Patents

Literature

91results about How to "Improved magnetic field distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

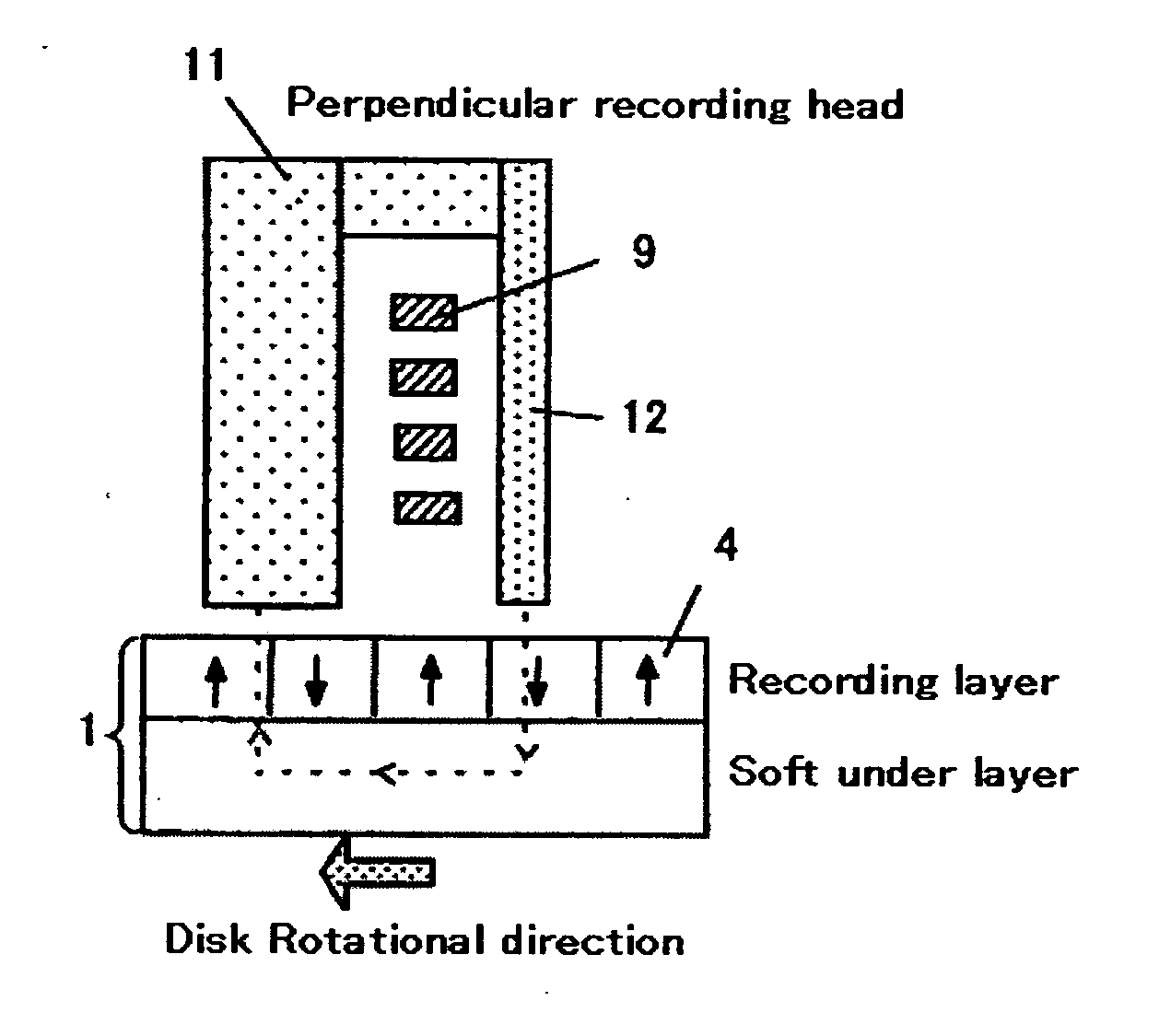

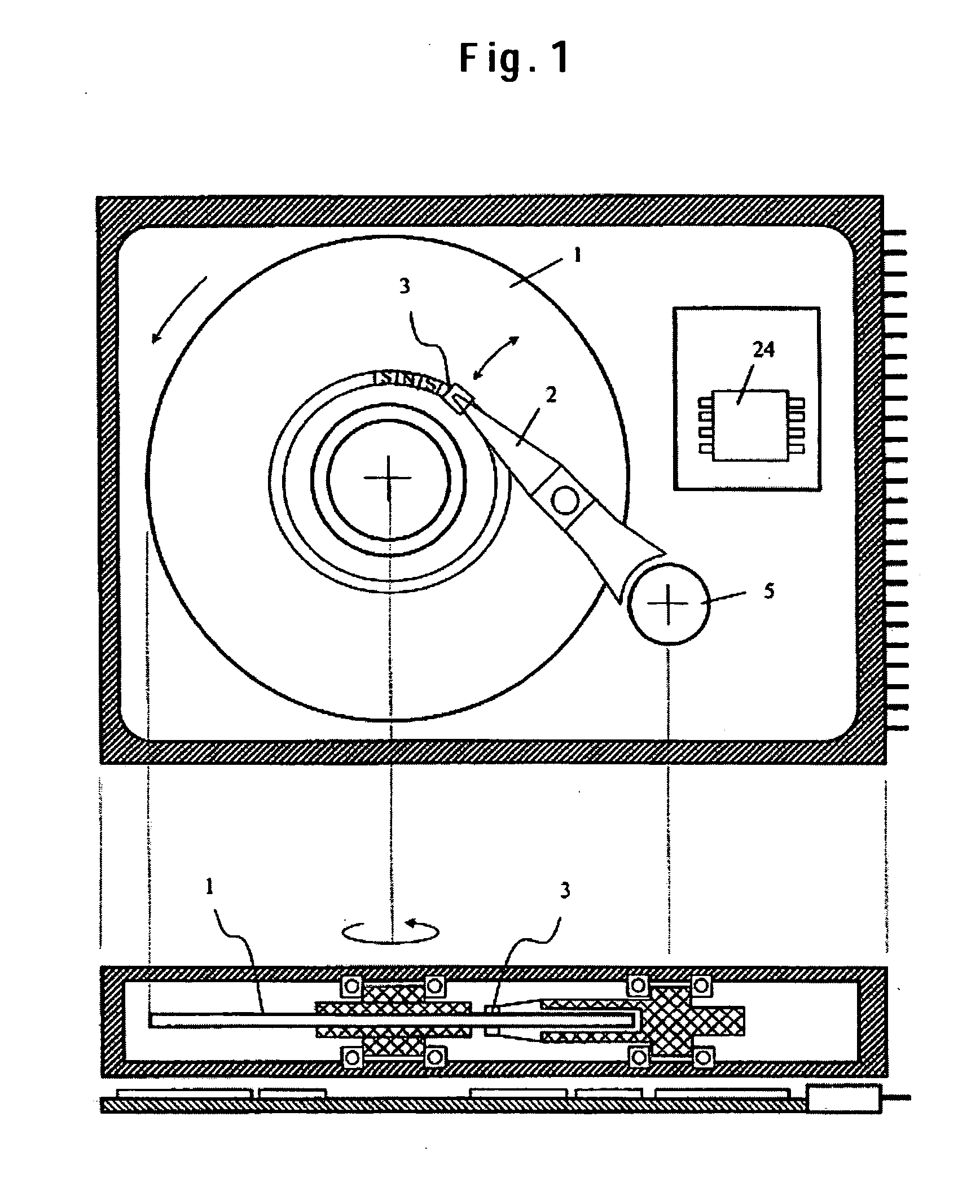

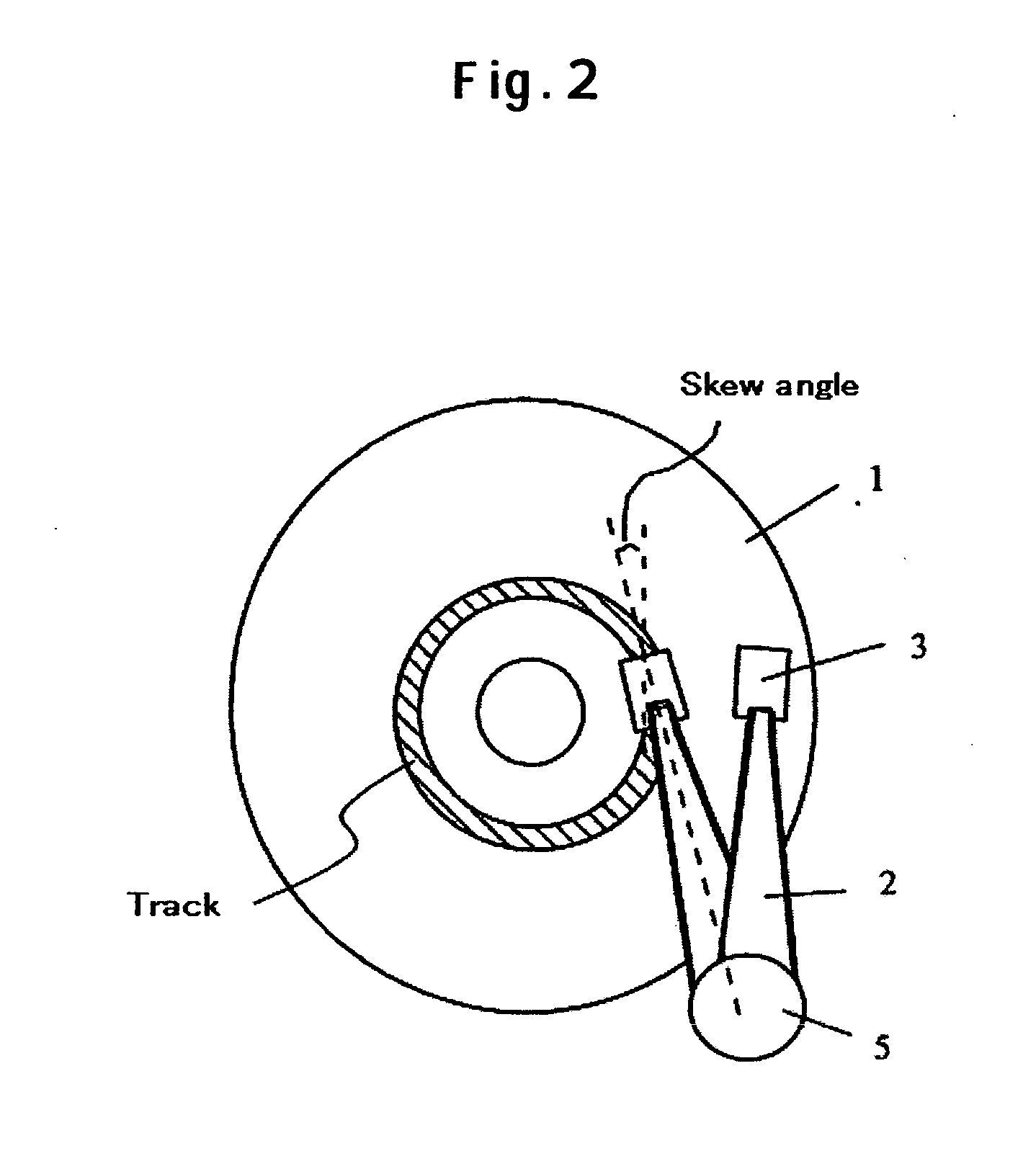

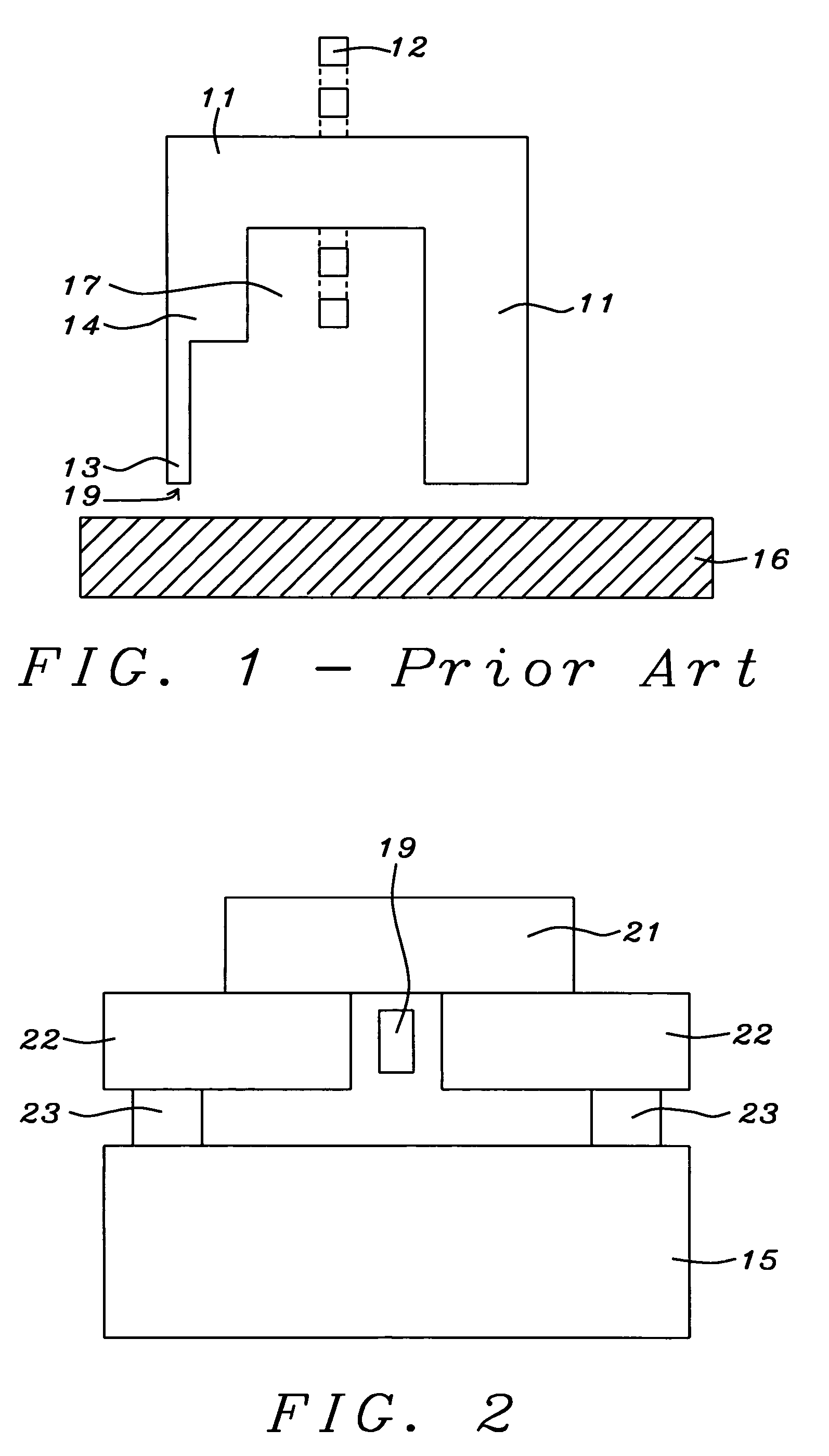

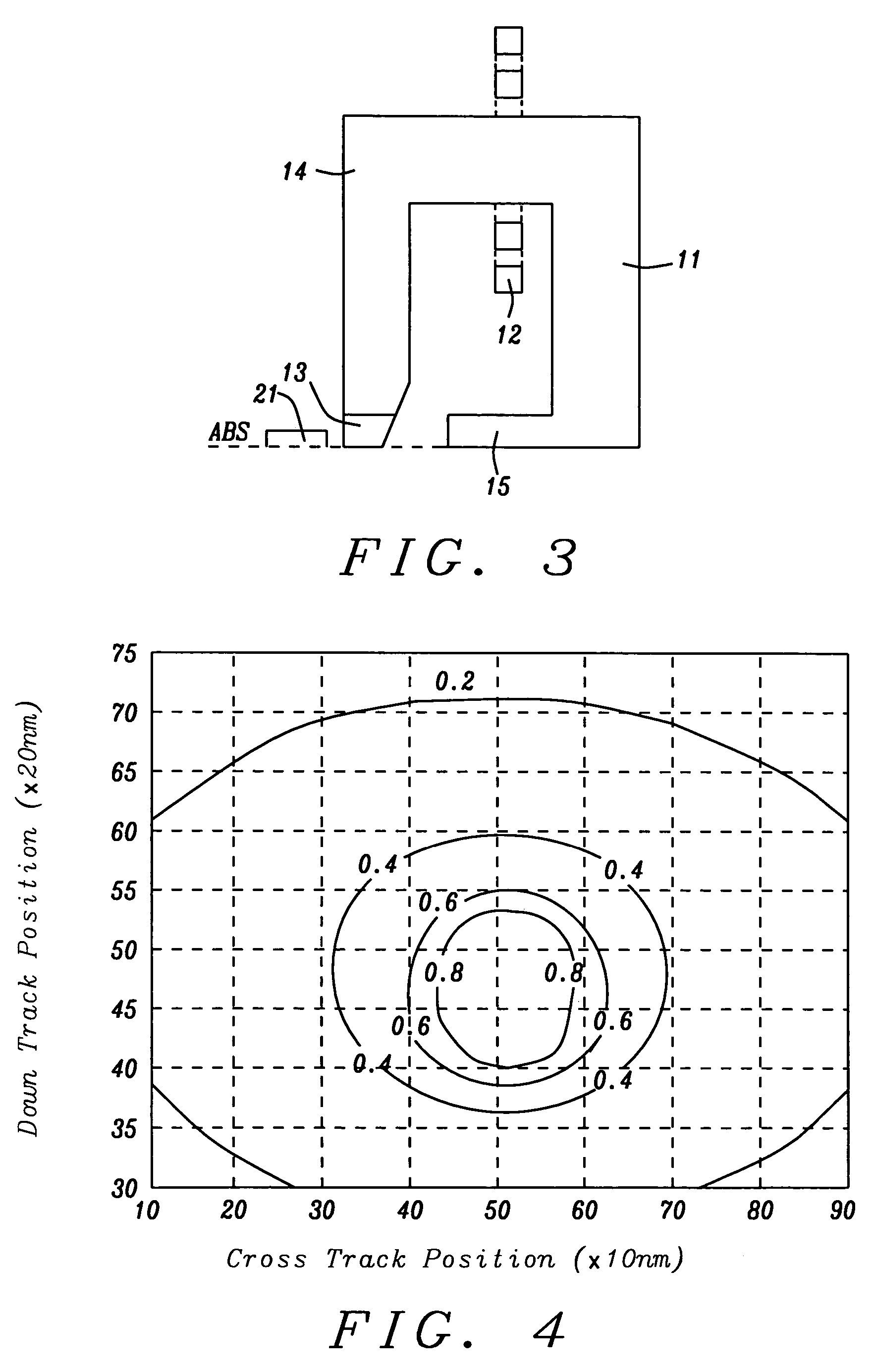

Magnetic recording head for perpendicular recording, fabrication process, and magnetic disk storage apparatus mounting the magnetic head

InactiveUS20050141137A1Improving recording magnetic field gradientIncreasing the thicknessManufacture head surfaceHeads using thin filmsMagnetic field gradientMagnetic media

Embodiments of the invention provide a perpendicular magnetic writing head with a suppressed effective track width to be written on a magnetic medium while increasing writing magnetic field gradient. In one embodiment a trailing side shield is disposed by way of a gap film to a main pole of a perpendicular writing magnetic head. A gap distance (Gt) on a trailing side of the main pole and a gap distance (Gs) on a lateral side of the main pole is defined as Gt<Gt, and a thickness (Gd) from an air bearing surface of the shield is made equal to or less than a throat height. Alternatively, the thickness of Gd on the side of the main pole is reduced to less than that on the trailing side of the main pole. Further, for preventing defoliation of the shield upon fabrication of the air bearing surface, a thickness for a portion away from the main pole is increased.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

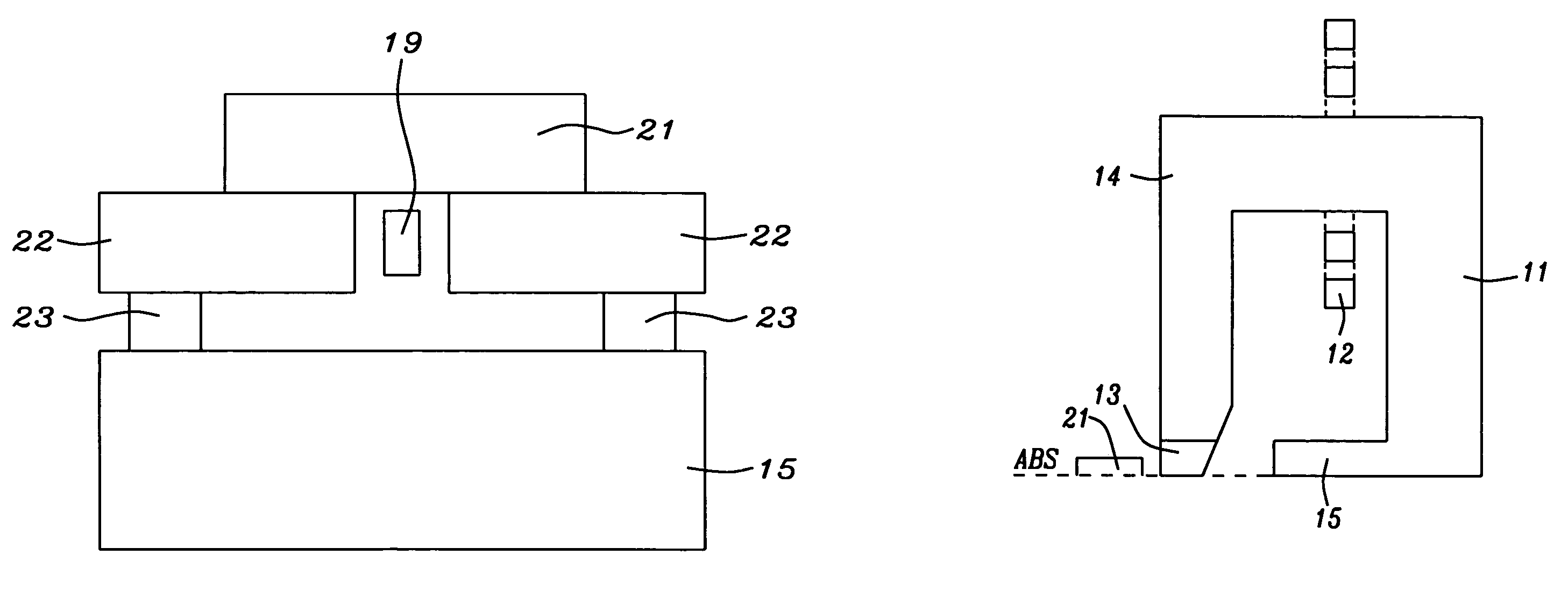

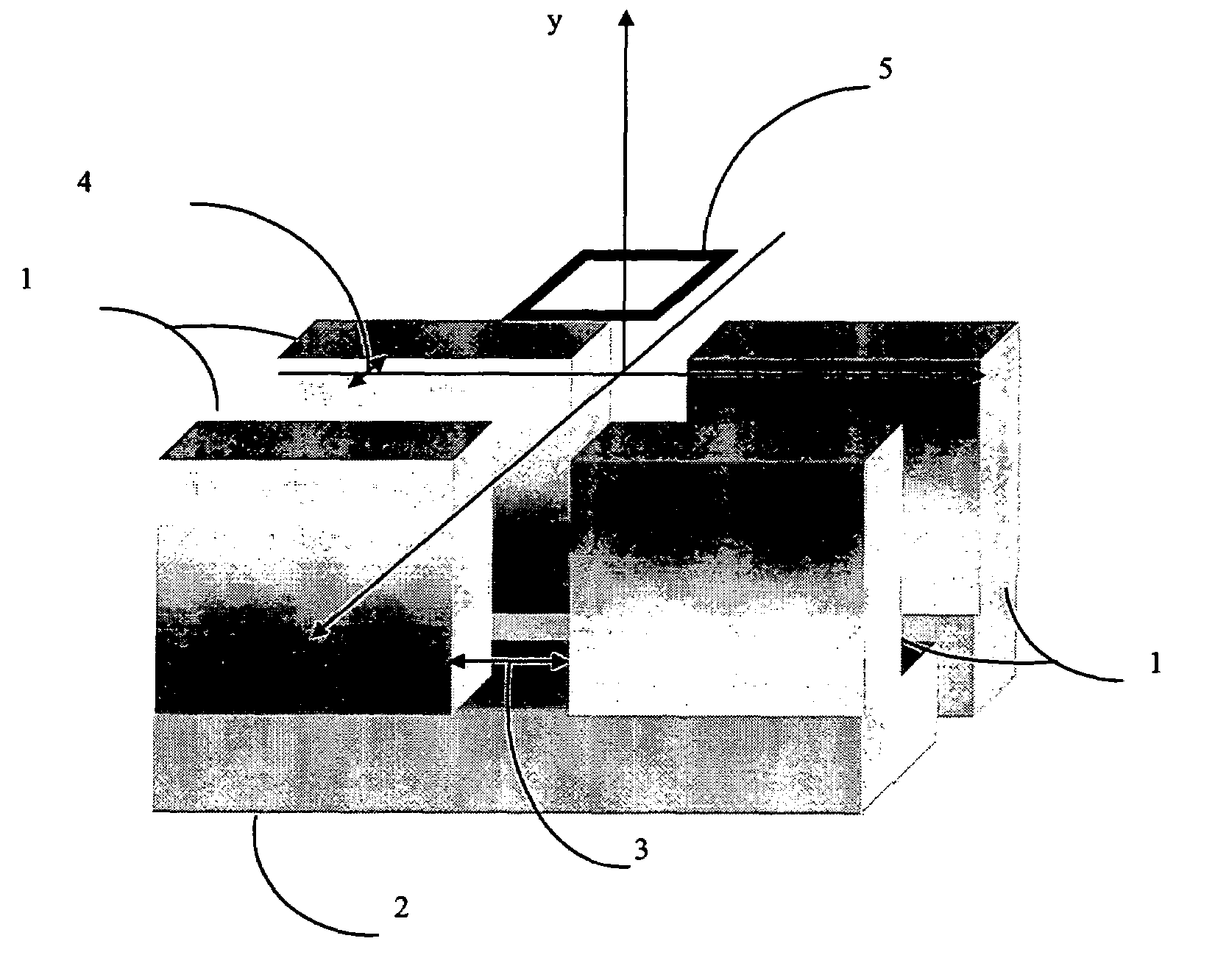

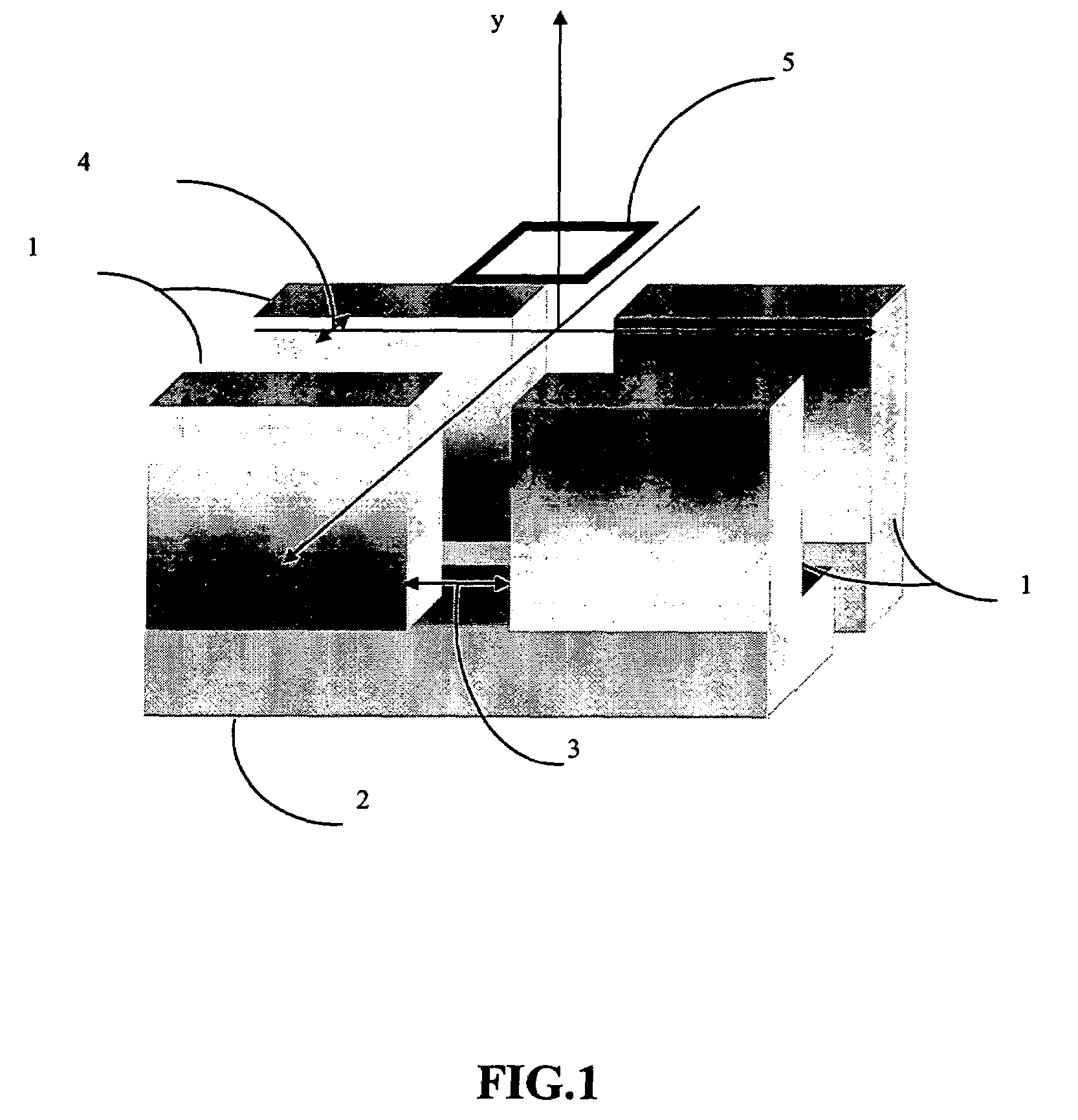

Process of manufacturing a four-sided shield structure for a perpendicular write head

ActiveUS7322095B2Improved magnetic field distributionElectrical transducersManufacture head surfaceLeading edgeEngineering

