral part; and the roller group is arranged at the bottom part. Preferably, the area of the top part and the area of the lateral part are respectively greater than the area of the lateral part. The multifunctional man-carrying intelligent luggage case has object accommodating, man carrying, electricizing and positioning functions, is suitable for realizing short-distance traffic transferring in the travel process, also provides a solving scheme for solving the short-distance traffic problem of the last 1km from a subway station to home or to the office room, and makes people conveniently trip.

Owner:易强

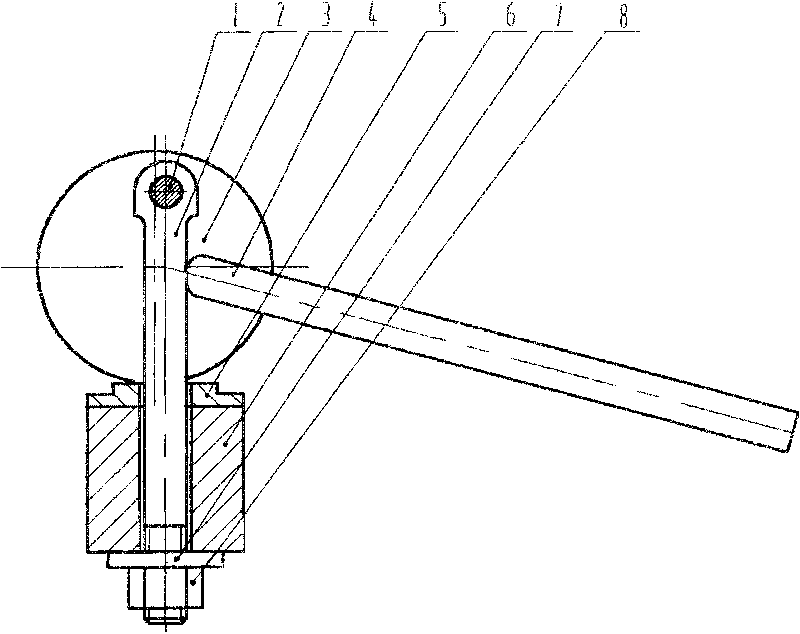

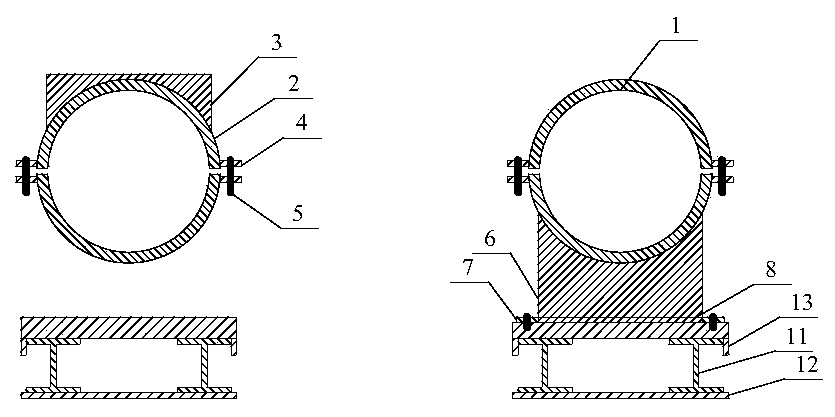

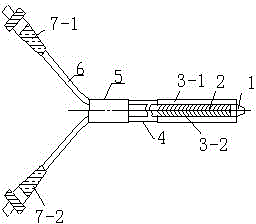

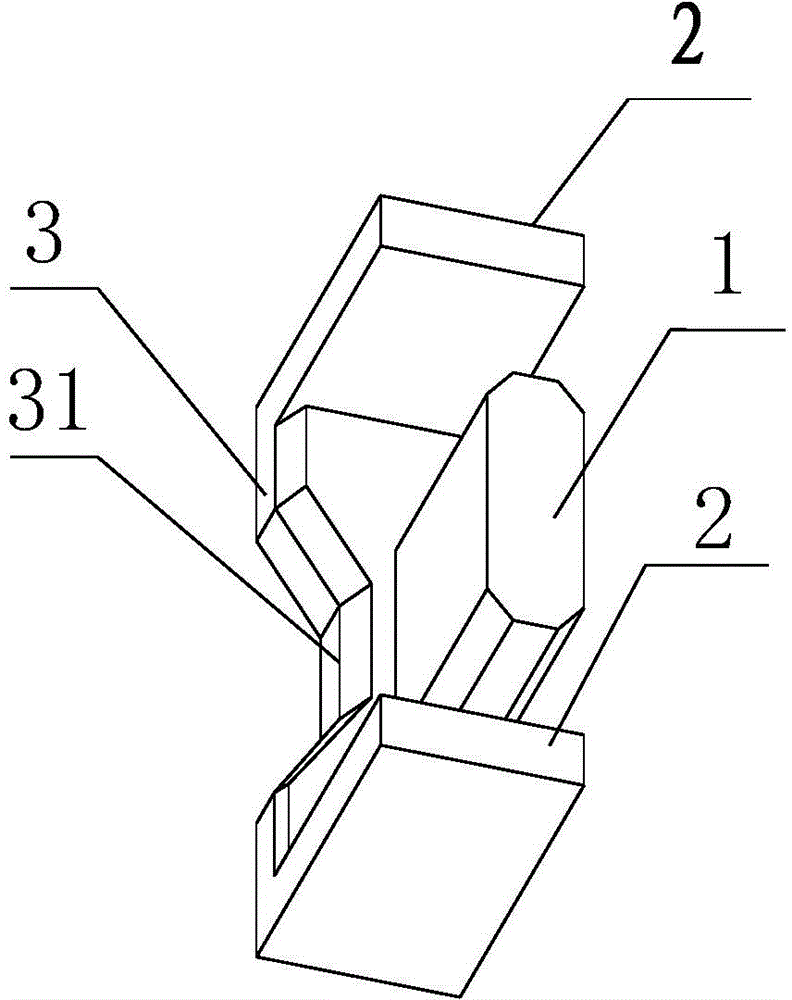

Intermediate-infrared hollow optical fiber ATR coupling probe

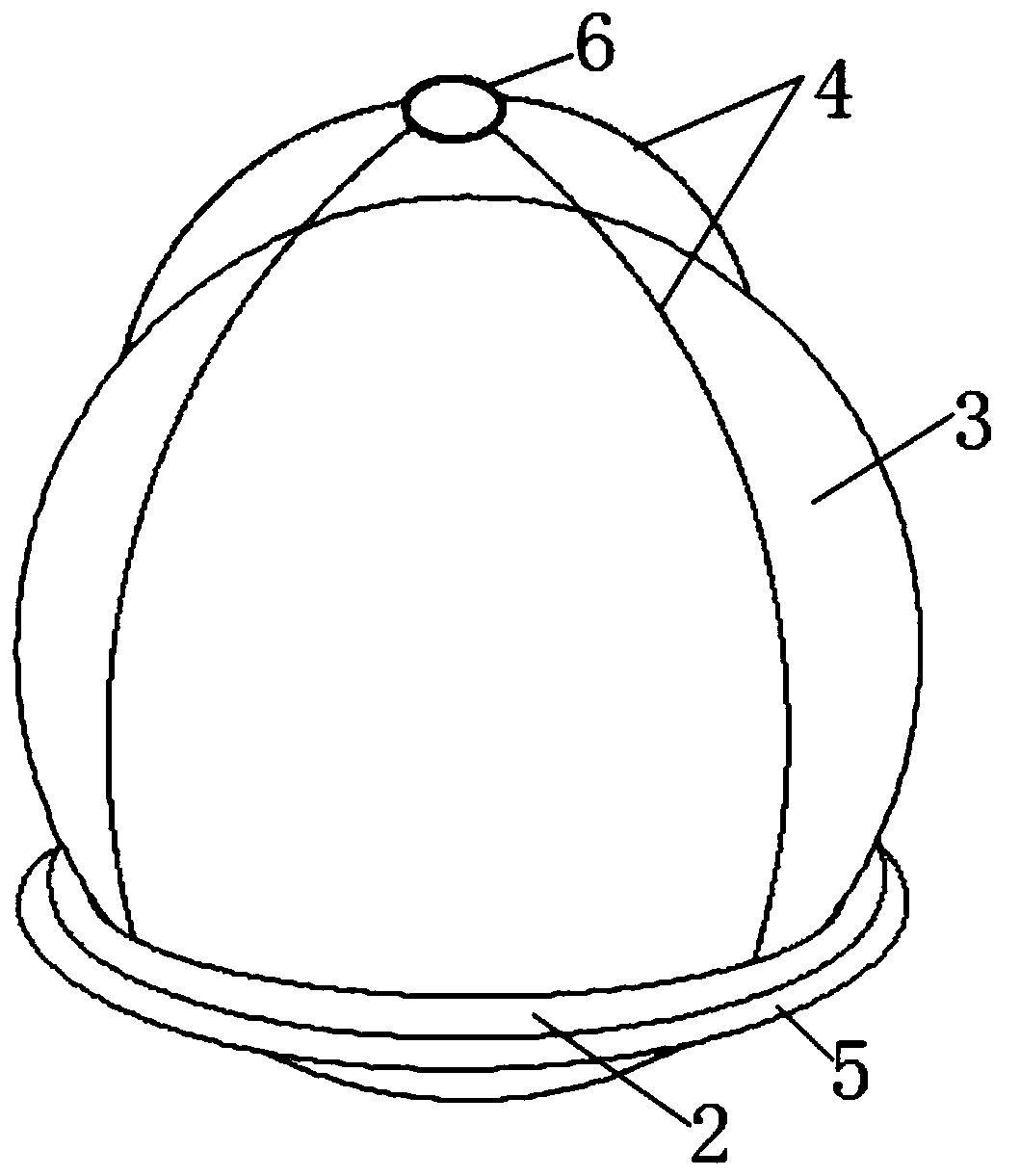

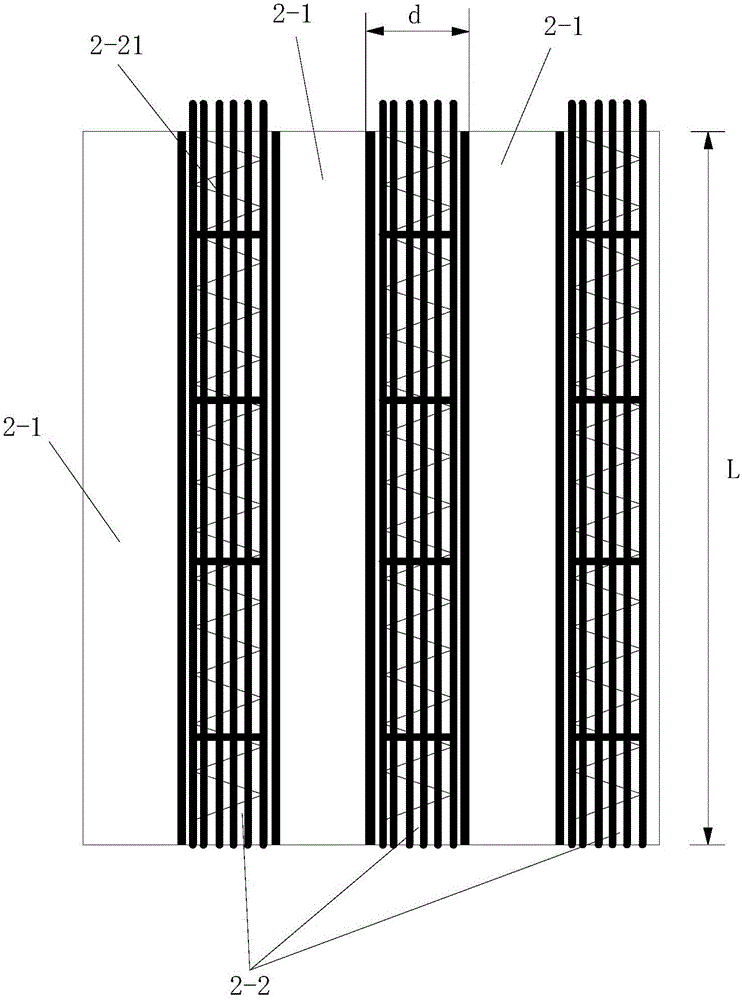

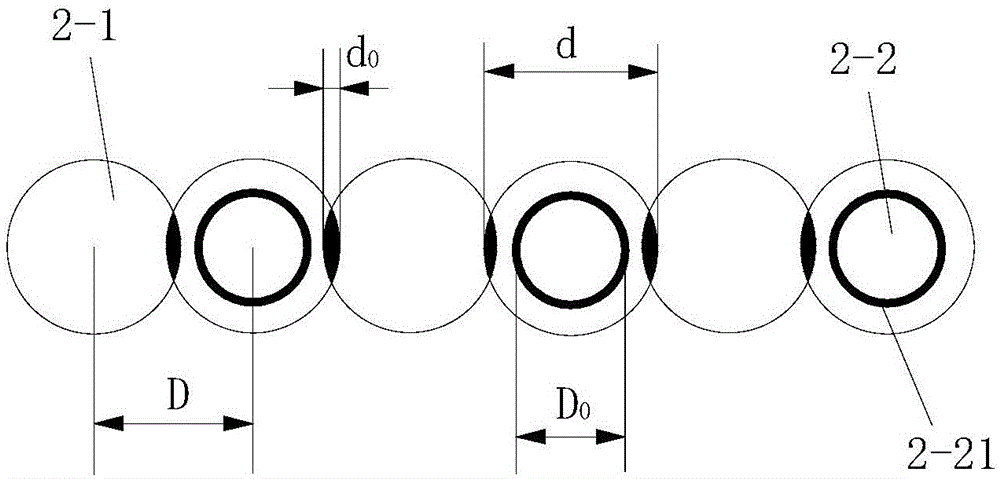

ActiveCN104535539AFlexible operationEasy to operateMaterial analysis by optical meansCouplingPhotonics

The invention discloses an intermediate-infrared hollow optical fiber ATR coupling probe and belongs to the technical fields of biomedical photonics and molecular spectrometric measurement and devices. The intermediate-infrared hollow optical fiber ATR coupling probe comprises an ATR crystal probe (1), an incident optical fiber (2-1), an emergent optical fiber (2-2), a handle cover (3), a dual-optical-fiber protective layer (4), a single-optical-fiber protective layer (6), a connecting sleeve (5), an incident optical fiber jumper (7-1) and an emergent optical fiber jumper (7-2). With the adoption of a method for coupling an intermediate-infrared hollow optical fiber and a ZnSe crystal probe, the probe is flexible and convenient due to reasonable design, small-area single-point detection and in-situ measurement can be realized, spectral deformation caused by factors such as light scattering is avoided, the infrared spectroscopy quality is improved, the probe is suitable for in-vivo detection or living body detection and has wide application prospects in the field of biomedicines, and the application range of the ATR spectral measurement technology in the field of biomedical engineering is widened.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

