Chassis with bus structure

A bus structure and chassis technology, applied in the direction of support structure installation, etc., can solve the problems of low installation strength, inapplicability, failure, etc., to achieve the effect of satisfying installation reliability, improving assembly efficiency, and saving material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

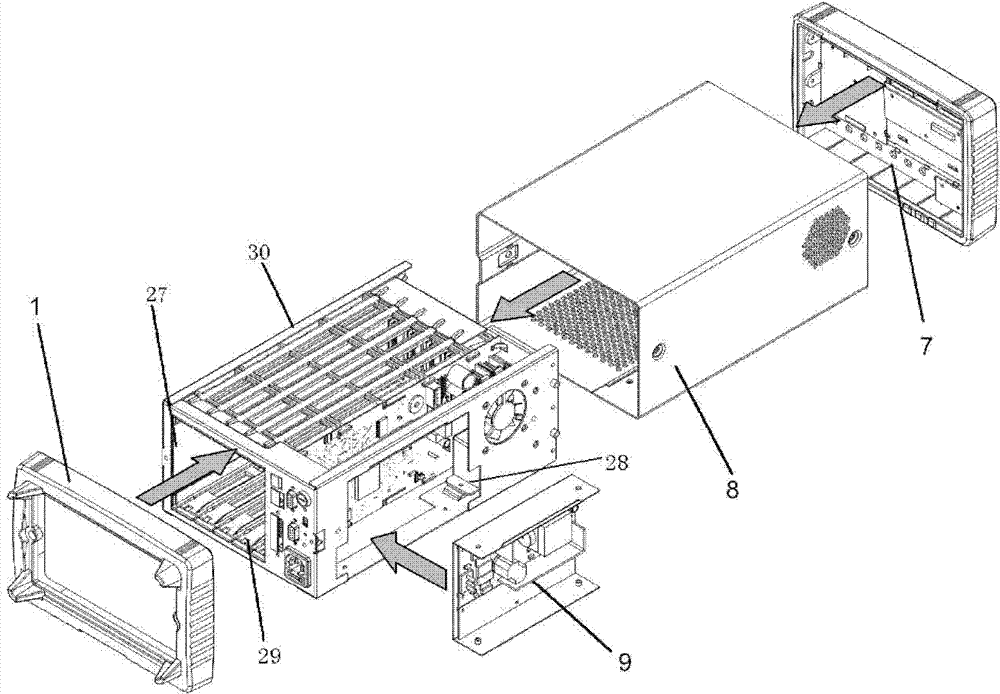

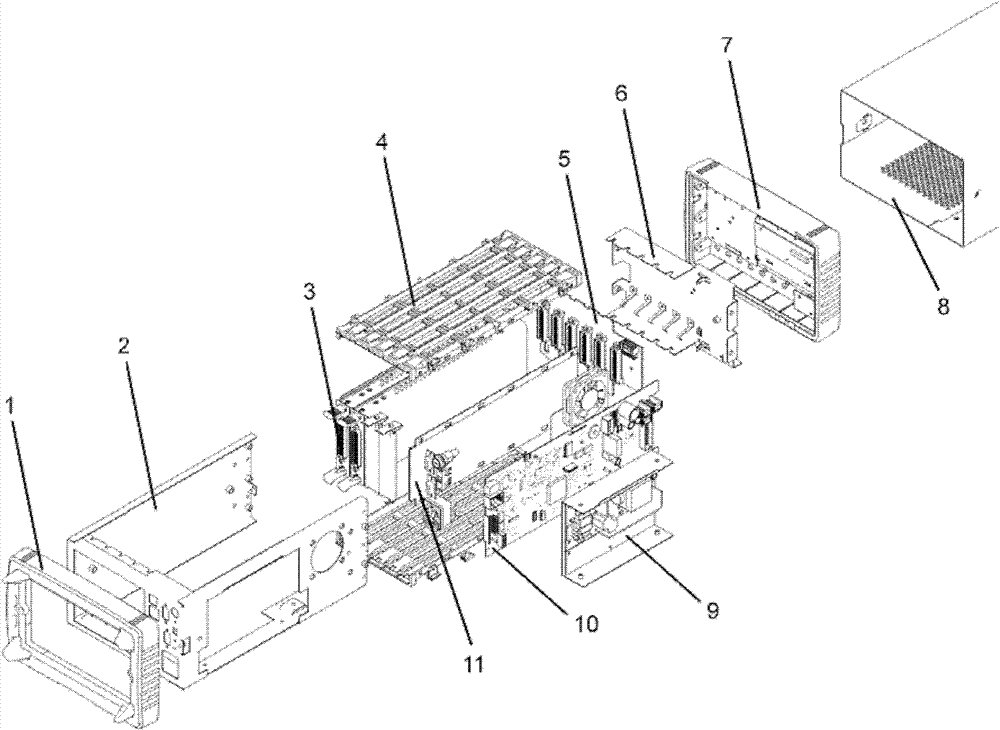

[0047] Such as figure 1 , 2 As shown, this embodiment provides a chassis with a bus structure, including a rear end cover 1, a sleeve 8, an instrument frame 30, a module card 3, a main control board 10, a power module 9, and a front panel 7. The sleeve 8, an instrument frame 30 is arranged, the rear end