Efficient energy-saving high conductivity weather-proof overhead insulated cable and manufacturing method thereof

An overhead insulated cable, high-efficiency and energy-saving technology, applied in the direction of insulated cables, cable/conductor manufacturing, insulated conductors, etc., can solve the problems of wasting labor, large consumables per unit length, and large energy consumption, so as to improve service life and use safety Performance, product cost performance improvement, and the effect of increasing the heat dissipation surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the drawings.

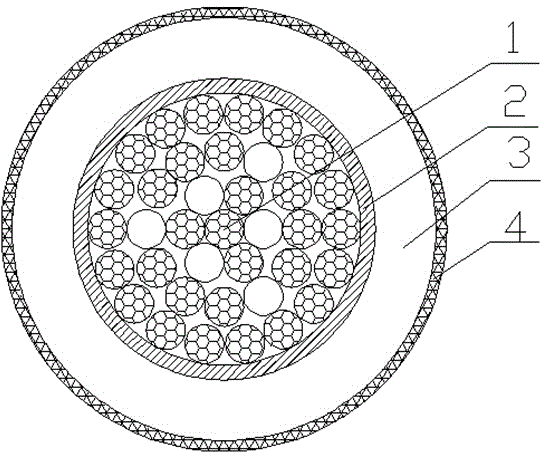

[0022] Such as figure 1 The illustrated high-efficiency, energy-saving, high-conductivity and weather-resistant overhead insulated cable includes a high-efficiency, energy-saving, high-conductivity, expanded-diameter conductor 1 arranged in the center of the cable, a semi-conductive shielding layer 2 is extruded outside the high-conductivity, expanded-diameter conductor 1, and a semi-conductive shield Layer 2 is extruded with an insulating layer 3, and a moisture-proof and reflective layer 4 is extruded on the outermost layer of the cable.

[0023] Among them, the high-efficiency, energy-saving, high-conductivity, expanded diameter conductor 1 has four layers and is formed by stranding aluminum wires with a thickness of 2.54mm in a 1+6+12+18 mode, and its cross-section is 185mm 2 , The resistivity is at least 15% lower than the national regulations, and its electrical conductiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com