Straight optical path linear optical current sensor and current detection method

A current sensor and current detection technology, applied in the direction of measuring current/voltage, only measuring current, voltage/current isolation, etc., can solve the problems of restricting practicality, reducing the stability and reliability of transformers, and unsatisfactory effects, etc., to achieve Reduce the effect of birefringence, improve the magnetic field distribution, and eliminate the effect of reflection phase shift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

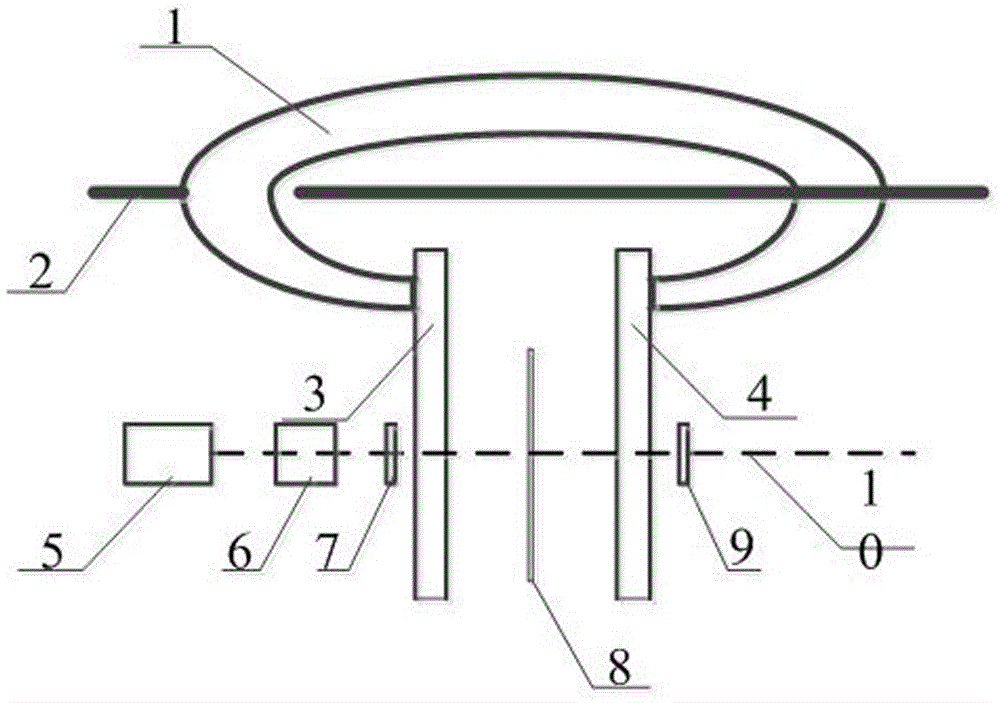

[0019] The present invention provides a linear optical current sensor through the optical line, such as figure 1 As shown, it includes: a light source 5, a collimator 6, a polarizer 7, a first magnetically conductive plate 3, a magneto-optical film 8, a second magnetically conductive plate 4, and a radial analyzer 9 arranged on the same optical path in sequence , to form a straight-through optical path; the first magnetically conductive plate 3 is arranged on one side of the air gap opening of the magnetic collecting ring 1 with an air gap, and the second magnetically conductive plate 4 is arranged on the side of the air gap opening of the magnetically collecting ring 1 The other side; also includes a current-carrying wire 2 passing through the magnet ring.

