Technique treatment method for induction heating of special-shaped piece

A technology of induction heat treatment and induction heating, which is applied in the direction of heat treatment furnace, heat treatment equipment, and process efficiency improvement. The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

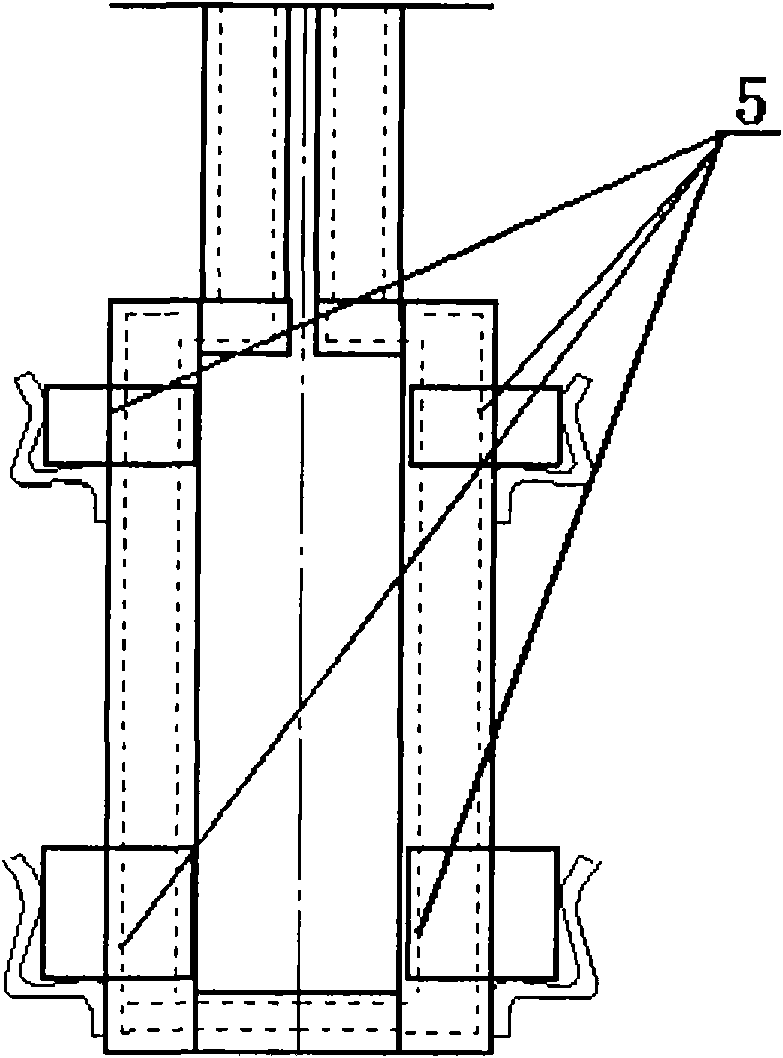

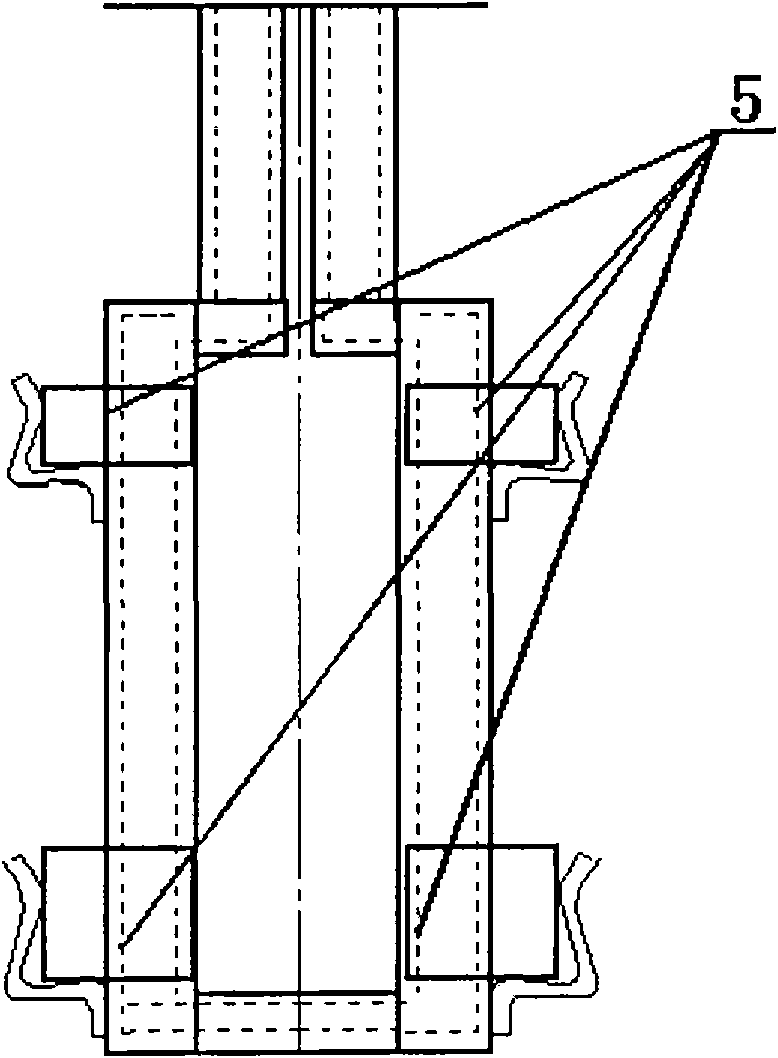

[0021] In this embodiment, according to the shape and technical requirements of the special-shaped parts, the induction heat treatment equipment with corresponding frequency and power is selected, the inductor is designed, the magnetic conductor 5 of the corresponding model and specification is selected, the magnetic conductor 5 is