Surface-slotted surface-mounted permanent magnet synchronous motor rotor structure

A permanent magnet synchronous motor, rotor structure technology, applied in the magnetic circuit shape/style/structure, magnetic circuit rotating parts, magnetic circuit and other directions, can solve the problems of reducing the utilization rate of rotor core, air gap magnetic field distortion, etc. Utilization rate, convenient processing, and the effect of facilitating installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] Take a 2kW 12-slot 8-pole permanent magnet motor as an example, use Ansoft Maxwell 2D motor electromagnetic field calculation software to perform electromagnetic calculations on the four proposed permanent magnet motors with different slotted rotor structures. The results are as follows Figure 3a~Figure 3e As shown, the obtained various magnetic field line distribution diagrams and magnetic field distribution cloud diagrams of various rotor structure motors can be seen from the diagrams that the rotor magnetic field distribution of the rotor surface slot structure of the present invention is more uniform, and the rotor core utilization rate is higher.

Embodiment 2

[0086] Taking a 2kW 12-slot 8-pole permanent magnet motor as an example, using Ansoft Maxwell 3D motor electromagnetic field calculation software to perform electromagnetic calculations on the four proposed permanent magnet motors with different slotted rotor structures, the results are as follows Figure 4a~Figure 4e Shown, the obtained various rotor structure motor magnetic density cloud map. It can be seen from the figure that the rotor magnetic field distribution of the rotor surface slotted structure of the present invention is more uniform, and the rotor core utilization rate is higher.

Embodiment 3

[0088] Taking a 2kW 12-slot 8-pole permanent magnet motor as an example, we give a schematic diagram of filling the slotted rotors of the four surface mount permanent magnet synchronous motors with non-magnetic and conductive fillers, such as Figure 5a ~ Figure 5d As shown in the figure, 10 is a non-magnetic and non-conductive filler. It can be seen from the figure that after filling the surface of the rotor, the surface of the rotor is smoother, which can reduce the wind wear of the motor.