Owner:HEADWAY TECH INC

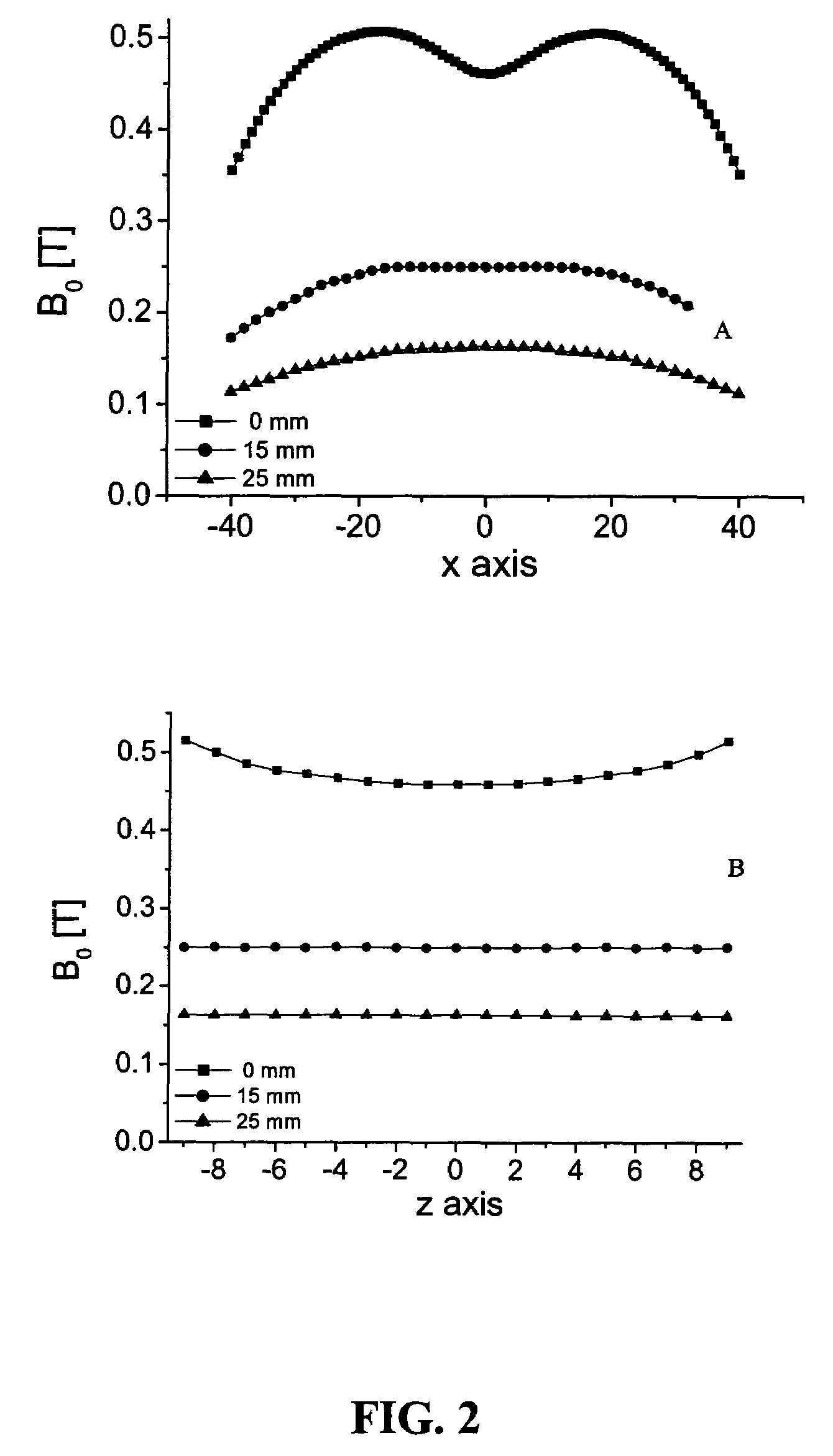

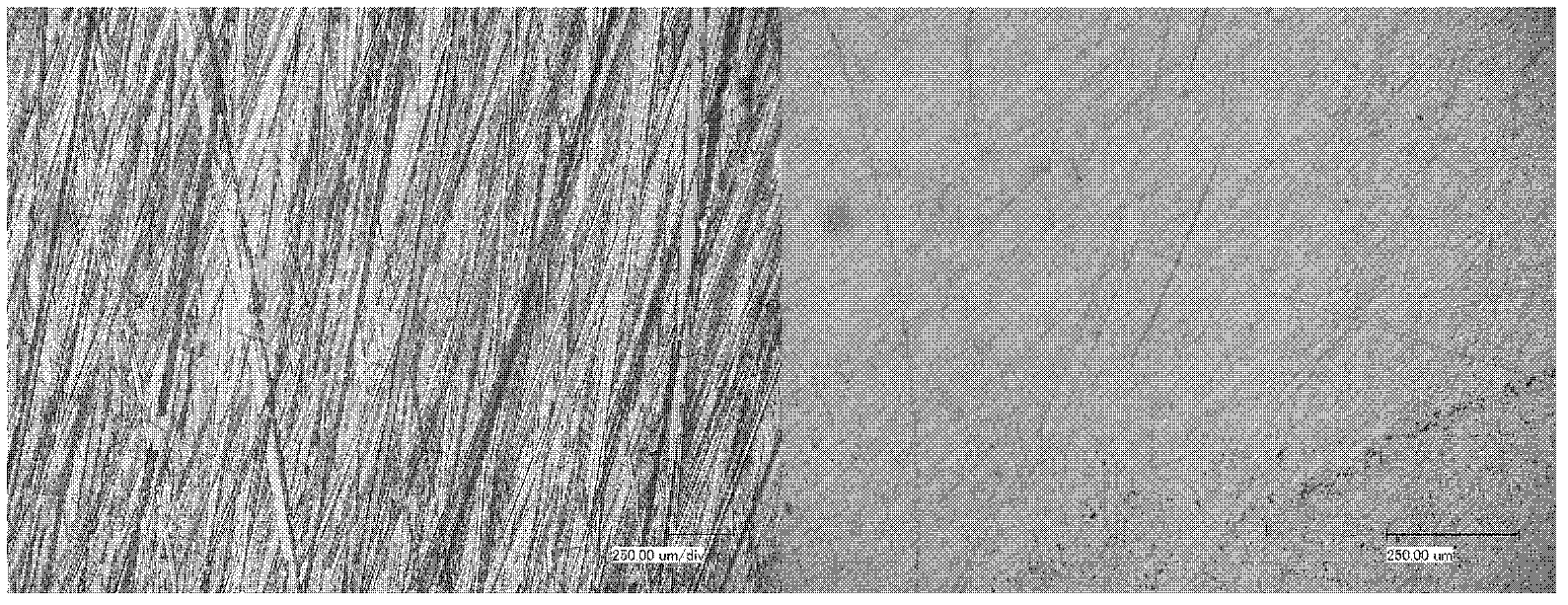

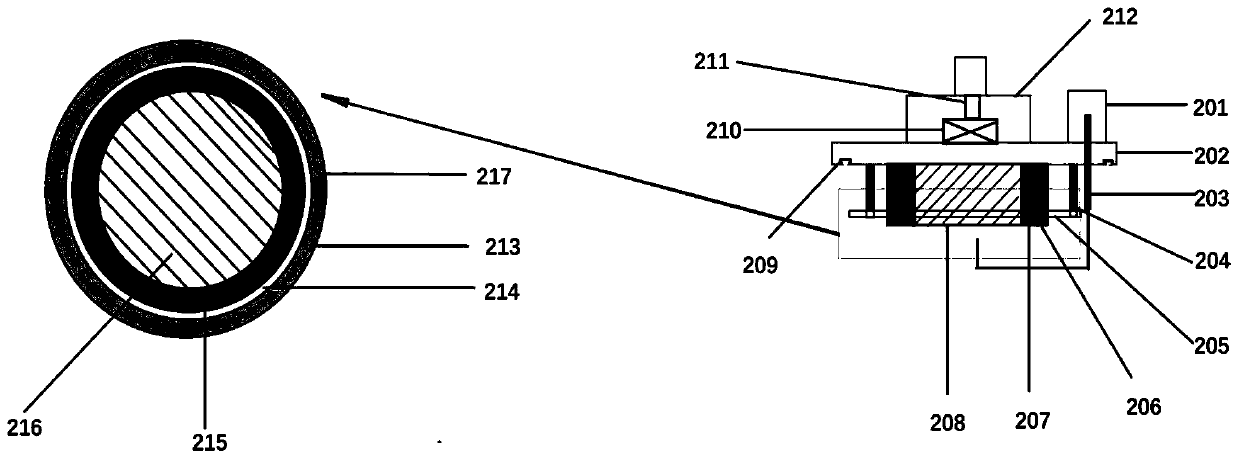

Single-sided NMR sensor with microscopic depth resolution

ActiveUS7358734B2Improve flatnessImproved magnetic field distributionMagnetic measurementsElectric/magnetic detectionNon destructiveHigh spatial resolution

A low-cost single-sided NMR sensor to produce depth profiles with microscopic spatial resolution is presented. The open geometry of the NMR sensor provides a non-invasive and non-destructive testing method to characterize the depth structure of objects of arbitrary size. The permanent magnet geometry generates one plane of constant magnetic field intensity parallel to the scanner surface. By combining the highly uniform static gradient with selective RF excitation, a thin flat sensitive slice can be defined. By moving the relative position between the slice and the object, one-dimensional profiles of the near surface of large samples are produced with high spatial resolution.

Owner:RWTH AACHEN UNIV

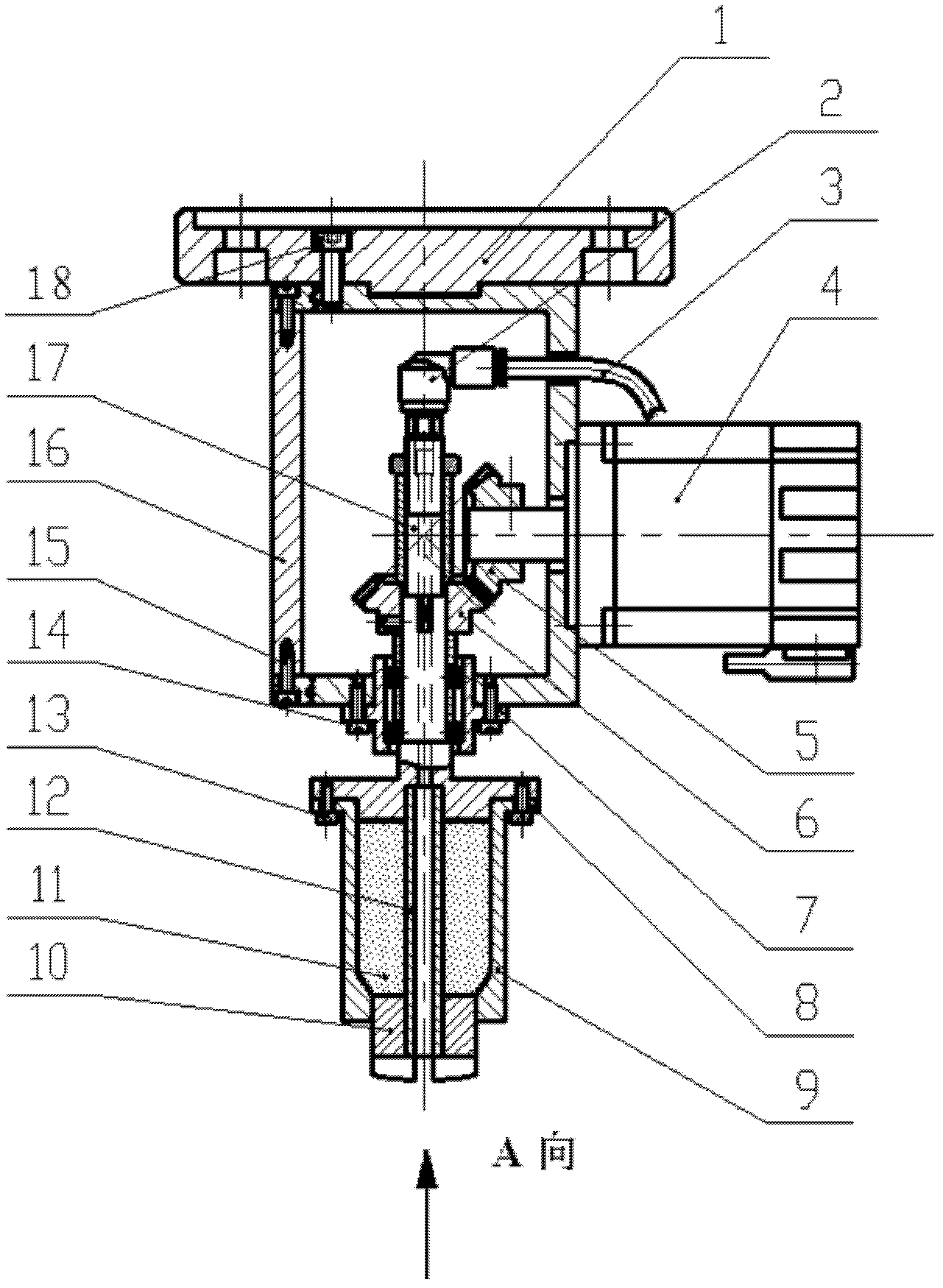

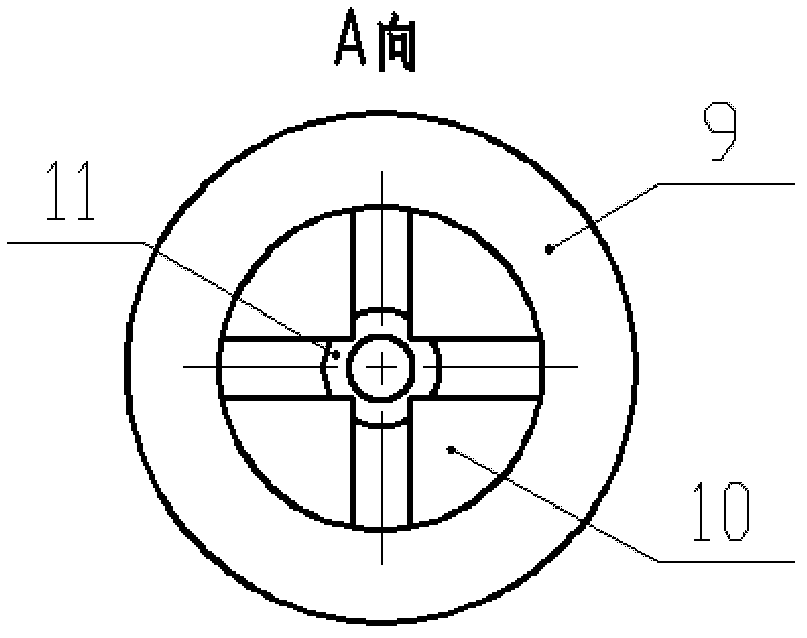

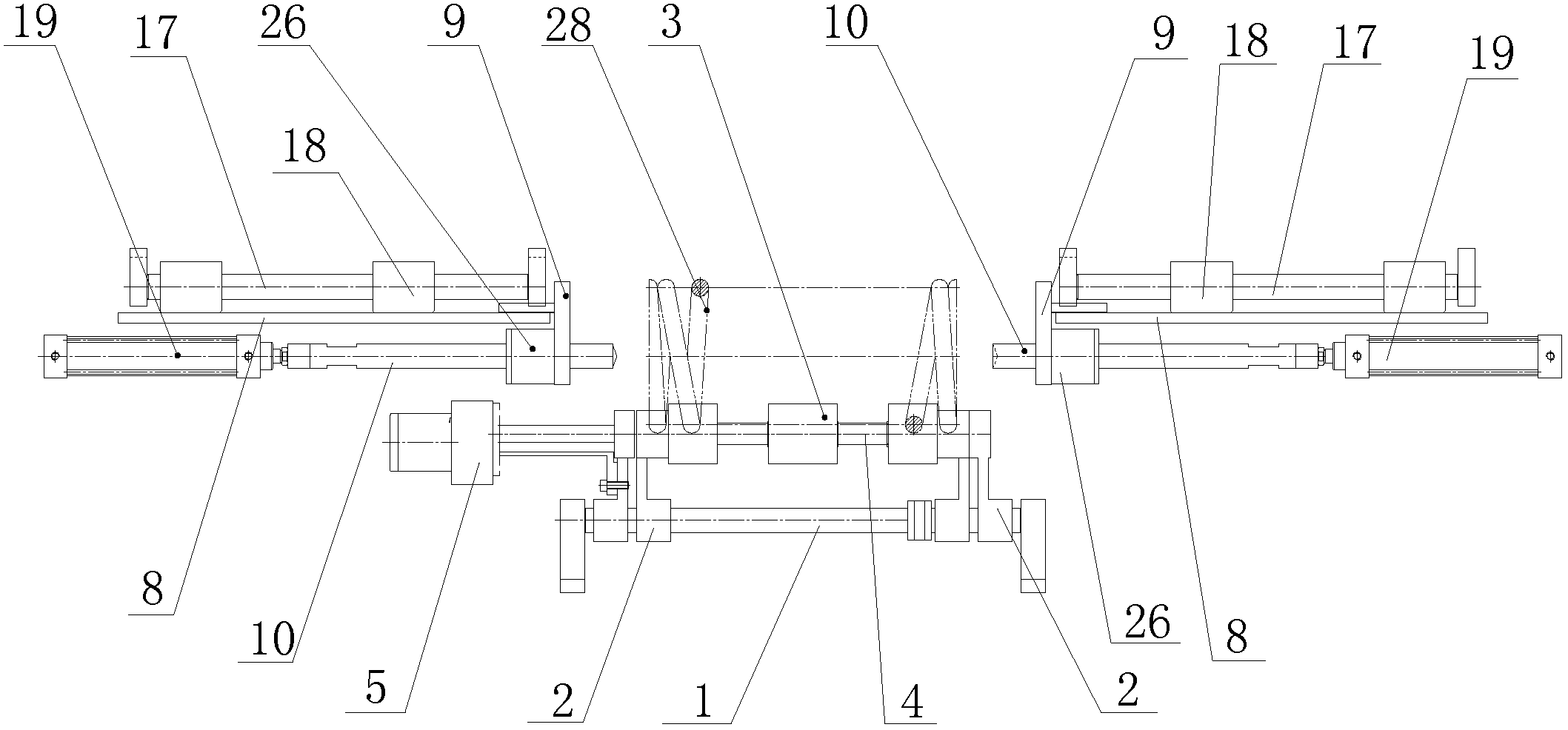

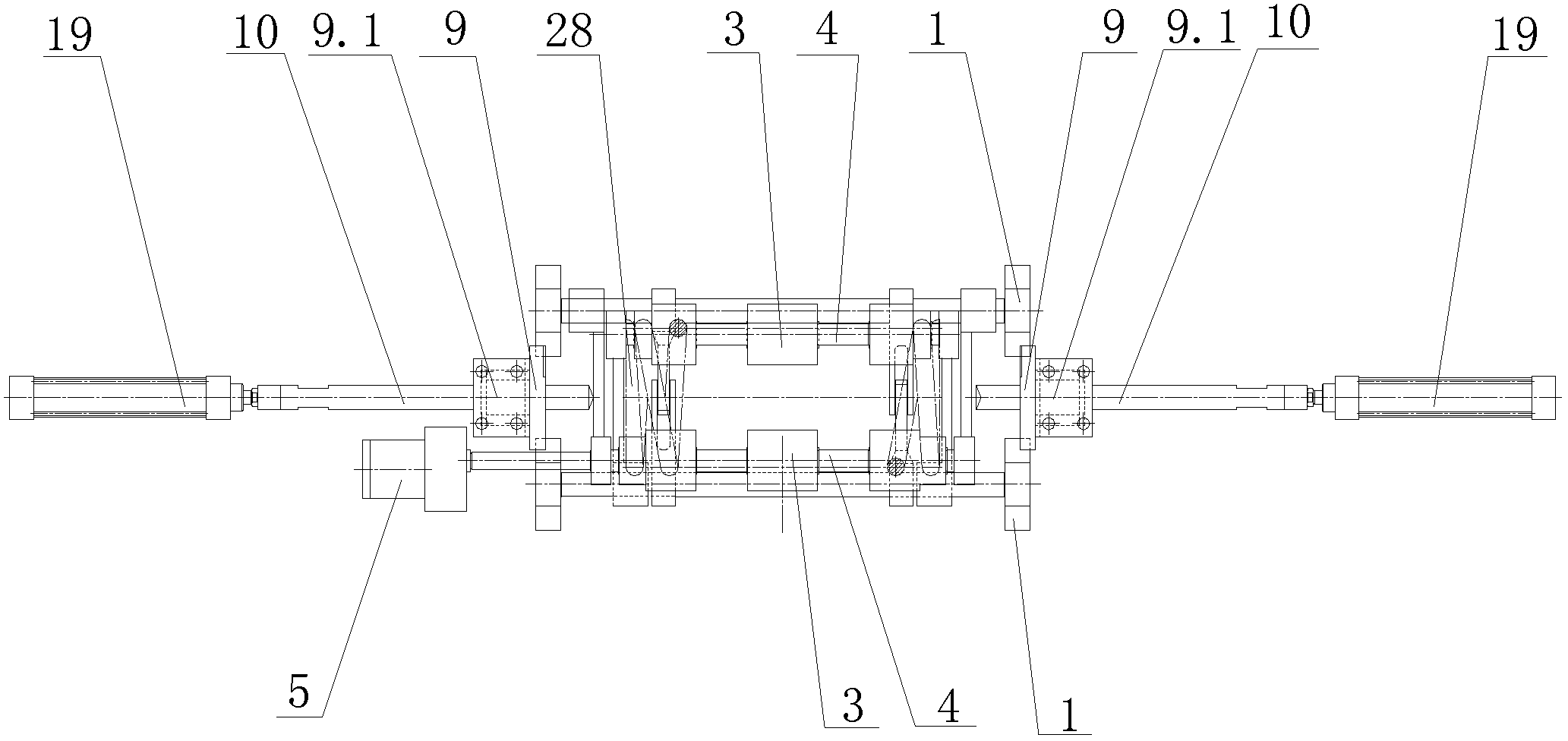

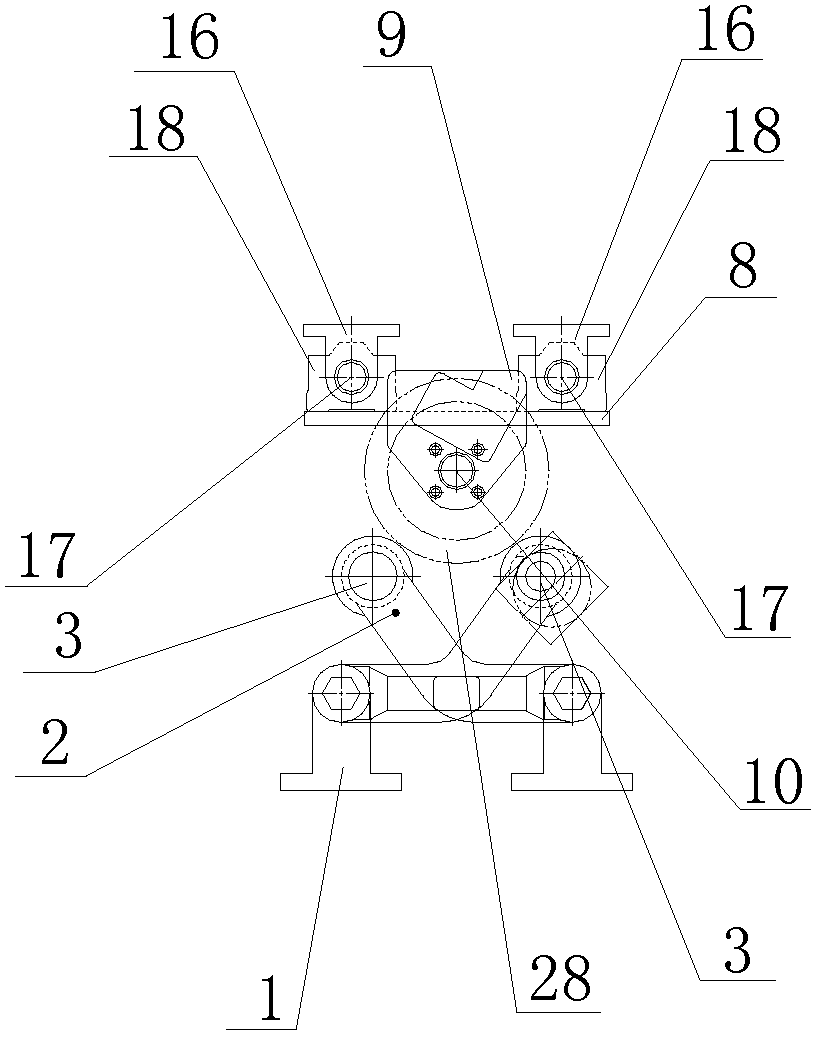

Magnetic grinding and polishing device for large curved surface

The invention discloses a magnetic grinding and polishing device for a large curved surface capable of continuously grinding and polishing a curved surface to obtain uniform surface quality finally. The magnetic grinding and polishing device comprises the following components: a main frame, a front-end supporting side plate, a side plate fixing bolt, a motor, a drive bevel gear, a driven bevel gear, a locating sleeve, a connecting bolt, a fastening bolt, a spindle, a magnetic pole, a grinding material and grinding liquid mixture conveying pipeline, a rotating joint, a magnetic shield, a flange disc, a flange locating bolt, a flange disc, a permanent magnet and a magnetic pole sleeve. The magnetic grinding and polishing device, provided by the invention, has the advantages of high processing efficiency, simple structure, low manufacturing cost and convenience for installation; the magnetic grinding and polishing device has an independent drive motor, convenience for connection with multiple processing equipment or devices, good university and no other external power. The magnetic grinding and polishing device can be widely applied to finish all kinds of curved surfaces, in particular to grind and polish a large-area complicated free curved surface. Technique grinding matched with the device has small temperature rise, high efficiency, difficulty in deformation of a processing work-piece, and no deterioration layer after processing.

