Injected bridge-cutoff aluminum profile used for inswinging casement window

A broken bridge aluminum and inner casement technology, which is applied in the direction of windows/doors, wing leaf layout, wing leaf frame, etc., can solve the problems of little impact on load bearing, high production cost, thick and wasteful materials, etc., and achieve material yield The effect of increasing, saving materials, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

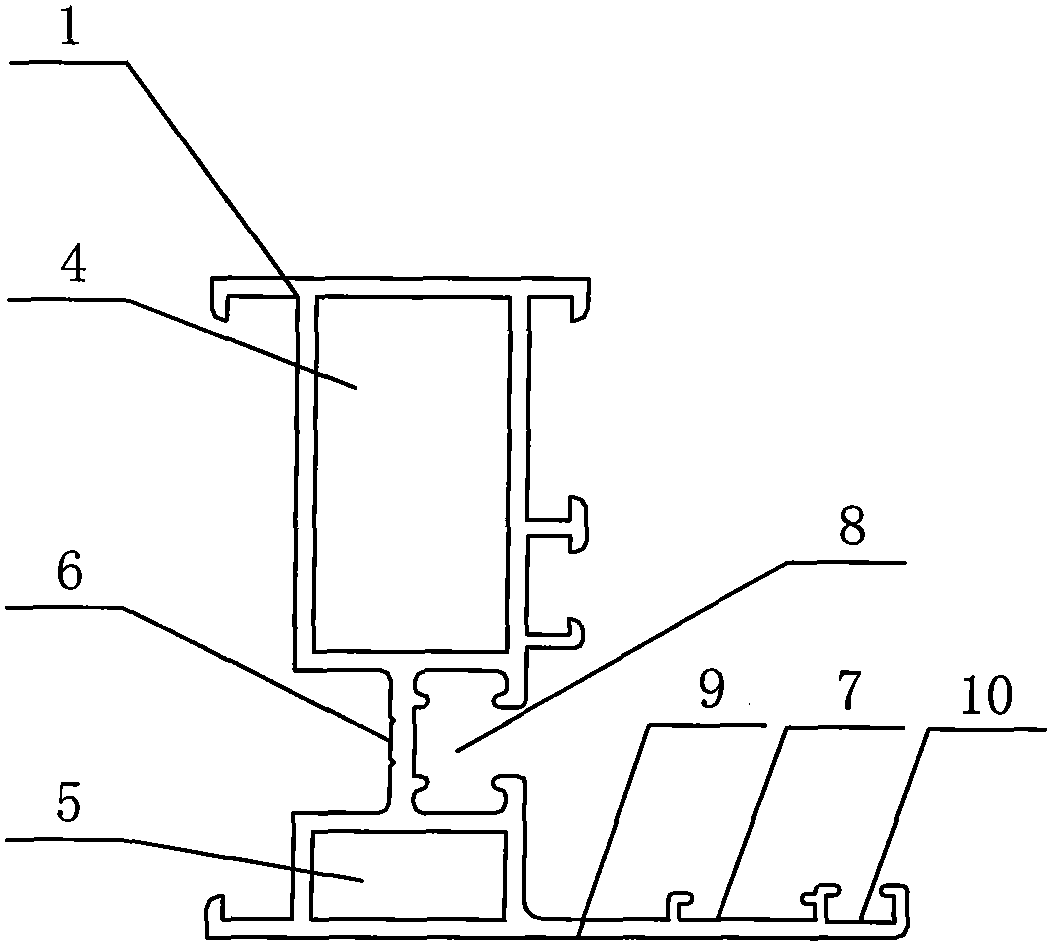

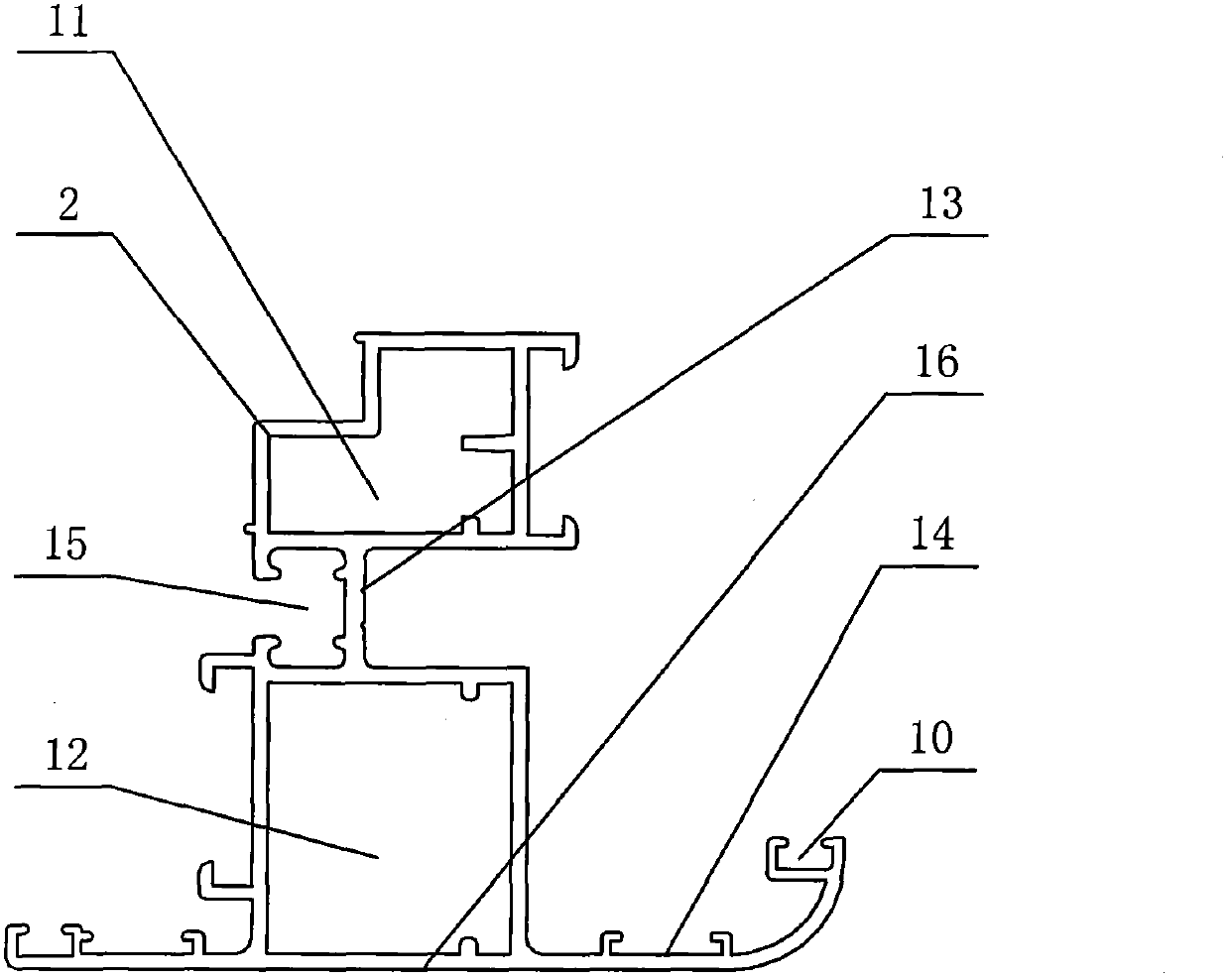

