DIN type interface laser device

A laser and interface technology, which is applied in lasers, laser components, laser optical equipment, etc., can solve problems such as low pass rate, large optical signal attenuation, poor alignment between ceramic core and connector, and achieve reasonable size design and reduce Effect of Lateral Offset and Angular Deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

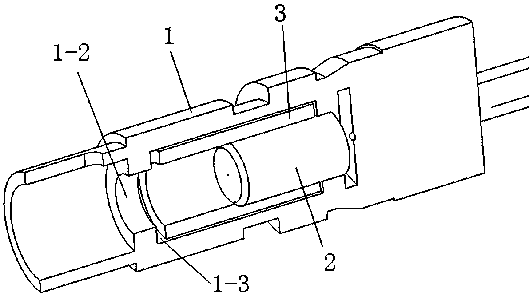

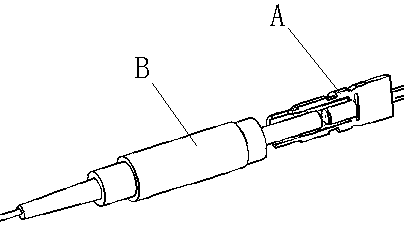

[0013] A DIN-type interface laser, the DIN-type interface laser includes a housing 1, a ceramic core 2, a positioning tube 3 and a TO laser; the inner hole of the housing 1 forms a plug-in section, a connecting section and a Installation section; the left end of the plug-in section communicates with the external environment, and the middle part of the plug-in section is provided with an annular protrusion. The space on the right side of the limiting chamber 1-2 is recorded as the installation chamber 1-3; the left end of the connecting section communicates with the right end of the installation chamber 1-3, the right end of the connecting section communicates with the installation section, and the middle part of the connecting section is provided with a stepped surface , the connecting section on the left side of the step surface forms a plug-in cavity, the connecting section on the right side of the step surface forms a light-guiding cavity, and the inner diameter of the plug-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com