Deposition device

A deposition device and deposition chamber technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of difficulty in forming plasma, high cathode target material, low target material utilization rate, etc., and achieve improvement The effect of working stability, avoidance of ablation, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

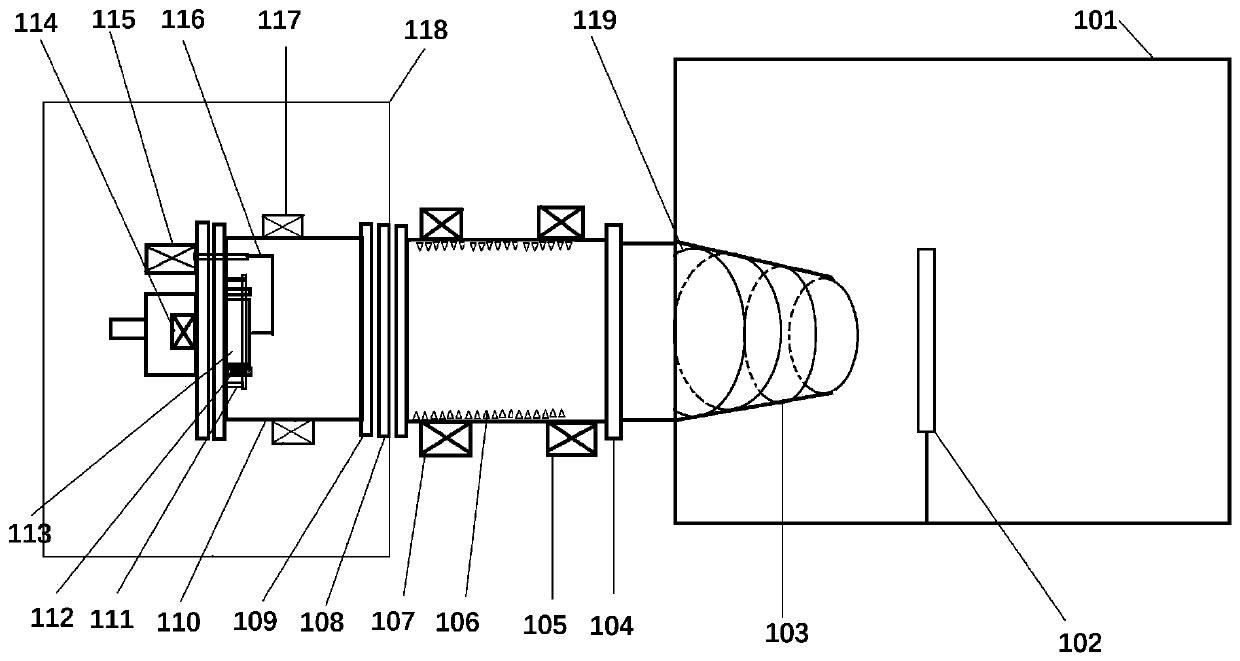

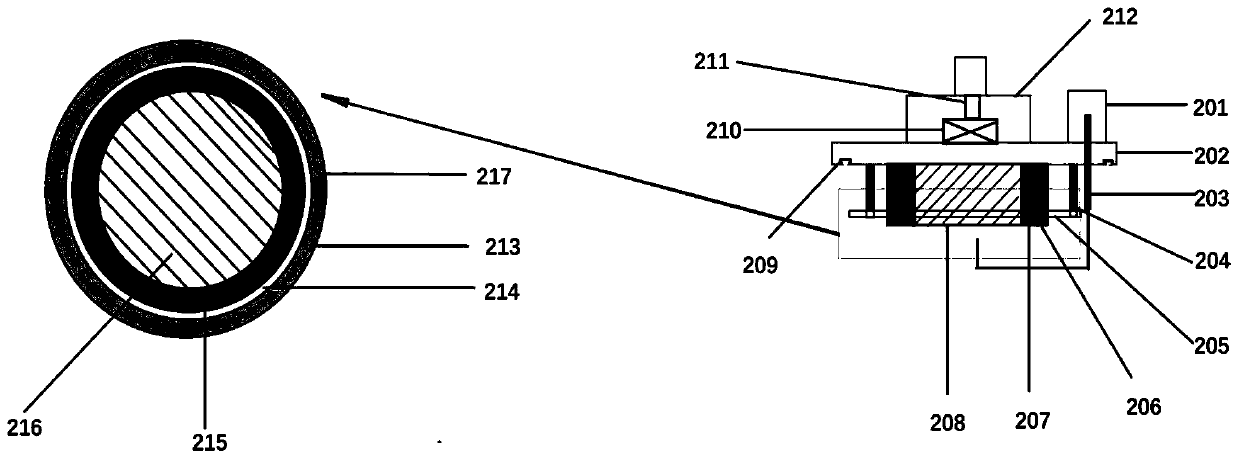

[0069] The cathode material is metal Mg, diameter Φ100, thickness 20mm, arcing current 10A, arcing voltage 20V, vacuum chamber vacuum 1×10 -3 pa;

[0070] During normal operation, the cathode target temperature is 30°C, and the gap between the auxiliary anode system and the shielding ring is 1mm;

[0071] The length of the control line package is 60mm, the number of turns is 3000 turns, the distance from the top plane of the cathode is 50mm, the current of the line package is 8A, the frequency is 15Hz, and the pulse width is 100μs;

[0072] The length of the anode cylinder is 120mm, the inside and outside of the part close to the cathode 60mm is made of stainless steel, and the rest is magnetically permeable material, the relative magnetic permeability is 500, the permanent magnet on the anode cylinder is 30mm away from the outer plane of the cathode trigger, and the permanent magnet strength is 300mT;

[0073] The length of the straight tube magnetic filter is 250mm, the too...

Embodiment 2

[0077] The cathode material is metal Mg, the diameter is Φ100, the thickness is 20mm, the arcing current is 15A, the arcing voltage is 20V, and the vacuum chamber vacuum is 1×10 -3 Pa;

[0078] During normal operation, the cathode target temperature is 20°C, and the gap between the auxiliary anode system and the shielding ring is 1mm;

[0079] The length of the control line package is 60mm, the number of turns is 3500 turns, the distance from the top plane of the cathode is 50mm, the current of the line package is 8A, the frequency is 15Hz, and the pulse width is 100μs;

[0080] The length of the anode cylinder is 120mm, the inside and outside of the part close to the cathode 60mm is made of stainless steel, and the rest is magnetically permeable material, the relative magnetic permeability is 500, the permanent magnet on the anode cylinder is 30mm away from the outer plane of the cathode trigger, and the permanent magnet strength is 300mT;

[0081] The length of the straight...

Embodiment 3

[0085] The cathode material is metal Mg, the diameter is Φ100, the thickness is 20mm, the arcing current is 20A, the arcing voltage is 20V, and the vacuum in the vacuum chamber is 1×10 -3 Pa;

[0086] During normal operation, the temperature of the cathode target is 15°C, the gap between the auxiliary anode system and the shielding ring is 1mm; the length of the control wire package is 60mm, the number of turns is 4000 turns, the distance from the top plane of the cathode is 50mm, the current of the wire package is 8A, the frequency is 15Hz, and the pulse width is 100μs;

[0087] The length of the anode cylinder is 120mm, the inside and outside of the part close to the cathode 60mm is made of stainless steel, and the rest is magnetically permeable material, the relative magnetic permeability is 500, the permanent magnet on the anode cylinder is 30mm away from the outer plane of the cathode trigger, and the permanent magnet strength is 300mT;

[0088] The length of the straight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com