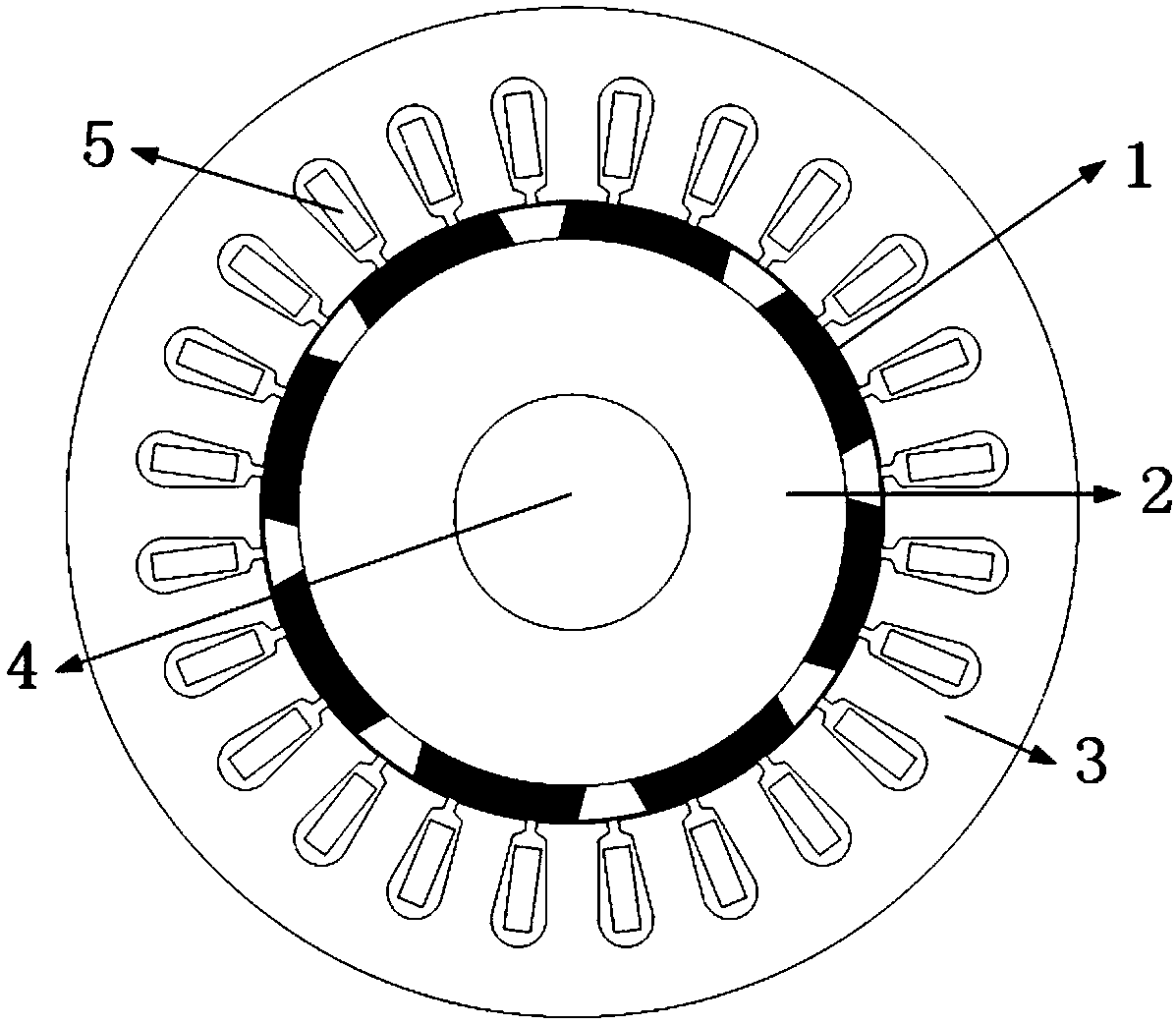

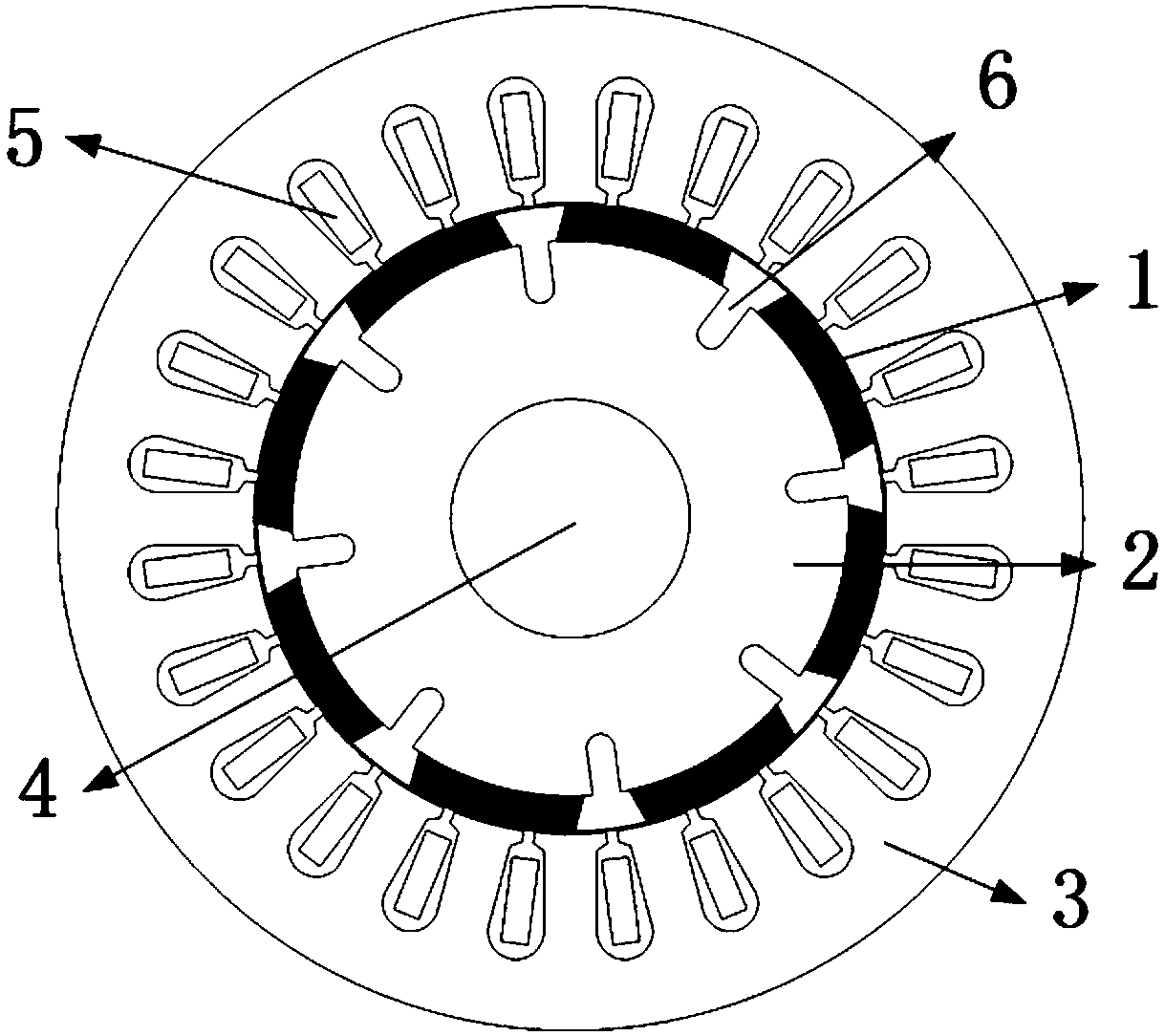

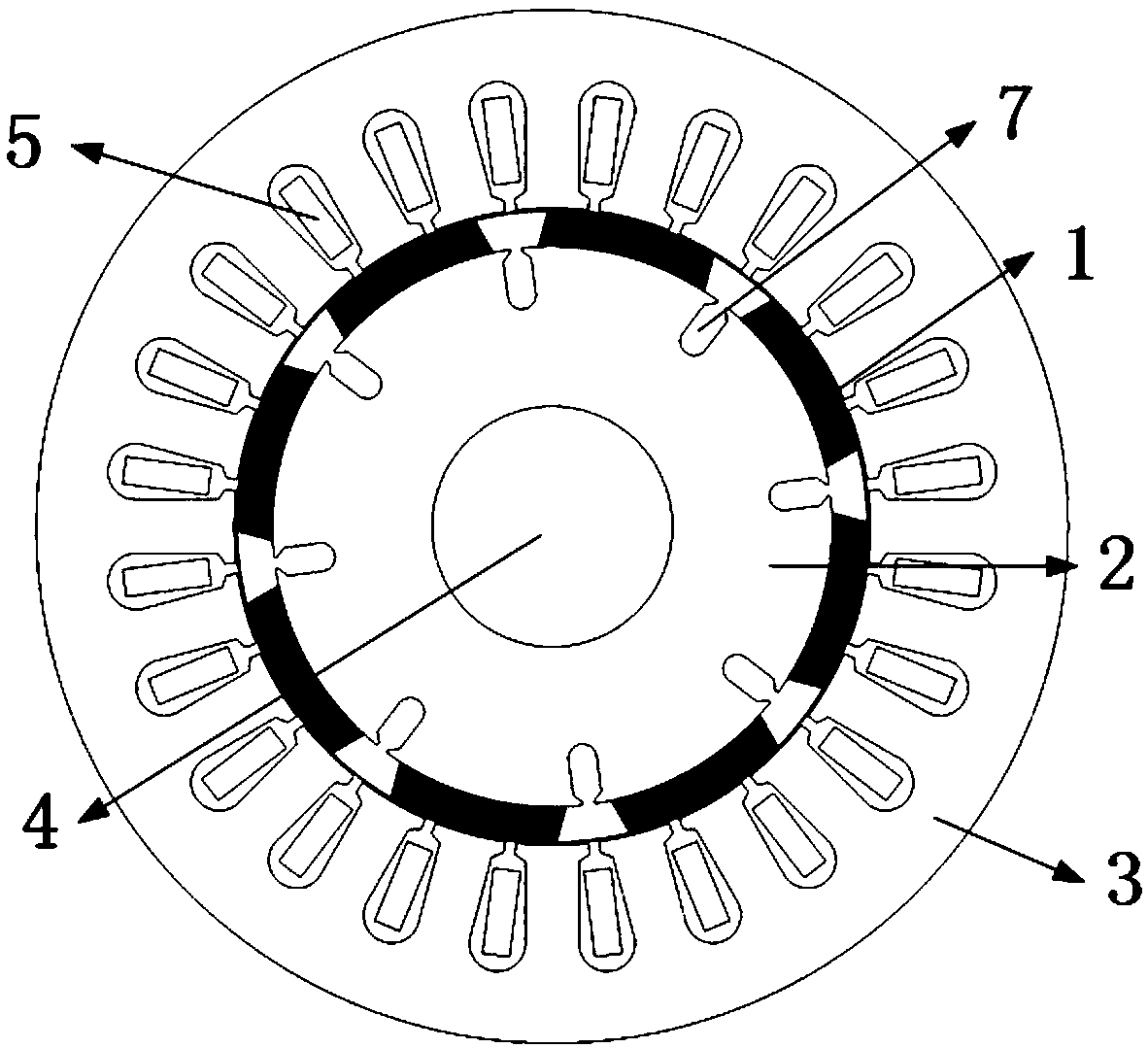

[0089] To sum up, the surface-mounted real-rotor surface-mounted high-efficiency permanent magnet synchronous motor rotor disclosed in the present invention, the specific implementation method of this new surface-slotted real-rotor surface-mounted high-efficiency permanent magnet synchronous motor is: The core part between the permanent magnets of each pole of the magnetic synchronous motor rotor is slotted to form radial slots (U open slot, U half closed slot, V open slot and V half closed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Notch width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com