Hoisting method for overhauling and dismantling vaporization flue fixed at first section of converter

A technology for fixing vaporization and hoisting methods, applied in the direction of manufacturing converters, etc., can solve the problems of large dismantling work surface, prolong maintenance time, and dismantle many parts, and achieve the effect of reducing construction cost, reducing maintenance time, and improving efficiency and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

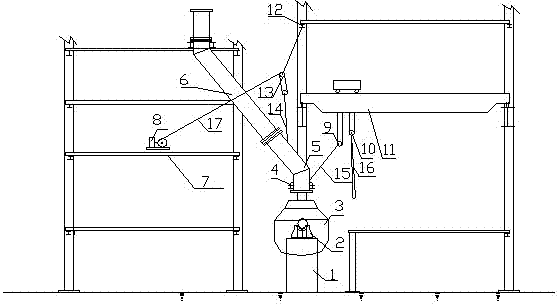

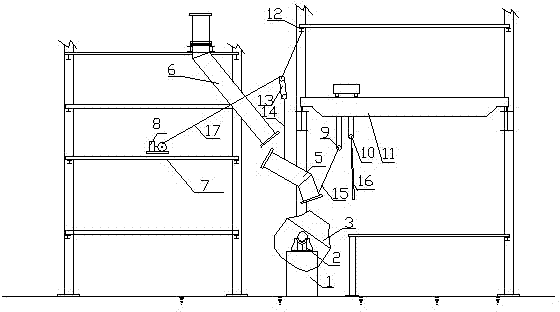

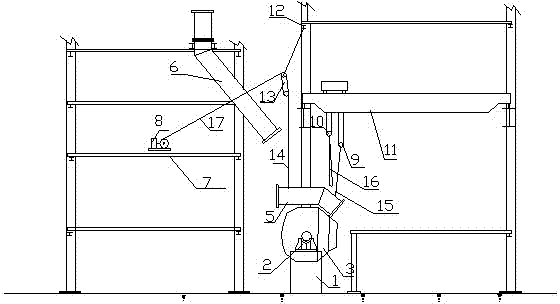

[0035] Example

[0036] In a steelmaking plant’s 60t converter vaporization cooling flue removal and replacement project, the first section of the fixed vaporization flue is 13 meters long and weighs 10t, but the demolition area is very small, so the lifting method is used for construction, and the entire removal and lifting process The operation was smoothly implemented, and the time for the removal and replacement of the first fixed vaporization flue was advanced from 5 days to 3 days. The converter production resumed quickly, the effect was very obvious, the removal efficiency was high, and the product protection was good. The construction steps are:

[0037] 1. Set up lifting equipment:

[0038] 1) Set up a hoisting device:

[0039] Place a hoist 8 for driving the pulley block 13 on the second-layer platform 7 at the rear of the converter, and the power of the hoist 8 is 15kw;

[0040] 2) Set the pulley block:

[0041] The pulley block 13 is fixed on the oxygen lance platform beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com