Owner:UNIV OF SCI & TECH LIAONING

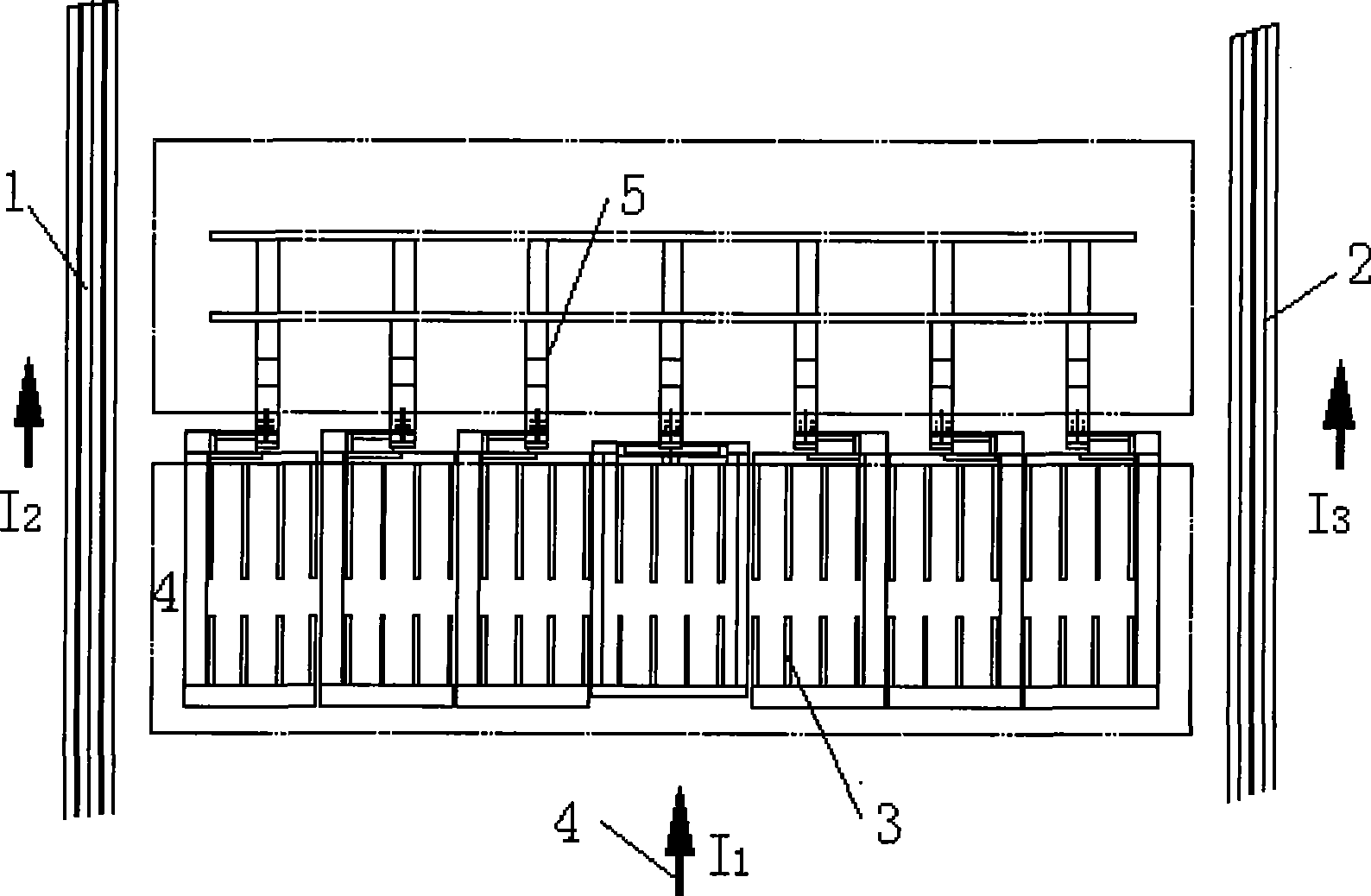

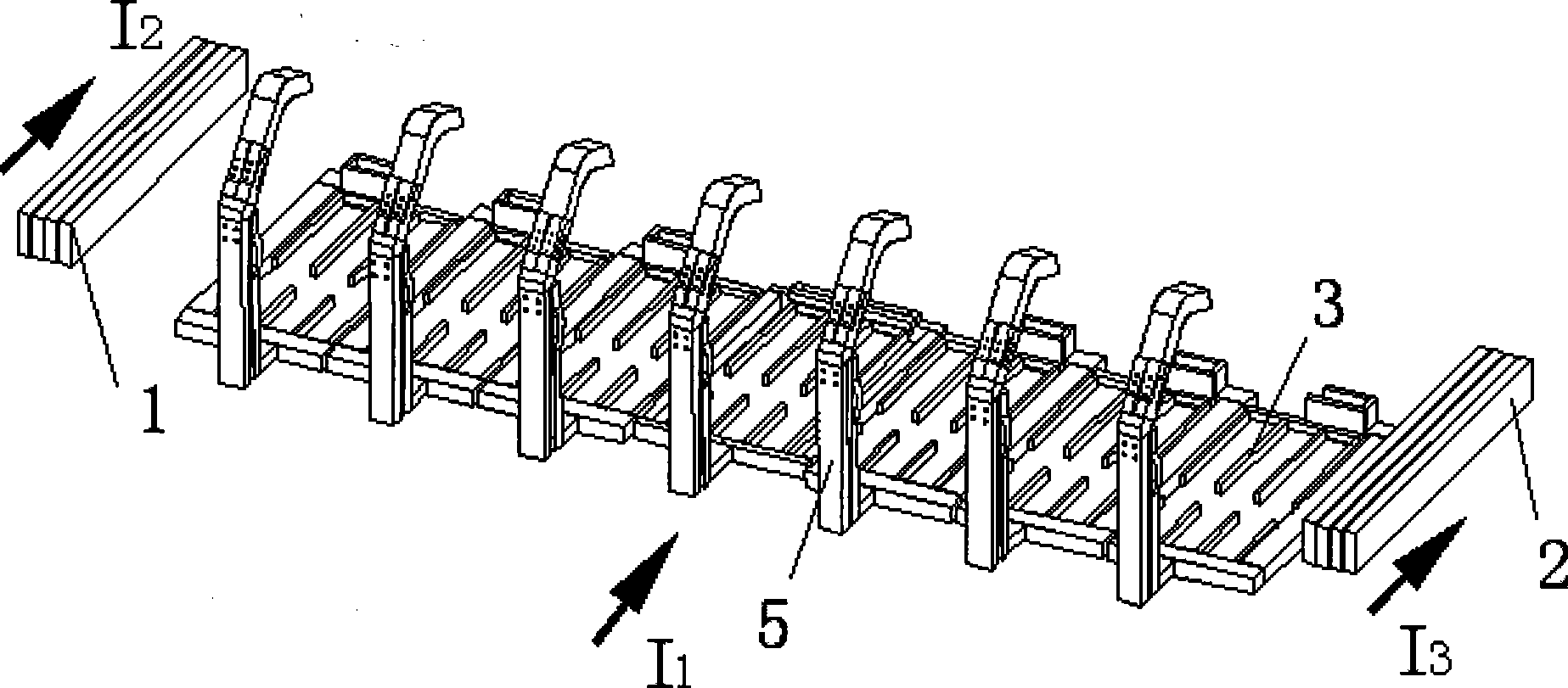

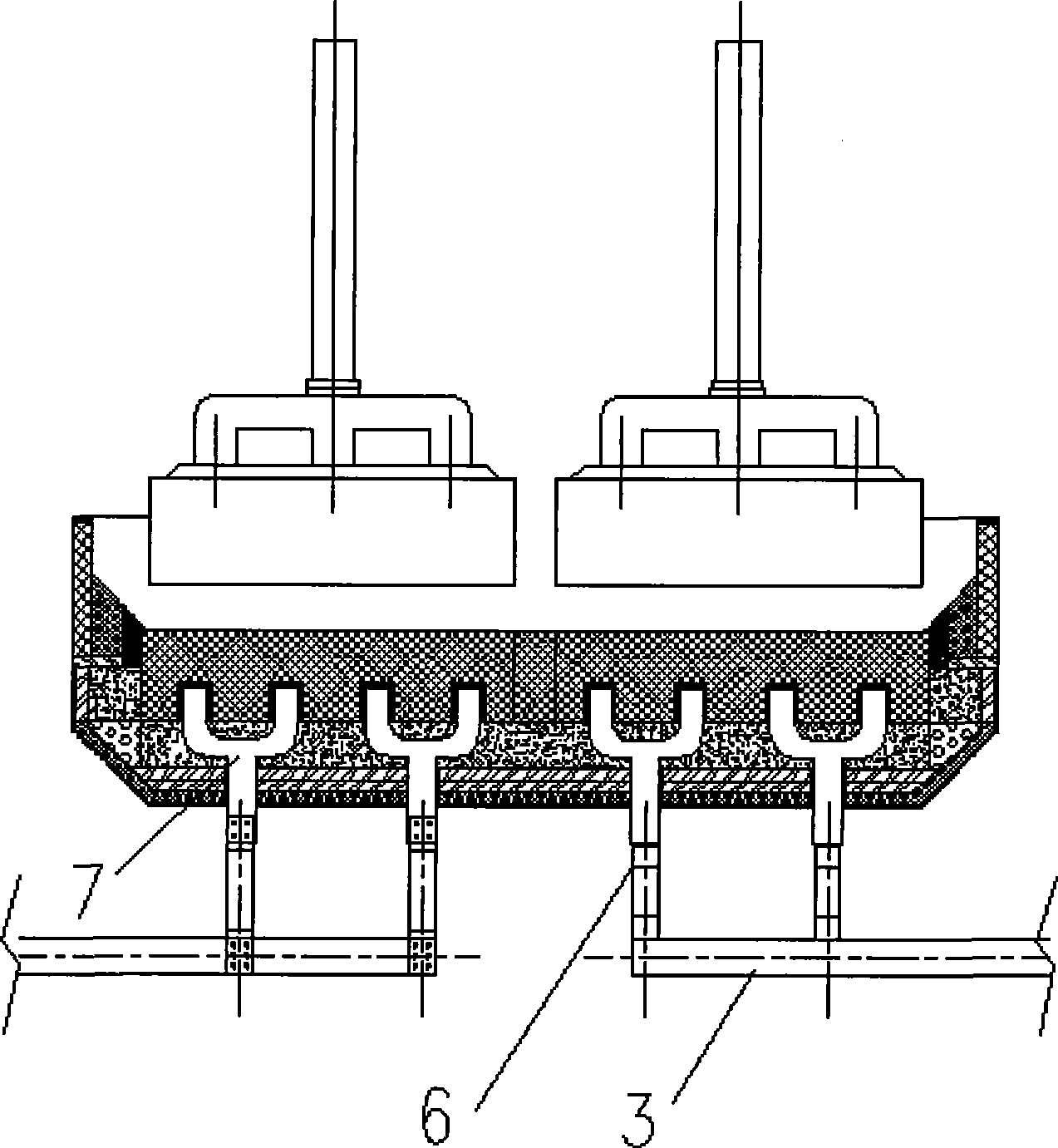

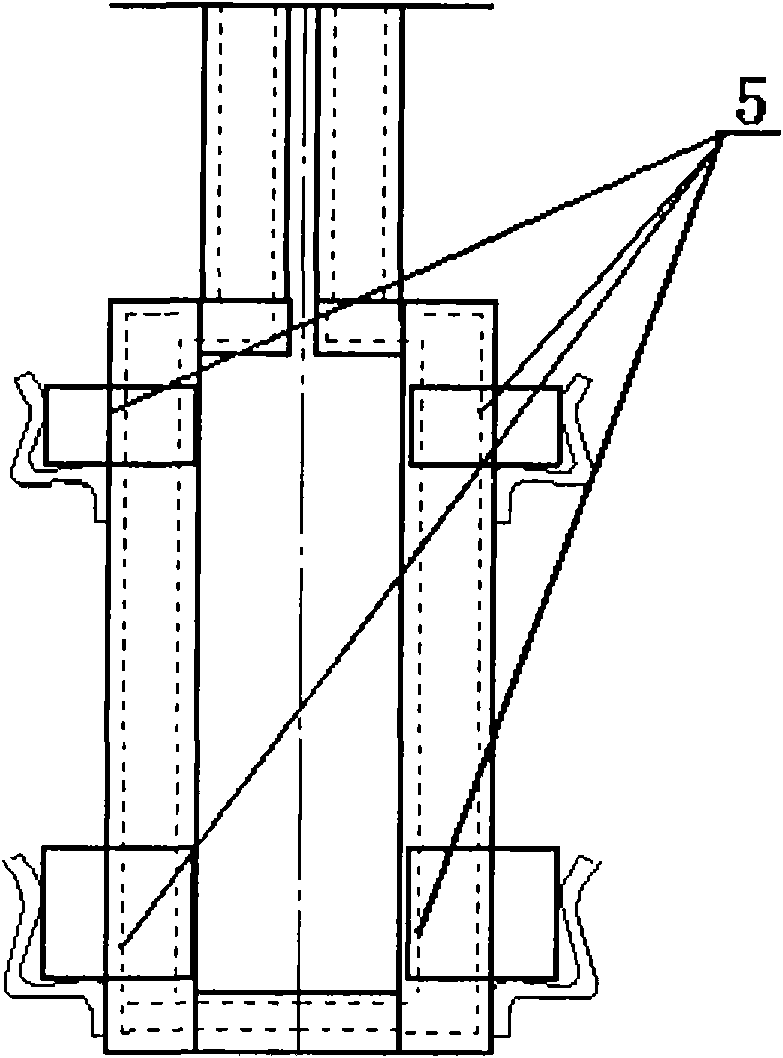

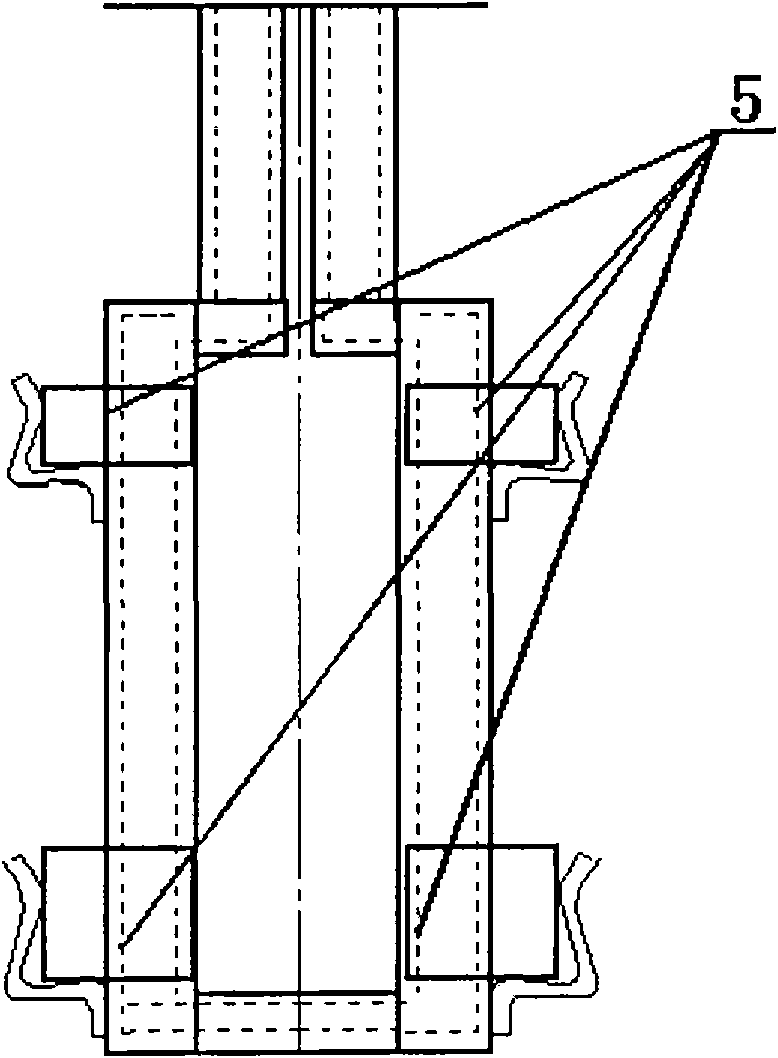

Aluminum cell bus-bar compensation structure with outlet at cell bottom

The invention discloses an external busbar compensating structure for an aluminum cell the bottom of which is provided with outgoing lines, which belongs to the technical field of metallic aluminum electrolysis. The external busbar compensating structure for the aluminum cell is as follows: an external compensating busbar is respectively arranged on both ends of the prior aluminum cell along the potline current direction, and the current direction in the external compensating busbars is the same with the potline current direction; cell bottom cathode busbars the number of which corresponds to that of bottom electric cathode steel bars are arranged at the bottom of the cell, connected with the cathode steel bars and connected with each other through soft cathode strips; and the external compensating busbars and the cell bottom cathode busbars correct the magnetic field of the cell and compensate the magnetic field of cells in the adjacent row together. The external busbar compensating structure for the aluminum cell solves the problems of large use amount and complex configuration of the cathode busbars of each cell, reduces the use amount of the cathode busbars and the cell pitch, simplifies the design difficulty, is favorable to find out the optimum busbar configuration means, and easily makes magnetic field distribution and the stability of fused masses in the cell optimum.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND +1

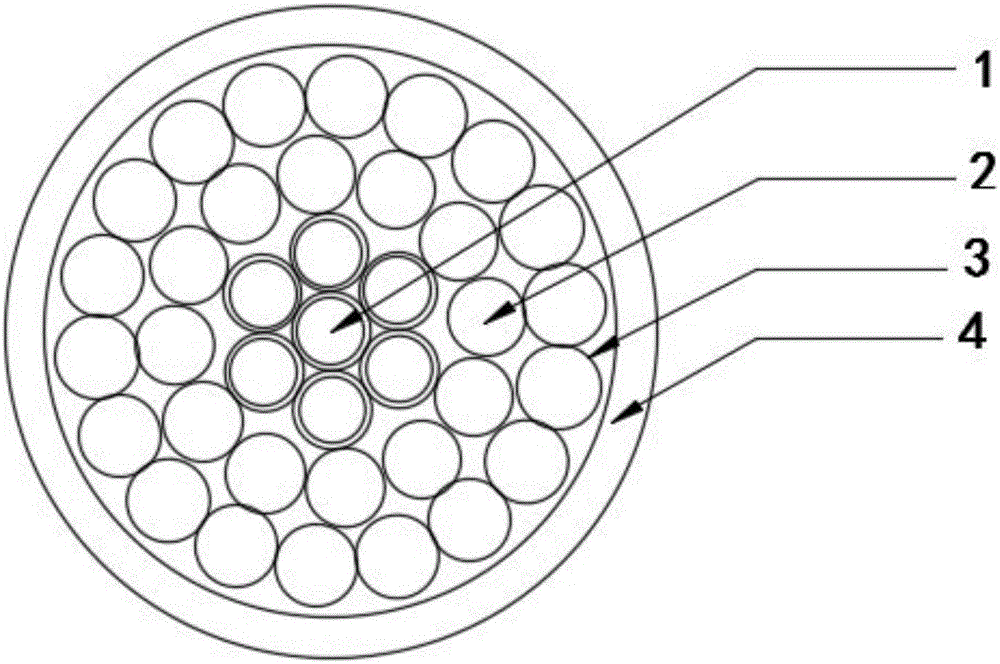

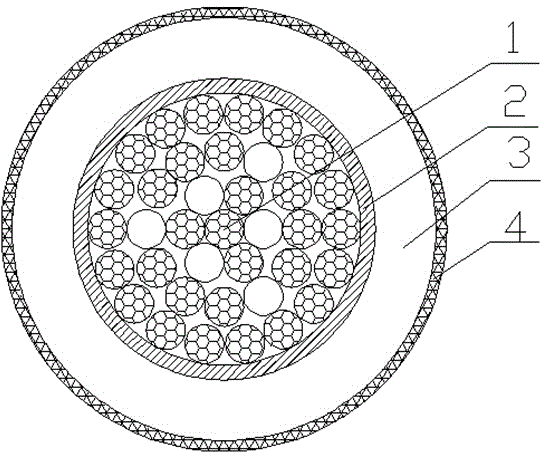

Aluminum-coated steel high-conductivity overhead insulated cable and production process thereof

InactiveCN106653199AAnti-galvanic corrosionHas fog corrosion resistanceInsulated cablesManufacturing extensible conductors/cablesPolyvinyl chlorideAluminum can

The invention discloses an aluminum-coated steel high-conductivity overhead insulated cable and a production process thereof. The cable sequentially comprises a 20.3% IACS aluminum-coated steel core, a 62.5% IACS hard aluminum wire, a conductor shielding layer and a weather-resistant insulated layer from inside to outside, wherein the 20.3% IACS aluminum-coated steel core is a stranded wire formed by coating the surface of a patented steel wire with an aluminum rod with the purity of 99.70%; the 62.5% IACS hard aluminum wire is formed by stranding a hard aluminum wire with the conductivity of 62.5% IACS, the tensile strength higher than 160MPa and the strength uniformity lower than 25MPa; the shielding layer is made from a crosslinked polyethylene or non-crosslinked polyethylene material; and the weather-resistant insulated layer is made from a polyethylene, polyvinyl chloride or crosslinked polyethylene material. According to the cable, a conductor adopts an aluminum-coated steel core high-conductivity aluminum stranded wire structure; the aluminum-coated steel core has electrochemical corrosion resistance and fog corrosion resistance in comparison with a general steel core; the conductor life is prolonged; and high-conductivity aluminum can effectively reduce line loss and improve power transmission efficiency.

Owner:FAR EAST CABLE +2

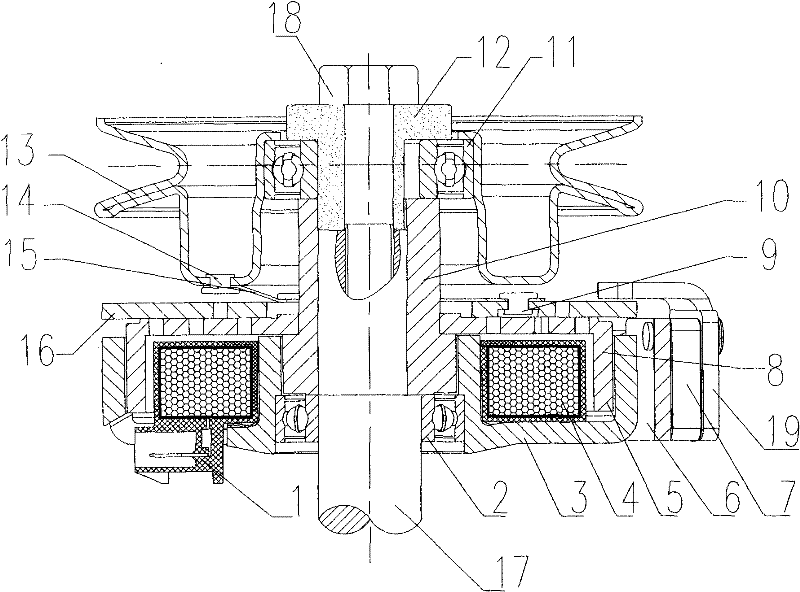

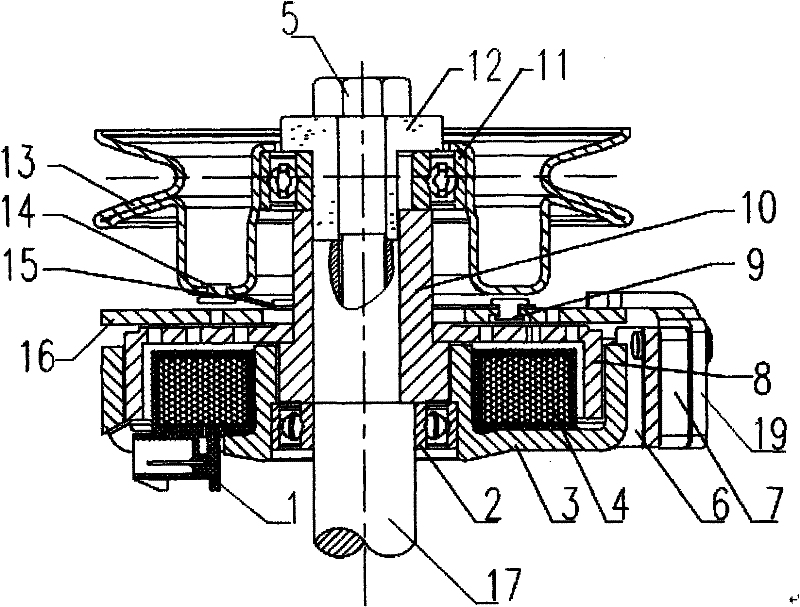

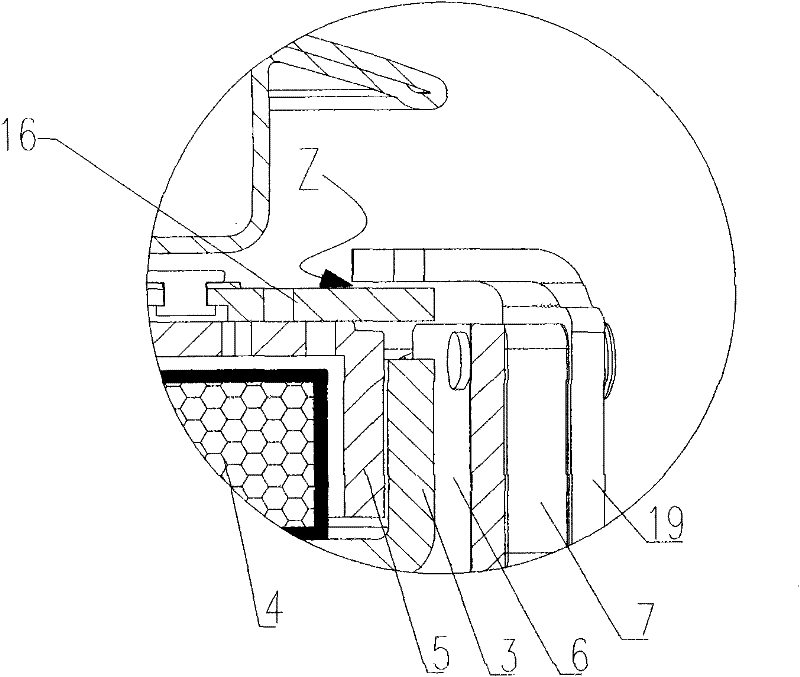

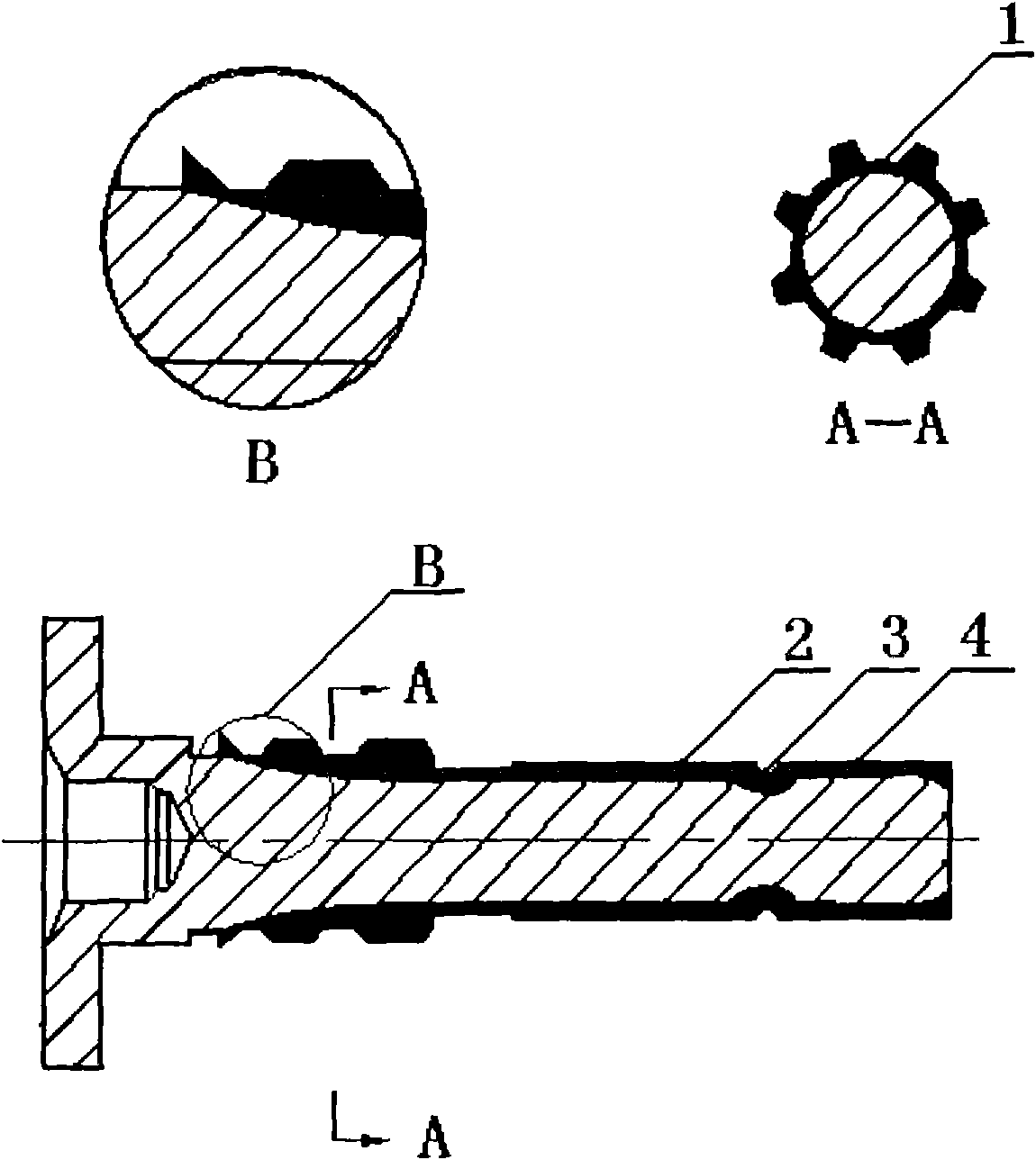

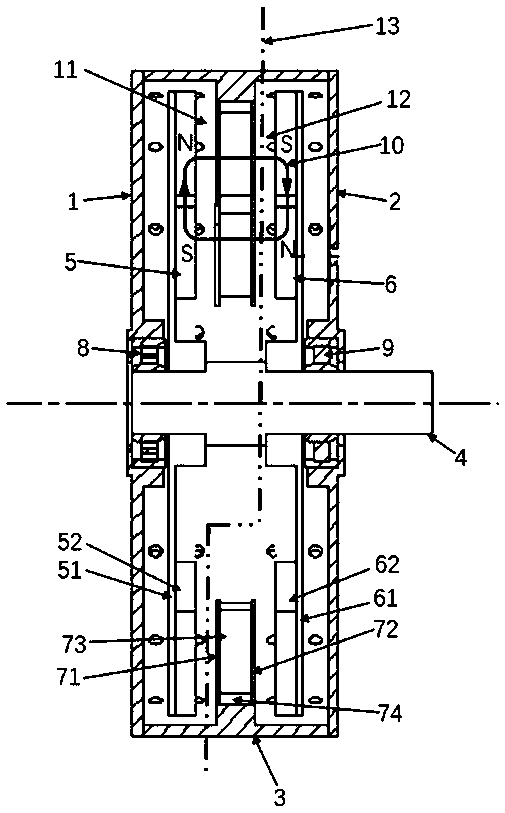

an electromagnetic clutch

ActiveCN102287457ASmall electromagnetic forceReduce power consumptionMagnetically actuated clutchesElectromagnetic clutchDrive shaft

The invention discloses an electromagnetic clutch which belongs to the technical field of mechanical and electrical integration; a coil winding is arranged in a slot plate of the electromagnetic clutch; a pulley and the slot plate are connected through a central shaft; the central shaft and a rotor are tightly matched; both ends of the central shaft are respectively matched with a bearing which is arranged in the pulley and a bearing which is arranged in the slot plate; an armature and the pulley are connected through a leaf spring; a carriage is arranged on one side of the slot plate and is integrally assembled with the slot plate; one side of the carriage which is back to the slot plate is provided with two trays; and two permanent magnet bodies are respectively tabled in each tray with the polarity being opposite. Long arms of the two L-shaped permanent-magnet poles are respectively fitted to the tray and the permanent-magnet poles and are fastened by screws, short arms of L-shaped permanent-magnet poles face to the direction of the armature, and the two permanent magnets are laid in the shape of figure eight. The size of the electromagnetic clutch provided by the invention is reduced, so that the clutch manufacturing cost and the power consumption are reduced, the structure is simple and reliable, and the braking effect is significantly improved.

Owner:成都瑞迪智驱科技股份有限公司

Technique treatment method for induction heating of special-shaped piece

InactiveCN101962705AReduce energy consumptionGuaranteed compliance with technical requirementsIncreasing energy efficiencyFurnace typesConstant powerElectrical field strength

Owner:上海上大热处理有限公司

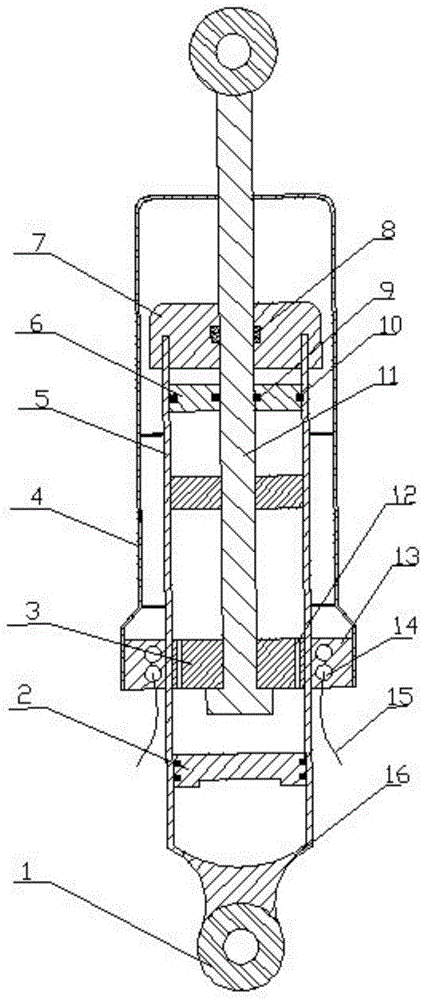

Coil externally-wrapping magnetorheological fluid damper

InactiveCN104963983AImproved magnetic field distributionLarge damping forceSpringsNon-rotating vibration suppressionMagnetEngineering

Provided is a coil externally-wrapping magnetorheological fluid damper. The coil externally-wrapping magnetorheological fluid damper is characterized in that the outside of a working cylinder barrel is provided with a dust-proof housing, one end of which is fixed with guide magnets and coils; a guide groove is formed in outside of the working cylinder barrel; relative sliding is achieved between the dust-proof housing and the working cylinder barrel by means of a steel ball in the guide groove; the coils are fixed in damping holes, just opposite to a piston, of the housings; and coefficient of viscosity of a magnetorheological fluid is affected by current magnitude of the coils such that output of damping force of the damper is thus affected. The coil externally-wrapping magnetorheological fluid damper has following beneficial effects: the excitation coils surround the outside of the working cylinder such that heat of the working cylinder barrel in work can be timely dispersed and magnetic field distribution near the working cylinder can be improved; therefore, the damper has great damping force and a wider adjusting range of damping force; the coils can be easily detached for replacement if damage occurs so that the coils are economical and practical; service lifetime of the damper is prolonged and usage performance of the coil externally-wrapping magnetorheological fluid damper is enhanced; and compared with a conventional mode that a middle hole is casted in the piston rod, the mode that the coils are directly placed outside is more convenient and has an easy process.

