Brushless electromagnetic and double-radial permanent magnet hybrid excitation driving motor

A hybrid excitation and drive motor technology, which is applied in the direction of electric components, magnetic circuit rotating parts, magnetic circuits, etc., can solve the problems of reduced cost performance of motors, waste of permanent magnet steel materials, and increased cost of motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the present invention is described in further detail, so that those skilled in the art can implement accordingly with reference to the description:

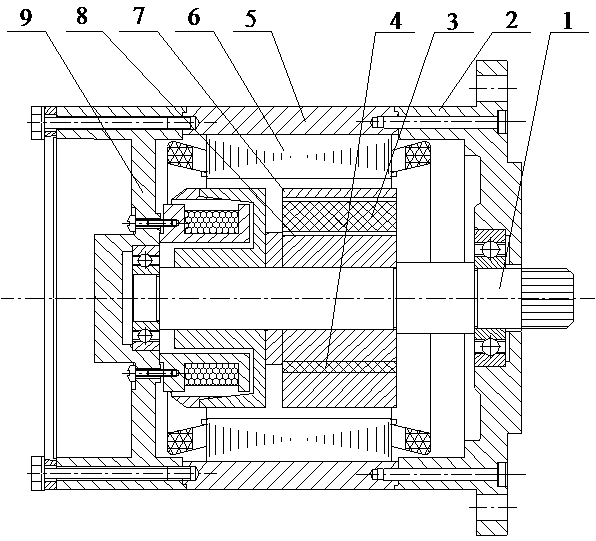

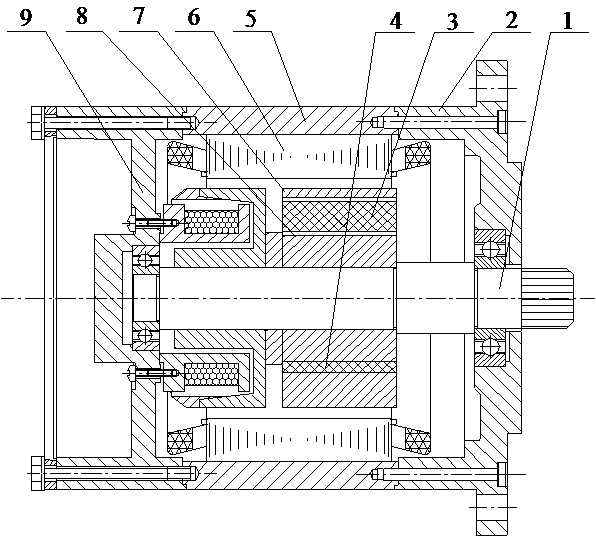

[0015] The brushless electromagnetic and dual radial permanent magnet hybrid excitation drive motor consists of a front cover 2, a rear end cover 9, a casing 5, a hybrid excitation rotor, and a stator 6. It is characterized in that the hybrid excitation rotor has a carbon brushless slip ring structure Composed of claw pole electric excitation rotor and double radial permanent magnet rotor;

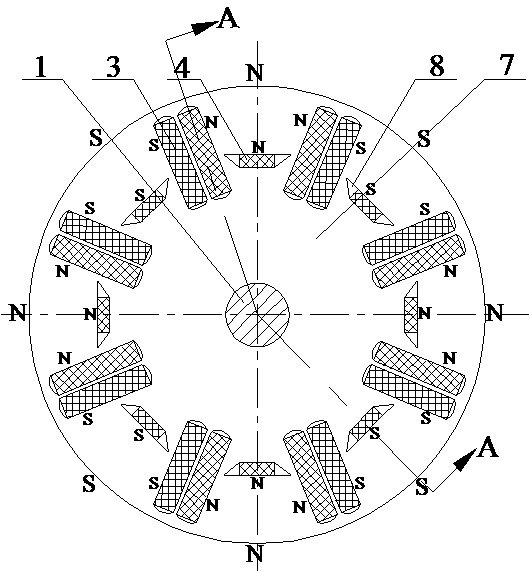

[0016] The dual-radial permanent magnet rotor includes a shaft 1, a first magnet 3, a second magnet 4, a rotor core 7, and magnetic isolation holes 8. Even pairs of first magnets 3 are evenly distributed on the rotor core 7, and each pair of first magnets The cross-section of 3 is V-shaped with an inner end opening, and the arc lengths corresponding to the outer ends of each pair of first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com