processed, and the magnetic conductor 5 is added to the place where the magnetic field concentration is required , forming a complete induction heater.

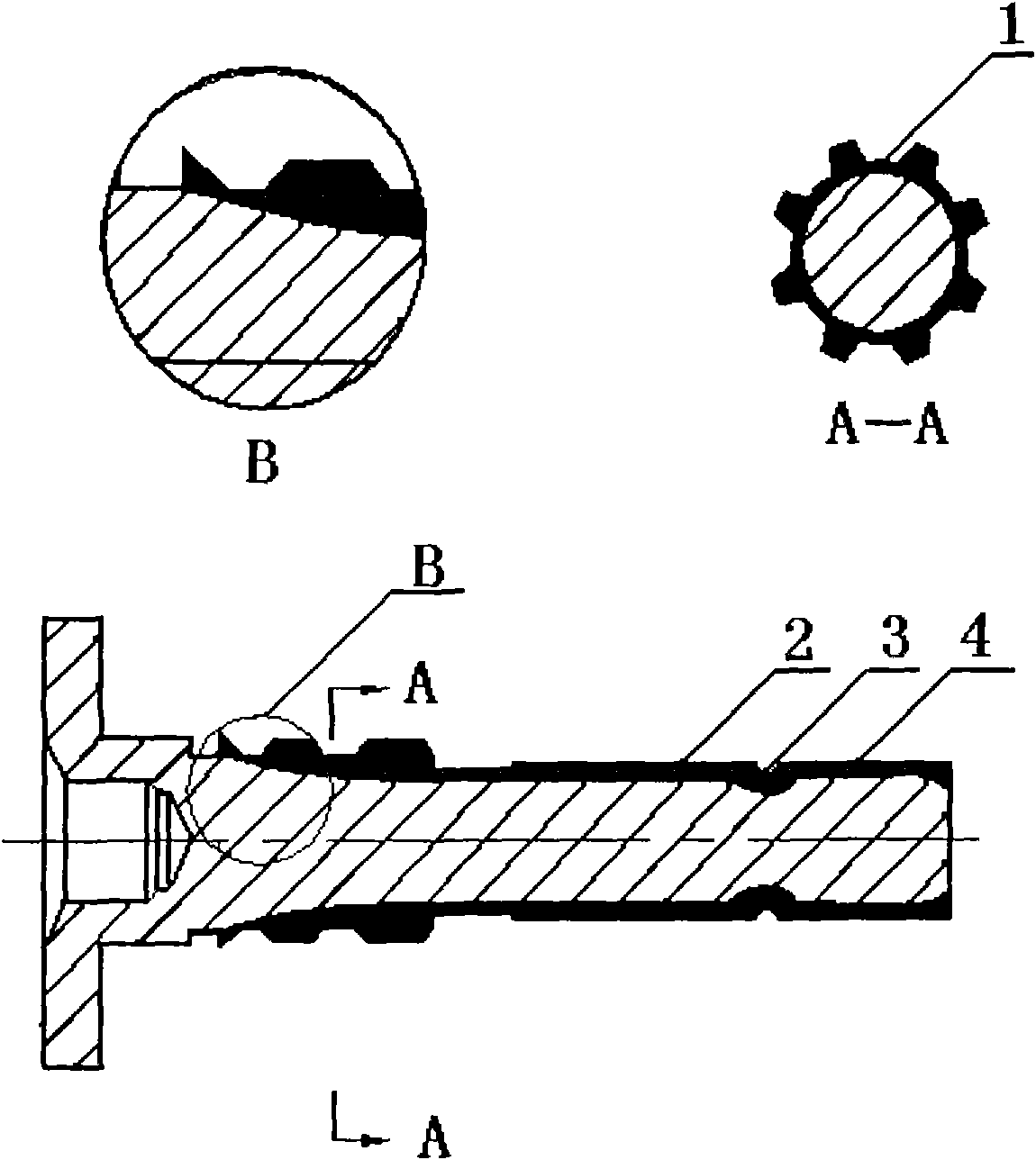

[0022] In this embodiment, the drive shaft of the automobile motor is used as the test object, and the technical requirements are as follows (see figure 1 ): Material 45 steel, surface hardness 45-55HRC, hardened layer as shown in the label 1, 2, 3, 4, the depth of the hardened layer 1, 2, 3, 4: 450HV 0.3 =0.3-1.5mm, the technical difficulty of this part is that the shaft diameter of the part is different from the size of the tooth part, and the distance between the tooth top and the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com