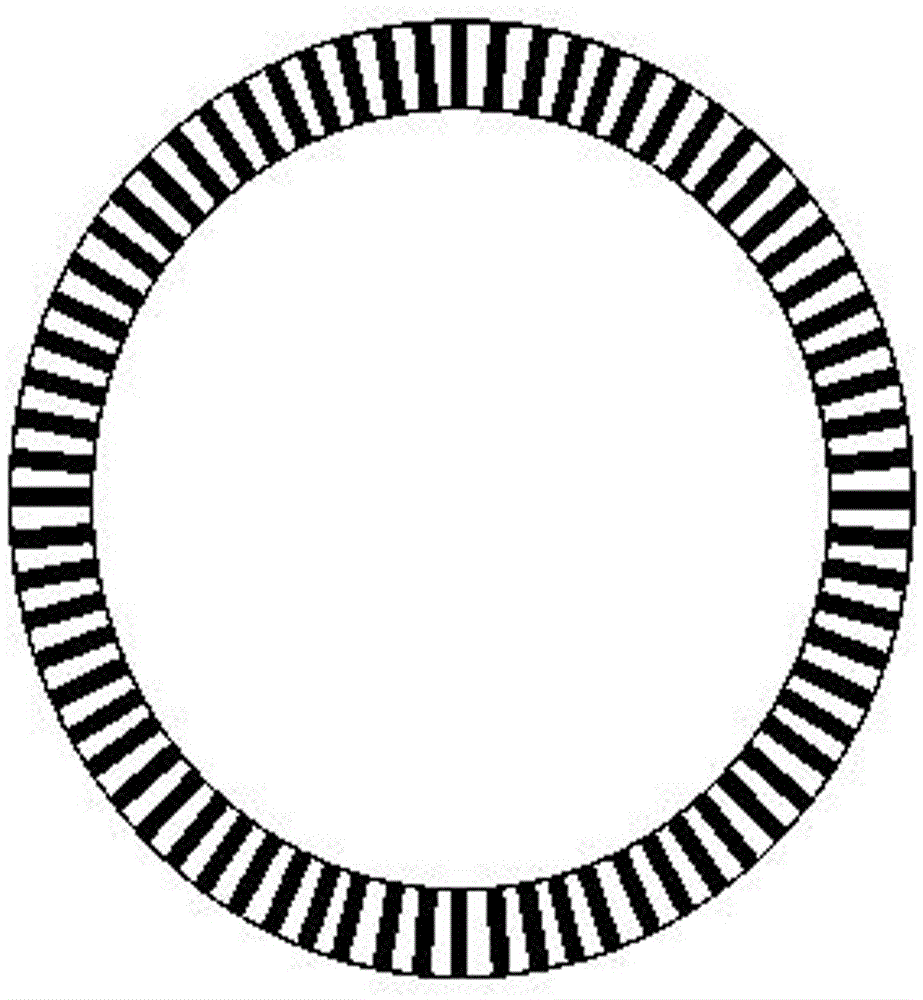

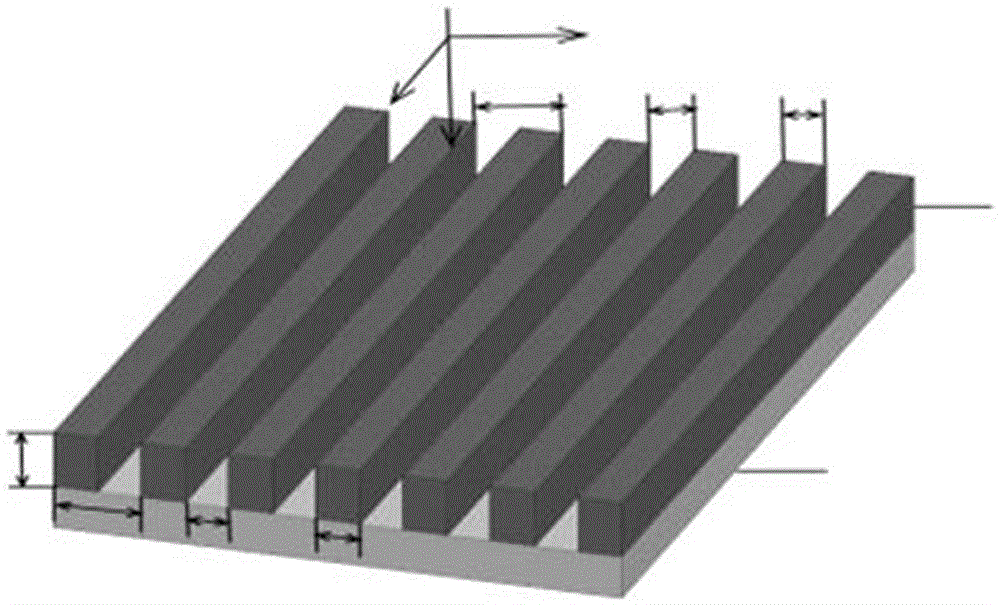

[0020] Further, in this embodiment, the air gap of the magnetic collecting ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com