Additive manufacturing protective device and using method thereof

A technology for additive manufacturing and protective devices, applied in the directions of manufacturing auxiliary devices, processing and manufacturing, additive processing, etc., can solve the problems of high cost and long production cycle, and achieve low manufacturing cost, space reduction, time saving and operating cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

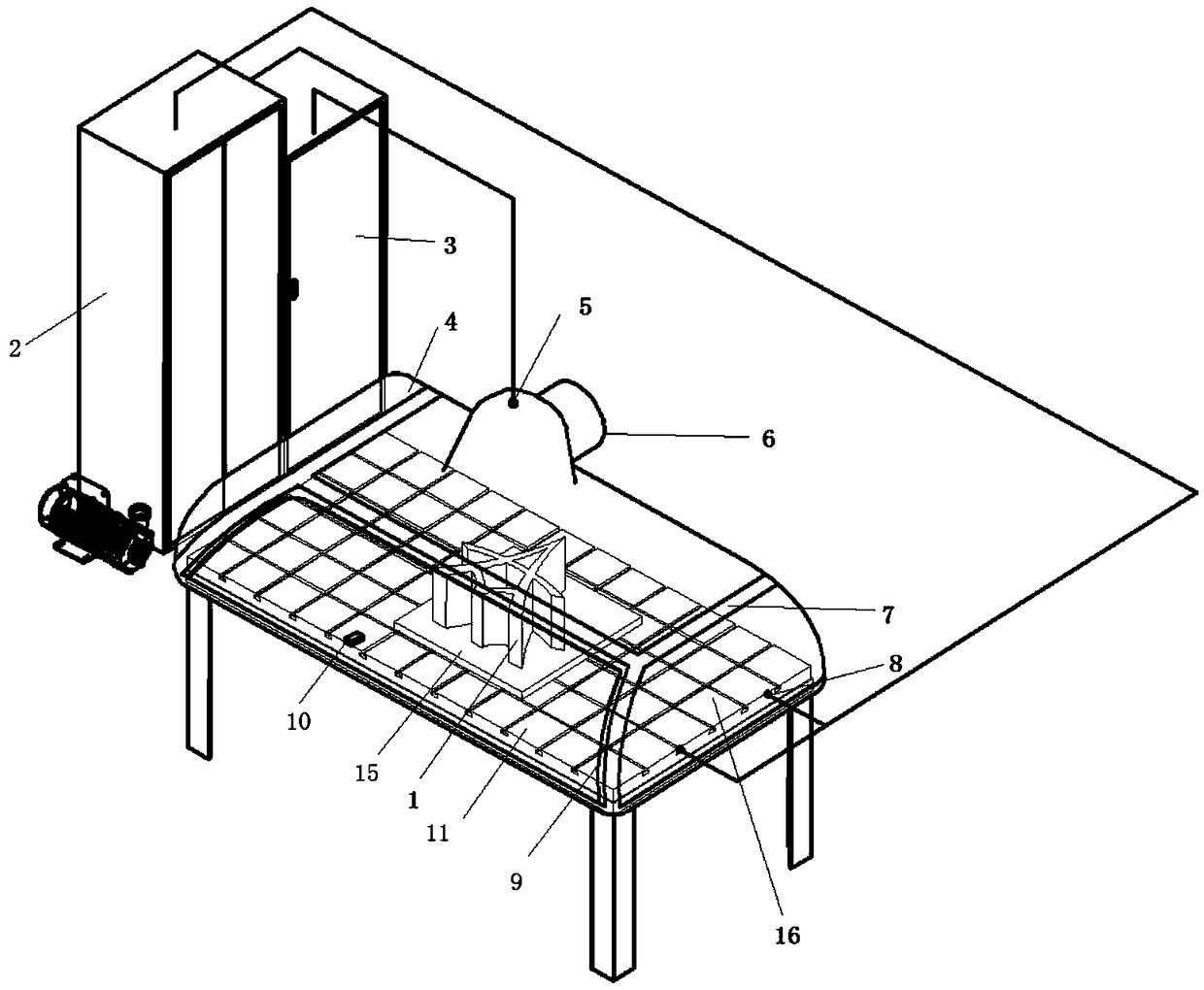

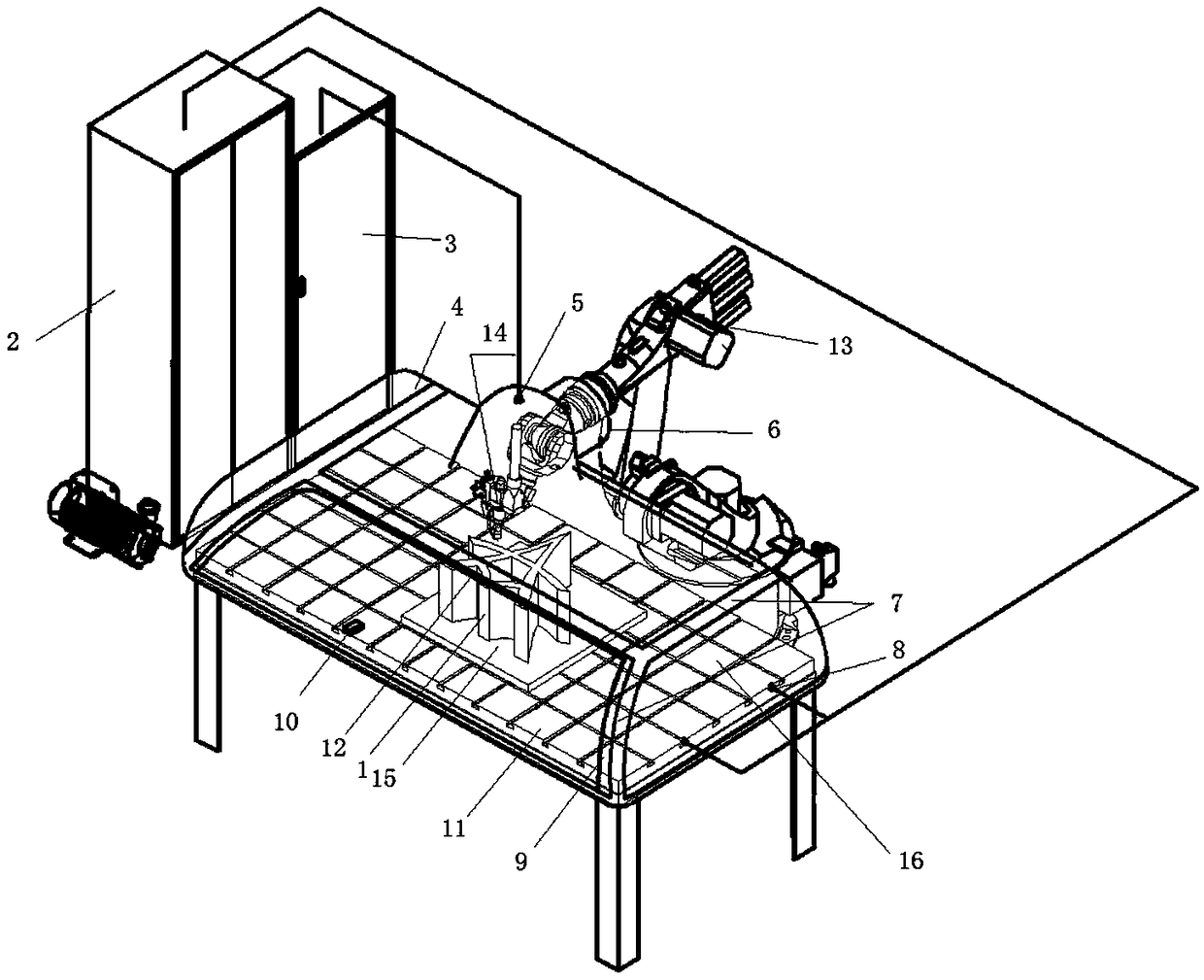

[0036] The present invention is described in further detail below in conjunction with accompanying drawing:

[0037] see figure 1 , the present invention discloses a protective device for additive manufacturing and its use method. The device includes: a protective cover 4, an internal environment adjustment unit 2 and a dust and smoke processing unit 3; the protective cover 4 is made of a flexible transparent flame-retardant material, composed of It consists of two sides, one top and one bottom, and the adjacent sides of the protective cover 4, and between each side and the top are fixedly connected by air column 7; all air columns 7 can be connected in series, and are controlled by an air pump or multiple air columns. Each air pump provides air; it can also be independent, and the air is provided by a separate air pump; the protective cover 4 is supported by the air column 7, and the working platform 11 is wrapped by the bottom surface and four sides of the protective cover 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com