Ventilation hole structure for rainproof type relay

A relay and ventilation hole technology, applied in relays, electromagnetic relays, electromagnetic relay detailed information, etc., can solve the problems affecting the working performance of the internal parts of the relay, reducing the waterproof ability of the relay, etc., to achieve the effect of simple design and improved rainproof ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

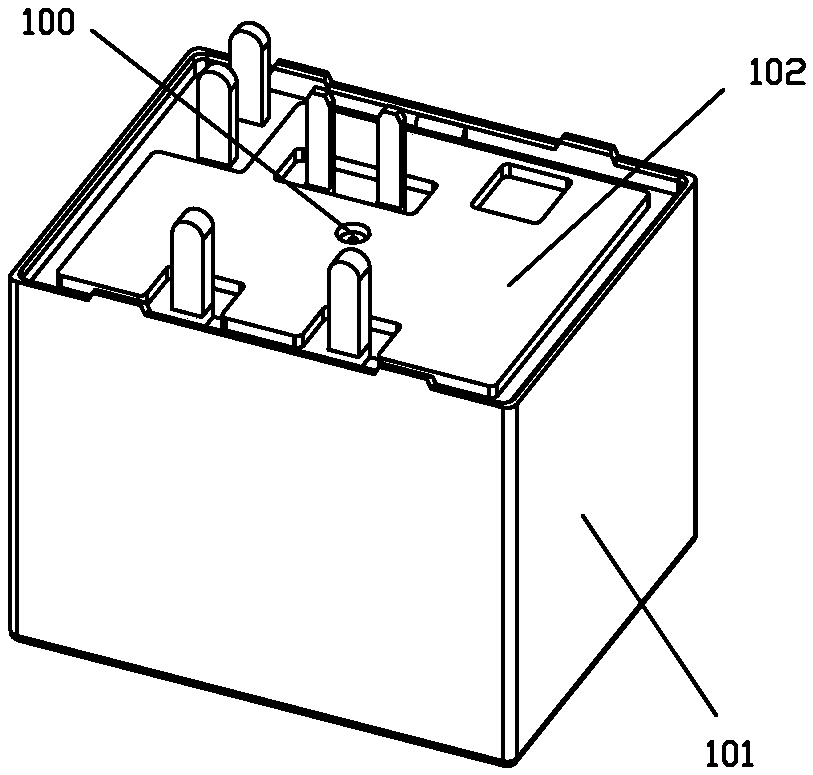

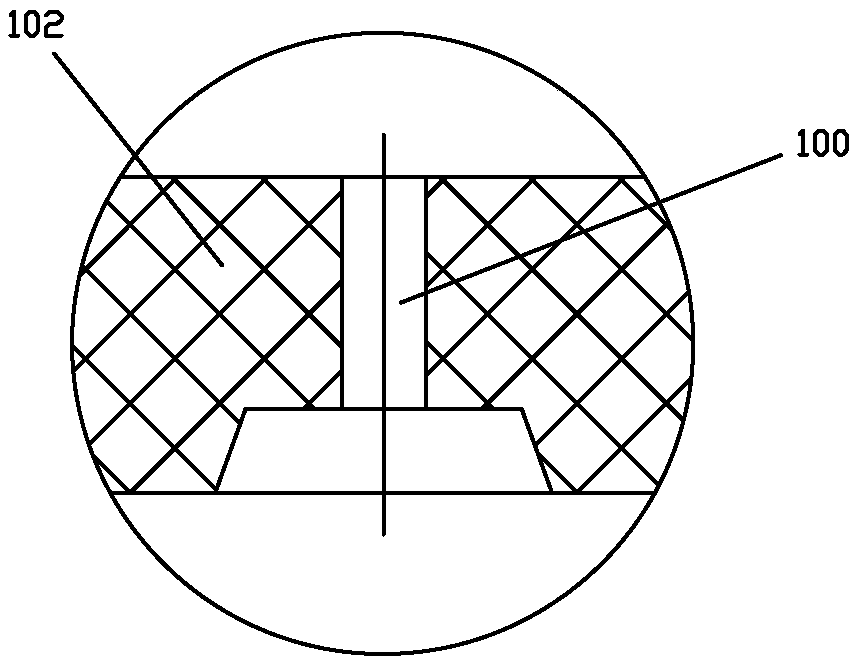

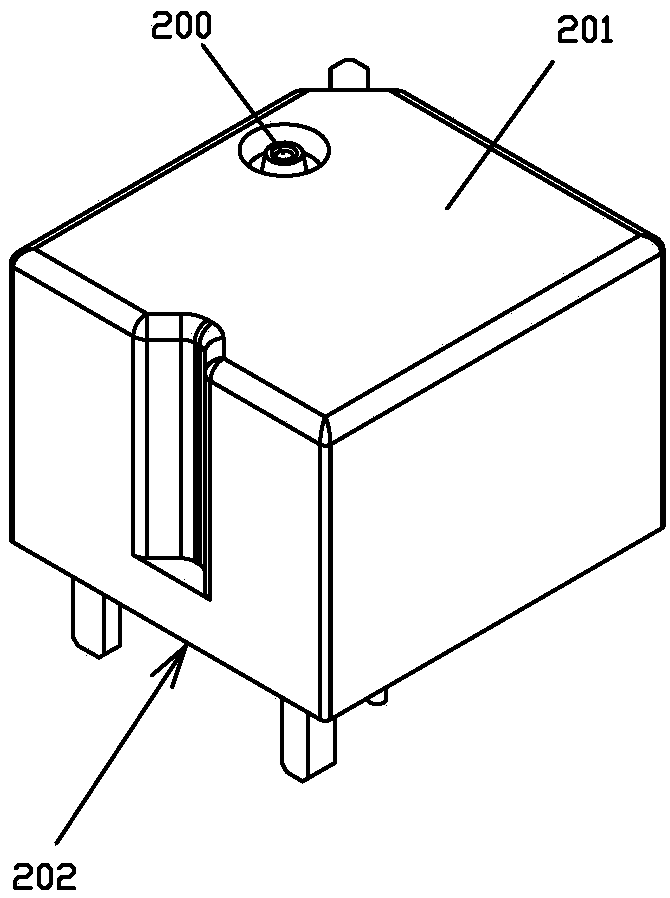

[0039] see Figure 5 to Figure 11 As shown, the ventilation hole structure of a rainproof relay of the present invention includes a housing 1 and a base 2; the housing 1 has a cavity 11 with an opening facing downward so as to accommodate the internal parts of the relay (such as the magnetic circuit of the relay parts, pushing parts, dynamic and static contacts, etc.); the base 2 is embedded in the bottom of the shell 1, that is, the base 2 is embedded in the bottom of the inner cavity 11 of the shell 1; The top extends downwards to form a vertical rib 12, the bottom surface of the rib 12 is provided with a groove 3 with the opening facing downward, and a through hole 13 is provided on one of the side walls of the housing 1, and the through hole 13 is connected to the The grooves 3 are connected, and the grooves 3 are configured as a structure with a large mouth and a small interior, and the through hole 13 and the groove 3 form a vent hole of the relay.

[0040] In this embo...

Embodiment 2

[0051] see Figure 12 to Figure 14 As shown, the air hole structure of a rainproof relay of the present invention differs from that of Embodiment 1 in that the inclined groove 32 is arranged on the outside, and the straight groove 31 is arranged on the inside.

Embodiment 3

[0053] see Figure 15 As shown, the air hole structure of a rainproof relay of the present invention differs from the first embodiment in that the housing 1 is a single shell structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com