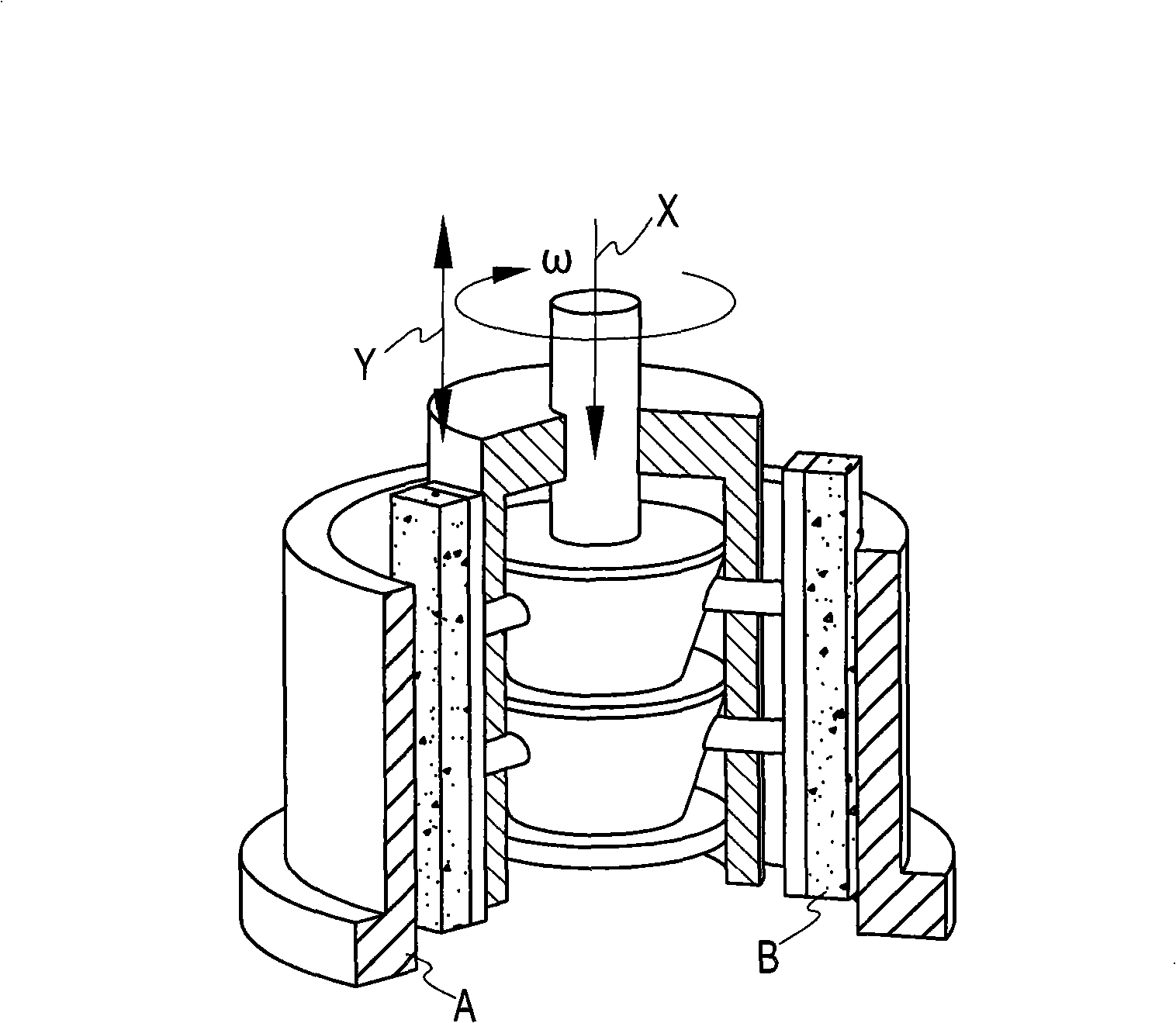

Direct drive type honing device

A direct-drive, honing technology, applied in honing machine tools, metal processing equipment, manufacturing tools, etc., can solve the problems of long manufacturing cycle, high cost, poor adaptability, etc., to reduce the manufacturing cycle, reduce production costs, and improve product life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Wherein, the same parts adopt the same reference numerals.