wall of the instrument frame 30 is provided with a module card inlet 27, the side wall is provided with a power module socket 28, and a module card guide rail 29, a main control board 10 and a bus backplane 5 are arranged inside, and the main The control board 10 is arranged on the side wall of the module card guide rail 29 and connected to the power module 9 , and the power module 9 is arranged on the power module socket 28 .

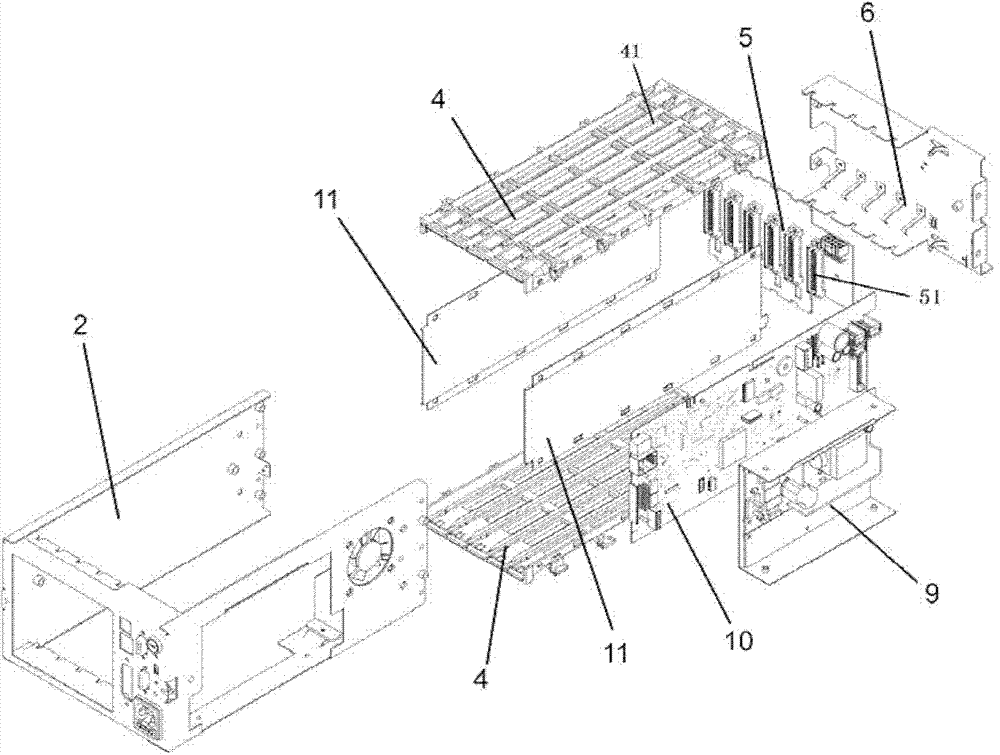

[0048] Such as figure 2 , 3 As shown, the inside of the front frame 6 is longitudinally provided with a bus backplane 5, and the module card 3 is inserted into the module card guide rail 29 through the module card inlet 27 and inserted into the bus ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com