Method for correcting chucking faults of electrohydraulic proportioning valve by utilizing electromagnetic attraction force

An electro-hydraulic proportional valve and electromagnetic suction technology, which is applied in fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problems that the proportional valve control system cannot be applied, and cannot ensure troubleshooting, etc., and achieves simple structure and easy use. Good effect and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings.

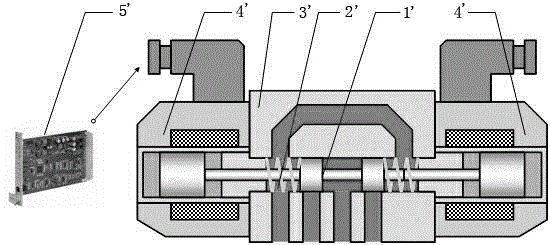

[0032] The structure of ordinary electro-hydraulic proportional valve is as follows: figure 1 As shown, it includes a valve core 1' and a valve body, and the valve body includes a valve cavity 2' and a valve wall 3'. As for other parts, generally also comprise proportional amplifier 5 ', proportional electromagnet 4 '. Proportional electromagnet 4 ' also can be single, replaces with back-moving spring at the other end. The proportional electromagnet cooperates with the spool, and drives the spool through the proportional electromagnet. The moving iron core of general proportional electromagnet 4 ' bears on spool 1 '. By changing the position of the spool 1' in the valve cavity of the valve body, the proportional valve can realize the change of fluid flow direction and on-off. The foregoing is the prior art, and will not be repeated h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com