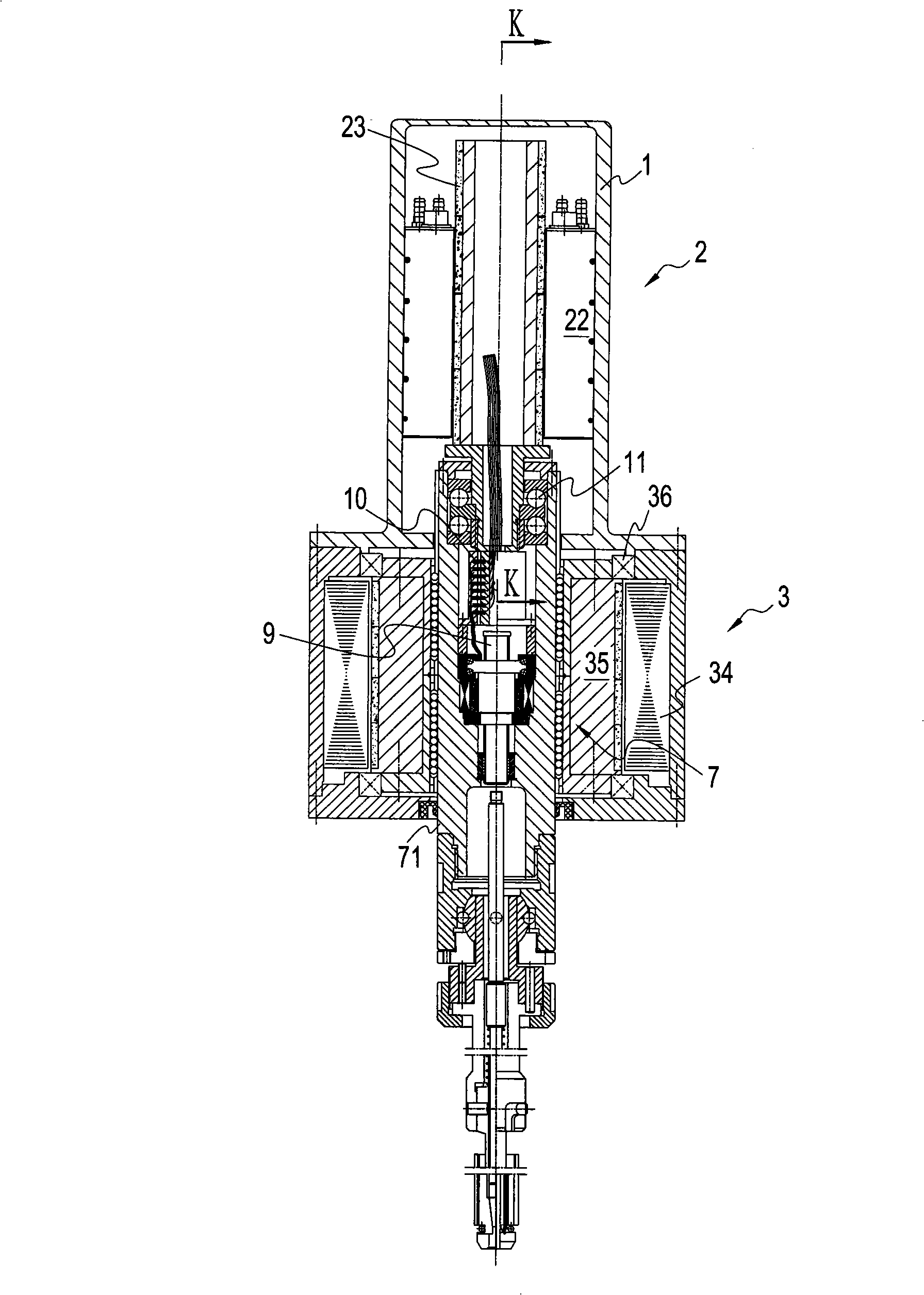

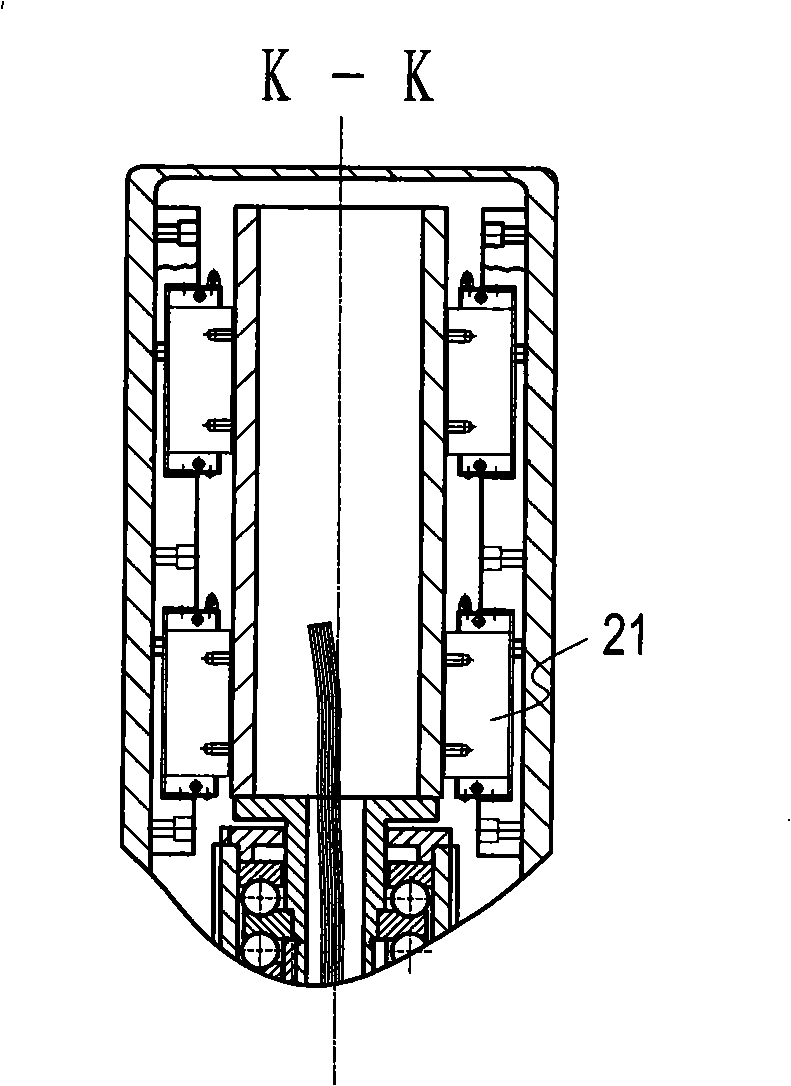

[0029] figure 2 Shown is a sectional view of a honing device according to a preferred embodiment of the present invention, image 3 Shown is figure 2 Among them, the partial cross-sectional view along the line K-K has particularly shown the rolling linear guide rail pair 21 (which will be further explained later).

[0030] The honing device according to the above-mentioned preferred embodiment of the present invention includes: a housing 1 and a main shaft 71, a direct-drive linear motor 2, and a direct-drive rotary motor 3, wherein the direct-drive linear motor 2 and the direct-drive rotary motor 3 are installed in series; The linear drive motor 2 is installed at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com