Method of forming fiber-aluminum alloy composite part

A composite material and aluminum alloy technology, applied in the field of composite materials, can solve the problems of low elongation of fiber materials, achieve high specific strength, tight fit, and improve stiffness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

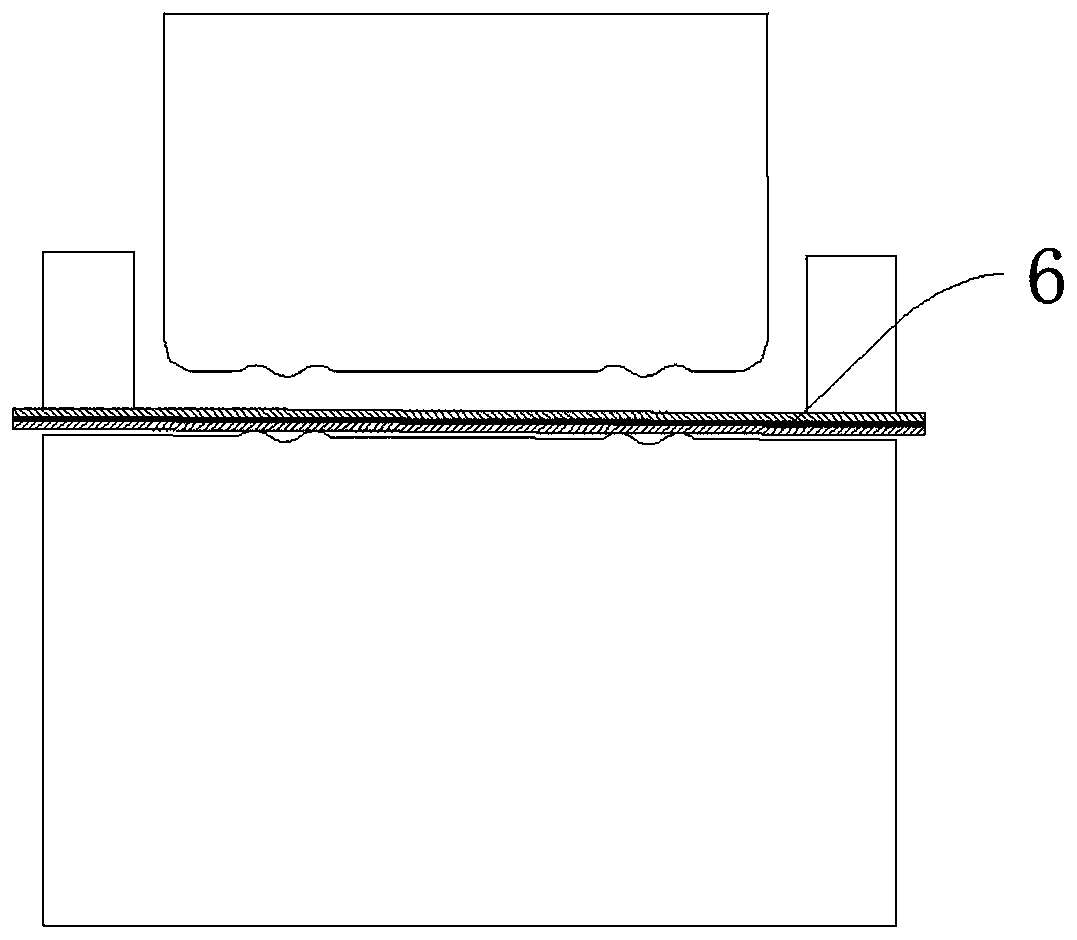

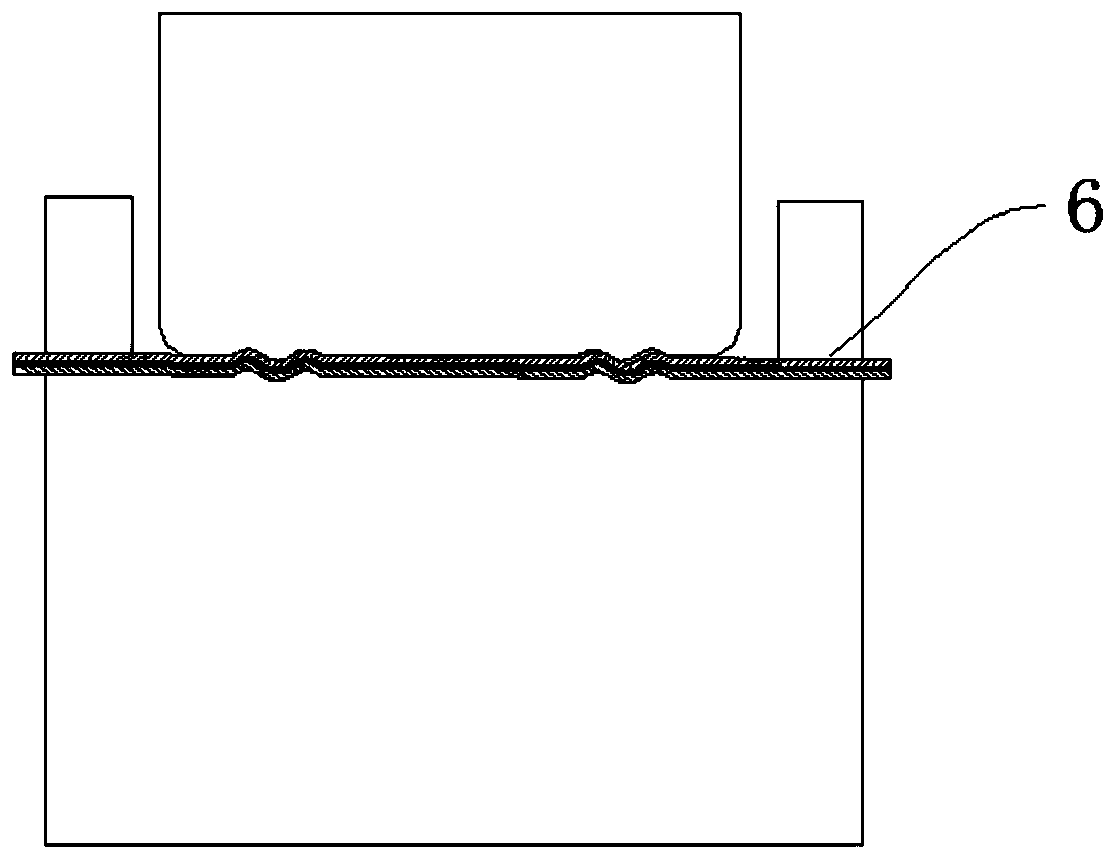

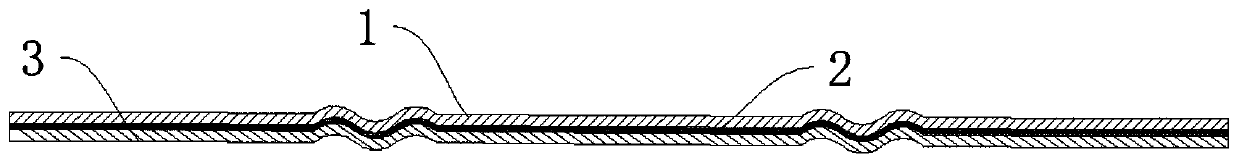

[0057] Please refer to figure 1 , with reference to figure 2 with Figure 5 , the embodiment of the present application provides a fiber-aluminum alloy composite part forming process, which can overcome the defect of low elongation of the fiber material in the stamping forming process, and can improve the strength of the fiber-aluminum alloy composite part.

[0058] The implementation steps of the process method for forming the fiber-aluminum alloy composite parts are as follows:

[0059] S1, according to the shape of the part, the aluminum alloy plate (including the first aluminum alloy plate 1 and the second aluminum alloy plate 3) and the fiber cloth 2 are cut according to the shape of the part to obtain a blank of 400 mm × 250 mm;

[0060] S2, performing solid solution treatment on the first aluminum alloy plate 1 and the second aluminum alloy plate 3 at 535° C. for 30 minutes, and immediately performing the first solid solution treatment on the first aluminum alloy pla...

no. 2 example

[0066] Please refer to Image 6 , with reference to the first embodiment figure 1 , figure 2 , Figure 4 as well as Figure 5 The embodiment of the present application provides another method for forming fiber-aluminum alloy composite parts, which can overcome the defect of low elongation of fiber materials during stamping and forming, and can improve the strength of fiber-aluminum alloy composite parts.

[0067] The implementation steps of the process method for forming the fiber-aluminum alloy composite parts are as follows:

[0068] S1, according to the shape of the part, the aluminum alloy plate (including the first aluminum alloy plate 1 and the second aluminum alloy plate 3) and the fiber cloth 2 are cut according to the shape of the part, and the blanks of 1000mm×500mm are respectively obtained;

[0069] S2, performing solid solution treatment on the first aluminum alloy plate 1 and the second aluminum alloy plate 3 at 535° C. for 30 minutes, and immediately perfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com