High-strength energy-saving concrete load-bearing block

A technology of concrete and blocks, which is applied in the direction of building materials, can solve the problems of many thermal bridge points, small load-bearing surface, poor compressive capacity, etc., and achieve the effects of obvious heat insulation, reasonable size design structure, and good shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation of the high-strength energy-saving concrete load-bearing block according to the present invention, the structural functions, features and effects, will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

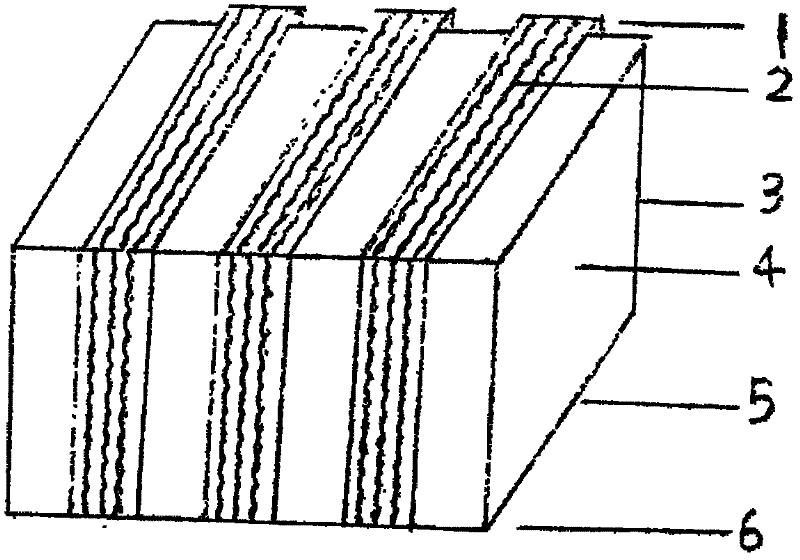

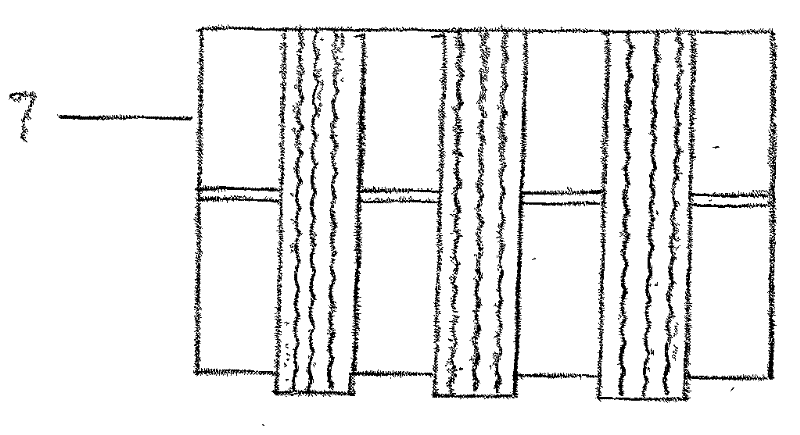

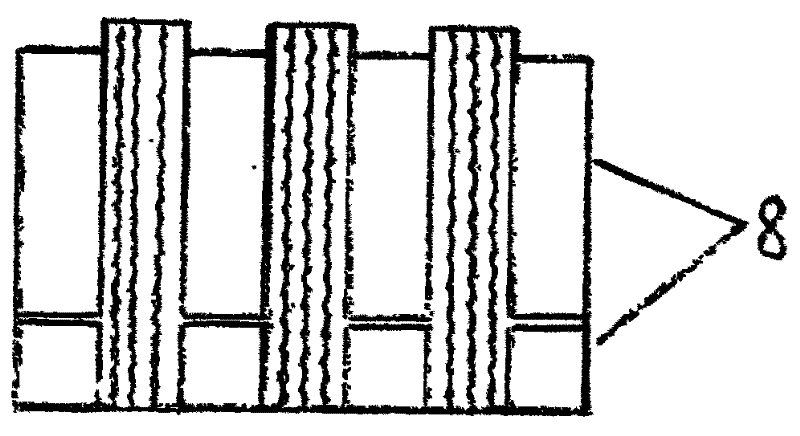

[0018] figure 1 Shown is the high-strength energy-saving concrete load-bearing block of the present invention, which is composed of 3 layers of insulation boards (2) and concrete, and the 3 layers of insulation boards are arranged in parallel in the concrete at intervals, and each layer of insulation boards is provided with 4-5 link holes ( 9, 10), the insulation board is fixed in the concrete through the connection holes, the connection holes of the adjacent two layers of insulation boards are staggered and not connected to each other, and the insulation board layer protrudes 1cm on one side of the block to form a mortar joint connected with other blocks (1). During masonry, the insulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com