Stator punching sheet of high-voltage permanent-magnet synchronous motor, winding stator and motor

A technology of stator punching and permanent magnet synchronization, which is applied in synchronous machines, synchronous machine parts, and electric components, etc., can solve the problem of uneven distribution of the air gap magnetic field of the motor, large cogging torque and core loss, and affect the running performance of the motor. and other problems, to achieve the effect of improving the air gap magnetic field distribution, reducing the core loss, and increasing the difficulty of embedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

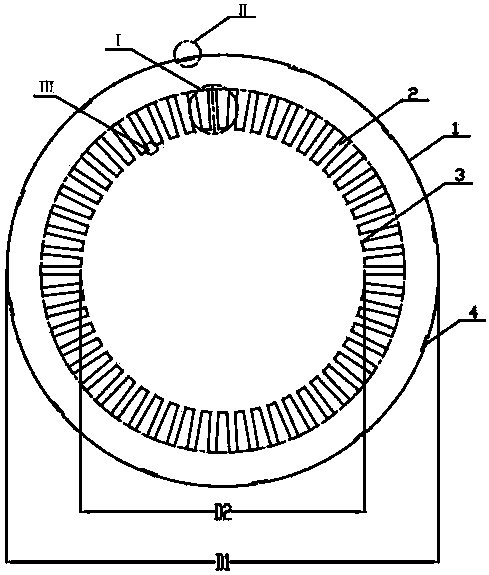

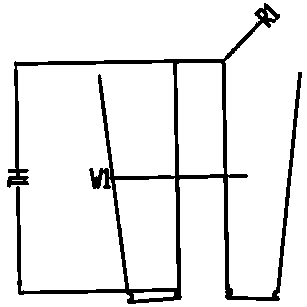

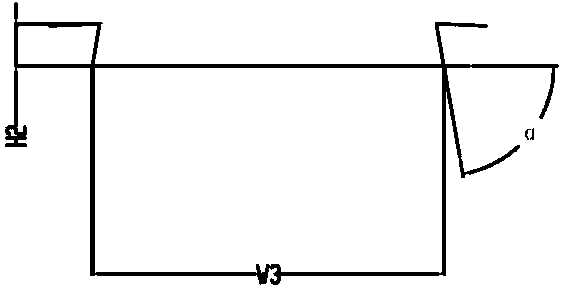

[0019] Referring to the accompanying drawings, a high-voltage permanent magnet synchronous motor stator stamping, including a stamping body 1, is characterized in that: the stator stamping body 1 is circular, the outer diameter D1 is 730 mm, and the inner diameter D2 is 480 mm. There are 54 evenly distributed rectangular winding slots 2 on the inner circle of the stator body 1, the slot width W1 is 13.7 mm, and the slot height H1 is 65 mm; the opening of the winding slot 2 is provided with a magnetic slot for placing magnetic slot wedges Wedge slot 3; Magnetic slot Wedge slot 3 is semicircular, its radius R2 is 1 mm, and the slot opening width W2 is 15.7 mm. The size of the arc radius R3 is 0.2mm; there are 12 uniformly distributed dovetail-shaped positioning slots 4 on the outer circle of the stator punching body 1, the size of the slot height H2 is 3 mm, the size of the slot bottom width W3 is 26 mm, and the slot shoulder is oblique Angle α degrees is 78°.

[0020] The pate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com