Owner:SHANDONG UNIV OF TECH

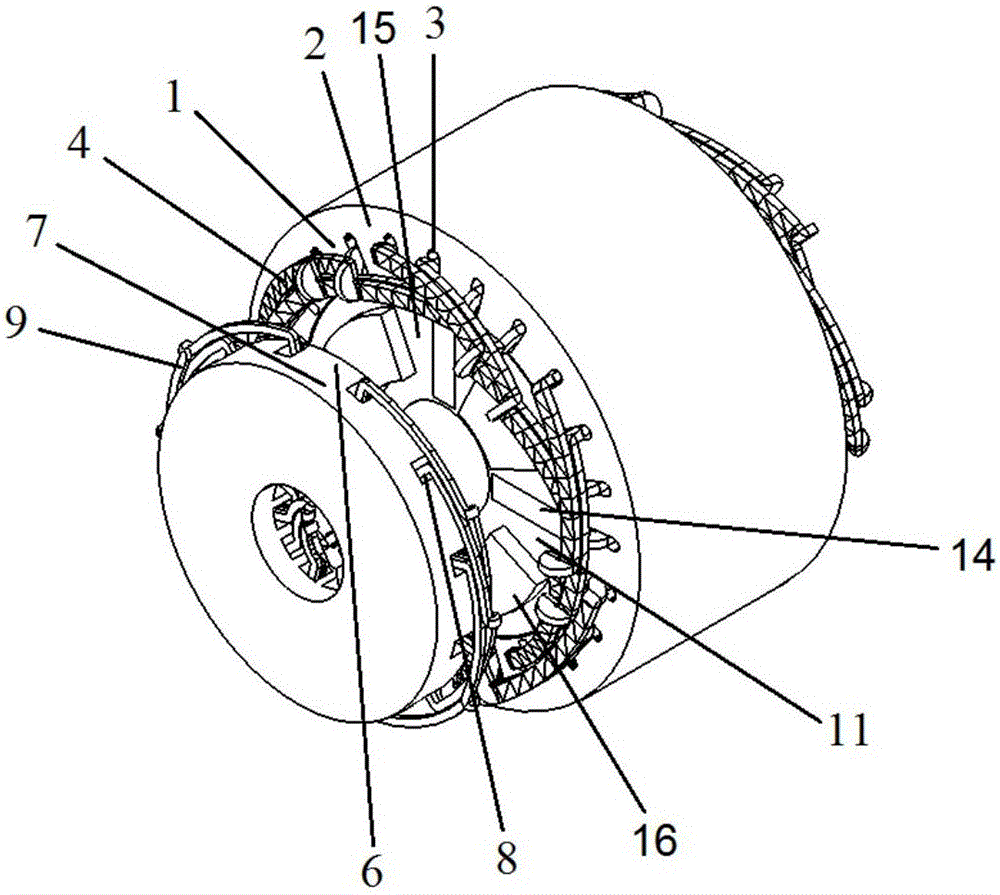

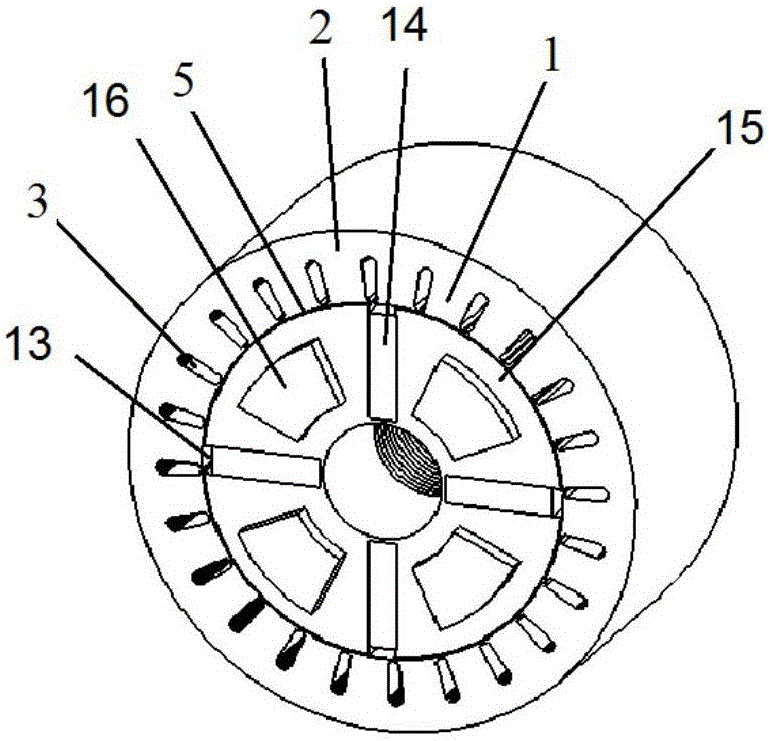

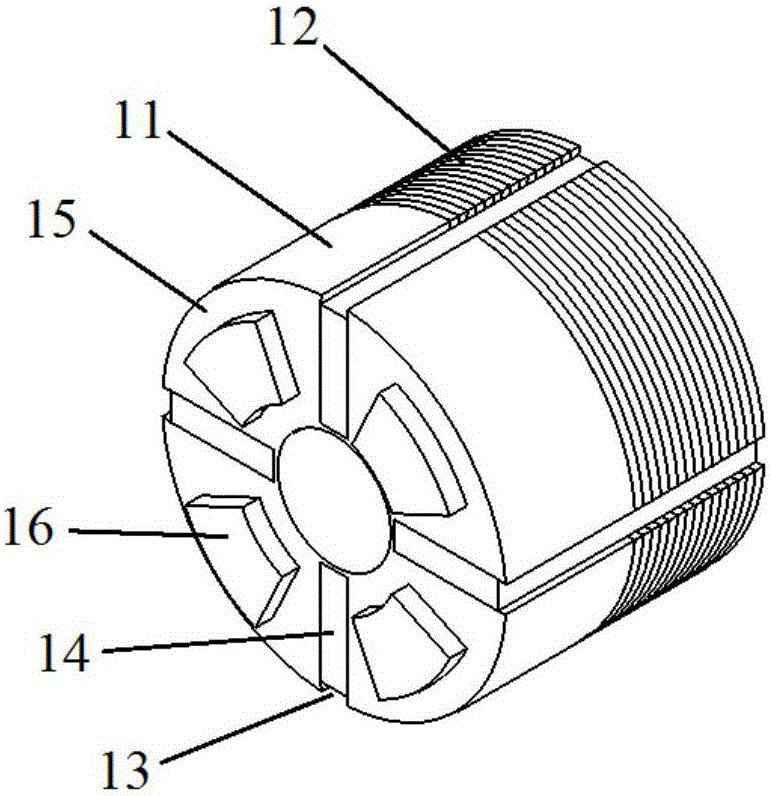

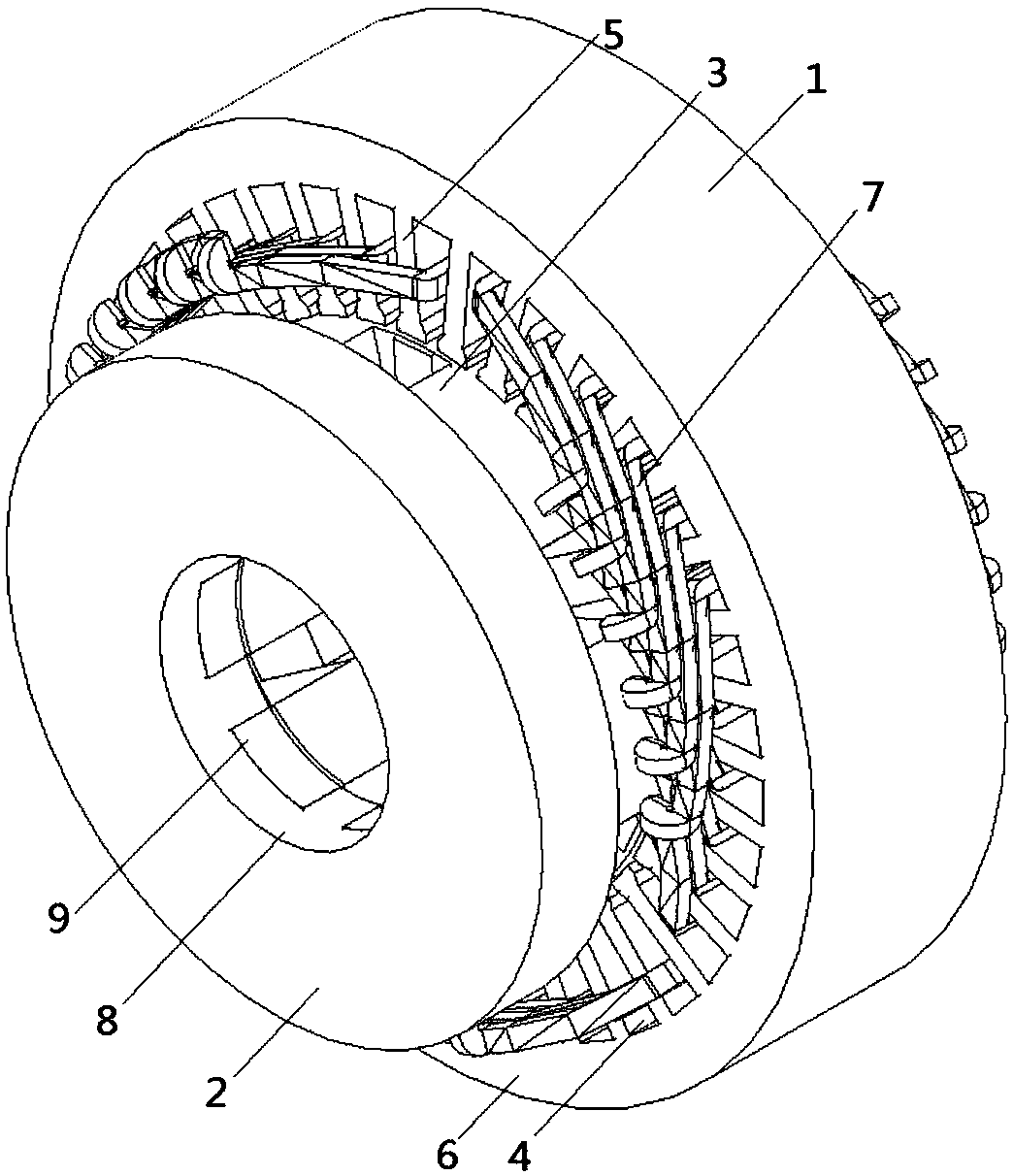

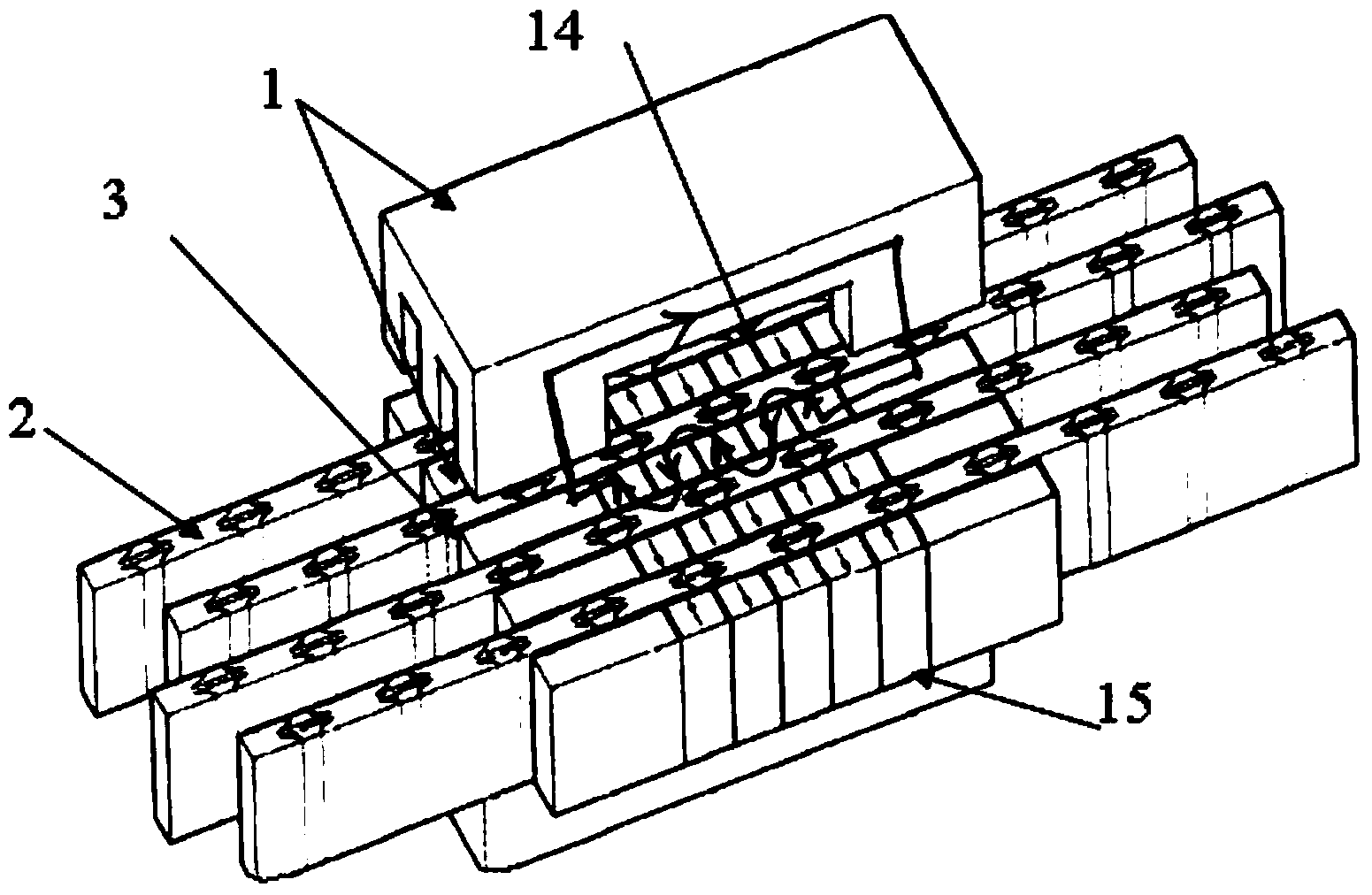

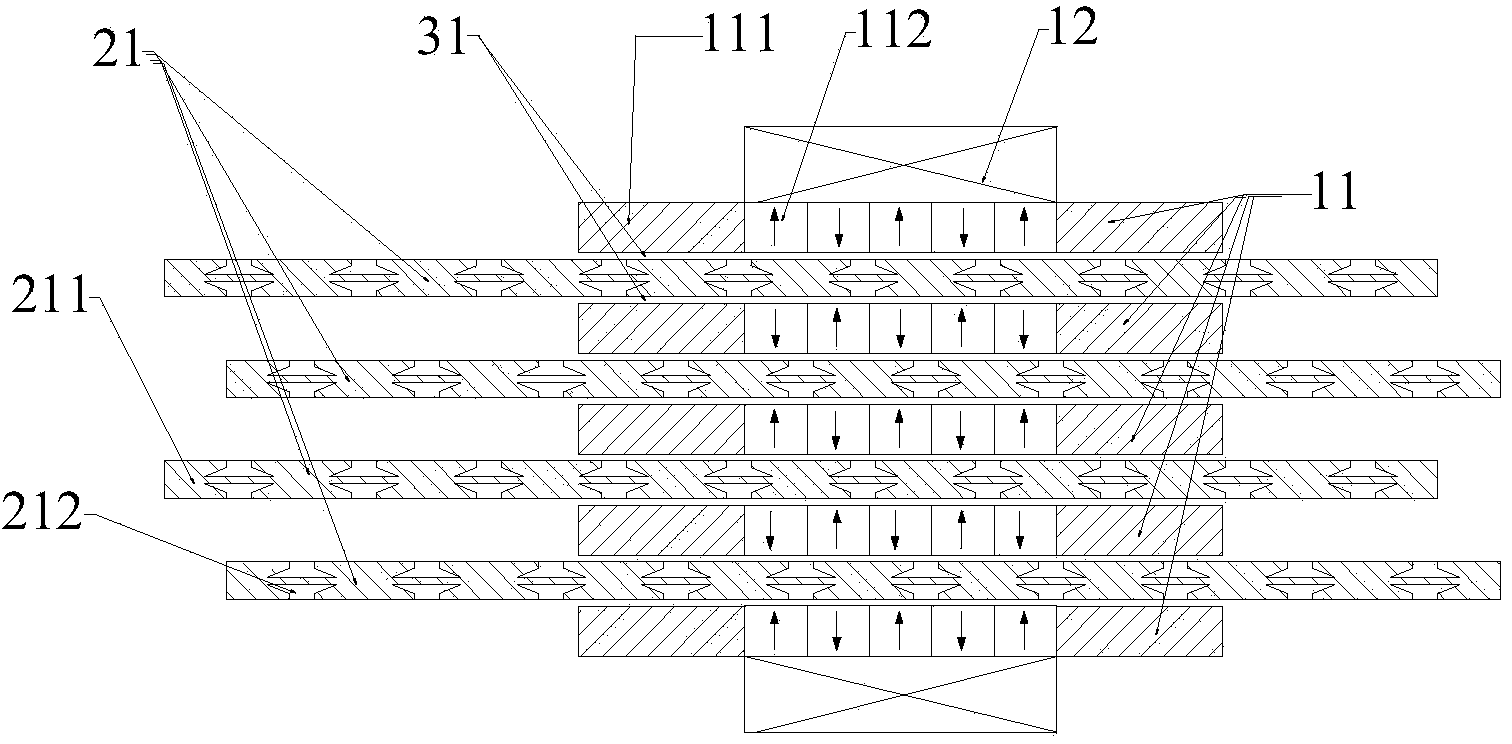

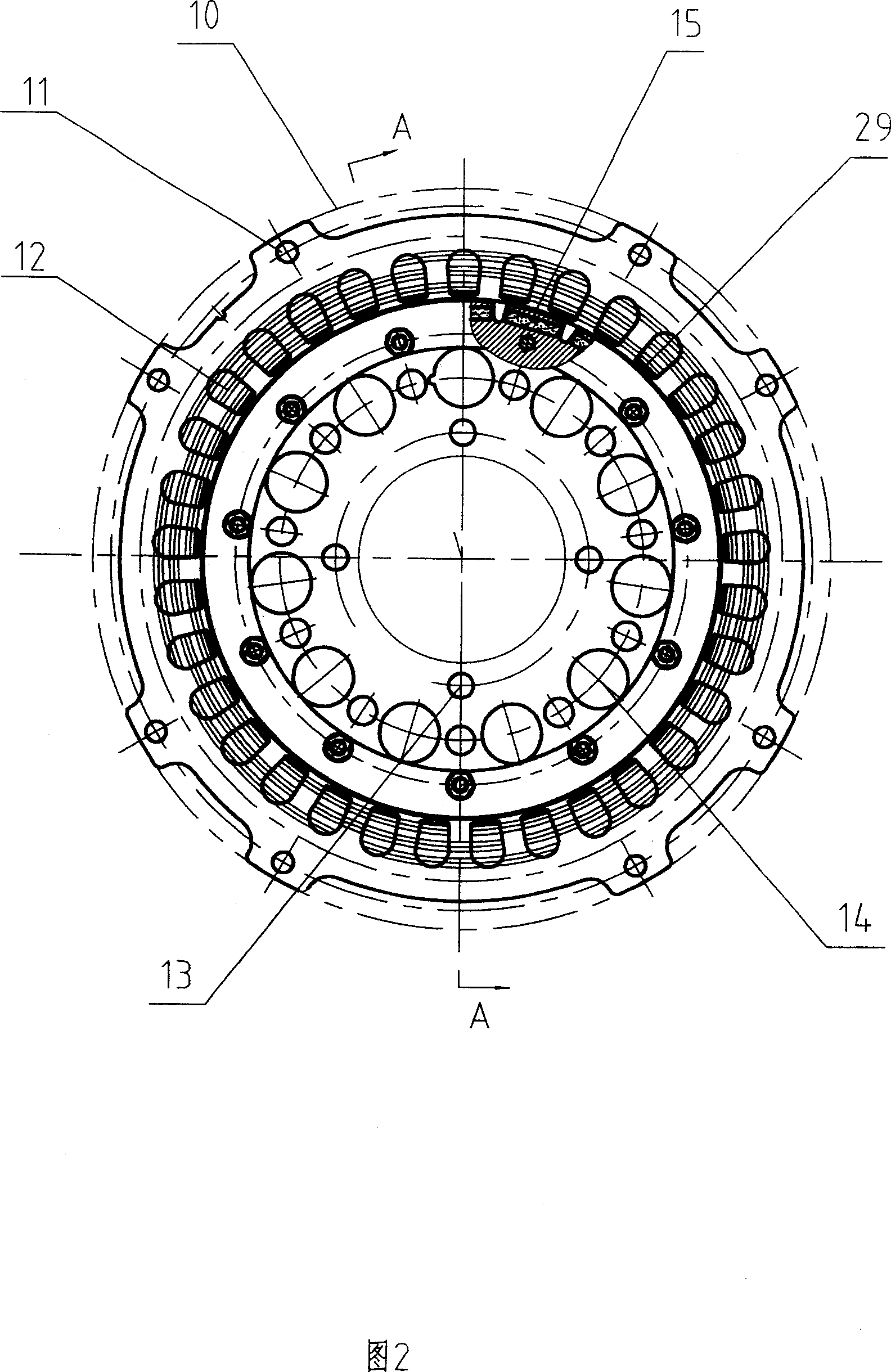

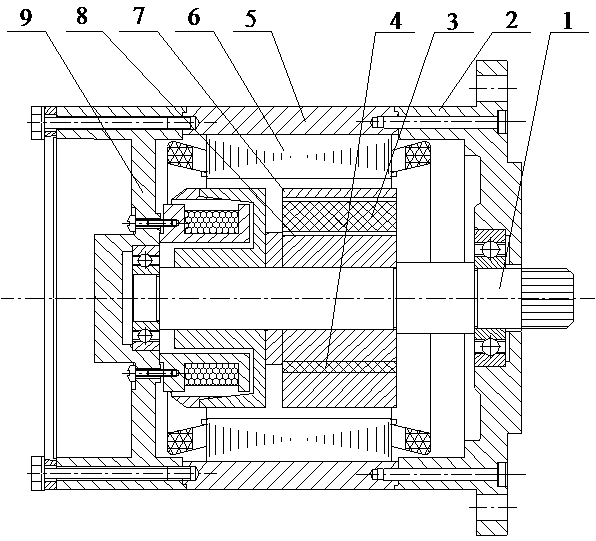

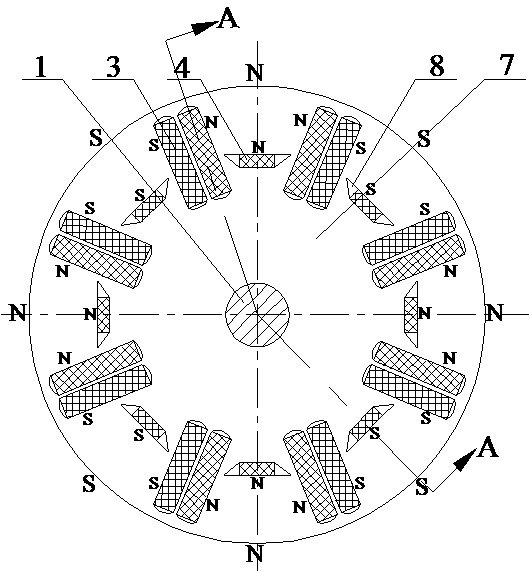

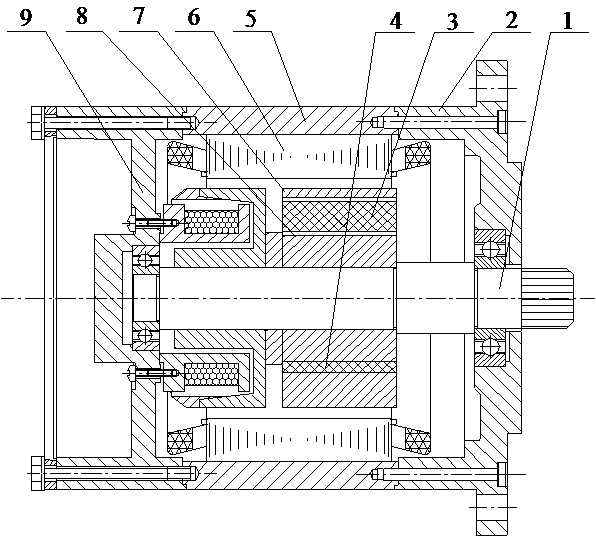

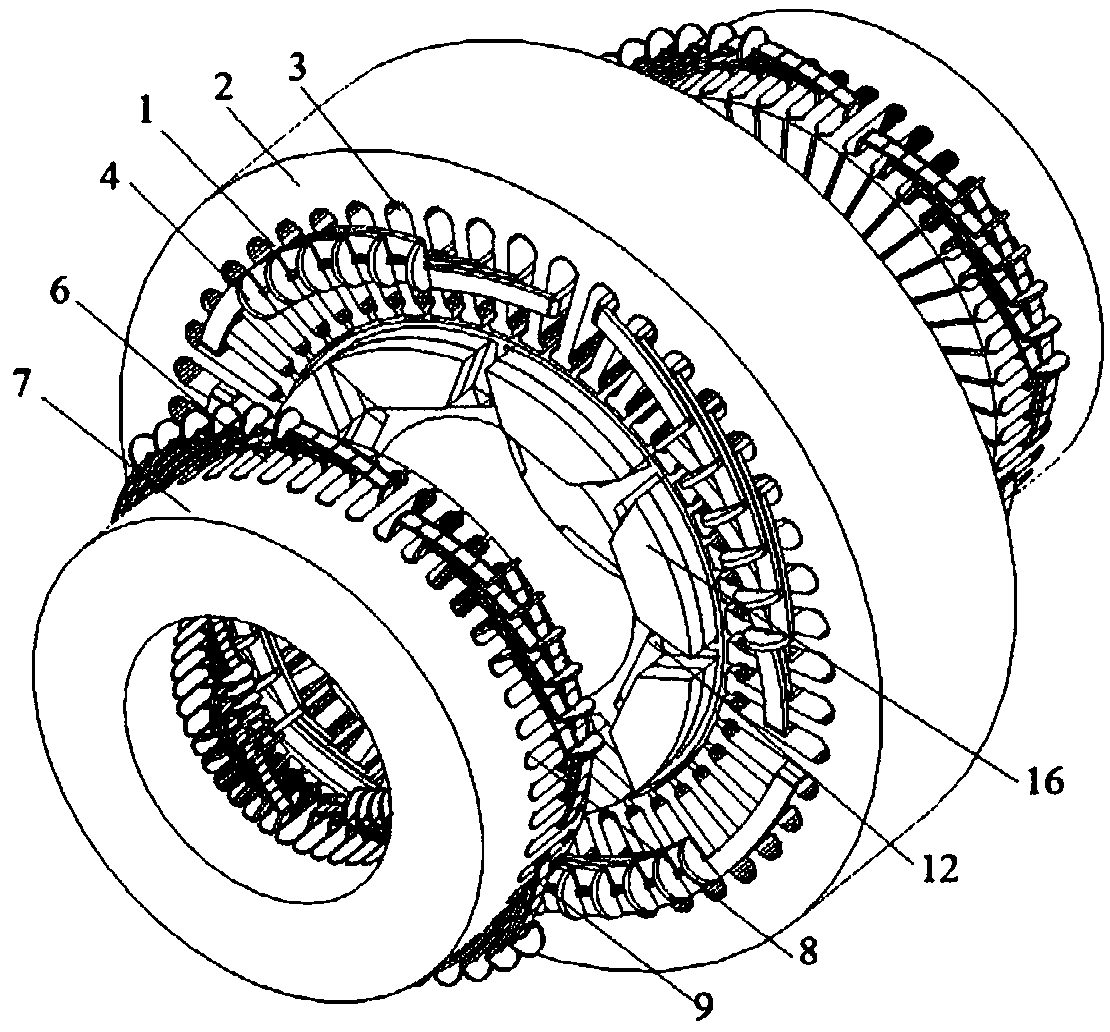

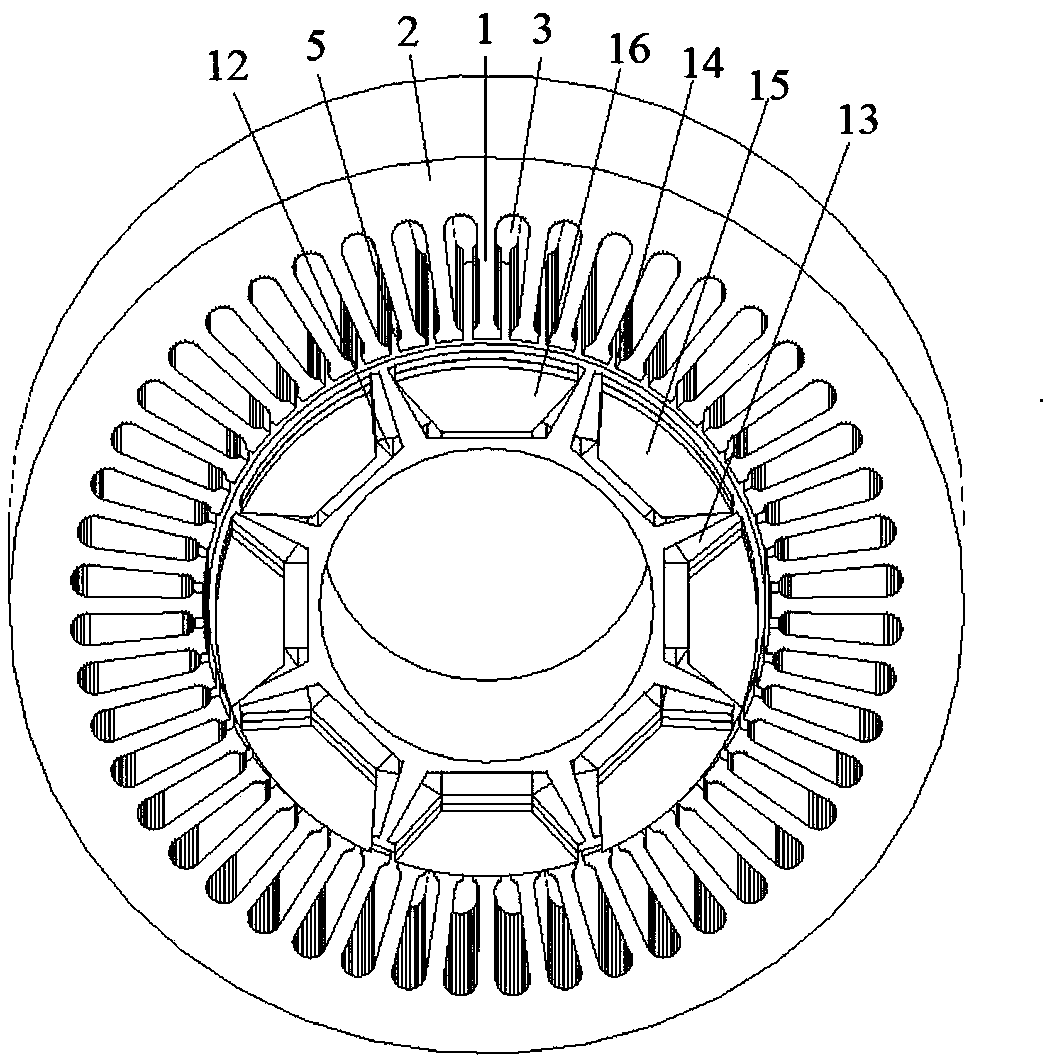

Permanent magnet synchronous motor with two stators, composite rotor structure and radial and axial mixed magnetic paths and method thereof

ActiveCN105790470AHigh torque densityHigh power densityMagnetic circuit rotating partsElectric machinesElectric machinePermanent magnet synchronous motor

The invention discloses a permanent magnet synchronous motor (PMSM) with two stators, a composite rotor structure and radial and axial mixed magnetic paths and a method thereof. The PMSM comprises a radial stator, an axial stator and a rotor, wherein the rotor is inserted in the radial stator and coaxially arranged with the radial stator, the axial stator is arranged on one end or two ends of the rotor, the axial stator and the rotor are concentric, a radial winding is arranged in the stator groove of the radial stator, an axial winding is arranged in the stator groove of the axial stator, a rotor groove is arranged in the rotor, a permanent magnet is placed in the rotor groove, the permanent magnet enables the rotor to generate a radial magnetic pole and an axial magnetic pole, the radial magnetic pole faces the radial stator of the motor, the axial magnetic pole faces the axial stator of the motor, and the motor generates radial and axial torques to form mixed magnetic paths. The radial magnetic flux and axial magnetic flux generated by the permanent magnet of the motor can be utilized, end portion magnetic leakage can be eliminated, the utilization rate of motor material is improved, and the weight of the motor is reduced.

