Downlight spring automatic assembling equipment

An automatic assembly and downlight technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problem of being unable to meet the development trend of high efficiency, high quality and low cost, difficult to choose between processing output and processing cost, and no automatic equipment for operation mode and other problems, to achieve the effect of simplified structure, high degree of automation and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

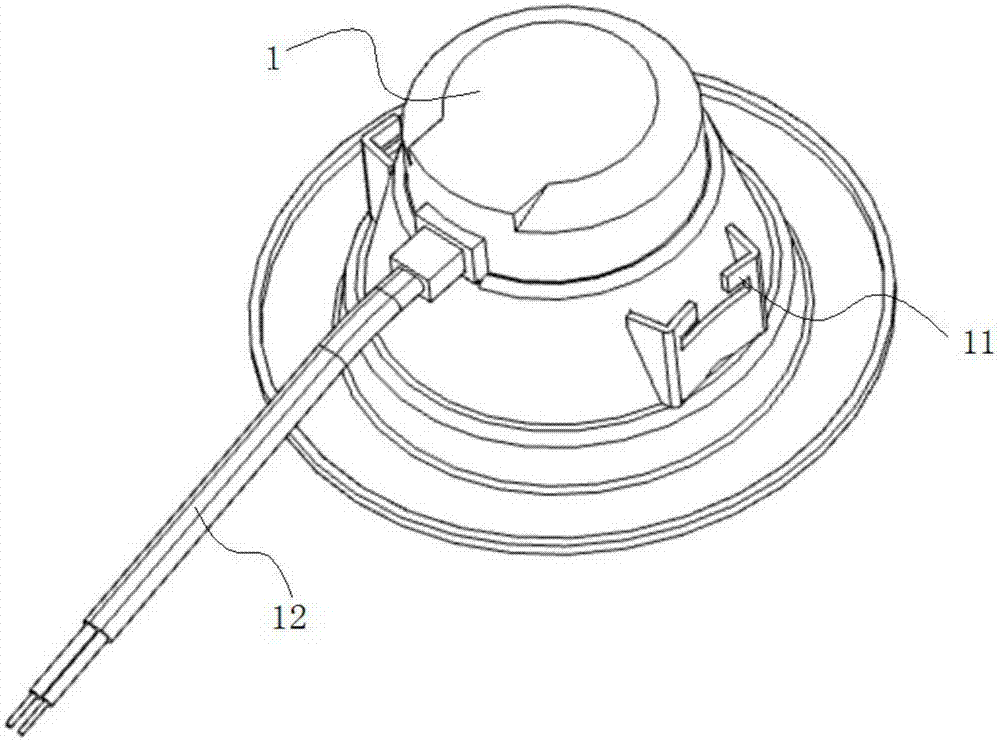

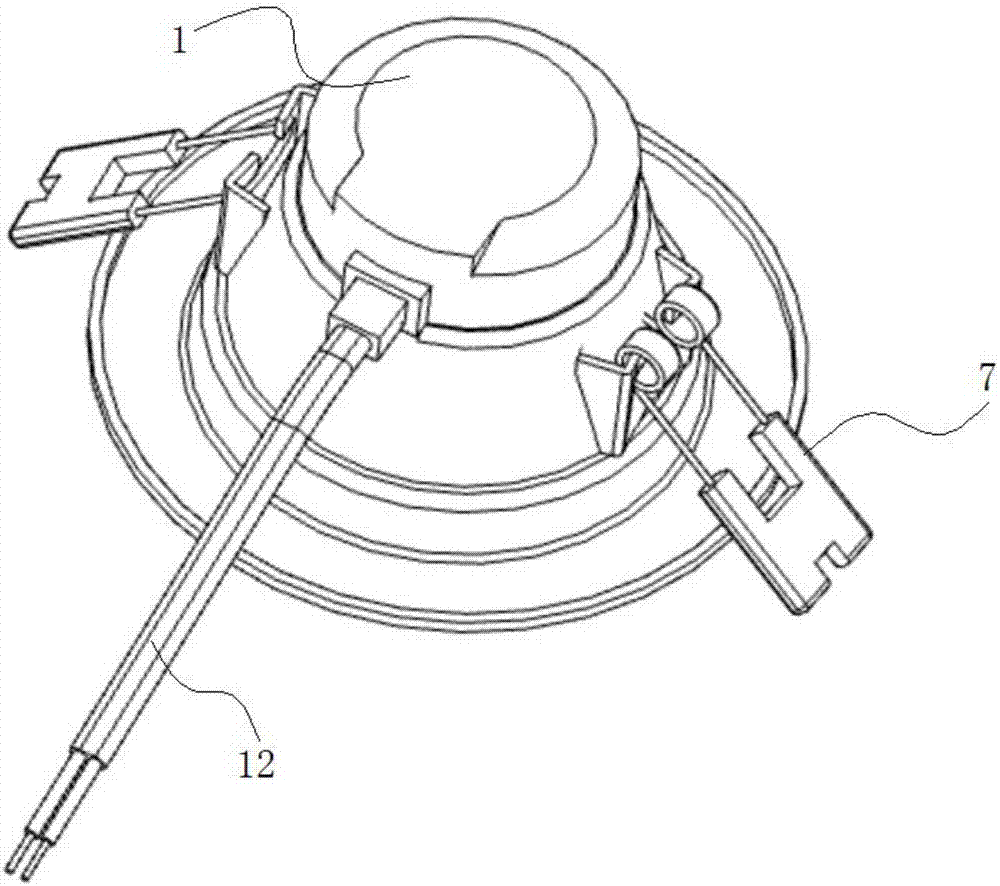

[0037] Embodiment: a kind of downlight spring automatic assembly equipment, such as Figure 1 to Figure 9 As shown, the outer walls of the left and right sides of the downlight 1 have spring slots 11 for installing springs, and the wires 12 of the