Design and verification method of winding coil of magnetic suspension linear motor

A winding coil and linear motor technology, applied to the shape/style/structure of winding conductors, can solve the problems of high cost and long manufacturing cycle of magnetic levitation linear motors, achieve reasonable size design and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

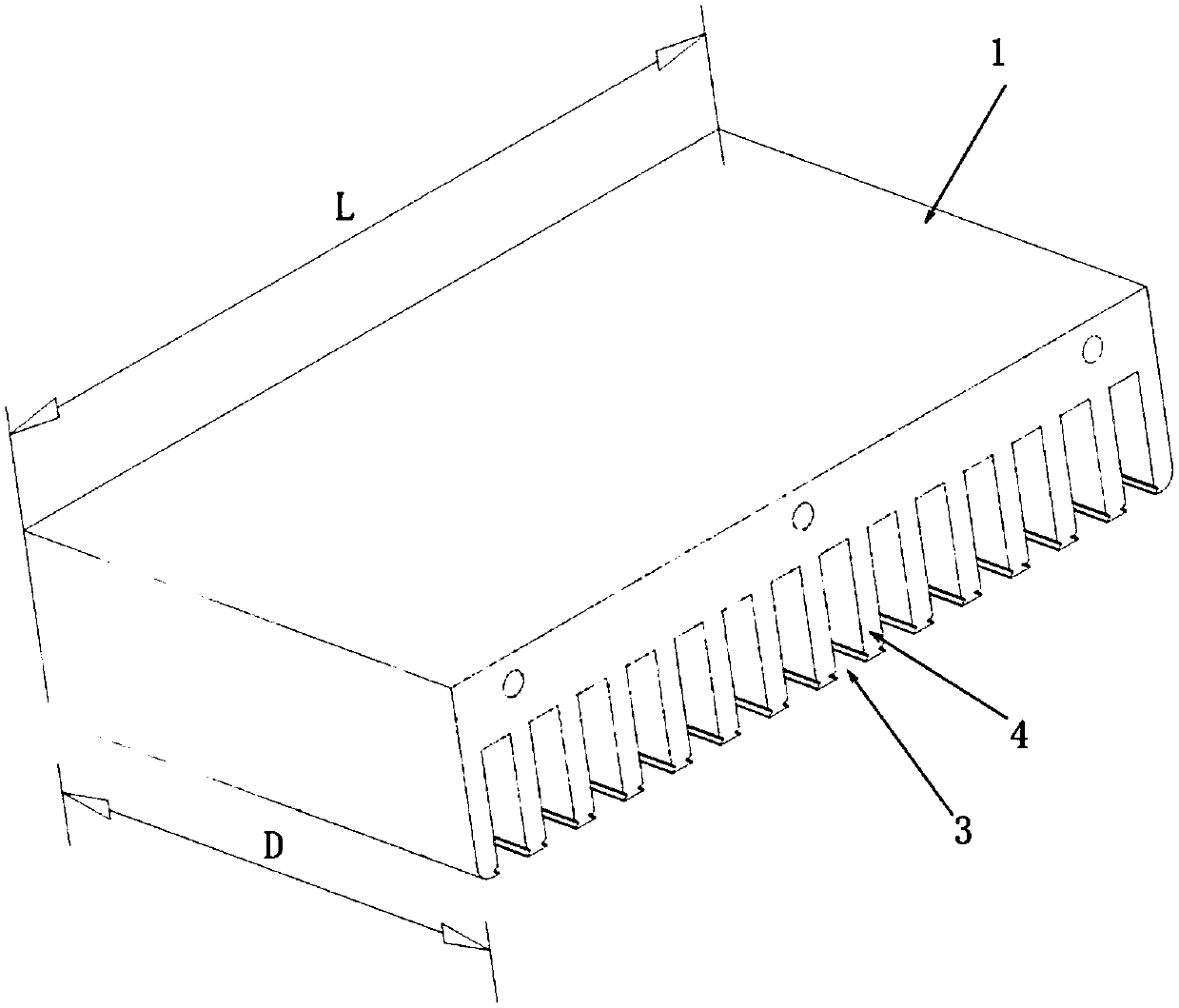

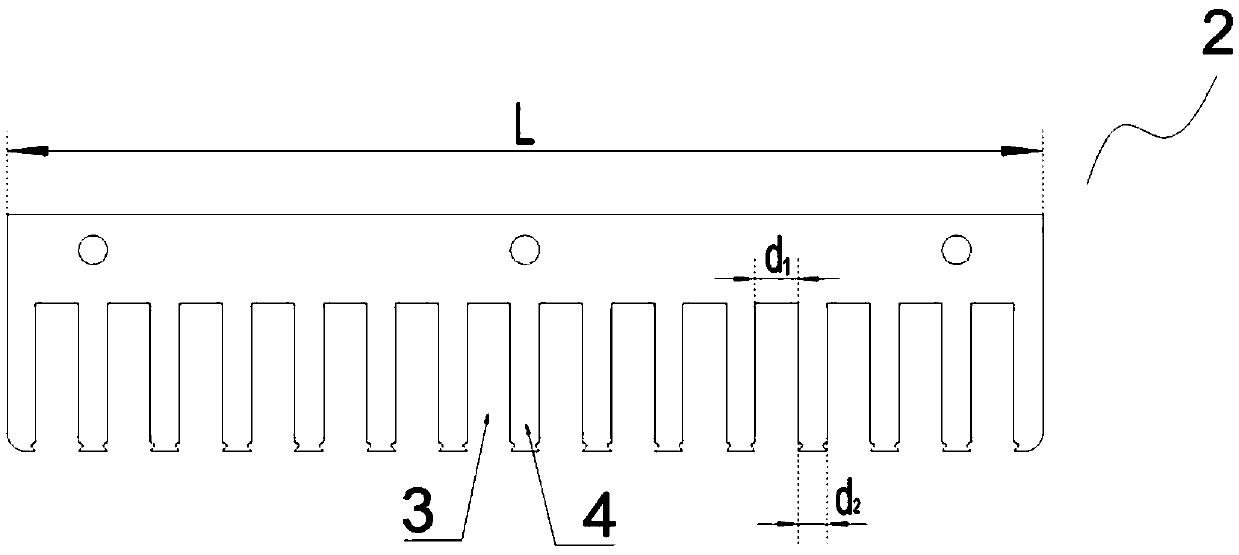

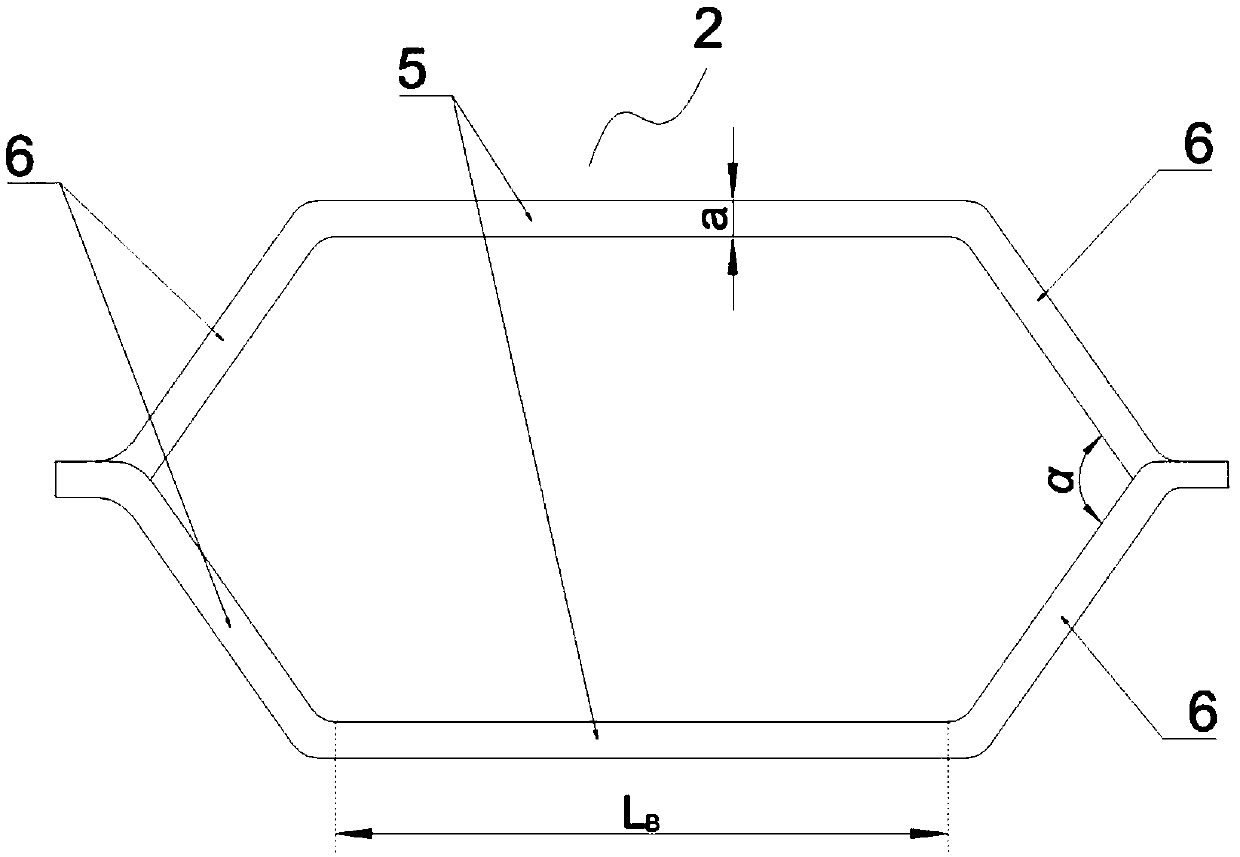

[0020] The design and verification method of the winding coil of a magnetic levitation linear motor of the present invention first calculates the theoretical design value of the primary stator core 1 and the winding coil 2 according to the design speed of the magnetic levitation train and the design principle of the linear motor, see Figure 1 ~ Figure 3 , where the theoretical design value of the stator core 1 includes the length L of the stator core, the width D of the stator core, and the width d of the stator slot 1 and the width d of the stator teeth 2 , the theoretical design value of the winding coil includes the coil half-turn length l c , the thickness a of the coil, the length L of the straight line part of the coil B And the angle α between the two hypotenuses of the isosceles triangle structure at the end of the winding coil, and the thickness of the coil a≤stator slot width d 1 , and then follow the steps below to verify the design:

[0021] (1) Compare whether...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com