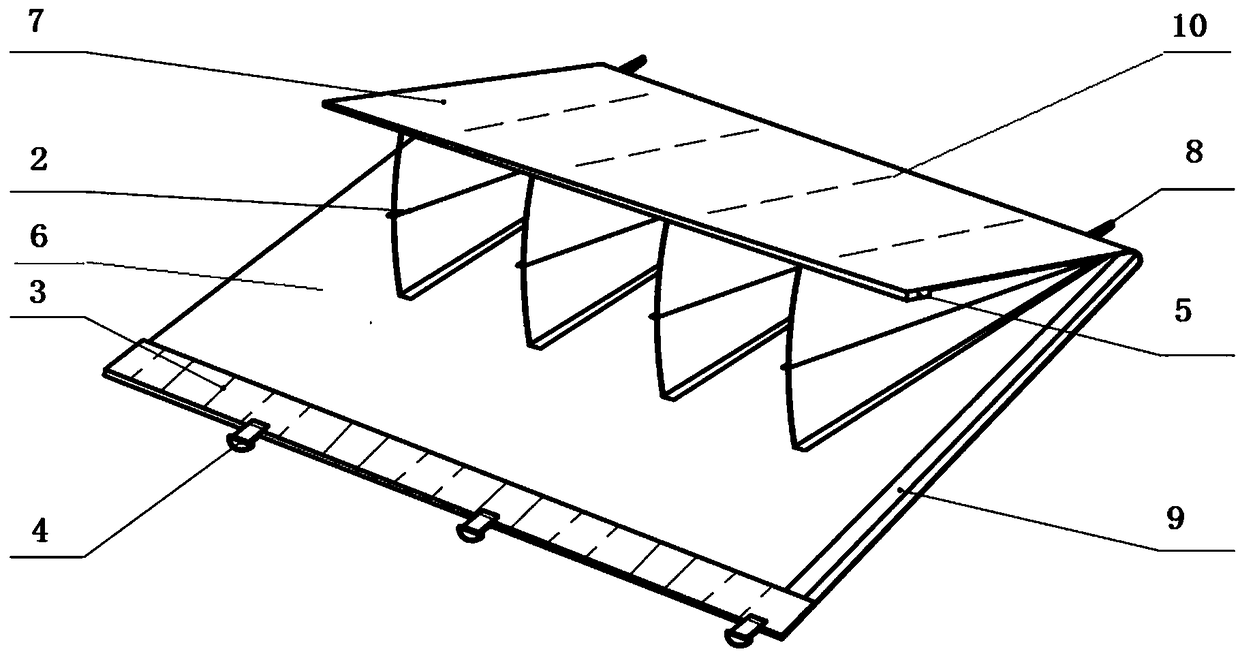

An intelligent portable flood protection belt and its application method

The invention relates to an intelligent portable flood control belt. The intelligent portable flood control belt comprises a fence, stretching cloth, a ballast fixture, fixing hasps and a floating part, wherein the fence comprises a first horizontal barrier part and a second horizontal barrier part; the first horizontal barrier part is in articulated connection with the second horizontal barrier part; a plurality of pieces of spaced foldable stretching cloth are arranged between the first horizontal barrier part and the second horizontal barrier part; water storage spaces formed between pieces of adjacent stretching cloth are located on a water facing side; the ballast fixture is fixedly arranged on the first horizontal barrier part; the fixing hasps are arranged on the ballast fixture and are used for fixing the ballast fixture; the ballast fixture and the fixing hasps are located on the water facing side; the floating part is fixedly arranged on the upper surface of the second horizontal barrier part. The intelligent portable flood control belt is simple in structure, reasonable in design, high in automation and intelligentization levels, low in maintenance cost, long in service life and convenient to mount and use, and can be widely applied to emergency usage of special conditions such as flood control regions and inspection well covers and the like.