Owner:SHANDONG UNIV

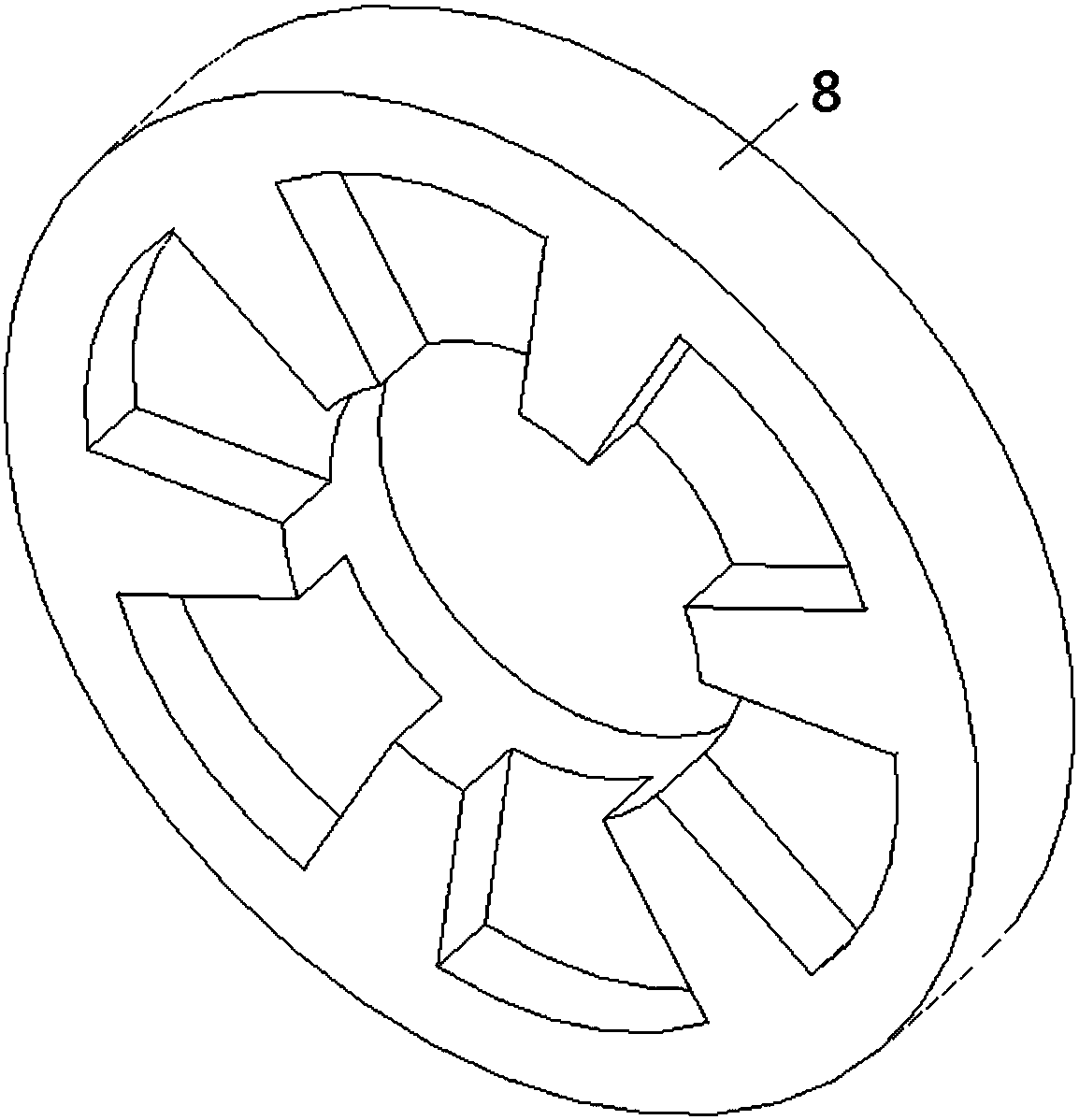

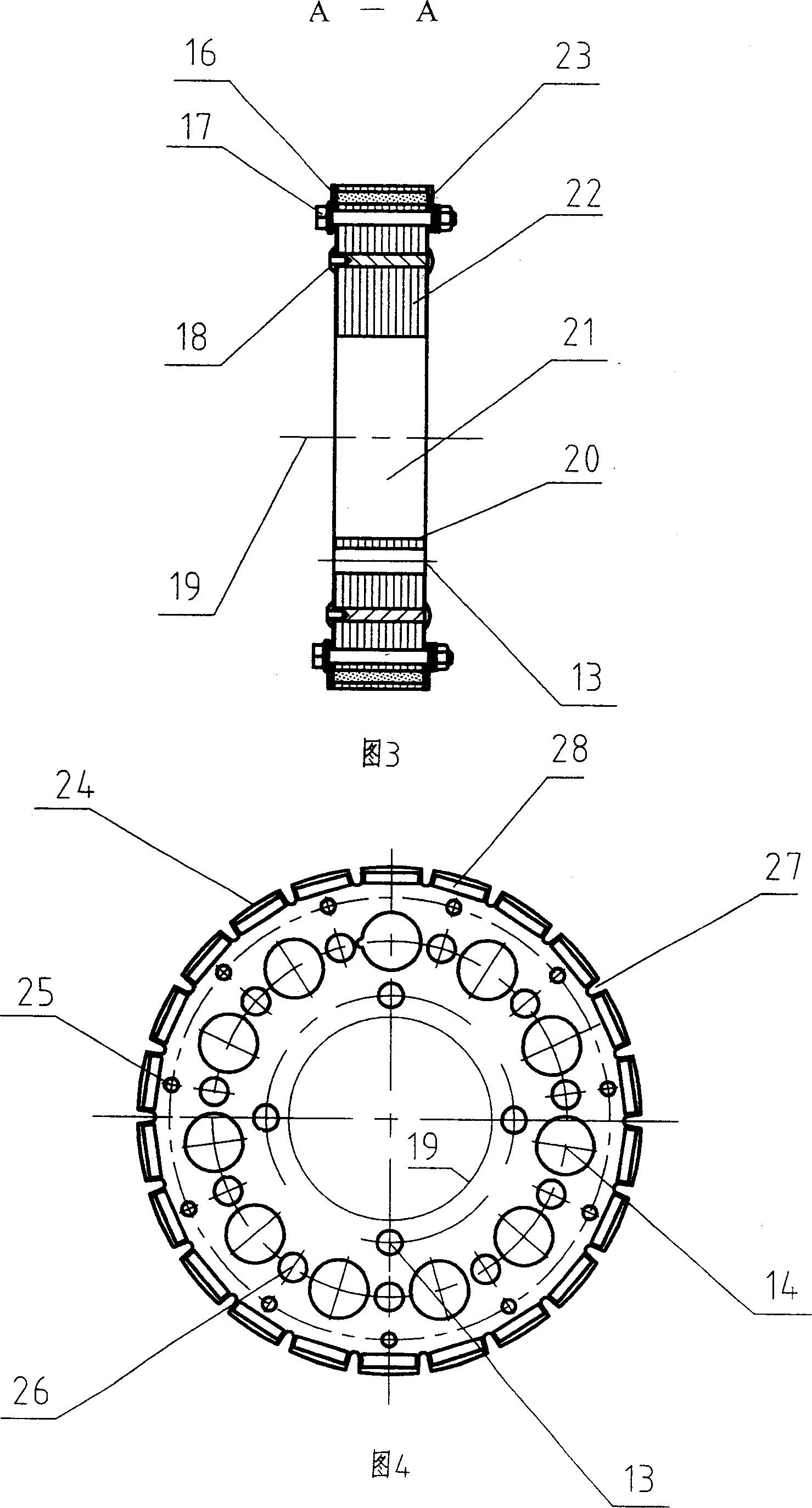

Double-rotor hybrid excitation permanent magnet synchronous motor for electric vehicle and method thereof

PendingCN108418368AAdequate heat dissipationImprove compactnessSynchronous machine detailsMagnetic circuit rotating partsElectric machinePermanent magnet synchronous motor

The invention discloses a double-rotor hybrid excitation permanent magnet synchronous motor for an electric vehicle and a method thereof. The motor comprises a radial stator, an axial rotor and a radial rotor. The radial rotor is placed inside the radial stator and is coaxially arranged with the radial stator. The radial rotor is provided with the axial rotor at the end portion, and the axial rotor is coaxially arranged with the radial rotor. The axial rotor is driven by a servo motor to rotate, so that the axial rotor and the radial rotor maintain the same rotational speed. The radial rotor is provided with a permanent magnet thereon. A part of the magnetic flux generated by the permanent magnet enters the radial stator through a radial gap to generate a radial main magnetic flux, and theother part enters the axial rotor through an axial air gap to generate an axial main magnetic flux. The axial magnetic flux and the radial magnetic flux are in a parallel relationship. The axial magnetic flux of the radial rotor can be adjusted by changing the relative positions of the axial rotor and the radial rotor. Therefore, the radial magnetic flux of the radial rotor is indirectly controlled, the hybrid excitation function is achieved and the economic operating range of the electric vehicle drive motor is expanded.

Owner:SHANDONG UNIV

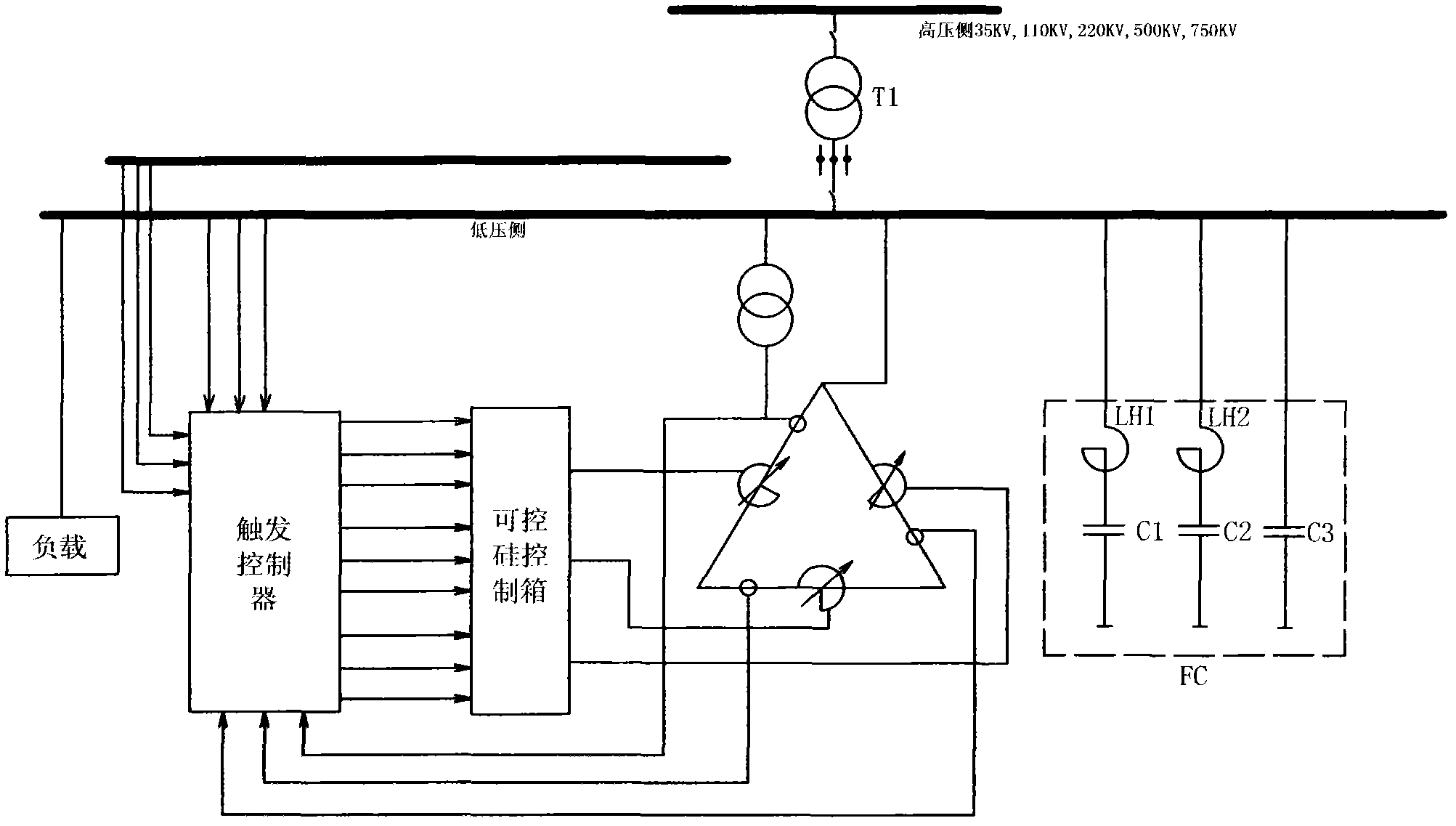

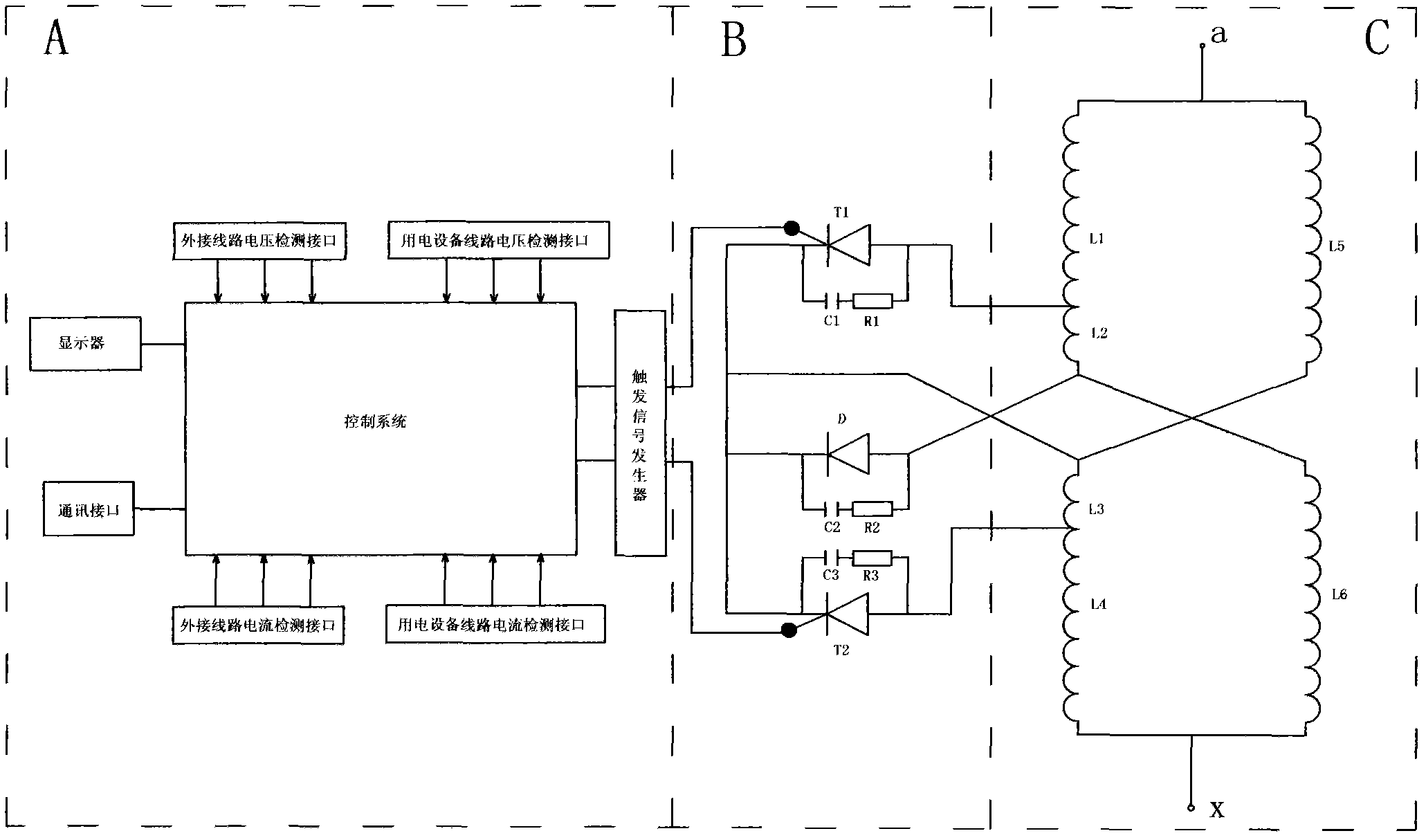

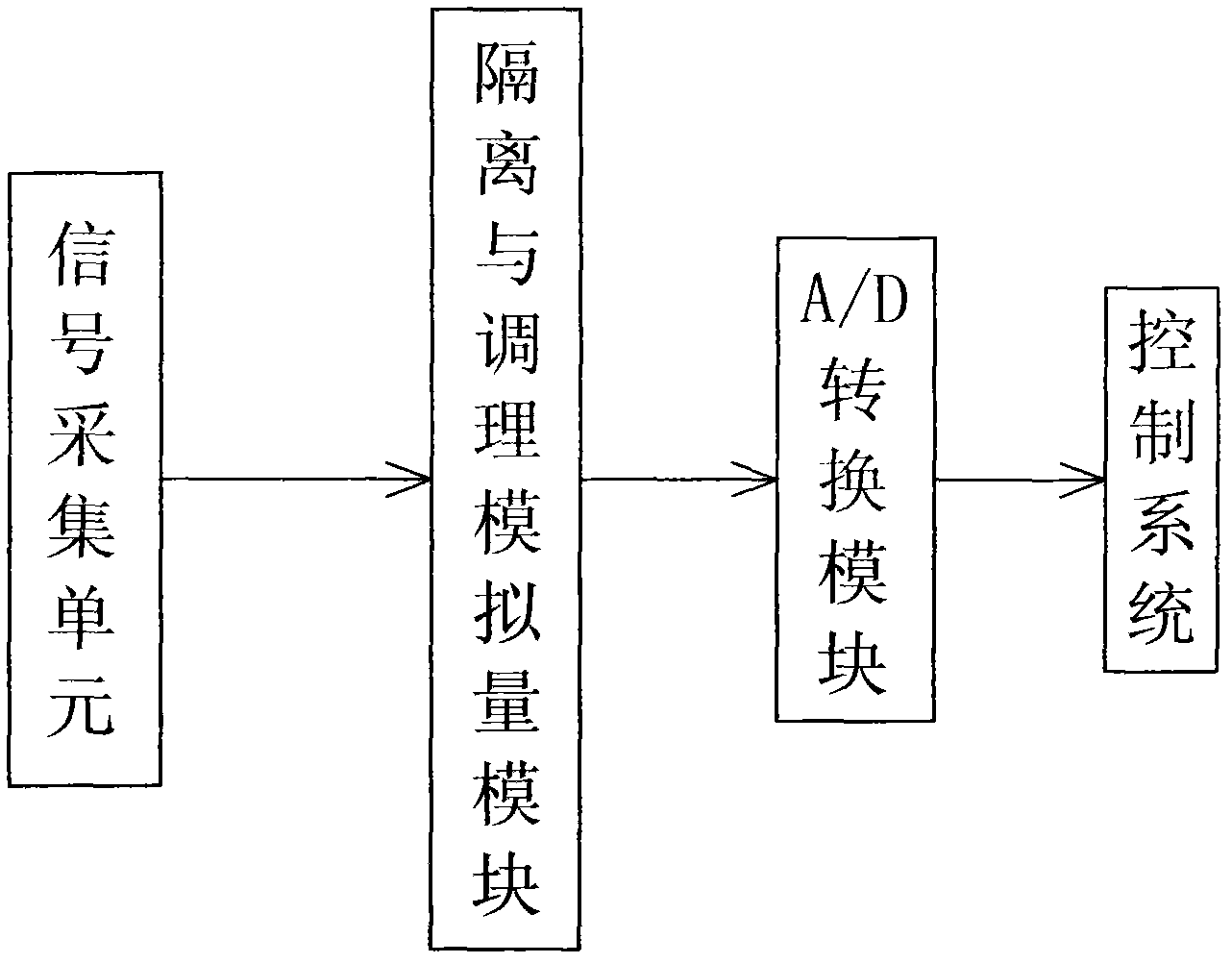

Dynamic reactive compensation system based on magnetic control electric reactor

InactiveCN102810867AIncrease active power outputImprove efficiencyReactive power adjustment/elimination/compensationReactive power compensationOvervoltageEngineering

The invention relates to a dynamic reactive compensation system based on a magnetic control electric reactor. The dynamic reactive compensation system comprises a passive filter FC and an MCR (Magnetic Control Reactor), wherein the passive filter FC is used for reactive compensation and harmonic filter, the MCR is used for balancing an inductive load. The dynamic reactive compensation system disclosed by the invention has the advantages that the reliability if high, 20-year basic maintenance-free running can be realized, and the maintaining and repairing cost can be reduced to a large extent; the response ability is quick, and the response speed can be up to 20ms; the regulating range is large, and the regulating range in more than 100 times can be reached; the occupied area is small, the installation is convenient, and a device can be naturally cooled by adopting an oil immersion mode; the harmonic wave is small and has no pollution to a power grid and has no any bad influence on a capacitor group, and the traditional device is conveniently utilized in a reform occasion; the overload ability is strong, 30-second 100% overload and half-hour 40% overload can be realized; the consumption is less, the MCR is in large capacity, the consumption is less than 0.5%, and in a common system, only 0.8%-1.5% of the consumption can be realized; the overvoltage ability is strong, the voltage limiting ability is good, and the dynamic reactive compensation system has a natural automatic voltage limiting ability; and no electromagnetic pollution works on the environment and the human body.

Owner:青岛海电电气有限公司

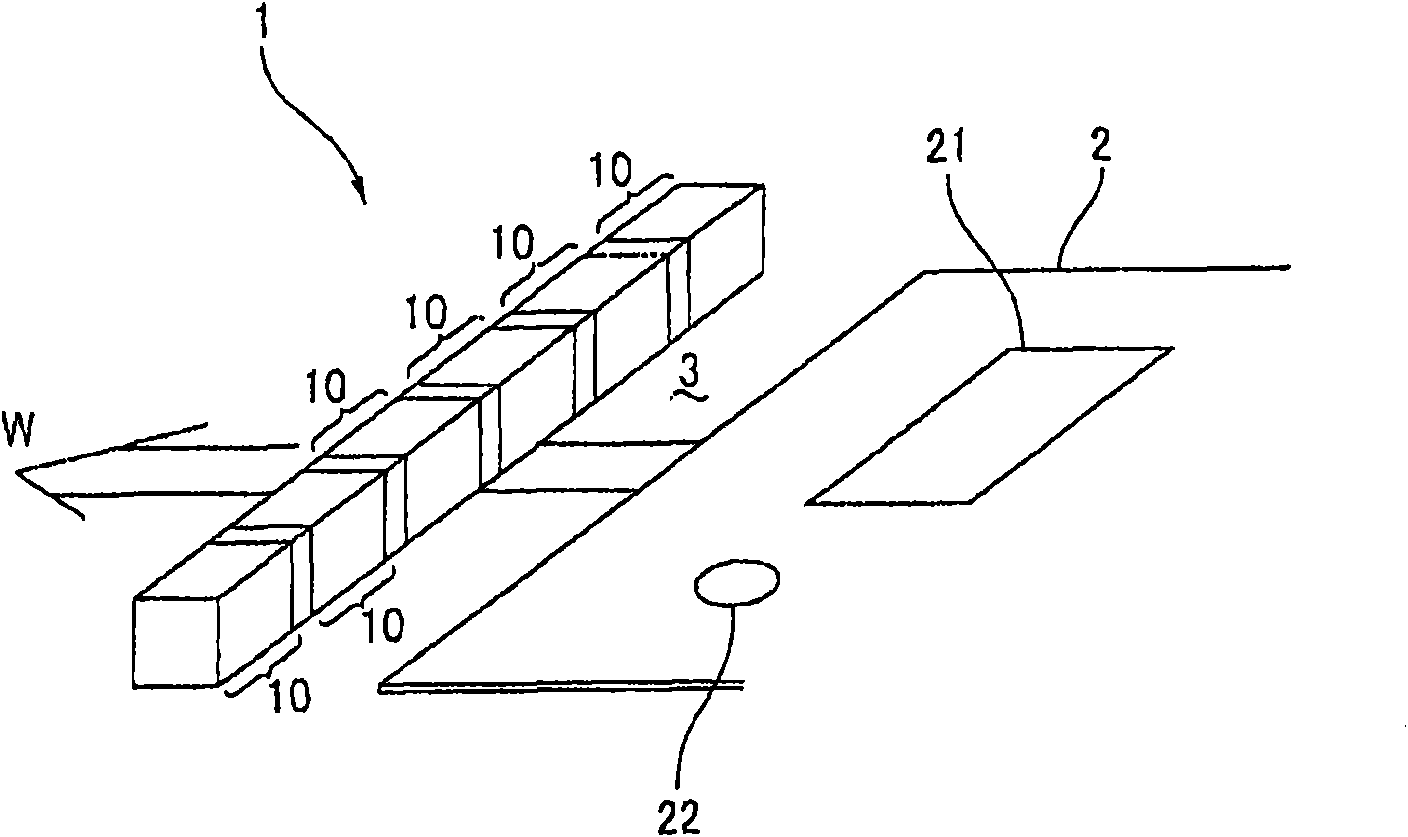

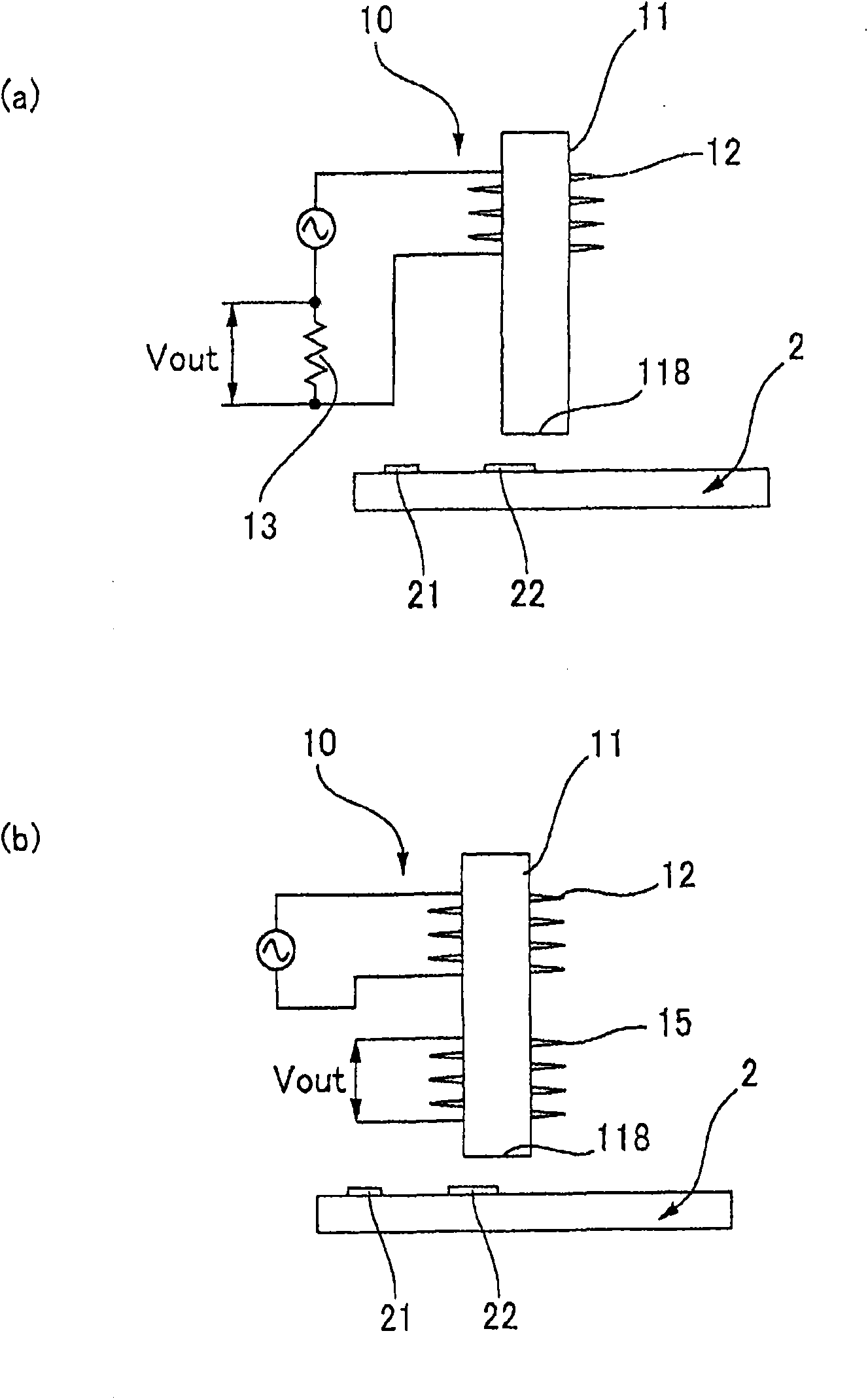

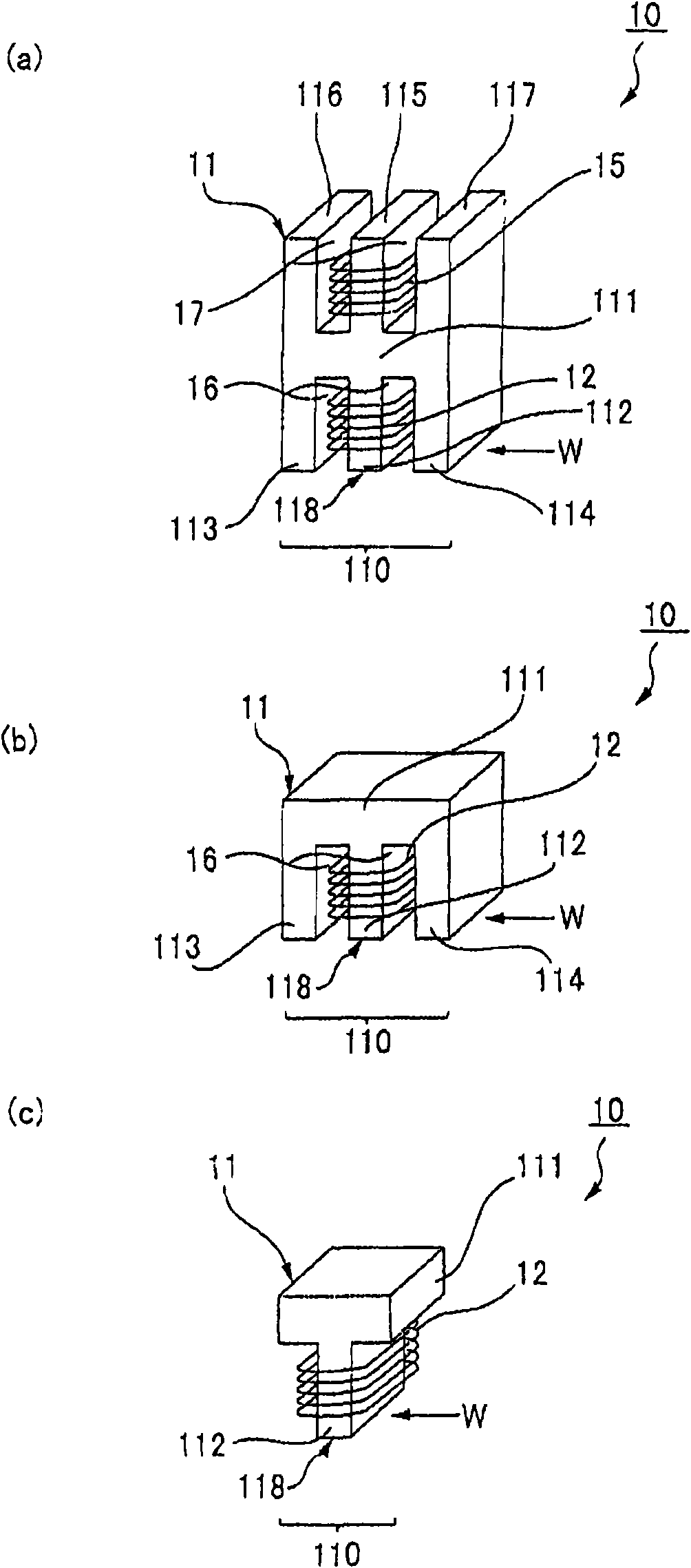

Magnetic sensor and device for identifying sheet

InactiveCN101777206AConductiveAvoid getting stuckPaper-money testing devicesCoin countersWear resistantIdentification device

A magnetic sensor (10) comprises a core body (11) having a sensor face (110) whereupon an air gap (16) is opened, and an exciting coil (12) arranged in the air gap (16). A nonmagnetic wear resistant member (18) exhibiting conductivity is arranged in the air gap (16) on the side closer to the sensor face (110) than the exciting coil (12). A sheet identifying device (1), which is provided with the magnetic sensor (10) arranged on a conveyance passage (3) for the sheet (2) and identifies the sheet (2) being conveyed on the conveyance passage (3) based on the detection results from the magnetic sensor (10), comprises a core body (11) equipped with a magneto-sensitive portion (118) directed toward the conveyance passage (3), and an exciting coil (12) wound around the core body (11) in order to detect a pattern for generating a magnetic field in the conveyance passage (3) when an AC current is supplied. The magnetic sensor detects a first pattern (21) formed on the sheet (2) by a magnetic material and a second pattern (22) formed on the sheet (2) by a nonmagnetic material based on the detection results of magnetic field variation caused when the sheet (2) is conveyed on the conveyance passage (3).