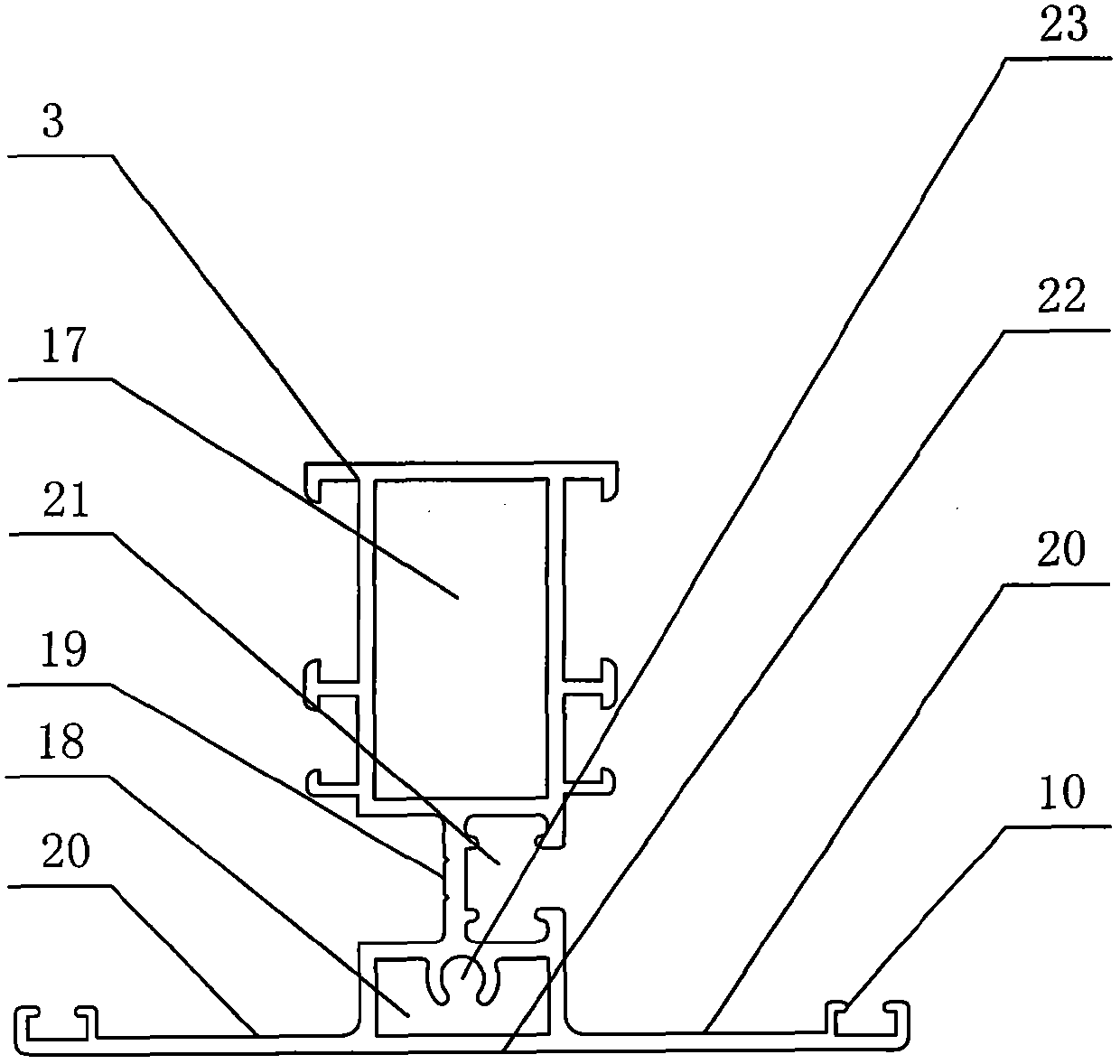

[0017] Specific embodiments: a perfusion broken bridge aluminum profile for inner casement windows, which includes a window frame 1, a window sash 2 and a stile 3, and the window frame 1 includes a frame material inner cavity 4, a frame material outer cavity 5, and a frame material Partition plate 6 and frame material connecting plate 7, one end of frame material partition plate 6 is connected with the middle part of the inner wall of frame material inner chamber 4, the other end is connected with the middle part of inner wall of frame material outer cavity 5, and frame material partition plate 6 is connected with frame material partition plate 6 The inner wall of the frame material inner chamber 4 and the inner wall of the frame material outer cavity 5 on one side form a frame material injection cavity 8, the thickness of the frame material partition 6 is 1.6 mm, the inner wall of the frame material inner cavity 4, and the frame material outer cavity 5 The thickness of the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com