Axial permanent-magnet motor

A permanent magnet motor, axial technology, used in motors, synchronous motors with stationary armatures and rotating magnets, electric vehicles, etc., can solve the problems of large stator yoke, low coil filling factor, affecting motor power, etc. , to increase the filling density, optimize the magnetic field distribution, and reduce the iron loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

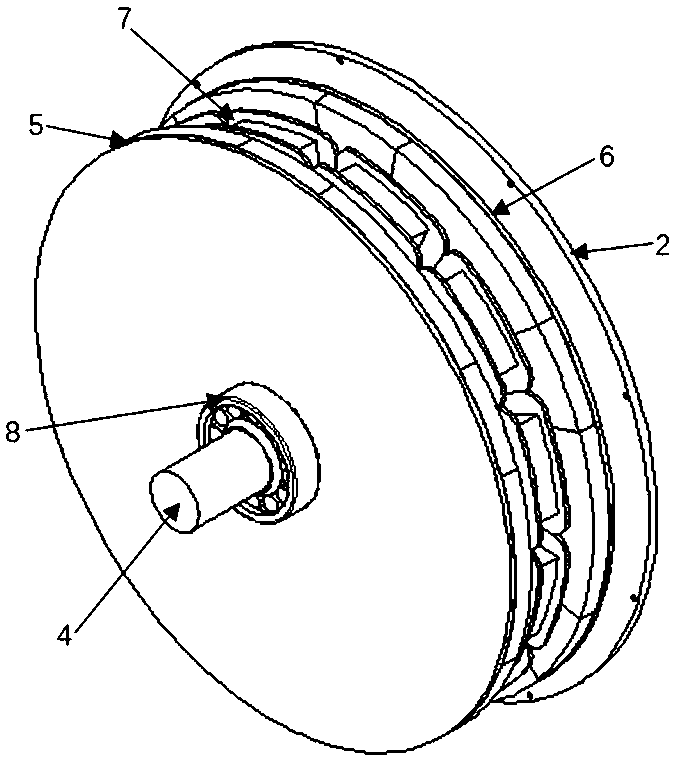

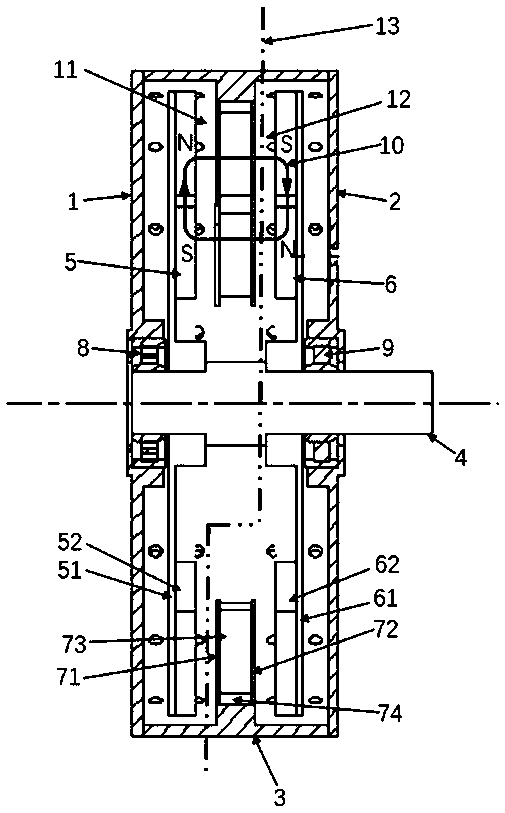

[0035] see figure 2 , an axial permanent magnet motor includes an annular casing 3, a stator 7, a first rotor 5, a second rotor 6 and a rotating shaft 4; the stator 7 is coaxially installed in the axial middle of the casing 3; the rotating shaft 4 passes through The axial middle part and both ends of the stator 7 are rotatably mounted on the casing 3 through bearings. The first rotor 5 and the second rotor 6 are mirror-symmetrically mounted on the rotating shaft 4 on both sides of the stator 7, and rotate with the rotating shaft 4; the magnetic circuit formed is: starting from the first magnet of the first rotor 5, passing through The first coil of the stator 7 enters the first magnet on the second rotor opposite to the first magnet of the first rotor, passes through the iron core of the second rotor, enters the second magnet of the second rotor, and passes through the stator and the first magnet. The second coil adjacent to the coil enters the second magnet on the first rot...

Embodiment 2

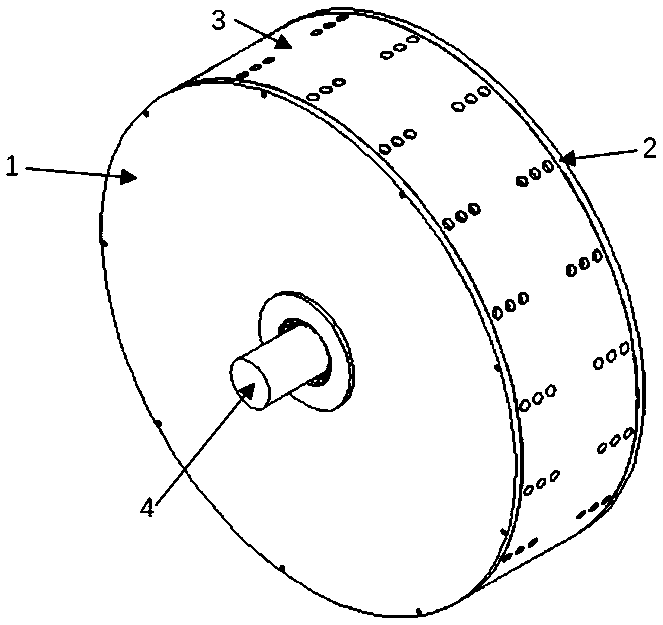

[0048] see figure 1 , when the motor is used in a place that does not need to be sealed, cooling holes are evenly distributed on the circumference of the casing 3, which improves the cooling effect of the motor.

[0049] The outer diameter of the stator 7 is 100 mm, and the axial distance between the first permanent magnet 52 or the second permanent magnet 62 and the stator 7 is 3 mm.

[0050] In the present invention, the number of stator coils and the number of permanent magnets of the rotor may be different, for example, 12 stator coils correspond to 10 permanent magnets of the rotor. In this way, it can be guaranteed that the stator coil will not be in the same position as a certain permanent magnet at any time, and it can be ensured that energizing the motor at any time and any position can generate torque rotation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com