Motor stator, pole shoe processing method thereof and permanent magnet motor

A motor stator and processing method technology, applied in the manufacture of stator/rotor body, electrical components, electromechanical devices, etc., can solve the problems of high production cost, motor noise, poor vibration performance, non-sinusoidal air gap flux density waveform, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

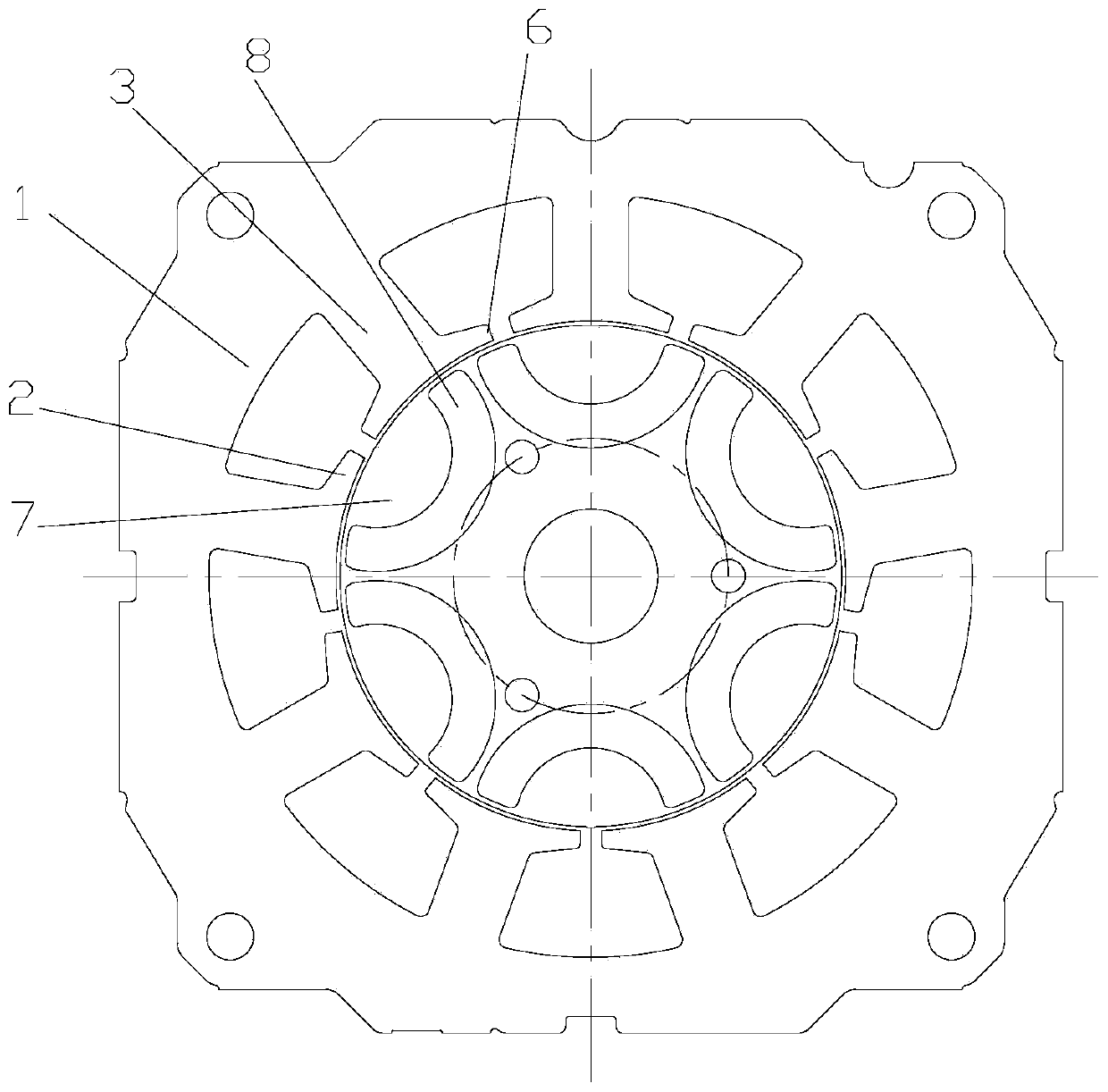

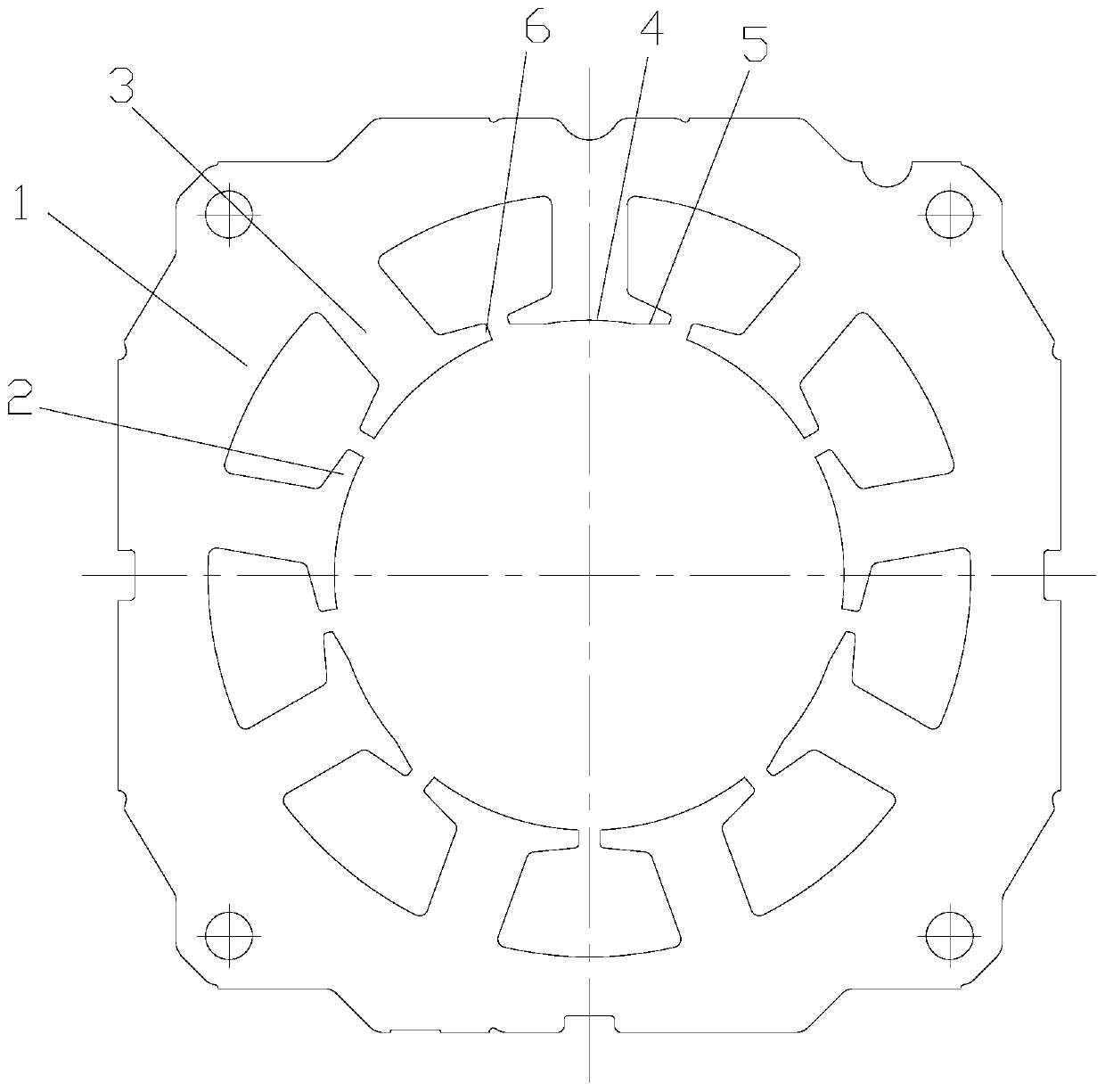

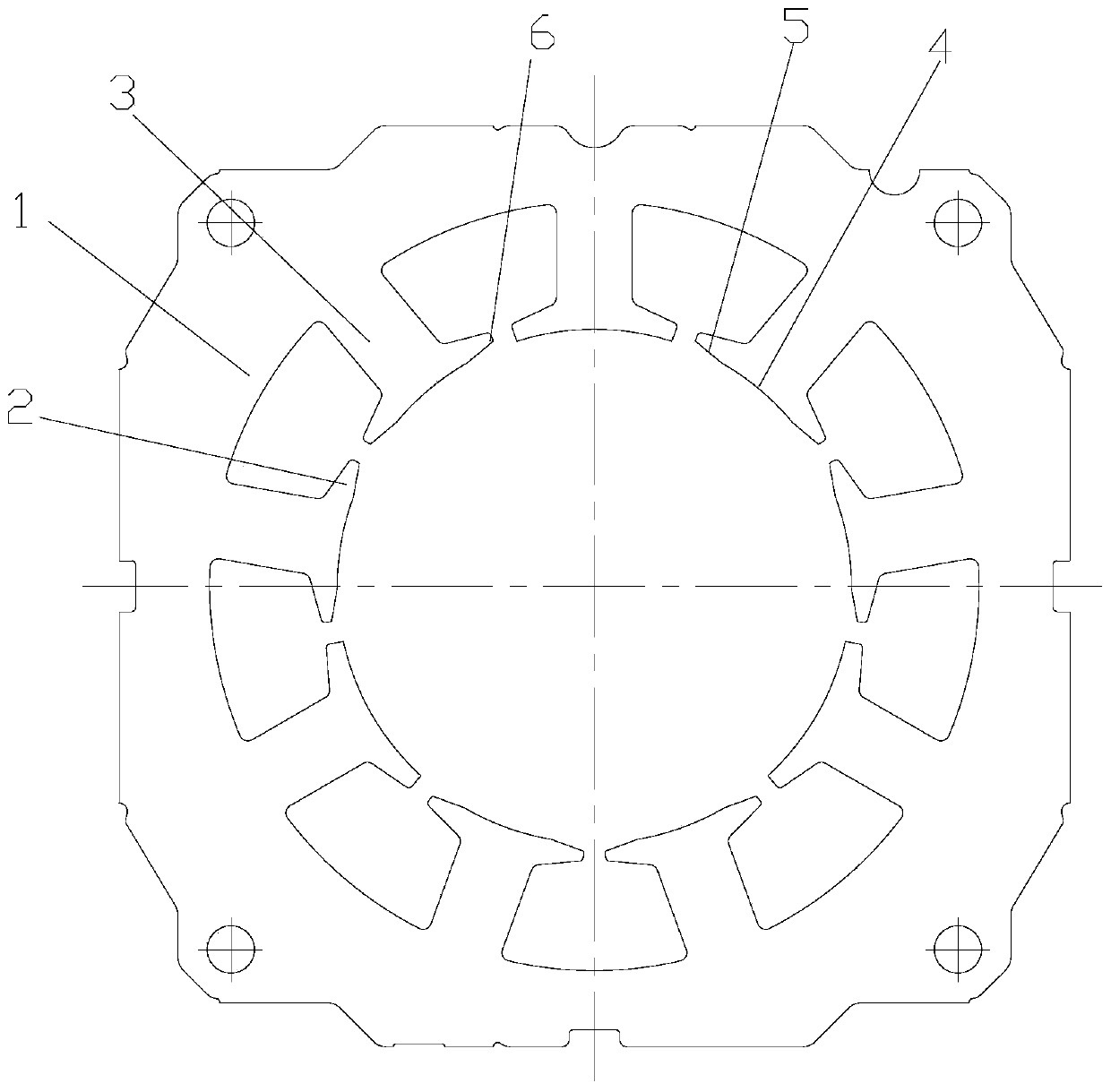

[0041] see in conjunction Figure 1 to Figure 9 As shown, according to the embodiment of the present application, the motor stator includes a yoke 1, a pole piece 2 and a stator tooth 3, and the stator tooth 3 is connected between the yoke 1 and the pole piece 2, and is perpendicular to the central axis of the yoke 1 In the cross-section, at least part of the pole shoe 2 has chamfered edges, and the radially inner peripheral wall of the chamfered pole shoe 2 includes a circular arc segment 4 extending in the circumferential direction and a straight line segment 5 located at both ends of the arc segment 4, the two straight line segments 5. It is symmetrical about the center line OH of the stator tooth 3 where the pole shoe 2 is located. The intersection point of the straight line segment 5 and the arc segment 4 is the cut pole point I, and the connection line between the cut pole point I at one end and the stator center O is OI, and OI and The angle formed by the centerline OH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com