Owner:SANKYO SEIKI MFG CO LTD

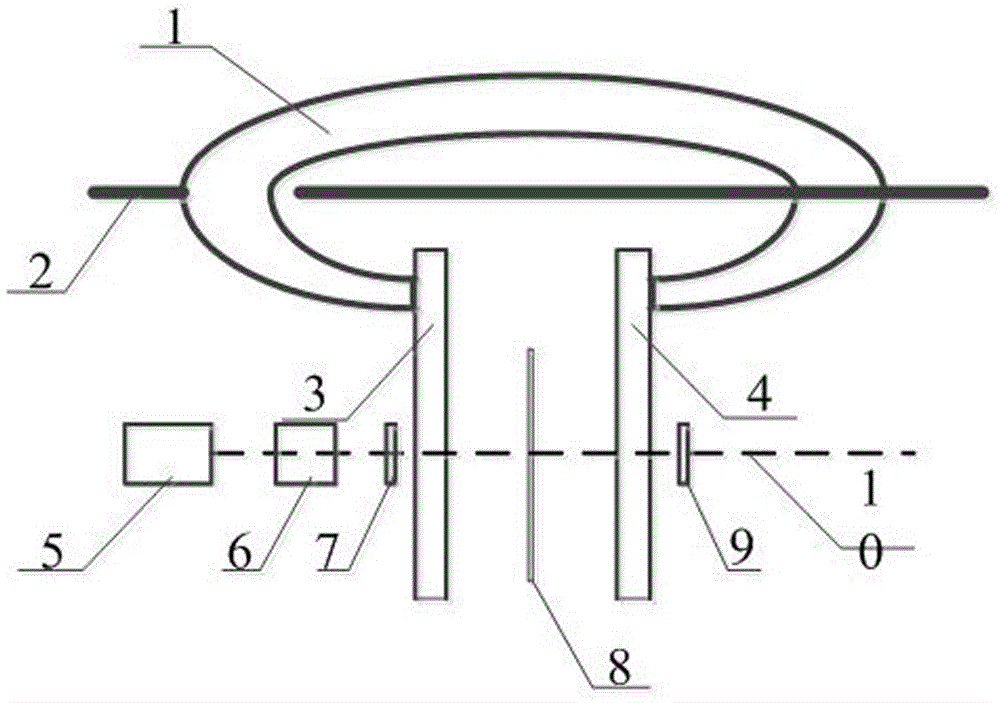

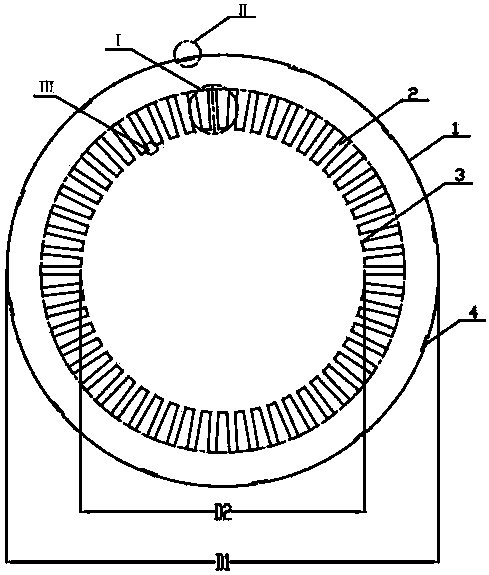

Straight optical path linear optical current sensor and current detection method

InactiveCN106597053AReduces the effects of birefringenceAchieving Linear MeasurementsCurrent measurements onlyVoltage/current isolationGratingLight spot

The invention relates to a straight optical path linear optical current sensor and a current detection method. The sensor comprises a light source, a collimator, a polarizer, a first magnetic conduction plate, a magneto optical film, a second magnetic conduction plate and a radial polarization grating. The first magnetic conduction plate is arranged at one side of an air gapped ferromagnetic concentrator ring air gap opening, and the second magnetic conduction plate is arranged at the other side of the ferromagnetic concentrator ring air gap opening. The sensor also comprises a current-carrying wire which goes through a ferromagnetic concentrator ring. The detection method comprises the steps that: a light signal from the light source passes the collimator, the polarizer, the first magnetic conduction plate, the magneto optical film and the second magnetic conduction plate to reaches the radial polarization grating, a light spot with a fixed shaped is obtained by radial polarization, and through measuring the rotation angle of the light spot, the current value to be measured in the current-carrying wire is obtained. According to the device and the method of the invention, the reflection phase shift is eliminated, the measurement sensitivity is increased, the detection mode is independent of optical power, and the ranges and sensitivity of linear measurement and dynamic measurement are improved greatly.

Owner:FUZHOU UNIV

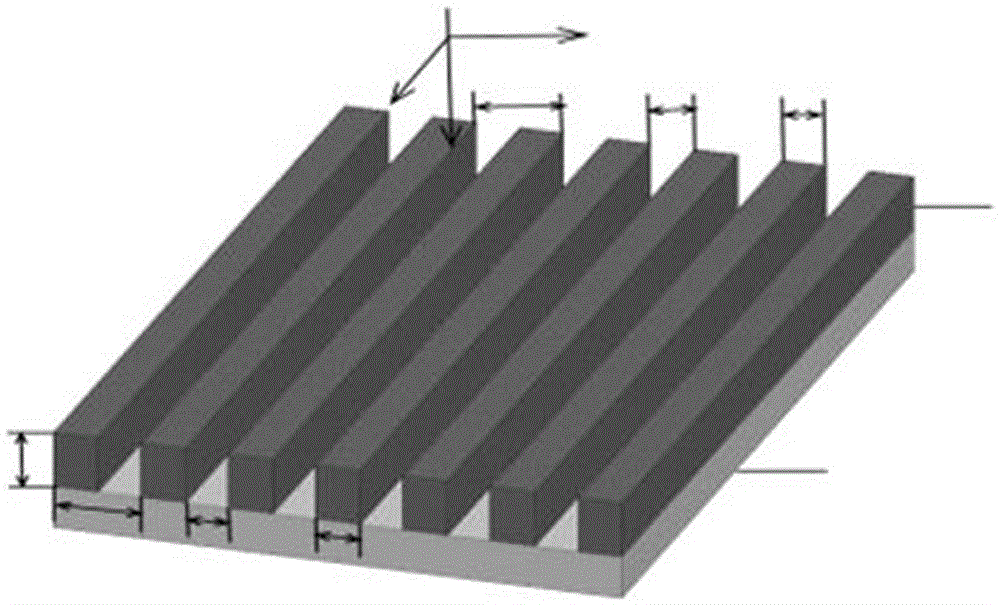

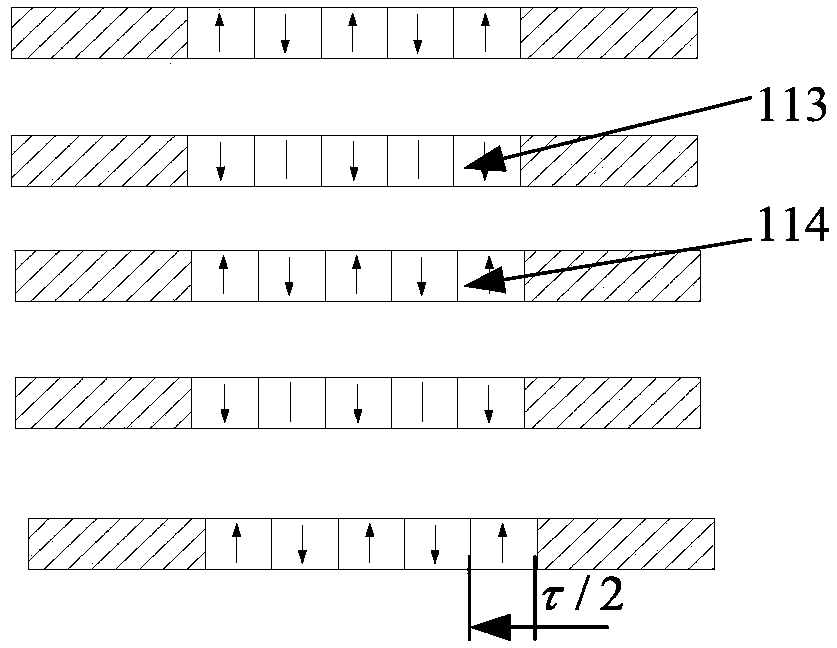

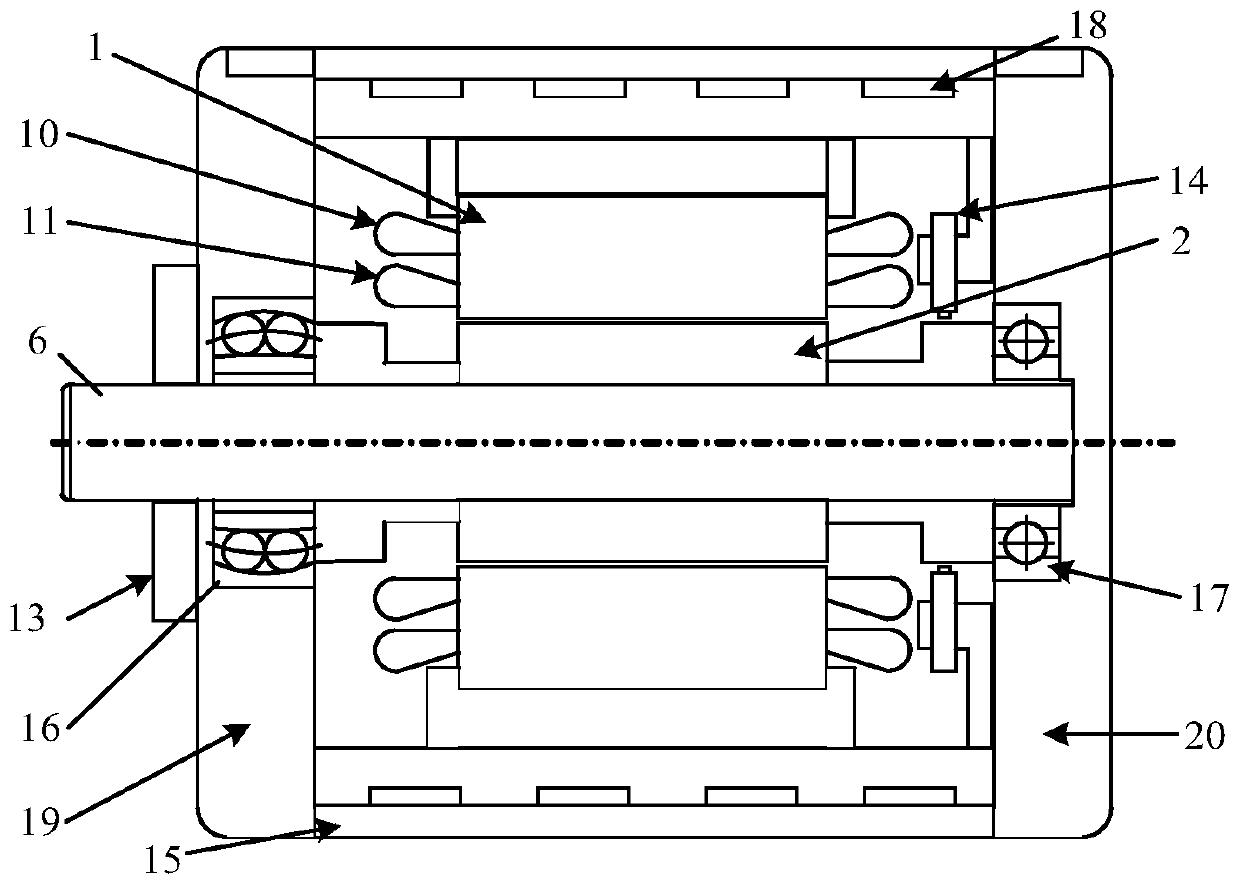

Three-dimensional magnetic flux permanent magnet linear motor of multi-air-gap independent winding structure

InactiveCN103915971AIncrease thrust densityIncrease the air gap areaPropulsion systemsElectric machinePermanent magnet linear motor

The invention provides a three-dimensional magnetic flux permanent magnet linear motor of a multi-air-gap independent winding structure and belongs to the technical field of motors. The three-dimensional magnetic flux permanent magnet linear motor comprises a primary assembly, a secondary assembly and multiple air gaps. The primary assembly comprises n primary units and armature windings, and the primary units are arranged perpendicular to the horizontal direction. An array composed of 2m+1 permanent magnets arrayed in a polarity staggering mode is arranged on each primary unit, the width of each permanent magnet is T / 2 (T is polar distance), and two rectangular grooves are formed by annular magnetic permeability iron cores arranged at the two ends of each permanent magnet and the permanent magnet, and the armature windings are arranged in two grooves in the vertical direction and are the same in phase. The secondary assembly is composed of n-1 secondary units, wherein the secondary units and the primary units are arrayed perpendicular to the horizontal direction in a staggered mode, and non-magnetic-permeability grooves or magnetism isolation bridges are arranged periodically arranged on secondary unit iron cores. The non-magnetic-permeability grooves of the adjacent secondary units are staggered by T / 2 distance in the horizontal direction. The motor is provided with 2n-2 air gaps. A three-dimensional magnetic circuit is adopted for the motor, high electromagnetic loads can be effectively achieved, and the motor has the advantages of being high in thrust density and reliability.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

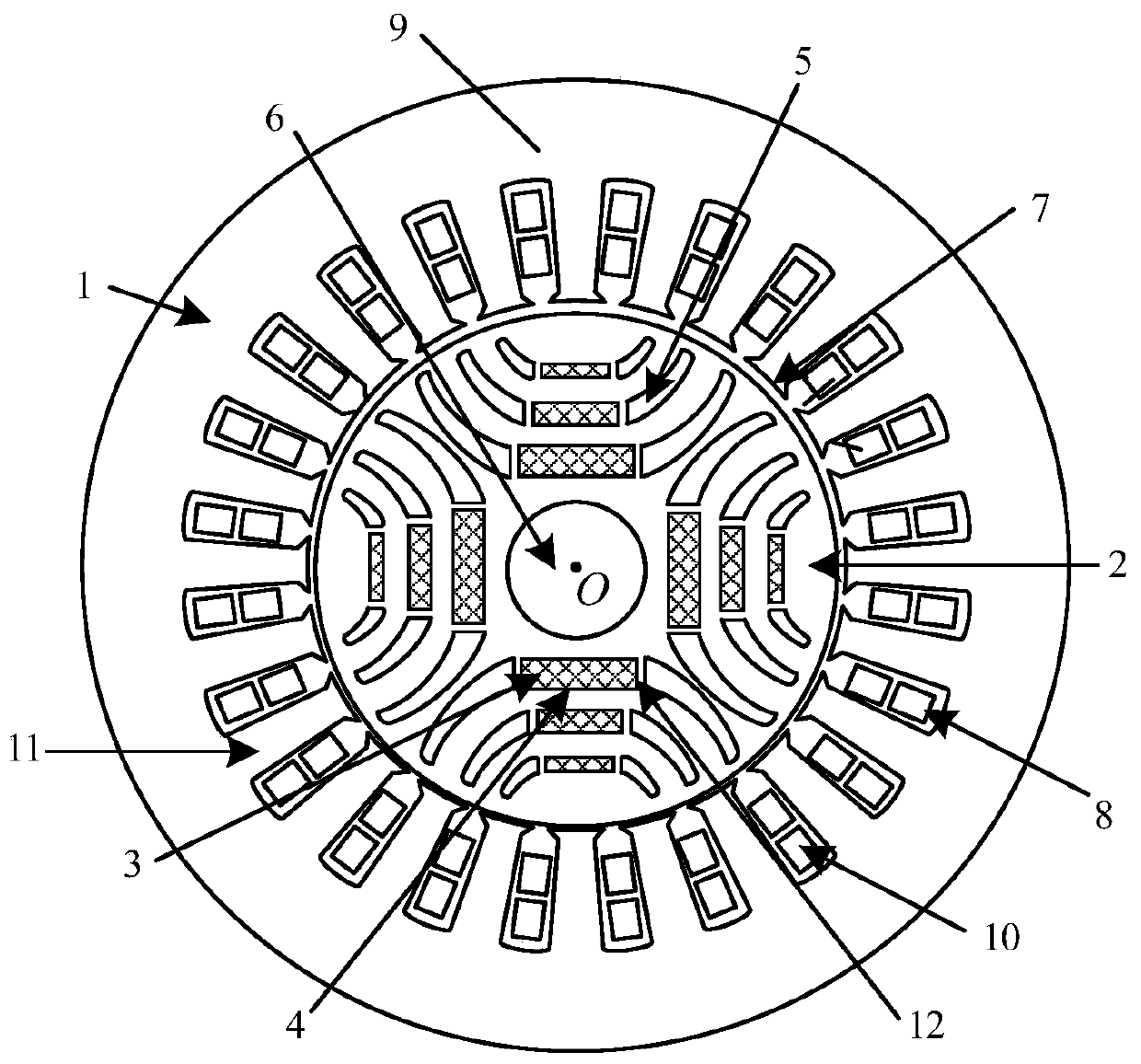

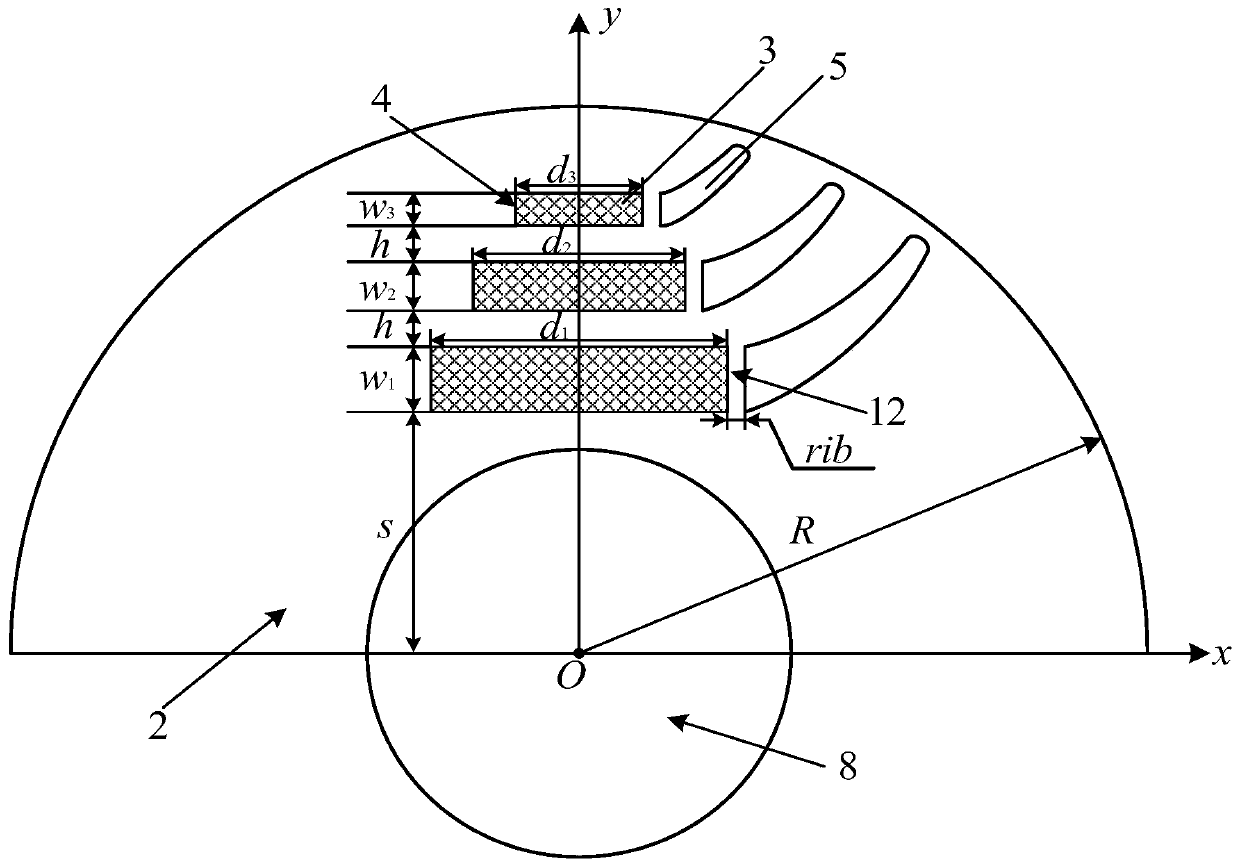

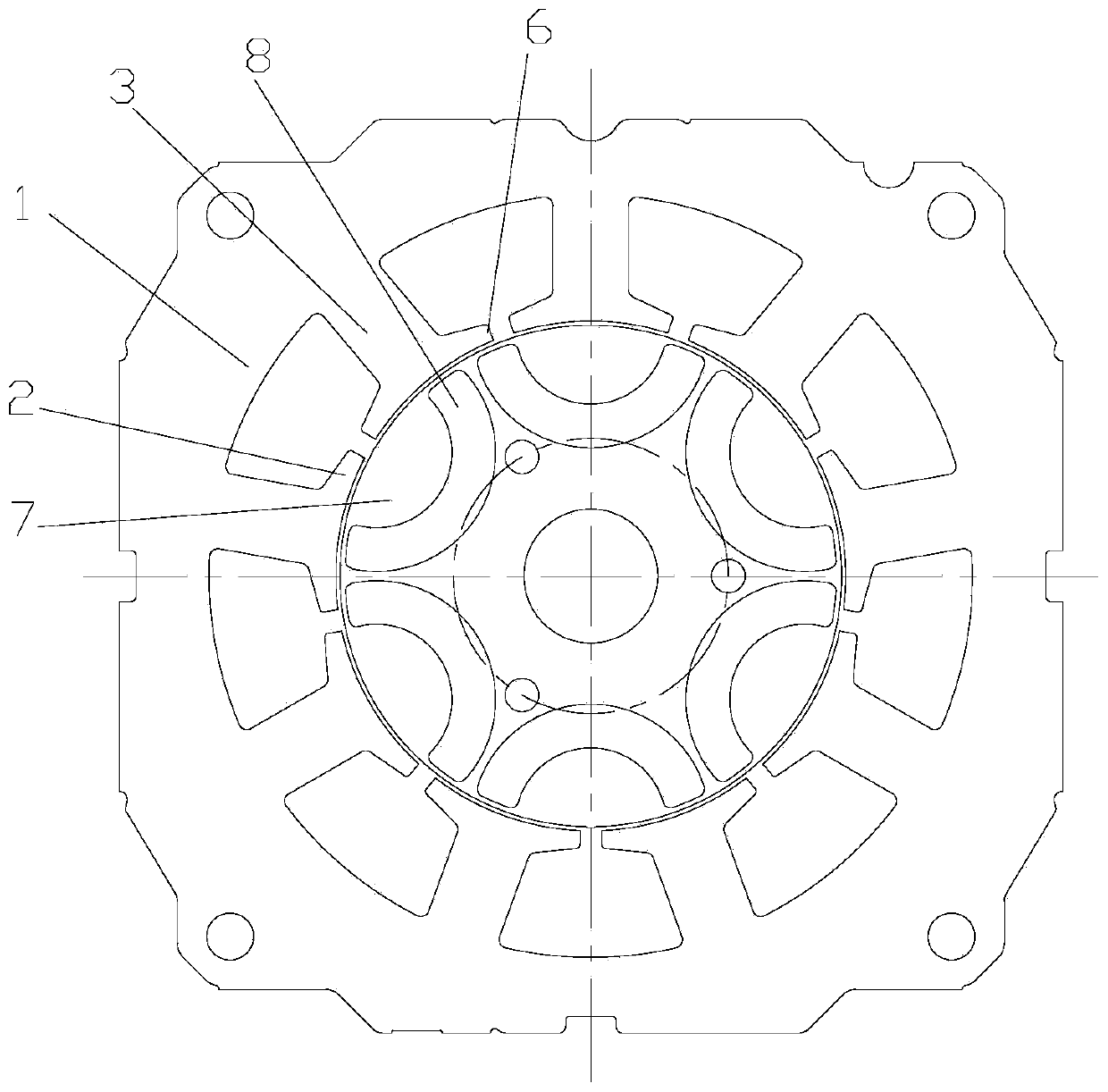

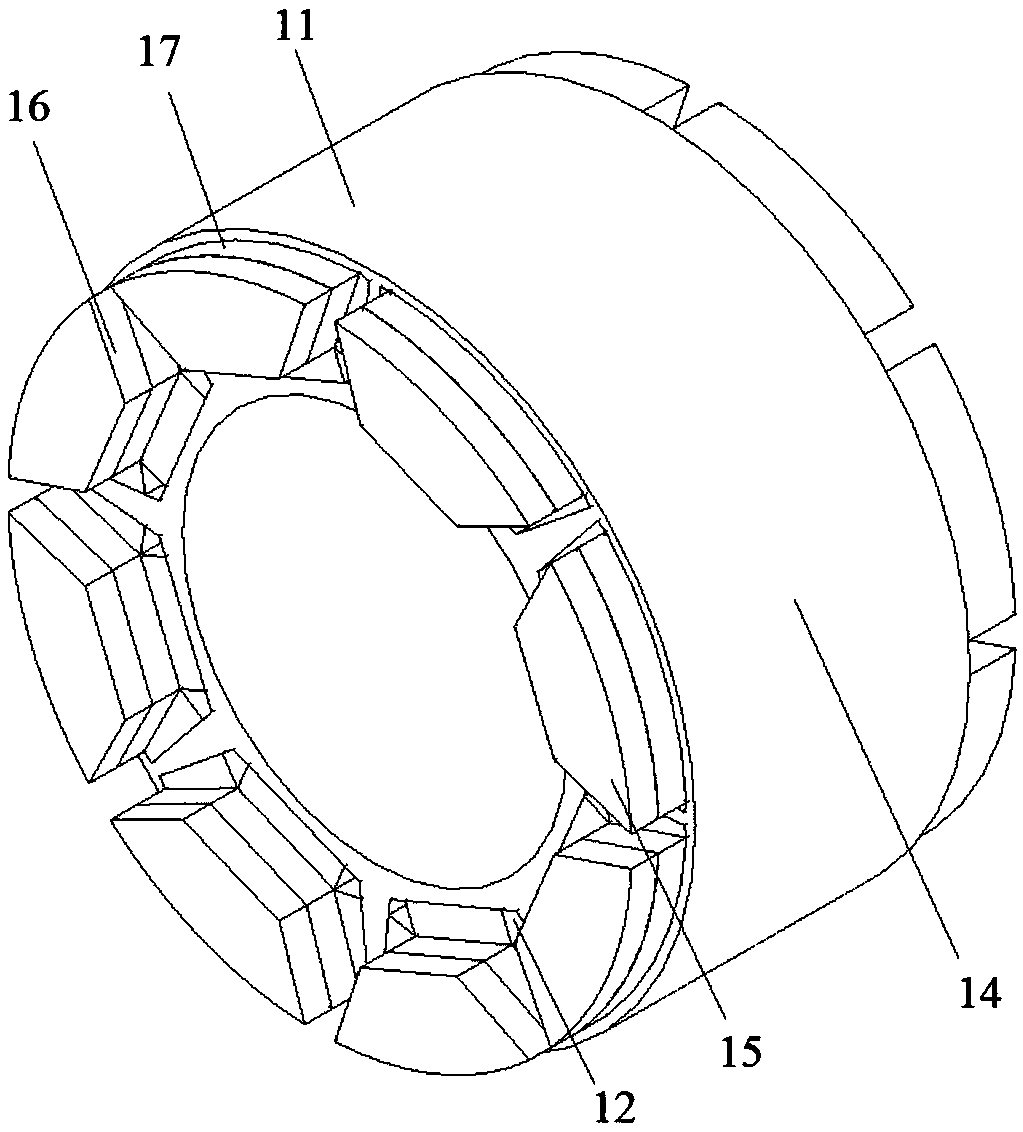

Rotor structure of permanent magnet auxiliary type bearingless synchronous reluctance motor

ActiveCN110971037AReduce workloadLarge degree of freedom of shape changeMagnetic circuit rotating partsSynchronous machine detailsMagnetic barrierSynchronous reluctance motor

The invention discloses a rotor structure of a permanent magnet auxiliary type bearingless synchronous reluctance motor. Four groups of magnetic barriers are uniformly and symmetrically arranged on the rotor structure in the circumferential direction; each group of magnetic barriers is divided into an inner layer, a middle layer and an outer layer from inside to outside; each layer of magnetic barrier comprises a rectangular permanent magnet mounting groove, two magnetic isolation bridges which are symmetrically distributed relative to the center line of the diameter direction of the permanentmagnet mounting groove, and two rib parts which are arranged between the permanent magnet mounting groove and the magnetic isolation bridges; a permanent magnet is fixedly embedded into the permanentmagnet mounting groove in each layer of magnetic barrier; the radial contour line of each magnetism isolating bridge comprises a magnetism isolating bridge outer boundary line, a magnetism isolatingbridge inner boundary line and a magnetism isolating bridge end part; and the two ends of the end of the magnetic isolation bridge are connected with the outer boundary line of the magnetic isolationbridge and the inner boundary line of the magnetic isolation bridge respectively, the outer boundary line of the magnetic isolation bridge, the inner boundary line of the magnetic isolation bridge andthe middle line of the magnetic isolation bridge are quadratic function curve segments, the end of the magnetic isolation bridge is composed of two Bezier cubic curves, and torque and suspension force pulsation are effectively reduced.

Owner:扬中市检验检测中心

Flaw detection device of buffer spring

ActiveCN103018322AGuaranteed to work properlyFree from outside interferenceMaterial magnetic variablesEngineeringUltimate tensile strength

The invention discloses a flaw detection device of a buffer spring. The flaw detection device of the buffer spring comprises a fixing seat, a rotary support, a roller, a connecting shaft and a rotary motor, wherein support seats are arranged at two ends of the fixing seat; transversely arranged fixing plates are arranged on the support seats; a piston of a first cylinder on each fixing plate is connected with a movable plate; a clamping electrode plate is arranged at one end of the movable plate; circumferential magnetic threading bars inserted into the buffer spring are arranged near the movable plate; the circumferential magnetic threading bars are oppositely arranged and respectively insulated with the movable plate and the clamping electrode plate; the clamping electrode plate and the two circumferential magnetic threading bars are connected with two poles of an external power supply; a convex arc surface is arranged at the end part of one circumferential magnetic threading bar; and a concave arc surface is arranged at the end corresponding to the other circumferential magnetic threading bar, and the convex arc surface is matched with the concave arc surface. By adopting the flaw detection device, the magnetization intensity and the magnetic field distribution of the circumferential magnetic threading bars can be improved; a magnetization effect of the buffer spring for flaw detection is ensured; and interference in a magnetic circuit is avoided, and the flaw detection device can be widely applied to the fields of manufacturing and overhauling of railway vehicles.

