Aluminum-coated steel high-conductivity overhead insulated cable and production process thereof

An overhead insulated cable, high conductivity technology, applied in the direction of insulated cables, the manufacture of extensible conductors/cables, insulated conductors, etc., can solve the problems of low conductivity, poor tensile strength, and low service life, so as to improve the conductivity performance, prolong service life, reduce production and laying costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

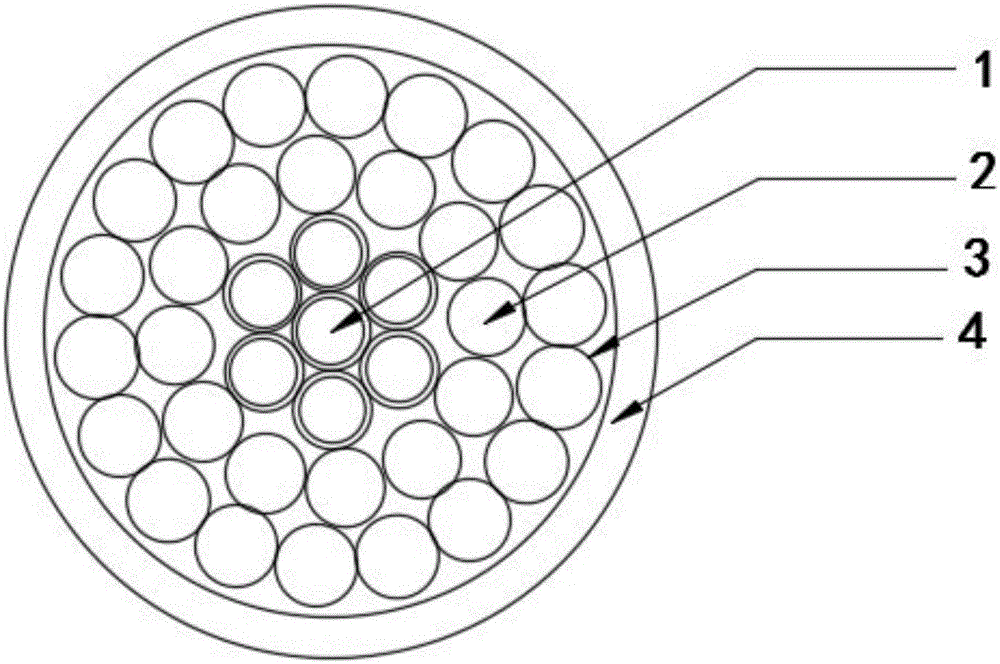

[0028] See figure 1 , a kind of aluminum-clad steel high-conductivity overhead insulated cable of the present embodiment, from the inside to the outside successively comprises the aluminum-clad steel core 1 of 20.3% IACS, the duralumin wire 2 of 62.5% IACS, the conductor shielding layer 3 and weather-resistant insulation Layer 4; 20.3% IACS aluminum-clad steel core 1 is a stranded wire coated on the surface of lead-hardened steel wire with a purity of 99.70% aluminum rod; 62.5% IACS duralumin wire 2 has a conductivity of 62.5% IACS, Twisted duralumin wires greater than 160MPa and less than 25MPa in strength uniformity; shielding layer 3 is made of cross-linked polyethylene or non-cross-linked polyethylene; weather-resistant insulating layer 4 is made of polyethylene or polyvinyl chloride or cross-linked polyethylene Material. The 20.3% IACS aluminum-clad steel core 1 and the 62.5% IACS duralumin wire 2 are stranded with a compression coefficient of 90% and an elongation of 3%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com