Yarn-dyed fabric design production method with quick response effect

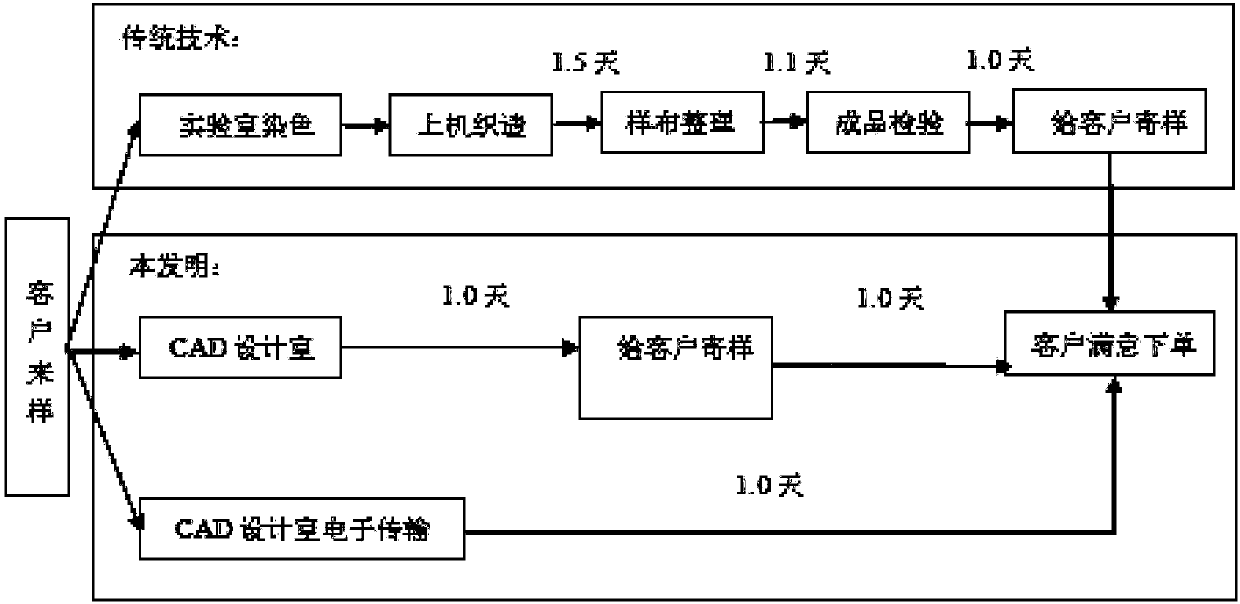

A fast-response, production-method technology, applied in design optimization/simulation, calculation, special data processing applications, etc., can solve problems such as time-consuming, and achieve the effect of solving exposure problems, shortening development cycles, and improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