Owner:CRRC YANGTZE CO LTD

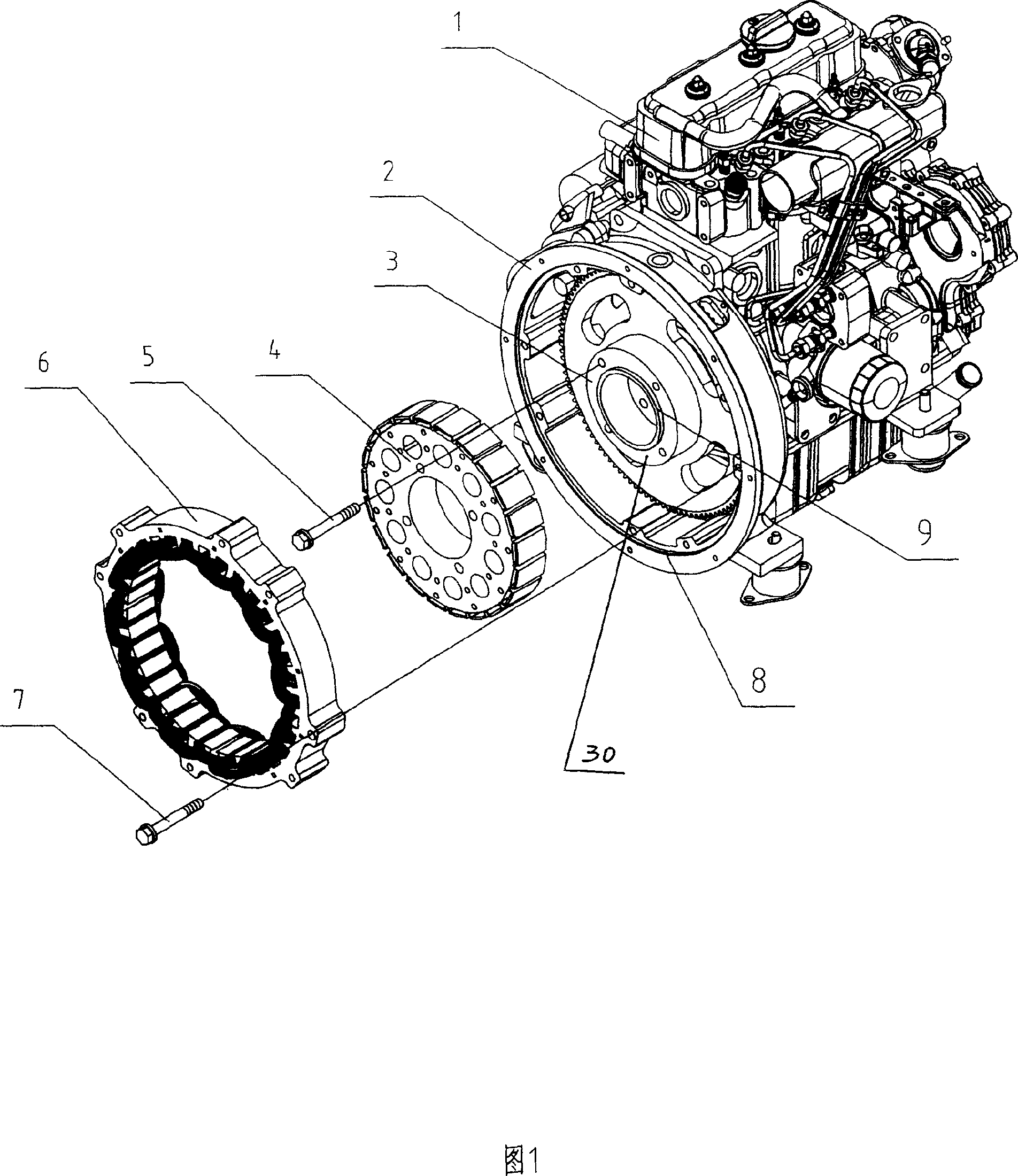

Rotor of multipole internal rotor permanent magnet generator

InactiveCN101005218AAvoid demagnetizationImprove stabilityMagnetic circuit rotating partsManufacturing stator/rotor bodiesMiniaturizationRare earth

The disclosed rotor of permanent magnet generator is suitable to permanent magnet generator in miniaturization, lightweight, and thin type. The rotor includes punched pieces of rotor, permanent magnets. Characters are that riveting punched pieces of rotor constitutes rotor body where slots for taking in permanent magnets are distributed around circumferencial direction. After taking in permanent magnets, rotor body is fixed on rotary body of generator directly. Structure with no bearing adopted in the invention makes rotor simple and compact farthest so as to save cost, raise service life, realize high output efficiency, and high output power. The invention guarantees that when rotor rotates, rare earth permanent magnet will not fall off, as well as reduces magnetic leakage, raises safety, stability and durability of rotor.

Owner:WUXI KIPOR POWER CO LTD

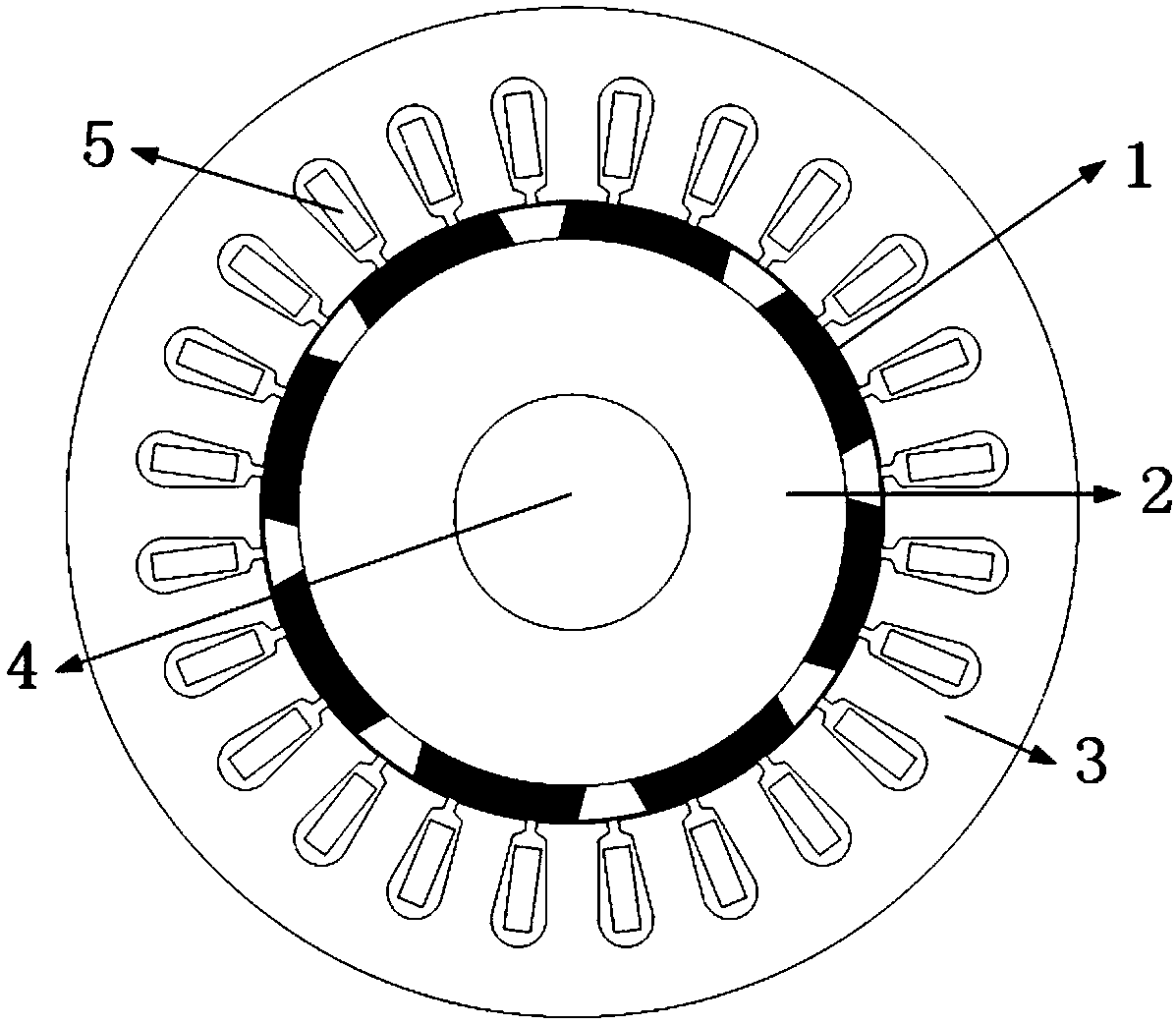

Surface-slotted surface-mounted permanent magnet synchronous motor rotor structure

InactiveCN109378913AEasy to installEasy to processMagnetic circuit rotating partsTechnical supportPhysics

The invention discloses a surface-slotted surface-mounted permanent magnet synchronous motor rotor structure and belongs to the design field of a high-performance permanent magnet motor body. The technical solution is that the core portion between permanent magnets in each pole of the surface-mounted permanent magnet synchronous motor rotor is provided with a radial slot filled with a non-magneticand non-conductive filler. The air gap distribution, the rotor core structure, an air gap and a rotor magnetic circuit can be changed through the slot between the positive and negative poles of the permanent magnets, thereby optimizing the rotor magnetic field distribution during the operation of the motor, weakening the surface magnetic saturation of the rotor, improving the utilization rate ofthe rotor core, and reducing rotor-side hysteresis loss and eddy current loss. Therefore, the invention can provide important theoretical support and technical support for the development of a new generation of high-efficiency surface-mounted permanent magnet synchronous motor.

Owner:XI AN JIAOTONG UNIV

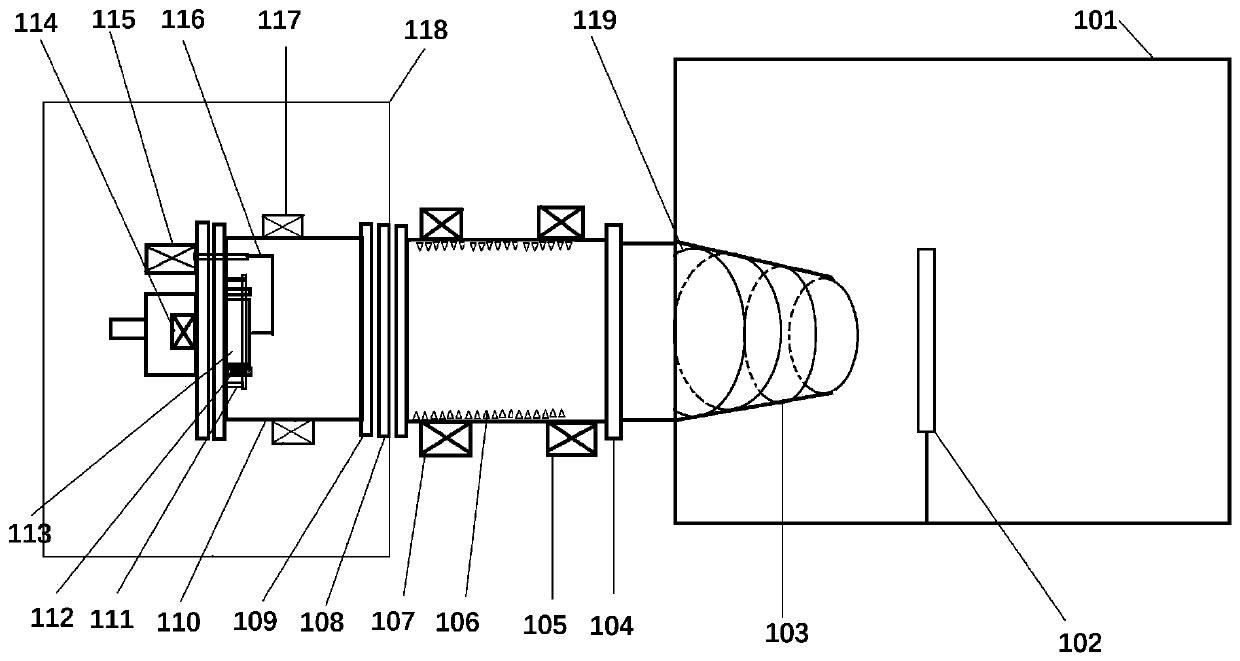

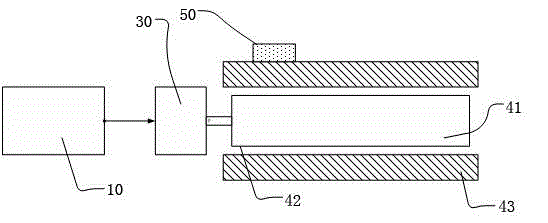

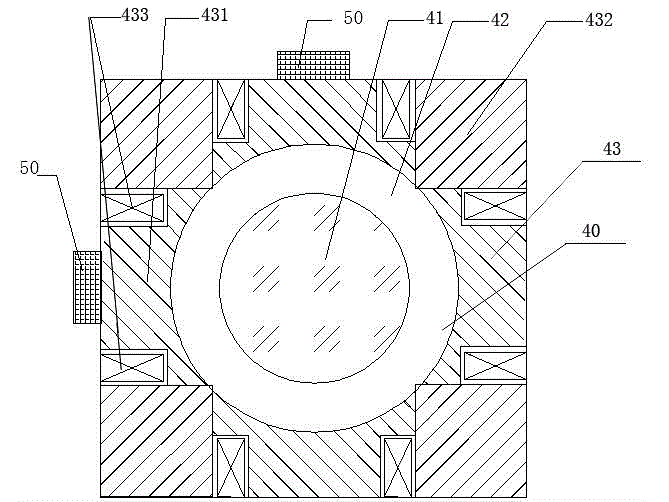

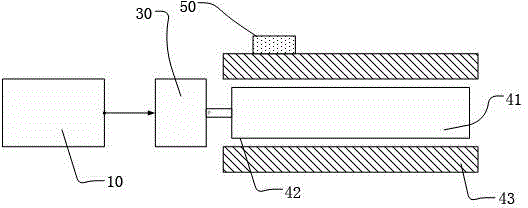

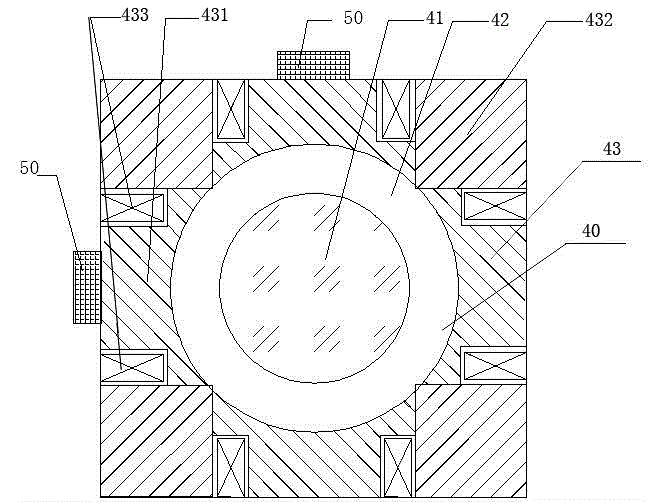

Deposition device

ActiveCN109881160AAvoid ablationGuaranteed purityVacuum evaporation coatingSputtering coatingStrong pulseNuclear astrophysics

The invention discloses a low-melting-point and active metal film deposition device which comprises a vacuum system, a cathode arc head, a strong pulsed magnetic field, a permanent magnet anode cylinder, a magnetic filter pipe and a focusing coil. Through implementing the low-melting-point and active metal film deposition device provided by the invention, the directivity of an ion arriving at thesurface of a coating workpiece is good, and meanwhile, low-melting-point metals such as Zn, Mg and Li can be deposited on the basis of the improved cooling cathode arc head, so that electric arc coating is realized; and under the vacuum protection, the surface deposition of active metals such as Na can be realized, and the technical blank of low-melting-point and active metal film deposition is filled. A magnetic filter device provided by the invention has a wide application prospect in nuclear astrophysics system targets and medicines.

Owner:BEIJING NORMAL UNIVERSITY

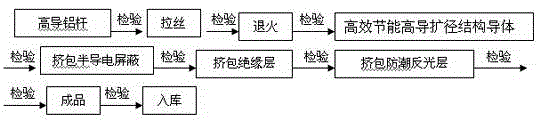

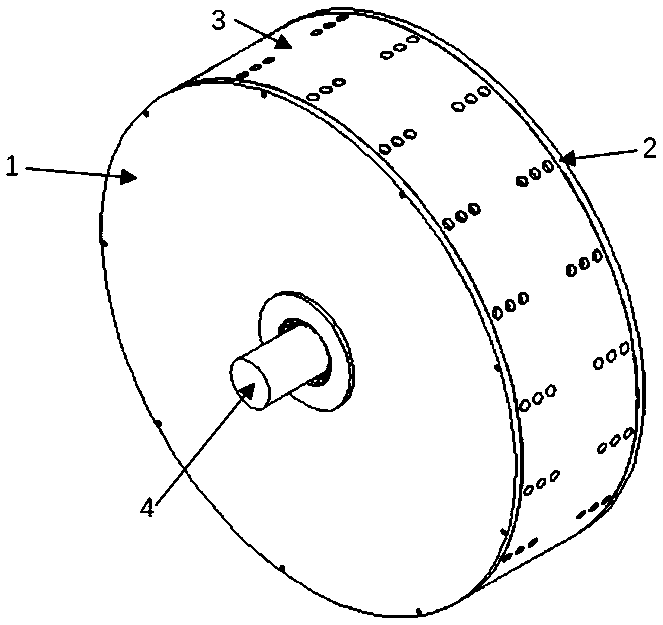

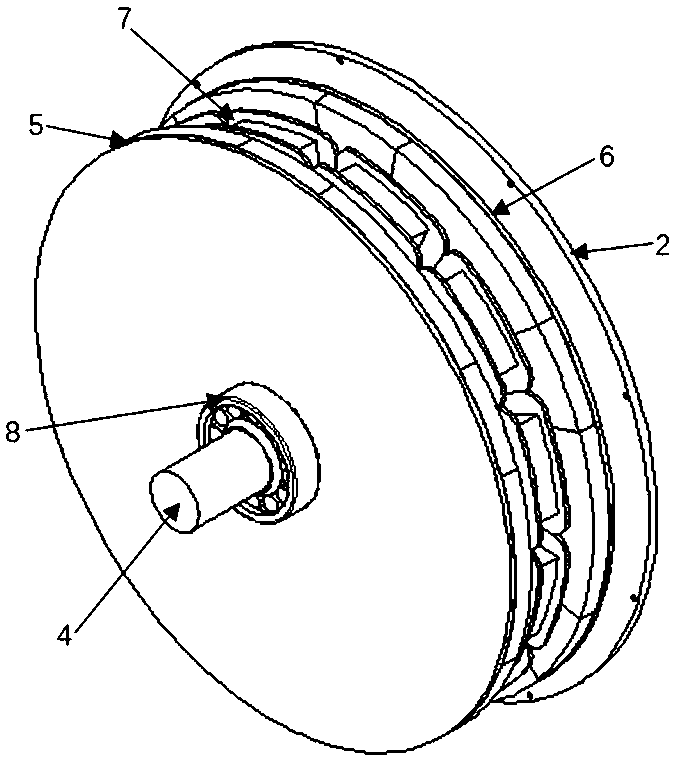

Efficient energy-saving high conductivity weather-proof overhead insulated cable and manufacturing method thereof

InactiveCN104900304ALow resistivityImprove conductivityClimate change adaptationInsulated cablesInsulation layerMaterial consumption

The present invention discloses an efficient energy-saving high conductivity weather-proof overhead insulated cable and a manufacturing method thereof. The cable comprises an efficient energy-saving high conductivity diameter expansion conductor arranged at the center of the cable, a semi-conductive shielding layer is extruded outside the high conductivity diameter expansion conductor, an insulation layer is extruded outside the semi-conductive shielding layer, and a moisture-proof reflective layer is extruded at the outermost layer of the cable. The efficient energy-saving high conductivity weather-proof overhead insulated cable (10kV) has the advantages of good conduction performance, insulation performance, reflection performance, UV prevention performance, moisture resistant performance, anti-bending performance and stability, the backward production capacity is eliminated, the scientific and technological achievement transformation is realized, the structural design is reasonable, the product cost performance is greatly improved, the outer diameter of the cable is reduced by at least 10%, the cable bending radius is greatly reduced, the conductive performance which is the load of the cable can be raised by more than 25%, the material consumption per unit length is reduced by at least 10%, the quality per unit length is reduced by at least 10%, the structural design is reasonable, resources are saved, and benefits are brought to people.

Owner:WUXI CITY HENG HUI CABLE

Axial permanent-magnet motor

InactiveCN107681854AReduce iron lossImprove power densityElectric machinesSynchronous machines with stationary armatures and rotating magnetsPermanent magnet motorElectric vehicle

The invention proposes an axial permanent-magnet motor structure. The axial permanent-magnet motor structure is characterized in that the motor is integratedly in a disc shape, a distribution mode ofdual rotors and an intermediate stator is employed, a magnetic flux direction is an axial direction, the two rotors rotate around the same rotation shaft, axial positions are fixed by end covers at positions, near to outer sides, of the two rotors and the rotation shaft, permanent magnets are arranged at inner sides of the rotors in a halbach form, the intermediate stator employs a yoke-free structure and is a formed in which multiple teeth are combined, the stator is fixed on an enclosure, and the enclosure is connected and fixed with the two end covers. Structure topological optimization isperformed on the enclosure, ventilation holes are formed in a surface of the enclosure, and heat dissipation of the motor is facilitated. Therefore, the axial permanent-magnet motor has the advantagesof small volume, small mass and high power density, and is applicable to occasions such as an electric vehicle and an aircraft. The invention further provides a rotor-free core structure design, andthe power density of the motor is further improved.

Owner:HEFEI UNIV OF TECH

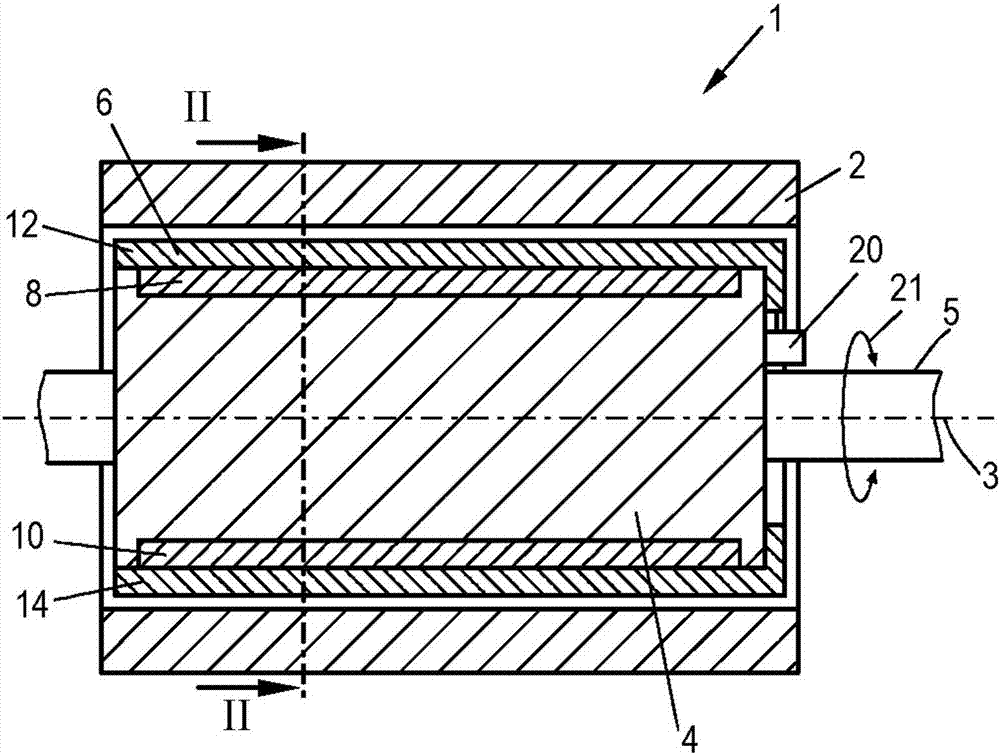

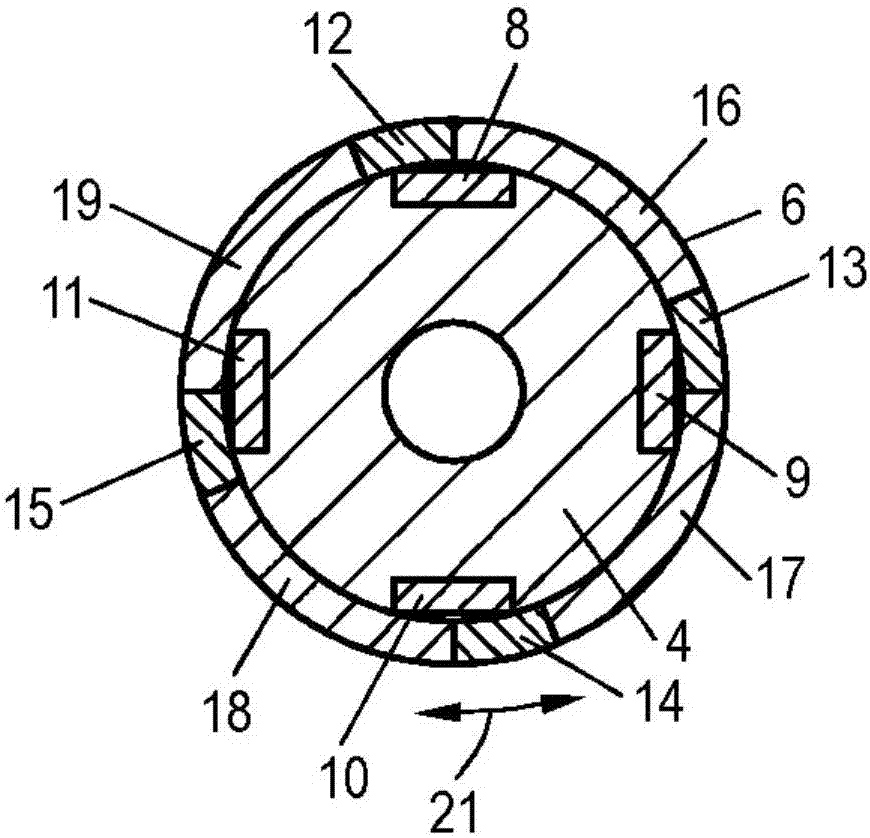

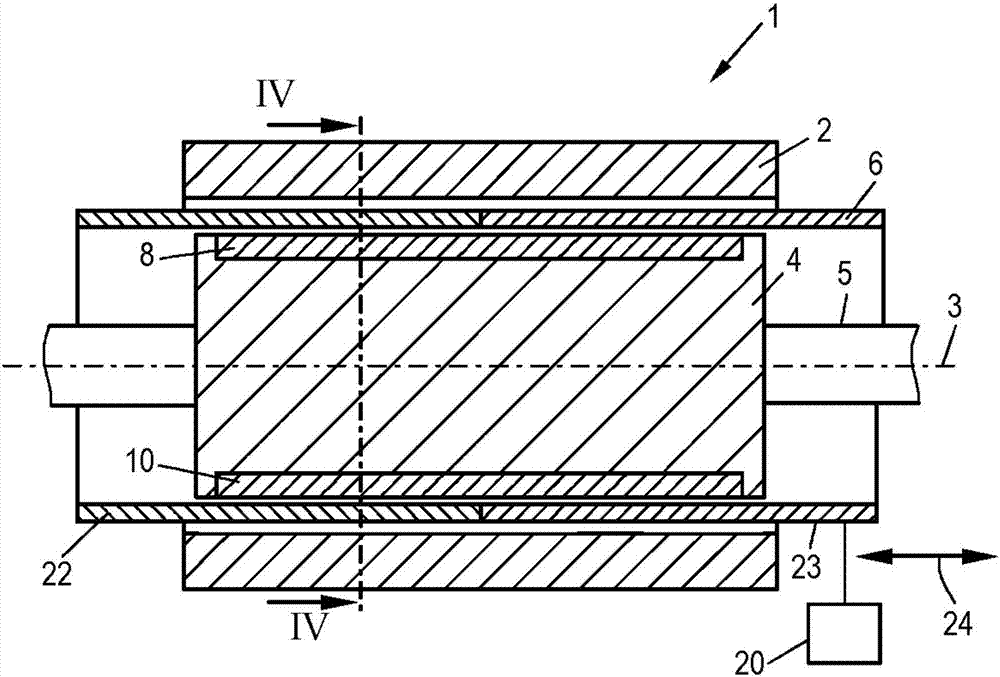

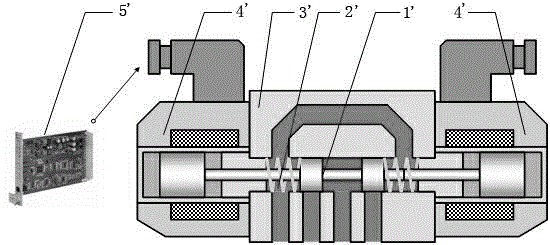

Motor Used For Motor Vehicle And Motor Vehicle

ActiveCN106921271AIncrease structural costsLow costMagnetic circuit rotating partsSynchronous machine detailsElectrical conductorEngineering

The present invention relates to a motor used for a motor vehicle. The motor comprises a stator 2 and a rotor 4, the rotor has at least one magnetic element 8-11 for generating a magnetic exciting field, wherein a shielding member 6 having at least one magnetic conductive conductor section is arranged between the stator 2 and the rotor 4, and the relative position of the shielding member 6 relative to the rotor can be adjusted, thereby changing a scheme that the at least one magnetic element 8-11 is covered by the at least one conductor section.

Owner:AUDI AG

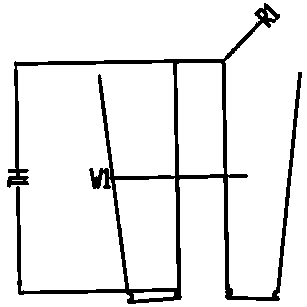

Method for correcting chucking faults of electrohydraulic proportioning valve by utilizing electromagnetic attraction force

The invention relates to a method for correcting chucking faults of an electrohydraulic proportioning valve by utilizing electromagnetic attraction force. The electrohydraulic proportioning valve comprises a valve core and a valve body provided with a valve cavity. The method comprises the steps of reformation and correction; the step of reformation refers to reforming the valve wall of the valve body into a specially-made valve wall; the specially-made valve wall comprises an upper main valve wall, a lower main valve wall, a left main valve wall, a right main valve wall, four magnetism isolating bands separating the main valve walls and arranged at the four top corners of the valve wall, and four groups of solenoid coils provided with magnetic-conductive frameworks and sleeved on the four main valve walls respectively; and the valve core and the main valve walls are made of magnetizer alloy, and the magnetism isolating bands are made of non-magnetizer alloy. Through the adoption of the technical scheme, chucking faults caused by pollution and radial off-balance pressure can be corrected conveniently and quickly by utilizing electromagnetic force.