downlight are backward, including a spring left and right automatic clamping device 2 and a spring front and rear automatic fork device 3. The clamping device is located on the left and right sides of the downlight and corresponds to the spring slot of the downlight, and the spring front and rear automatic shift fork device is located on the front side of the downlight;

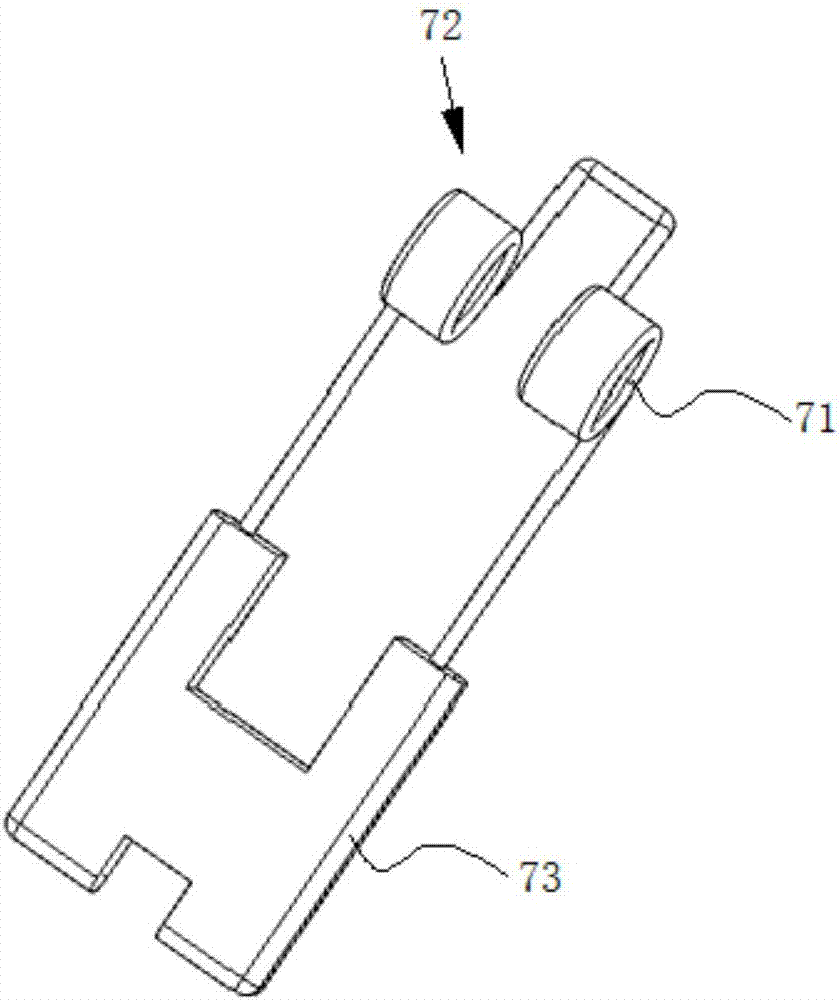

[0038] The left and right automatic clamping device of the spring includes a spring clamping mechanism 4 for clamping the spring, a spring close mechanism 5 for sending the spring close to the spring clamping groove, and a spring pushing mechanism 6 for pushing the spring into the spring clamping groove. Both the clamping mechanism and the spring pushing mechanism a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com