Magnetic grinding and polishing device for large curved surface

A magnetic grinding and polishing device technology, applied in the field of grinding and polishing devices, can solve the problems of large volume, complex structure, unsuitable for the use of robots and CNC machine tools, etc., to improve efficiency and quality, continuous processing, improve grinding quality and grinding The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

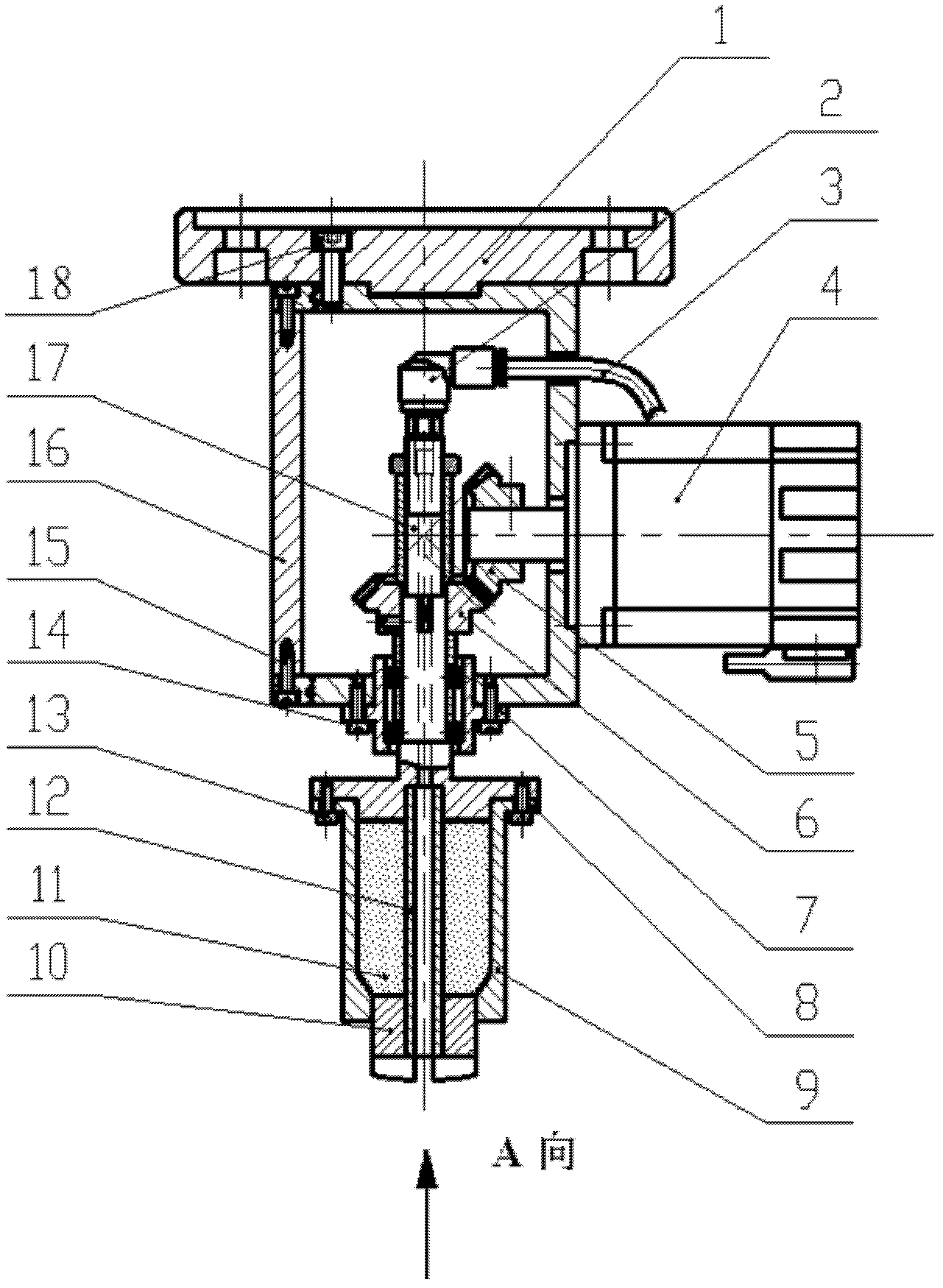

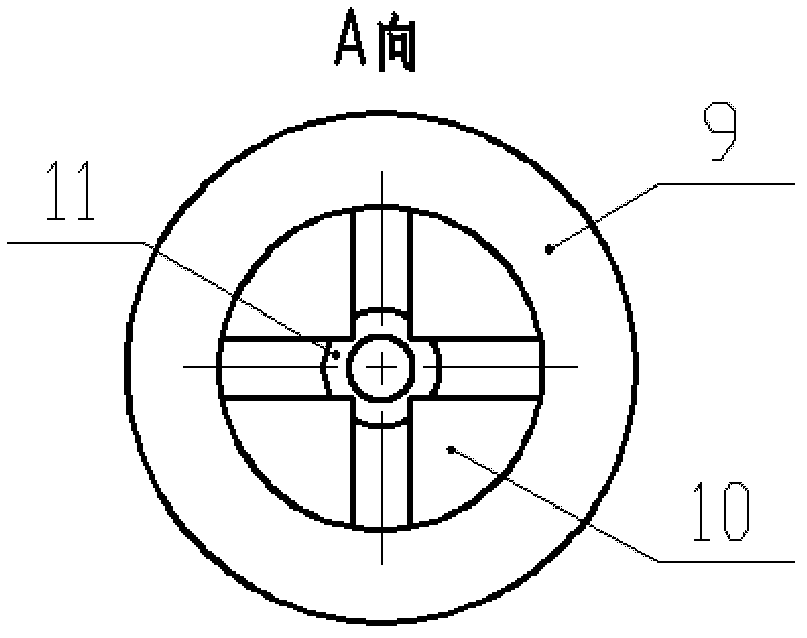

[0019] as attached figure 1 , attached figure 2 As shown, the specific structure of the large curved surface grinding and polishing device is as follows: the main frame 7, the front support side plate 16 is fixed with the main frame 7 by the side plate fixing bolts 15, and the materials of the main frame 7 and the front support side plate 15 are all metal aluminum , neither magnetic conduction, but also can reduce the weight of the whole device. The motor 4 is directly installed on the main frame 7. The motor 4 is a servo motor with a maximum speed of 3000r / min. It is connected with the servo driver and the motion control card installed on the computer. The parameters such as its speed are determined by the computer through the motion control card. The motor 4 drives the driving bevel gear 5, the driving bevel gear 5 meshes with the driven bevel gear 6, the transmission ratio is 1, and the hollow main shaft 17 is driven to rotate through the key. The main shaft 17 is positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com