Owner:SHAOXING UNIVERSITY

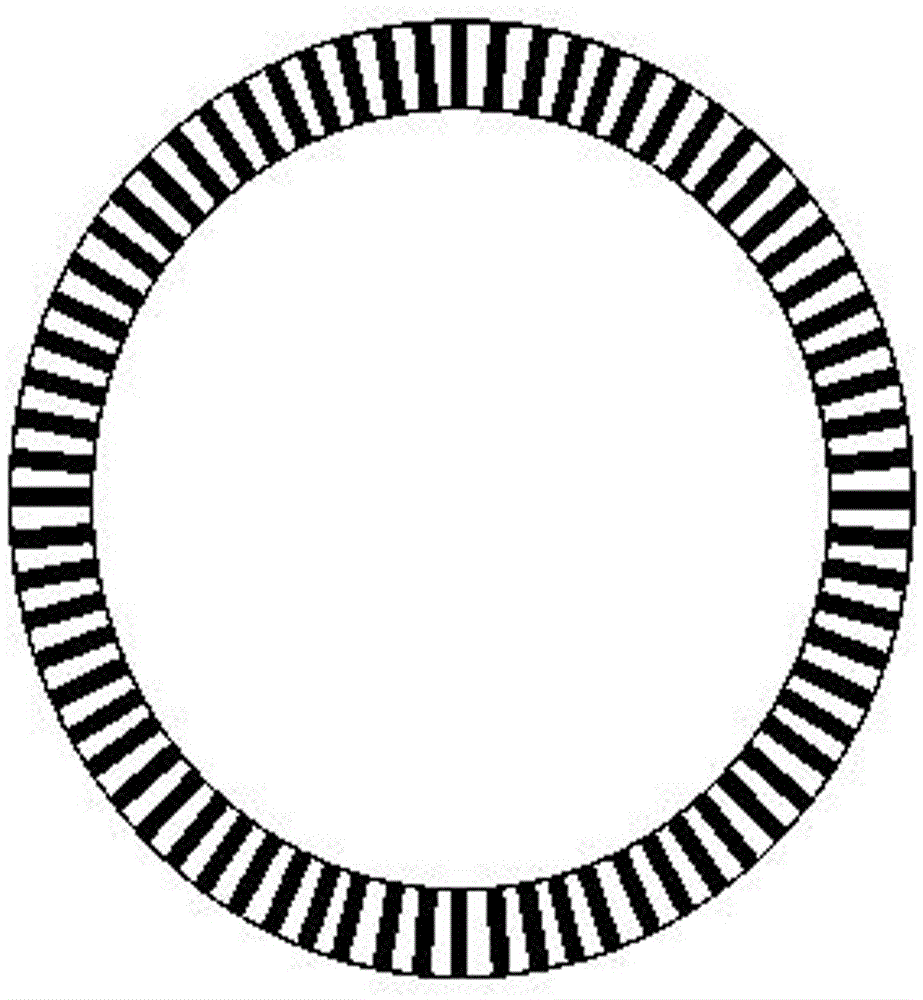

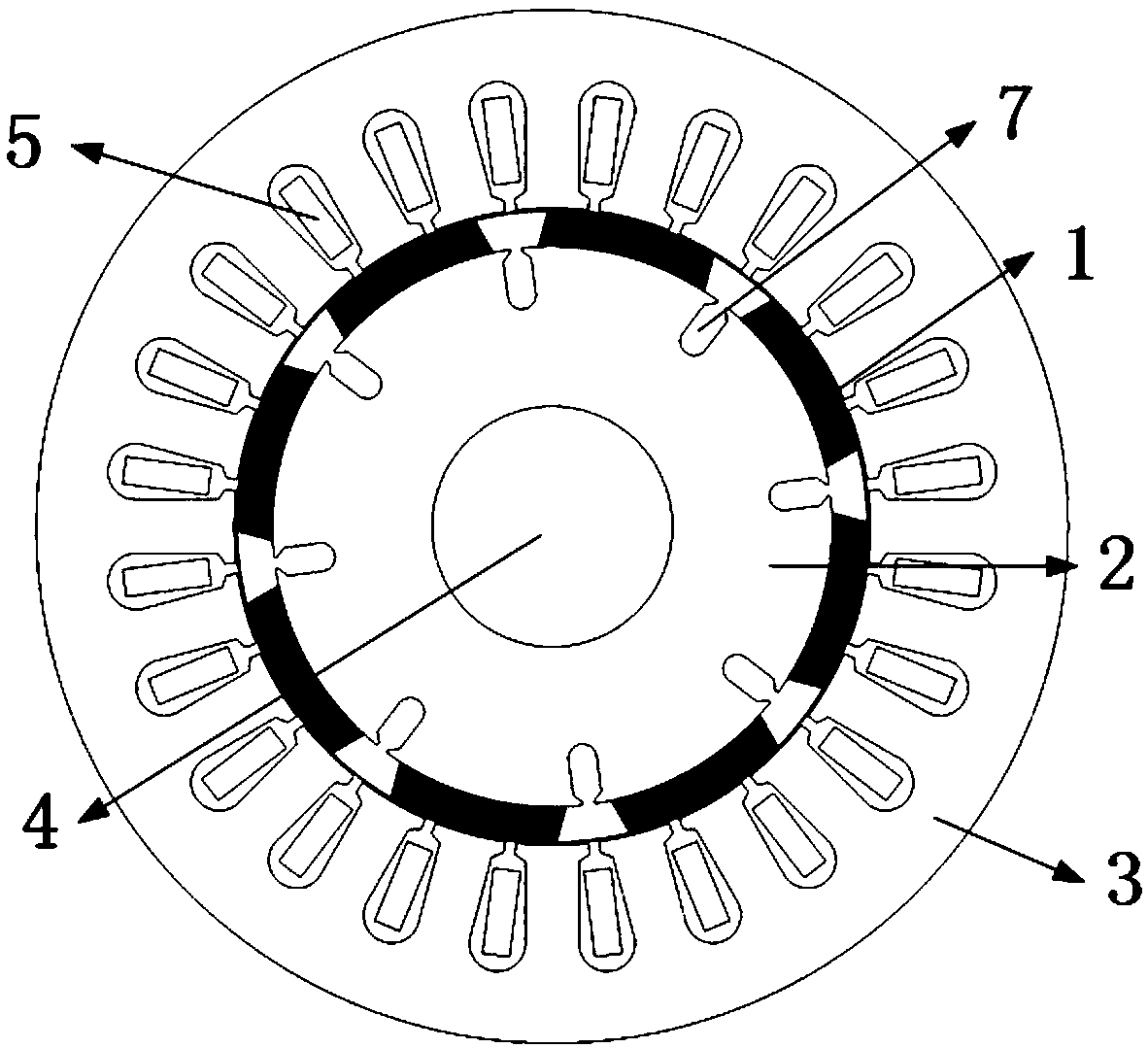

Stator punching sheet of high-voltage permanent-magnet synchronous motor, winding stator and motor

InactiveCN109638991AGuaranteed uptimeImprove performanceWindingsSynchronous machine detailsPunchingSynchronous motor

The invention discloses a stator punching sheet of a high-voltage permanent-magnet synchronous motor, a winding stator and the motor. A stator punching sheet body is in a round shape, 54 rectangular winding grooves are formed in the stator body and are uniformly distributed along a circumference, the widths W1 of the winding grooves are 13.7 millimeters, H1 of the winding grooves are 65 millimeters, a magnetic groove wedge slot is formed in a winding groove opening and is used for placing a magnetic groove wedge, 12 swallowtail positioning grooves are formed in an outer circle profile of the stator punching sheet body and are uniformly distributed along the circumference, the magnetic groove wedge slot is in a semi-circular shape, the radius R2 of the magnetic groove wedge slot is 1 millimeter, a fillet is arranged at a connection position of the magnetic groove wedge slot and the winding groove, the arc radius R3 is 0.2 millimeter, and the opening width W2 of the magnetic groove wedgeslot is 15.7 millimeters. The semi-circular magnetic groove wedge is employed, the air gap magnetic field distribution is improved, and the vibration and the noise of the motor are reduced; and an inner circle and an outer circle of the stator punching sheet and the winding groove are reasonable in design, the iron core loss of the motor is reduced, and the running performance of the motor is improved.

Owner:NANTONG UNIVERSITY

Brushless electromagnetic and double-radial permanent magnet hybrid excitation driving motor

InactiveCN109980818ACapable of gathering magnetismImproved magnetic field distributionMagnetic circuit rotating partsUltimate tensile strengthConductor Coil

The invention discloses a brushless electromagnetic and double-radial permanent magnet hybrid excitation driving motor, comprising a rotor core, an enclosure, a front end cover, a rear end cover and ashaft. The rotor core comprises a V-shaped first magnet, a second magnet and an electric excitation winding; the V-shaped first magnet has the magnetism gathering capability; the second magnet can avoid the permanent magnet material waste problem due to a combined structure while improving per-pole air gap magnetic field distribution and strength; the electric excitation winding can adjust the size of an air gap magnetic field; the fact that permanent magnet steel does not lose magnetism can be ensured; the magnetic field strength is high; and the output power is high.

Owner:SHANDONG UNIV OF TECH

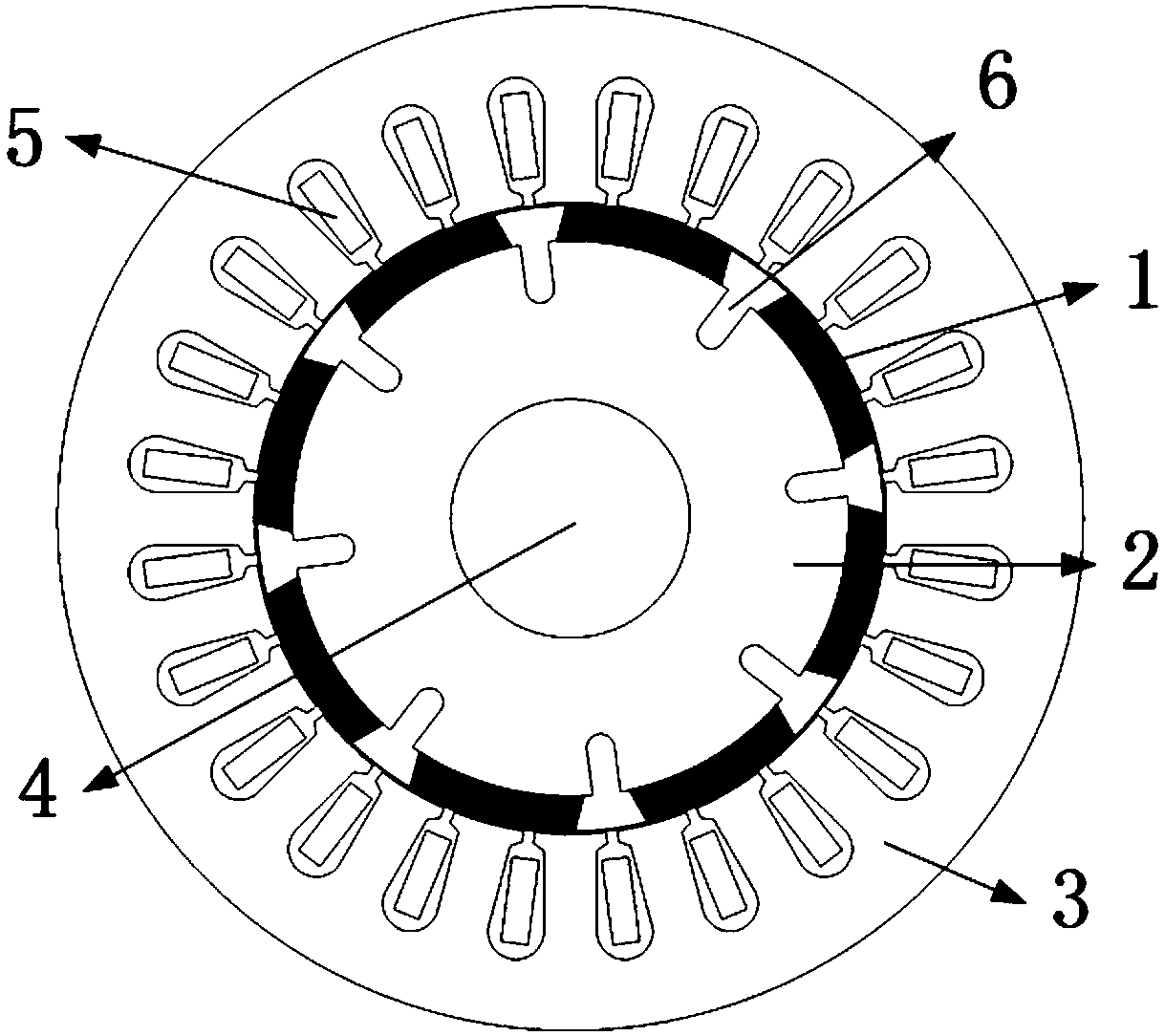

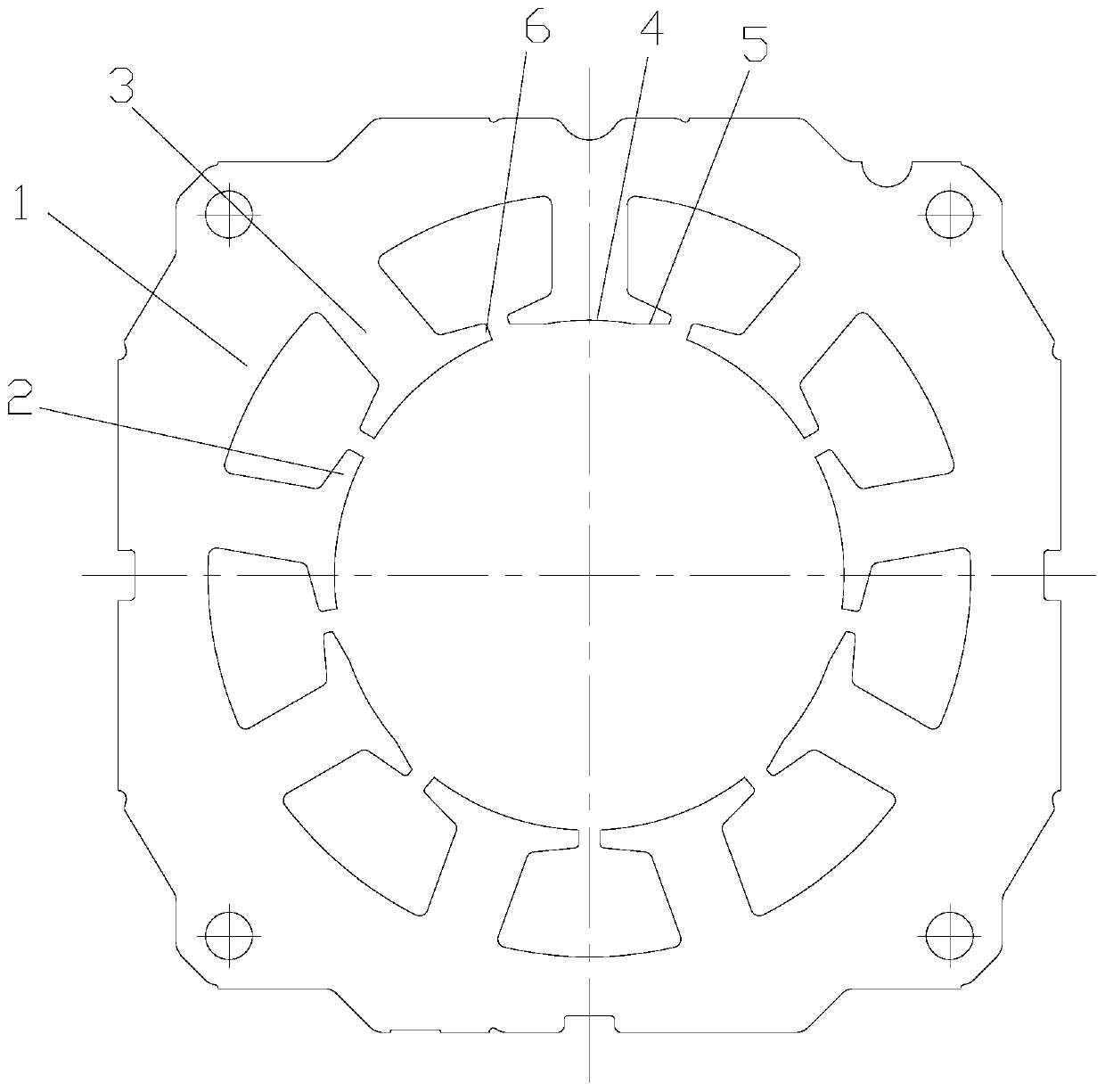

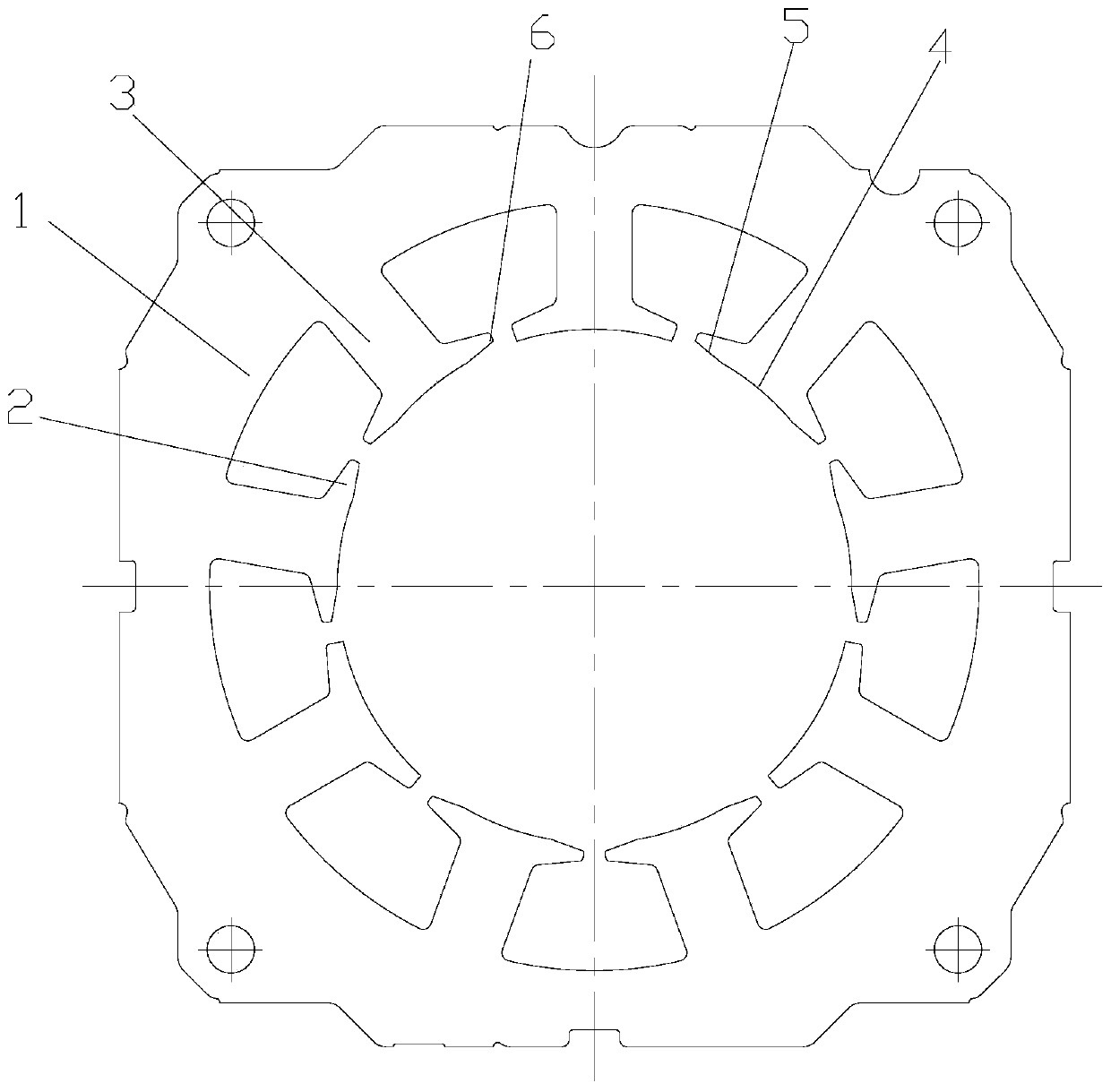

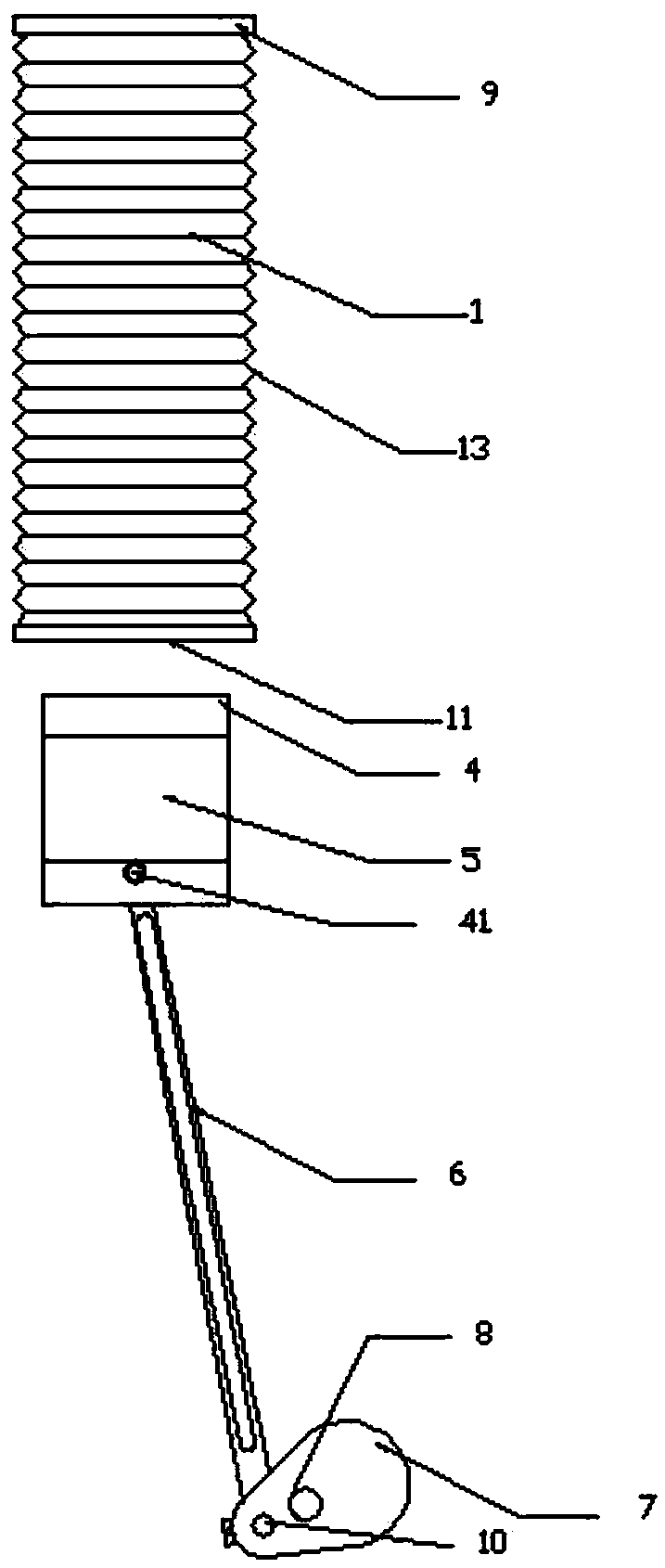

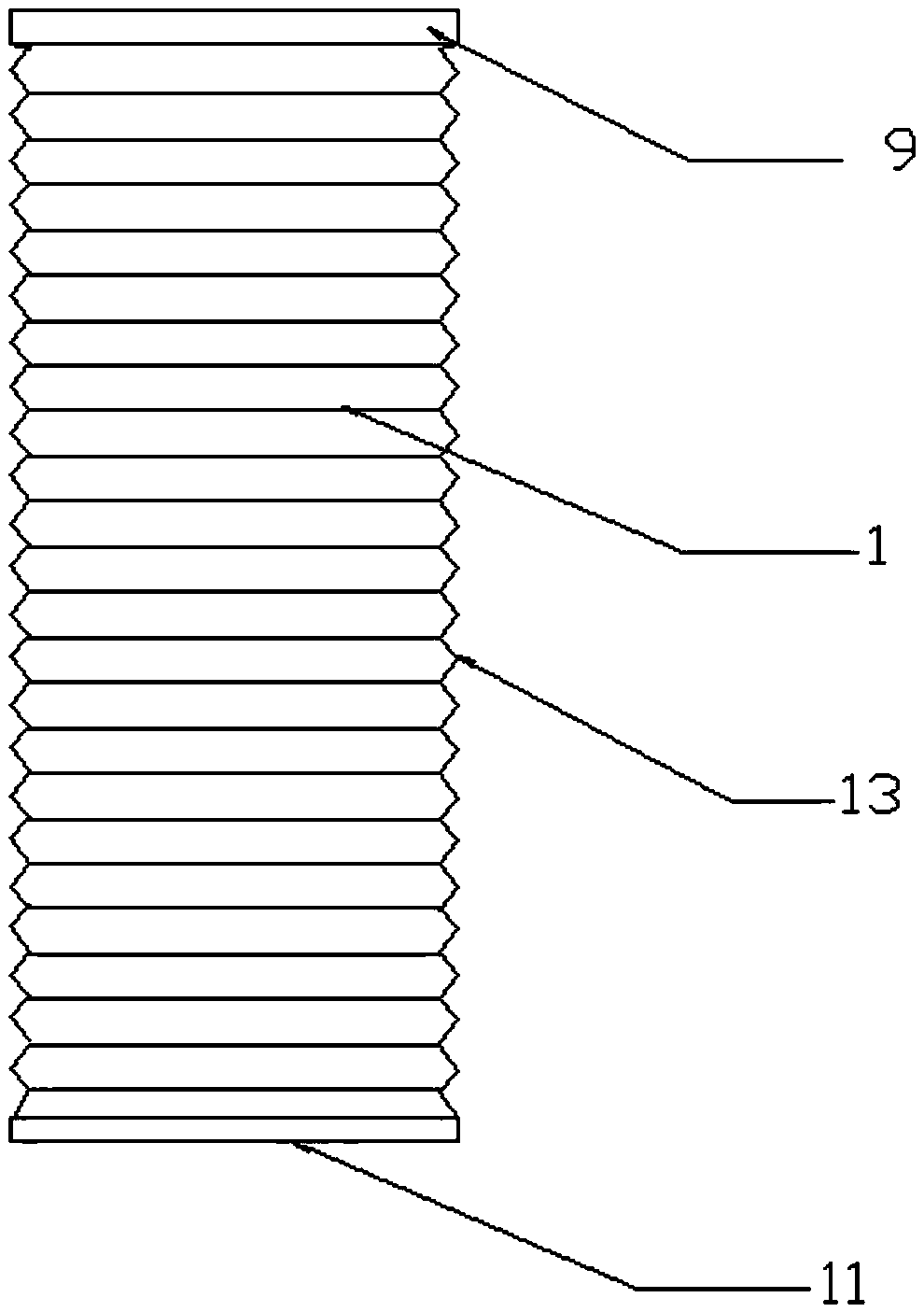

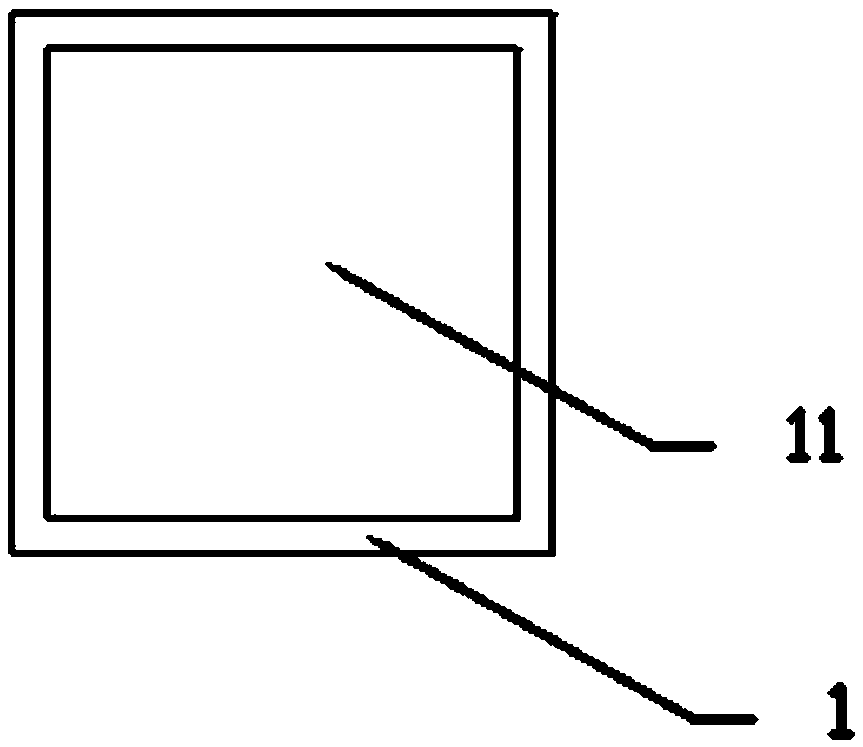

Motor stator, pole shoe processing method thereof and permanent magnet motor

ActiveCN110718974AStructural optimization of trimmingSimple structureMagnetic circuit stationary partsManufacturing stator/rotor bodiesElectric machinePermanent magnet motor

The invention provides a motor stator, a pole shoe processing method thereof and a permanent magnet motor. The motor stator comprises a yoke part (1), pole shoes (2) and stator teeth (3); in a cross section perpendicular to the central axis of the yoke portion (1), at least a part of the pole shoes (2) are provided with chamfered edges; the radial inner circumferential wall of the pole shoes (2) with the chamfered edge comprises an arc segment (4) and a straight line segment (5) located on the arc segment (4). An intersection point of the straight line segment (5) and the arc segment (4) is aclipping point I, the connecting line of the clipping point I at one end and the stator center O is OI, the included angle formed by OI and OH is phi, wherein theta>=phi>=theta / 2, theta = alpha-beta,alpha is the included angle between the center lines of two adjacent stator teeth (3), beta = pi / P, and P is the rotor pole number. According to the motor stator, the magnetic field distribution of the motor air gap can be improved, a back electromotive force harmonic content is greatly reduced, and the sine degree of the back electromotive force is improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Electrohydraulic proportioning valve capable of correcting chucking faults by utilizing electromagnetic attraction force

The invention relates to an electrohydraulic proportioning valve capable of correcting chucking faults by utilizing electromagnetic attraction force. The electrohydraulic proportioning valve comprises a valve core and a valve body provided with a valve cavity, wherein the valve body comprises a specially-made valve wall; the specially-made valve wall comprises an upper main valve wall, a lower main valve wall, a left main valve wall, a right main valve wall, four magnetism isolating bands separating the main valve walls and arranged at the four top corners of the valve wall, and four groups of solenoid coils provided with magnetic-conductive frameworks and sleeved on the four main valve walls respectively; and the valve core and the main valve walls are made of magnetizer alloy, and the magnetism isolating bands are made of non-magnetizer alloy. The electrohydraulic proportioning valve further comprises a power supply control device which is electrically connected with the four groups of solenoid coils of the specially-made valve wall and can control the on / off of the solenoid coils respectively. Through the adoption of the technical scheme, the electrohydraulic proportioning valve can correct chucking faults caused by pollution and radial off-balance pressure by utilizing electromagnetic attraction force conveniently and quickly.

Owner:SHAOXING UNIVERSITY

Dual three-phase permanent magnetic synchronous motor, electric automobile and method of dual three-phase permanent magnetic synchronous motor

ActiveCN109361300AReduce radial electrical loadReduce magnetic loadAC motor controlMagnetic circuit rotating partsConstant powerSynchronous motor

The invention provides a dual three-phase permanent magnetic synchronous motor, an electric automobile and a method of the dual three-phase permanent magnetic synchronous motor. Compared with a traditional multi-phase motor, dual three-phase permanent magnetic synchronous motor has the advantages that by placing an axial stator on an end portion of a rotor, the end portion of the rotor is made full use of, magnetic leakage effect of the end portion is reduced, a use ratio of a permanent magnet is increased, a better magnetism gathering effect can be generated since a permanent magnet is placedon a surface of an axial end of the rotor of the motor, the motor is enabled to be higher in iron core magnetic flux density and air gap magnetic flux density, a use ratio of an iron core material ofthe motor is increased, weight of the motor is reduced, power density and torque density of the motor are increased remarkably, and the weight of the motor is furtherly reduced; a magnetic circuit ofan axial end portion, without the permanent magnet, of the rotor of the motor is parallelly connected with a radial magnetic circuit of the motor, by regulating the mixed magnetic circuits, an operation range of constant power of the motor can be enlarged, and the defect that the power density and efficiency are decreased after the operation range of the constant power of a traditional permanentmagnetic synchronous motor is enlarged is overcome.

Owner:SHANDONG UNIV

Single-cylinder linear permanent magnet generator

The invention provides a single-cylinder linear permanent magnet generator, which comprises a machine cylinder, a sleeve, a permanent magnet group, a piston, a coil assembly, a connecting rod, two eccentric wheels, an output shaft and a crankshaft, wherein the machine cylinder comprises a machine body and a machine cavity; the sleeve is sleeved with the machine cavity in the machine body; the permanent magnet group is arranged between the machine body and the sleeve; the piston is assembled in the sleeve; the coil assembly winds one end of the piston and is fixed on the piston; the other end of the piston is connected with one end of the connecting rod; the other end of the connecting rod is connected with the crankshaft; the two eccentric wheels which rotate in the same direction and are the same in size are respectively assembled at two sides of the connected part of the connecting rod and the crankshaft; the crankshaft is connected with an input shaft; the input shaft is connected with a kinetic energy input mechanism; the machine body is in a cuboid structure; the sleeve is sleeved with the machine cavity in the machine body; and the sleeve and the piston are also in the cuboid structure. According to the single-cylinder linear permanent magnet generator, the coil winding the piston is lengthened, so as to generate relatively high current; control is simple and reliable; the response time is short; and a new energy source is adopted, so that the single-cylinder linear permanent magnet generator is environment-friendly and energy-saving.

Owner:GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com