Extension box oil seal hole clamp and worm wheel hole clamp combined four-station clamp

A four-station, hole-sealing technology, applied in the field of tooling fixtures, can solve the problems of rising fixture costs and low production capacity, and achieve the effects of reducing fixture costs, increasing production line productivity, and shortening the design and manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the drawings and embodiments:

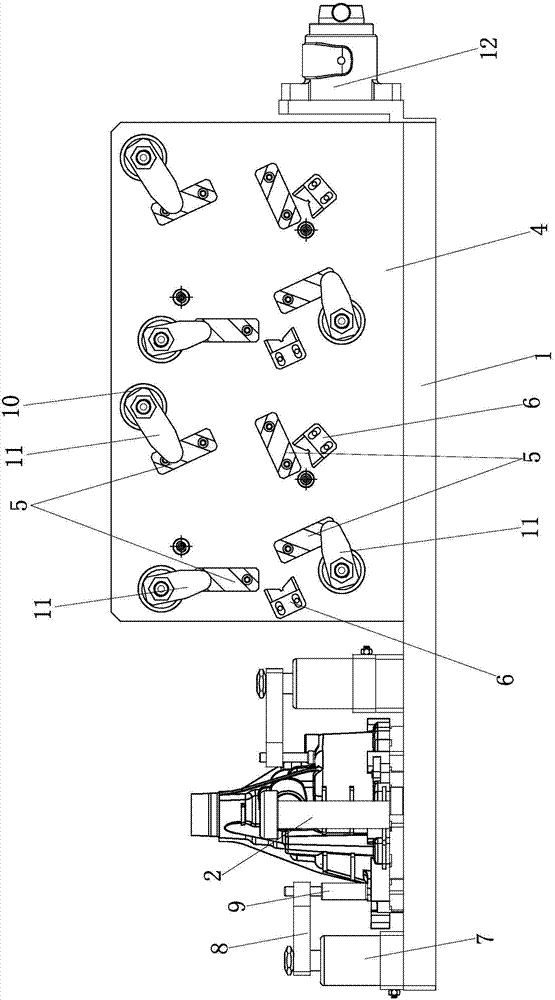

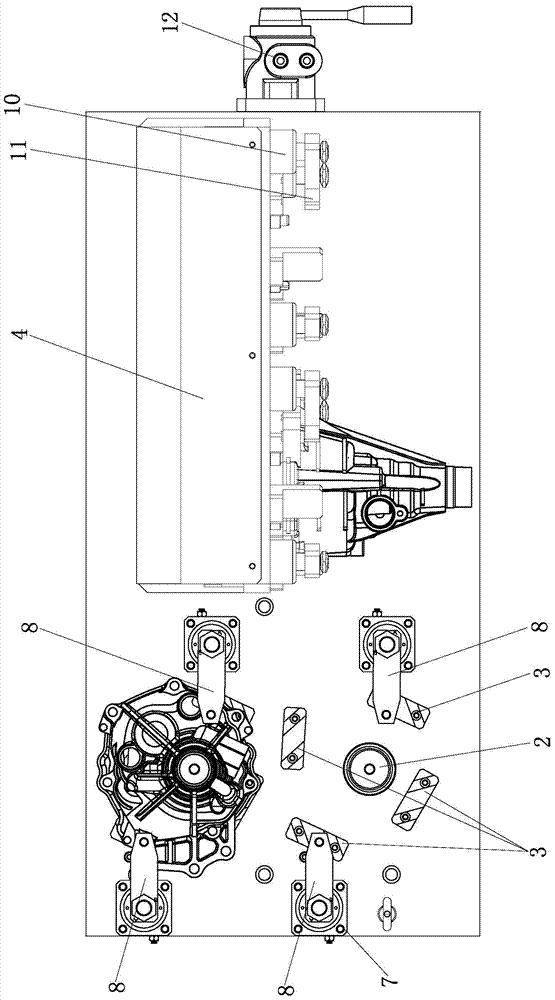

[0020] Such as figure 1 , 2 As shown, an extension box oil seal hole worm gear hole combination four-station fixture is mainly composed of a horizontal bottom plate 1, a positioning column 2, a first positioning pad 3, a first pressing component, a second positioning pad 5, and a V-shaped positioning The block 6, the second pressing component and the oil pressure valve 12 constitute. Wherein, the horizontal bottom plate 1 is a large rectangular plate, and the horizontal bottom plate 1 is fixed on the workbench of the machining center during installation. The left part of the top surface of the horizontal bottom plate 1 has two stations side by side, each station is composed of a positioning column 2, four first positioning pads 3 and two first pressing components, wherein the positioning The column 2 is vertically arranged, and the top surface of the positioning colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com