Motor Used For Motor Vehicle And Motor Vehicle

A technology of motor vehicles and rotors, applied in the direction of electromechanical devices, synchronous machines, electrical components, etc., can solve the problem of high movement costs, achieve the effect of simple movement coupling, simple cost, and increase structural cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

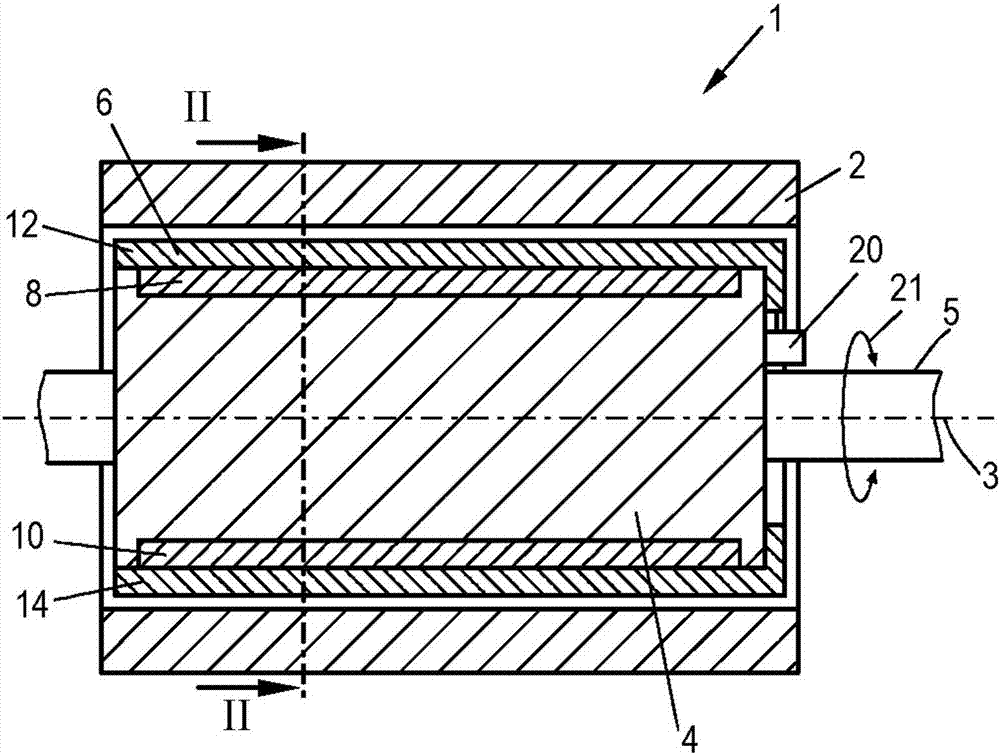

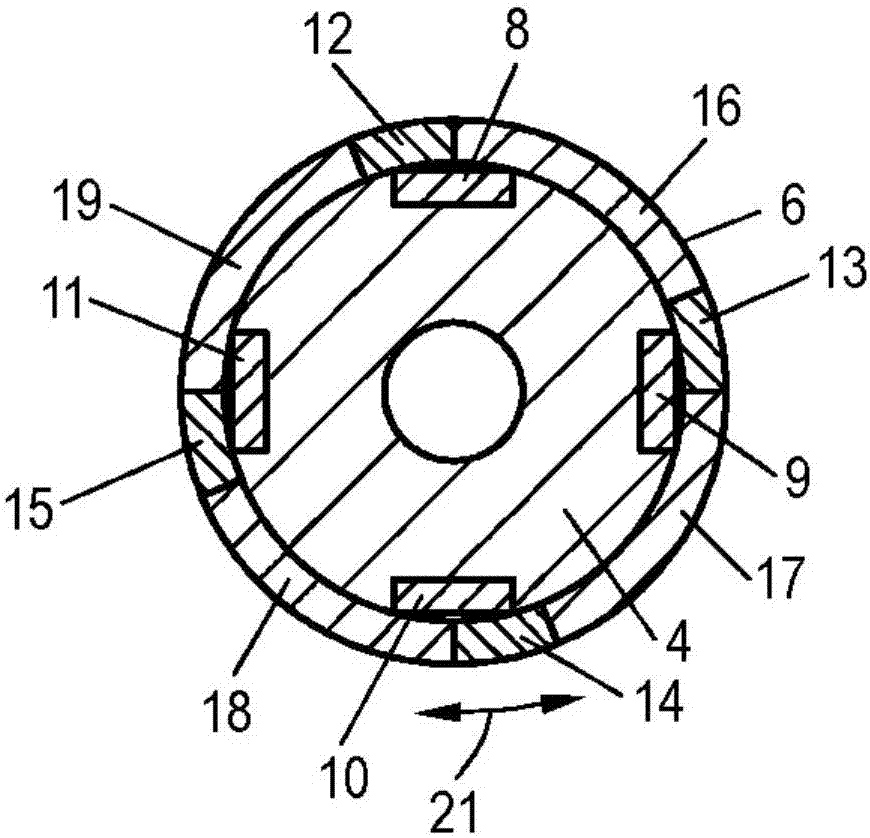

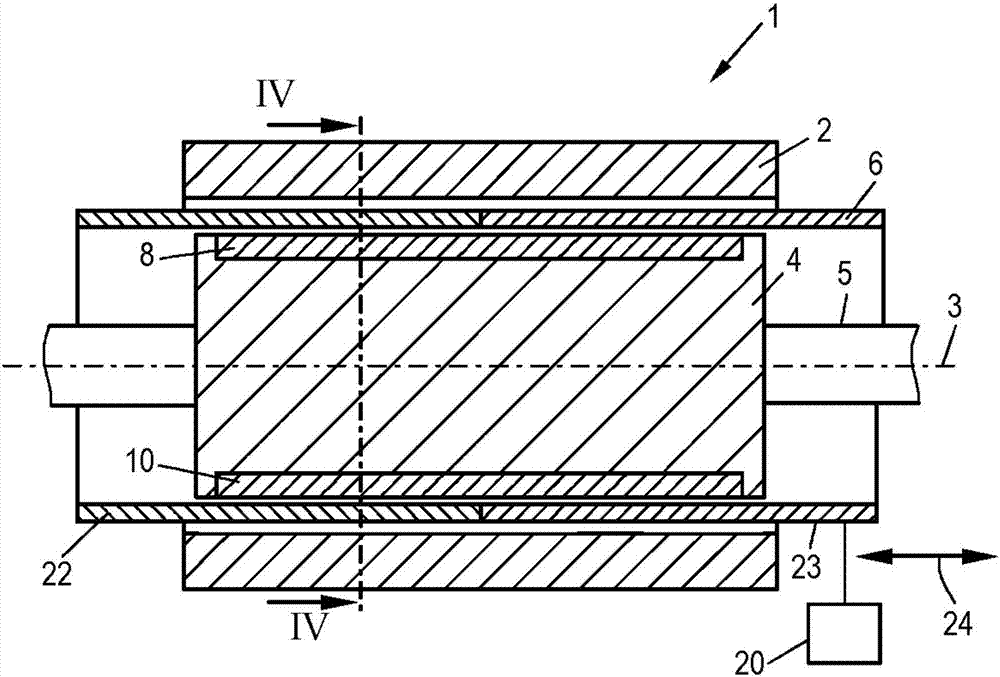

[0033] figure 1 A schematic diagram of an electric machine 1 is shown in cross section, comprising a stator 2 , a rotor 4 mounted rotatably about a rotor axis 3 , and a shaft 5 rotationally coupled to the rotor 4 . A shield 6 of cylindrical shape is arranged between the stator 2 and the rotor 4 . The electric machine 1 is designed as a permanently-magnet-excited synchronous electric machine in the form of a brushless DC motor or an electronically commutated DC motor.

[0034] The rotor 4 has four magnetic elements 8-11 in the form of surface-mounted permanent magnets embedded in recesses, wherein, in figure 1 Magnetic elements can be seen in 8,10. The magnetic elements 8 - 10 generate two pole pairs of the magnetic excitation field of the rotor 4 .

[0035] The shield 6 is rotationally coupled to the rotor 4 and is arranged rotatably about the rotor axis 3 relative to the rotor 4 . A shield 6 is rotatably arranged on the rotor 4 at the end face of the rotor 4 . For this p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com