Owner:BEIJING DRAINAGE EQUIP

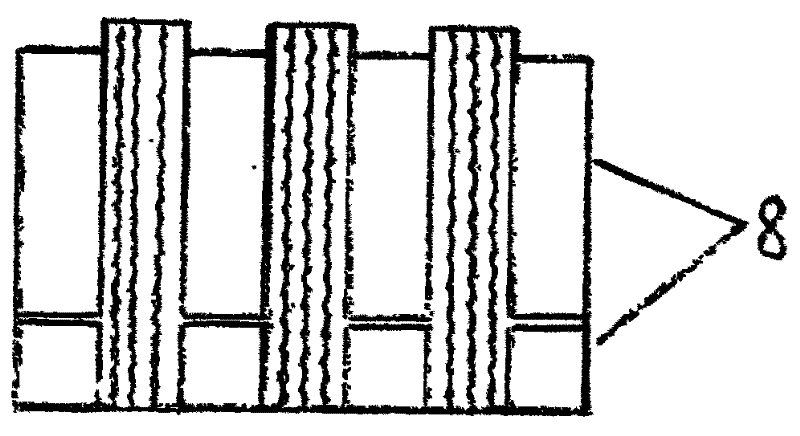

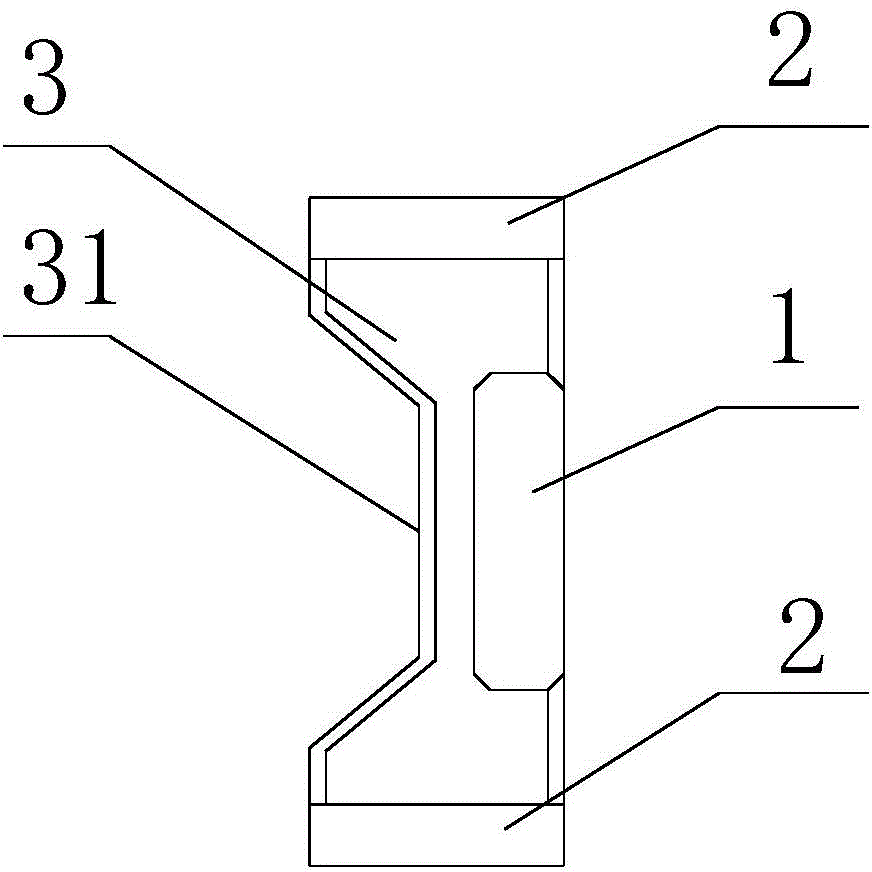

E-shaped bias magnetic core and circuit board using magnetic core

InactiveCN103985519AReasonable size designImprove stabilityTransformers/inductances magnetic coresPrinted circuit non-printed electric components associationConductor CoilElectrical and Electronics engineering

The invention discloses an E-shaped bias magnetic core. The section of the E-shaped bias magnetic core is E-shaped, a winding post is arranged at the middle part of a bottom plate, the length and width directions of the winding post are consistent with the length and width directions of the bottom plate, one side surface of the length direction of the winding post and one side surface of the length direction of the bottom plate are on the same plane, a trapezoidal opening which extends from the middle part to one side far away from the winding post is formed in the bottom plate, the lower base of the trapezoidal opening is far away from the winding post relative to the upper base of the trapezoidal opening, the length of the upper base of the trapezoidal opening is smaller than the length of the winding post, the length of the lower base of the trapezoidal opening is greater than the length of the winding post, the distance from the winding post to the upper base of the trapezoidal opening is smaller than the width of the winding post, the side edges of the winding post are chamfered and the edges of the upper surface of the bottom plate are chamfered. The E-shaped bias magnetic core disclosed by the invention has the advantages that the dimension design is reasonable, the effective working area of the magnetic core is large, the stability and the reliability of the electromagnetic property of the magnetic core are high and the coil is easy to wind. The invention additionally discloses a circuit board, which uses the E-shaped bias magnetic core.