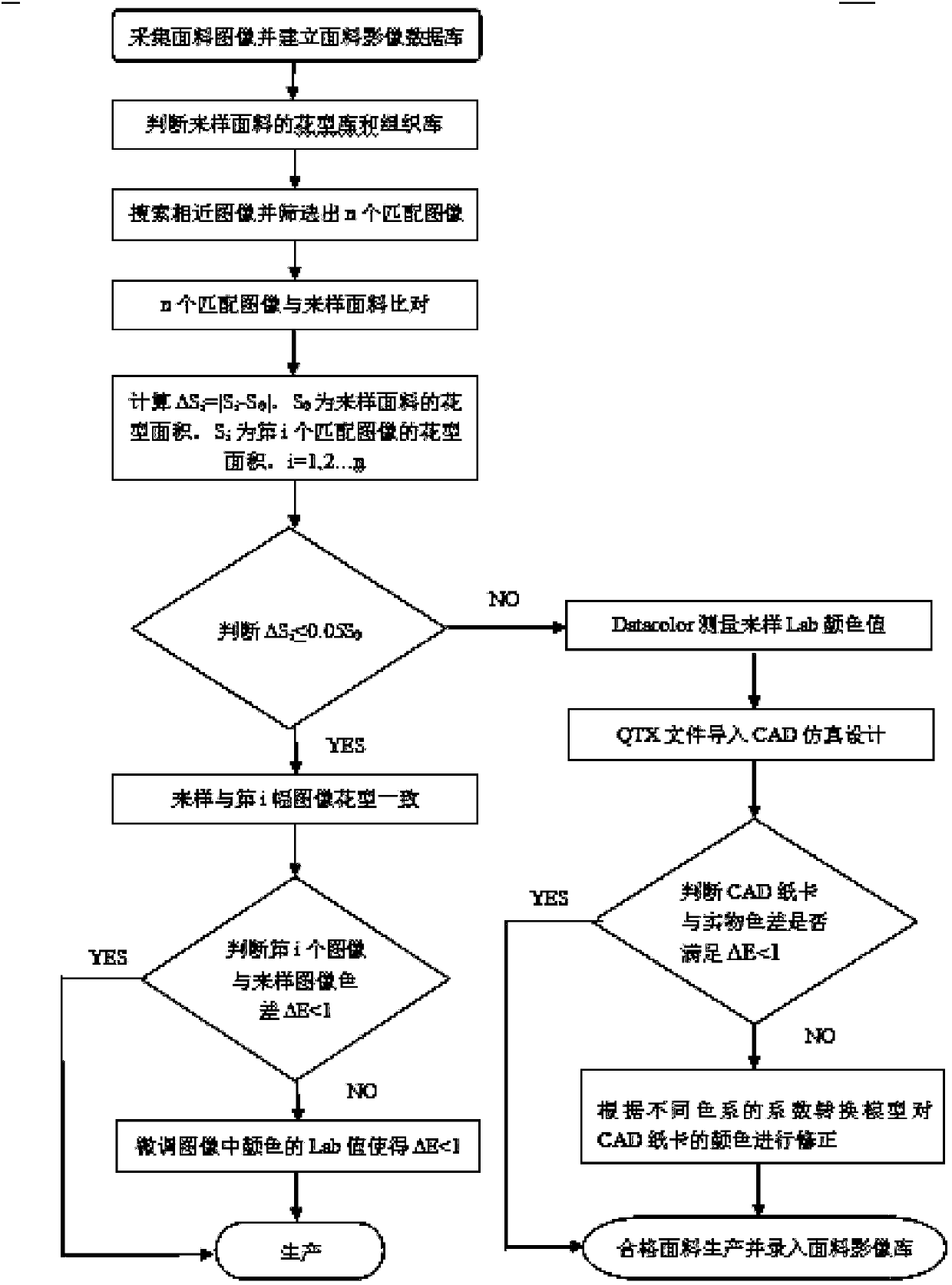

[0049] A fast-response yarn-dyed fabric design and production method, such as figure 1 As shown, the specific steps are as follows:

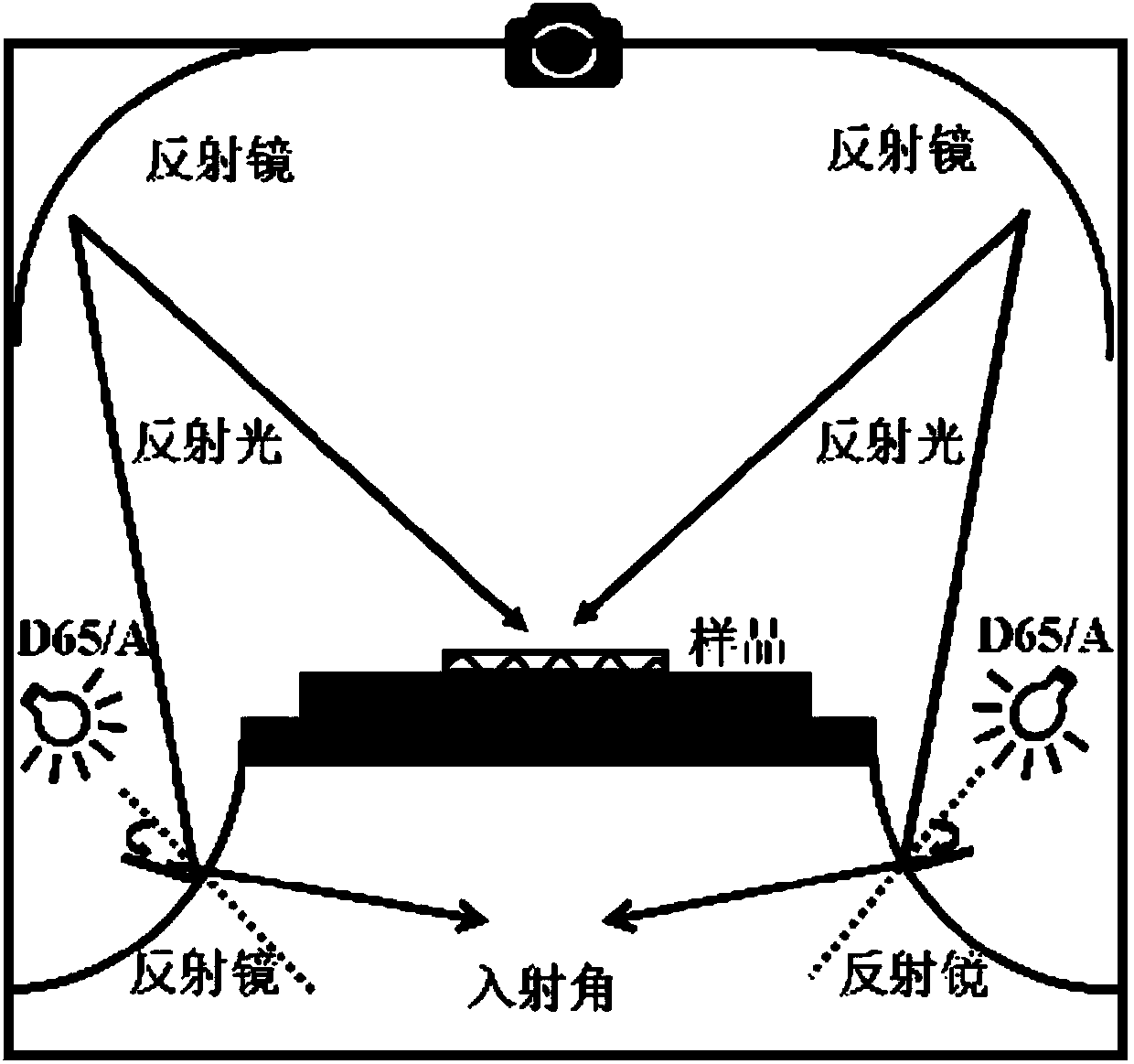

[0050] (1) After collecting the fabric image, classify it according to the pattern and organizational structure to establish the fabric image database; when collecting the fabric image, use a CCD camera to shoot, and the collection environment is as follows: figure 2 As shown, the acquisition environment is a sealed box, CIE standard illuminant D65 or CIE standard illuminant A, where the angle of D65 light source to the parabolic reflector is 20°-30°, and the angle of A light source to the parabolic reflector is 30° °-45°, the specific steps are as follows;

[0051] (1.1) Set the shooting parameters before shooting: aperture 5.6, shutter 1 / 13, use the monitor color calibrator to correct the color of the computer screen, and adjust the color difference between the background color of the monitor and the collected fabric to be greater than or eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com