Owner:ANHUI HUALIN MAGNETIC TECH

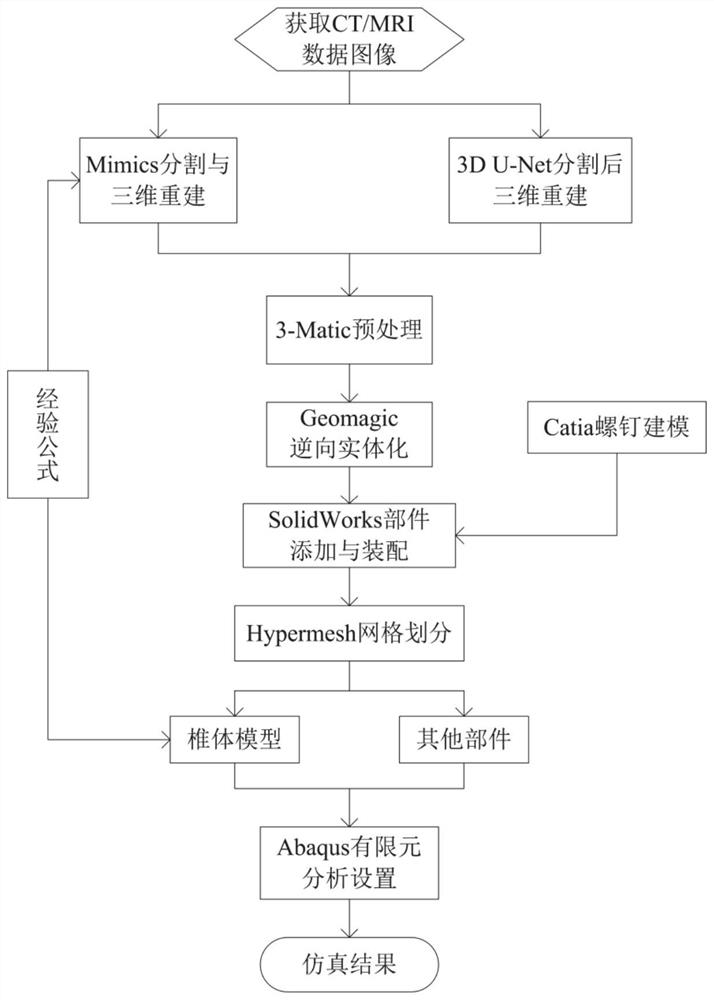

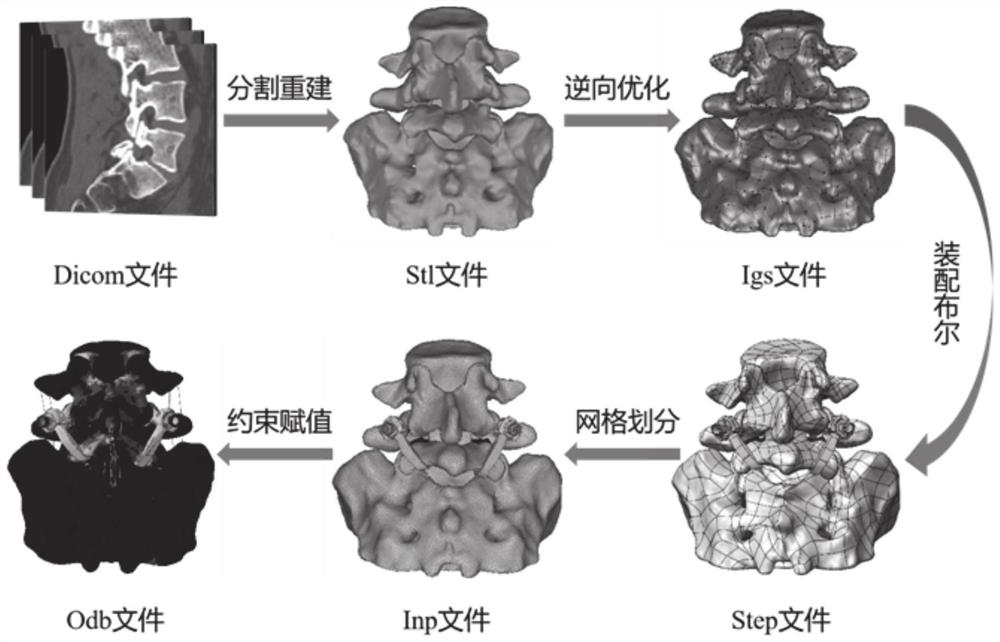

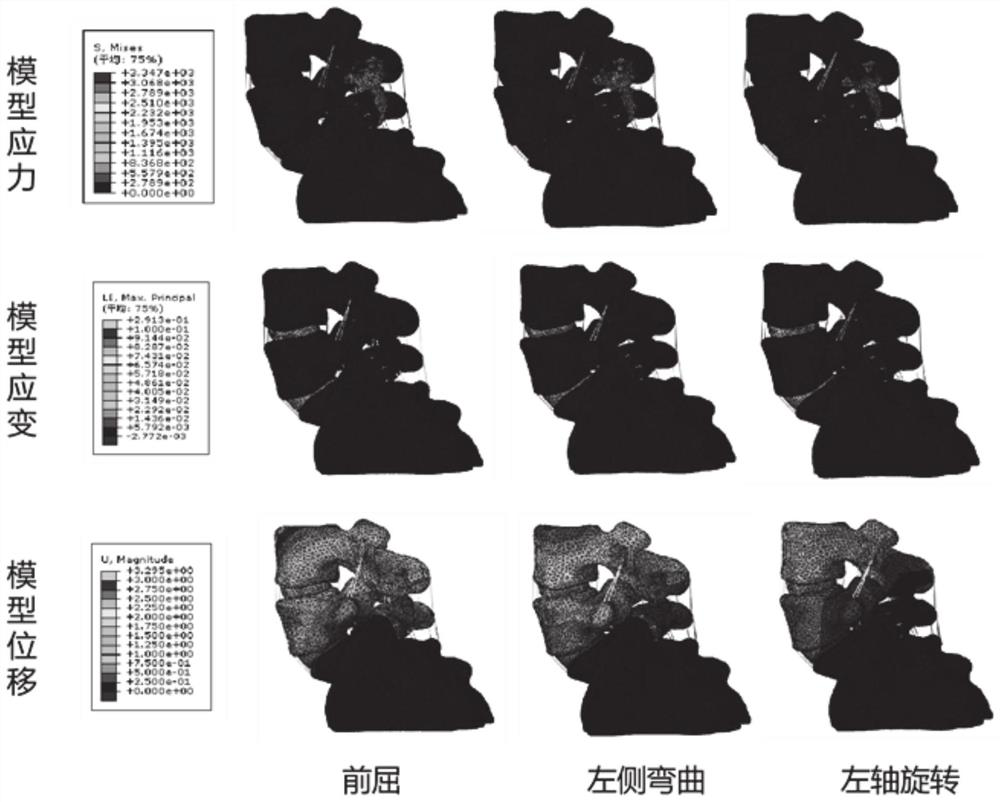

Simulation method and system of lumbar spondylolysis screw vertebral plate hook internal fixation system

PendingCN114429533AStrong simulation reductionHigh precisionMedical simulationMechanical/radiation/invasive therapiesElement analysisLumbar vertebrae

The invention provides a simulation method and system for a lumbar spondylolysis screw vertebral plate hook internal fixation system. The simulation method comprises the following steps: acquiring image data from the lumbar vertebra to the sacral vertebrae; segmenting and reconstructing the acquired image data to obtain a vertebral body three-dimensional model accompanied with lumbar spondylolysis; the three-dimensional model of the vertebral body is preprocessed; performing reverse materialization processing on the preprocessed cone three-dimensional model to obtain a cone curved surface model; according to the obtained vertebral body curved surface model, adding and assembling components of the lumbar spondylolysis screw vertebral plate hook internal fixation system to obtain an assembled curved surface model; performing grid division on each part to obtain a three-dimensional body grid of each part; carrying out material attribute assignment on the three-dimensional body mesh of the cone model by adopting an empirical formula; performing finite element analysis on the three-dimensional body mesh after material attribute assignment to obtain a simulation result; according to the invention, based on finite element analysis, more accurate analogue simulation of the lumbar spondylolysis screw vertebral plate hook internal fixation system is realized.

Owner:SHANDONG NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com